Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Briggs NStratton 170400

Caricato da

Bob HaysTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Briggs NStratton 170400

Caricato da

Bob HaysCopyright:

Formati disponibili

Operating and Maintenance lnstructions

Model Series 170400, 171400,1 90400, 195400

BRIGGS & STRATTON

Brigqs & Stratlon Corporation

Milwaukee. Wisconsin 53201

FOFf.r' NO

?i0367 4136

wARNING:0O NOT RUN THE ENGINE lN

AN

2. A.N.S-|- Slandard Salety Specilications

ENCLOSED AREA. b(hausl gases conlain carbon monoxide, an odorless and deadly poison,

A FIRE OR EXPLOSION CANOCCUR RESULTING IN PERSONAL INJURY IF THE FOLLOWNG INSTRUC. TIONS ARE NOT FOLLOWED:

ior rotary power lawn mowersspeciiya rnarimum blade lip speed ol 19,000lee1 per minute (96.5 melers per second), primarily lo reduce the danger trom

3.

Do norlamperwilh lheengine speed selected by the original equipment manufacturer. DO NOTTOUCH hol mufilers, cylinders orfins as conlacl may cause burns.

1.

DO NOT FILL GASOLINE TANK whils engrne is

running. Allow ngine to cool lor lwo minuls

blor retueling,

5.

2- Do not operale lhe engine when a6 odor ol

gasoline is presenl or other explosive condilions

6.

Dirlahd grassclippingsorotherdebras, in cooling lins or govemor parls can aflecl engine speed. See claning inslruclions in MAINIENANCE

TO PREVEN] HAND OR ARM INJURY, always

pull slartercord rapidlylo avoid kickbacki starling engine with a loose bladeorwithoula blade may .6use a severc kickback.

3.

ll gasoline is spilled, move machine away from the area ol lhe spilland avoid creating gly soLrrce of ignilion untilthe gasoline has evaporated.

7.

ALWAYS KEEP HANDS AND FEET CLEAR OF I\,IOVING OR ROIATING PARTS,

4. DO NOT STORE, SPILL OR USE

GASOLINE NEAR AN OPEN FLAME, or devices such as a stove, ,urnace, waler healer which ulilize a pilot lighl. or devices which can creale a spsrk.

8.

TO PREVENT ACCIOENIAL STAFTING when servicing the engine or equipmenl, always remov6lhespark plug orwirel.om lhe spark plug and inserl in holding lab shown on page 3Disconneclnegativewi.elrombatleryterminal,il

equipped wilh a 12 volt siarting system.

5- Reluel outdoors prelerably. or only in well

6. DO NOT OPERATE ENGINE WITHOUT

place, it necessary.

IVHEN WOBXING OI{ EOUIPiIENT

[,IUFFLEB. lnspecl mulfler periodically and re-

DO NOT STRIKE FLYWHEEL with a hard objecl or melal tool as this may cause llywheel to shaner in

oporalion, causing personal injury or properly

damag6, To remove llywheel, use Eriggs & Slrallon approvd tools only.

IN ITTEREST OF EI{VIRO}IMENT

7. Periodically clean the mutller arsa lo prvenl grass, dirl and combuslibl malerial trom accumulating.

8. DO NOT use lhis engine on any forest covered.

brush covered orgrasscovered unimprovd land unless a spark arresler is altached to lhe muJJler,

'HE A mulller which leaks because of rusl or da mage can

permil an increased exhausl noise level. Therefore, e)(amine the muttler periodically to be sure il js

lunctioning eflectively. To purchasea new muffler, see SERVICE AND REPAIR INFORMATION,

9. DONOToperaletheengineilaircleanerorcover

direclly over the carburelor air inlake is removed.

10. DO NOT choke ca6ureto. to slop the engine.

CAUIION OO NOT RUN ENGINE AT

EXCESSIVE

SPEEDS. Operaling an engine a! excessiv speds increasss the dsnger ol personaliniury.

Itlhis engine is not equipped wilh a spark '.tr arreslerand islo beused on anytoreslcovered. brush covred, or grass covered unimproved land, belore using on such land a spark arresler musl beadded lo

i)tl:

th6 multler. The arrester must be maintained in

elfective working order by the operalor. ln the Slate ol Calilornialheabove isrequired by law(Section 4442 of the Calilornia Public Resources Code). Other slales may have similar laws. Fedelal laws apply on ledera lands. See your Aulhori/ed &iggs I Slratlon Seru,ce Cenler lor spark arresler muttler oplions.

1. DO NOT TAMPER wlTH GOVERNOR SPRINGS,

GOVERNOR LINKS OR OTHER PABTS WHICH

MAY INCREASE THE GOVERNED ENGINE

SPEED.

THIS SYMBOL ANO/OR PROPERTY DAMAGE

ARE FOLLOWED CAREFULLY.

MEANS

I\,4AY

I TL Il]I], PERSONAL INJURY OCCUR UNLESS INSTRUCTIONS

Briggs & Stratton Service Center, To sewe you promptly and eflicienly,lhe Servics Contsr will nd lhe model. type and code nufiber on your engi e. Each Authorized Srvice Center ca.ds a slock ol

It service or repeir is needed, coniact an Aulhorized

Your nearest service center b listed ln th "Yellow Pages" under "Engins, Gasoline" or "Gasoline Engines". He is one of over 25.fi)0 authorized dealers avarlable to serve

original Briggs E Stratlon repair parls end 13 equipped with speclal srvlc6 tools, Traln6cl

mechanica asaureoxperl ropair servic on all Big93 I Stratlon enginee Major engine repaiB should nol b6 alt6mpted unlss you have the propertools and a lhorough knowledge of internal combuslion engine repair procedure.

ThB illuslratd book includs

"Thori$ ot Operation", oominlornetion coverlng lh adiu3tment. tun-up and repaiT procedures tor 2 through 16 H.P. single gylinder. 4 cycle models. lt is available from sny

Authorized Briggs & Slratlon

Numbr 270962.

lnon 3pciticslion3 end dlelld

Srvice Center. Ordr a8 Parl

This engine is a single-cylinder L'head, air-cooled

type.

iIODEL SERIES t 70400 and '171400

Bore. . . . . . . . . . Stroke .. .. .. ..

... .. .. .. .. .. .. ... .

WAFNING: For eleclricai salely, always remove cable lrom negalive G) side of lhe batlery belore attempting any repairs or haintenance.

STORAGE I}ISTRUCTIONS

Horsepower Max. ..... . . .. .. .. Torque (Fl. Lbs.) Max. Bore.

Displacemenl

.......

..

.. .. ..

.

.

. 3" (75-20 mm) 2-318" (60.33 mm)

1

16.79 cu. in. (275.1 cc)

...........

..

7.0 @ 3600 RPM 1.0 @ 2600 RPM

Engines to be stored over 30 day6 should be completely dralned ol fuel lo prvent gum dpo3ils lorming on $sntial carbu.etor p6rlq ful lilter and lank. NOTE:Theuse ol a tu6l add itive, suchasSTA-8lL@. or an equivalent willminimize lhe formalion ot luelgum cleposits during storage, Such an additivs may be added to lhegaso ine in lheluellank oflheengine, or to lhe gasoline in a storage conlainer.

. 3 (76.20 mm) . 2-314 (69.85 mm) Displacement 19.44 cu. in. (318.5 cc) Horsepower M6x... -..,.....,.,.. 8.0 @ 3600 RPM Torqu (Fl. Lbs.)Ma(. .........,. 12.7 @ 2500 RPM

Slroke

... .. .. .. ..-.-.. .. .. .. .. ..-. .. .-.. .. ..-.. .. .. .. .. ..

iIODEL SERIES 19q00 and 19s400

a. Alllu6lshould be removed fiom thtank. Run lhe

ngine unlil it stops from lack ol lu|. b. whi16ngine i3 stillwafin, drain olltrom cr6nkcaSe. Refill wilh lresh oil-

The horsepower ralings llsted arc establlshed ln accordance with the Soc'ely ol Aulomolive Enginoers Test Code-J607- For praclical operalion, the horcepower loading should nol exceed 85%oftheseralings. Engine power will decrease 3-1l2 for each 1,000 leet (304.8 m) above sea level and 1% lor each l0o

above 60' F (160 C).

ln some aree8, locallaw requires the usg ola r6i8lor

c, Femovesparkplug,pourapproximalelyl/2ounc

(15 cc) ot engine oil inlo cylinder and crank slowly lo distribute oil. Replace spark plug.

d. Clean dirt and chall from cylinder, cylinder head

lins, blower housing, rolaling screen and mulller

e. Slore in a clean and dry area.

WPICAL WIRING DIAGRAi'S

spark plug so es lo suppress ignilion signals. ll an engino was originally 6quippd wilh a rsistor spa* pluq. be surc lo use lhe sam lyp ol spark plug tor

TUNE.UP SPECIFICATIONS Spark Pluo TvDe Chamoion Shorl Plug cJ-8 Long Phrg J-8 RCJ.8 Resislor Shod Plug Resislor Long FJ-8

Autolite

235 295

Plug Spark Plug Gap

245

306

lnlake Valve Clearance . .. . ExhaustValve Clearance ..

.030" (.76 mm) .005"-.007" (.13-.18 mm) .009"-.011" (.23-.28 mm)

?sdo..el 3,305.??3 x7.5,303 107i,353 ..?330.3 x19a.224 1.3r,60. 1312,1! !.6!O3sa &0cr,72a .,r3A,?A3 .,?7050

3rra.39 3!.45.740 x!23orl 3,r3r343 3,93,35. .,i490&

AEAO THE OPERATiNG INSTRUCTIONS OF rHF EOUIPMENT THtS Et!c \E pOWEFS

FUEL NECOMMENOATIONS

SF, SE. SD or SC. Detergenr orts keep the e^gine cleaner and rerard the tormation of gum and varnish deposits. No specia additives shoutd be used with

RECOMMENDEO SAE VISCOSITY GRAOES

otL RECOmMENOArlOiIS Nole: Engln. b lhlpped lfltHOUT oit. Usea hrgh q ua rrty dtergent otr ctassitied ForService

Ourengines will operale satislactorityon any gasotine inlended lor aulomotave use. DO NOT MtX OtL WtTH

GASOLINE

I

(

rhn"i

.rr.oraraure

a

gasoline. Leacld gasoline may be used if lead,tree is nol available, A minimum ol 77 octane is recommended. The use ol lead-freegasoline resutts in fewer combuslion deposits and longer valve tite. NOTE: We DO NOT recommend lhe use ol gasotine which conlains alcohol, such as gasohot. However, il gasoline wilh alcohol is used, it MUST NOT contain lnorethan 10 percent Ethanotand MUSI buremoved

trom theengineduring srorage. DO NOt usegasotine containing Methanol. SeeSTORAGE tNSTRUCTIONS.

We recommend lhe use ol clean, tresh, tead-tree

DO NOT lill tuel tank to poinl rl ovedlowing. Allow approximately 1 /4' of tan,< space forfuel

svnna

o.;iiul,*da"no sw.: w :oo

if 10W-30 is

not

TYP AND COOE NIJMBENS ON BLOWEB HOUS NG

NOTE: 10W-40 oit may be used

TO FILL CBANKCASE WITH OIL

Place engine level. C ean area around oit lil belore removing oil ti I ptug or oit-minder, OIL FILL PLUG. Bemove oit titt plug or (optionat)oitmrnder. Fill crankcase to point ot overttowina. POUR Sl OWLY. Capac'ty approtimarety 2-3l4 pints (j.3 lilers) Beplace orl nllpluq or oit-mrnder.

EXIENDED OIL FtLL (Optaonat). Remove cap and dipsrick F|LL To FULL iitaRK on dipstick, pouR SLOWLY Capacrty apDroxrnarety 2-3ld pinls tt 3 lilers) Whencfeckrngor tev. pu sh or screw drpstick assembly lirmly but sowty unlitcap bo[oms on lube.

OO NOT OVERFILL. Dipsrick assembty must be se, curely assembled into ube at a trmes when enorne ,s operaling.

CHARGE BATTEFY

Charge batiery betore use on engines equipped wilh (OPTIONALj '2 volt etectric srader moror See equrpmenl manulaclurers recommendations.

FORM NO 270367-4/86

Starl, slore and fue engine in a level position.

DO NOT use a pressurized sladng lluid as severe internal engine dam6ge may occur due lo loss ot

lubrication.

OPEN FUEL VALVE

SPEEO CONTROL LEVER: Move speed conlrol lever to "RlJN. "FAST" or"START" posilion ilso equippd.

on ensines so equrpped.

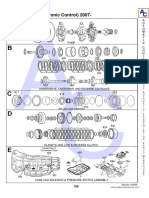

TYPICAI SPEED CON]FOLS

:")

TO START ENGINE

WABNING: ALWAYS KEEP HANOSAND FEET .CLEAR OF IVOWER BLADE OR OTHER

ROTATING [,4ACHINERY. CHOKE ENGINE: Engine may beequipped wilh ith6rmanual, 16mol or

choke-a-matic conlrols.

MANUAL CHOKE: Move ever as illuslraled.

Fewind St6rler. Grasp slertergip a3 illuslrated and pullslowly until starter ngages. Then pull

cord rapidly to overcome compression, prevenl kickback and start engine. Bepeat il necessary wilh choke opened slighlly. when

engine starts, open choke gradually.

Rope Starler, Wind th6

sla er rope around lhe

compression and provent kickback. Repeal il necessary with choke opened slightly. when engine stads, open choke gradually.

pulley in dir6clion shown by arrow. Pull lhe rope wilh e quick lullam slroko lo overcome

CHOKE-A-MATIC CONTROLS: ov conlrols as lar as possible loward "CHOKE'or "START".

TYPICAI CONTFOI STOP SWTCH:Move STOP switch away trom spark plug or to ON" position as illustraied, if so equipped.

CAt TION: Whn using rope starter lo crank engin, use caulion so knolled end ol rope does nol strik6 prsons standing nearbyElgctric Starter. T!rn key lo "STAnT" position and/or press starler butlon on powered equipmnt, The bsl starler liJe is providsd by using shortstanlng cyclsot several secondS, Prolongd cranking can damagethe

starler molor it crankd more than

l5

seconds per

minule. When engine slarls, open choke gradually.

NOIEi A warm engine requires lss choklng lhan a

cold engine, NOTE: Engine may noi slarl if conlrols on powered equipment do nol close choke lully. See AOJUSTt.4ENT seclion.

BUrroN

ffi*i

.F,

sunrrn

\l

TYPICAI SwlTCH

CAU]ION: The 120 voll eleclric slarler is equipped wilh a lhree-prong plug tor your safely. ll a longer extension cord is used, it should also have threeprong and three-hole plugs.

5, A warm baltery has much more slaning capacit than a cold ball6ry.

6. Use lresh winter grade fuel.

NOTE: Winter grade gasoline has higher volatility to

improve slarling. Do nol use gasoline llt over lrom

TO STOP EI{GI}IE Move conkol lo slow, then "STOP" or

It so

"OFF posilion. equipped, lurn keyorswitchto STOP"o. 'OFF" posalion, Do notchoke lhe carburelorlo slop engine,

NOTE: ll luel drips oul of carbu relor whilelrying to slart engine, the eng ine is over-choked. Pull slarter several times or actuale starter swilch wilh choke open.

When equipment is nol in operation, provide proleclion from di.ecl exposur to weathr,

colo wEltHER

1.

ge sure to uge th propr oil lor th tmperaturc

CAUT ON: Always remove key lrom switch when leaving mower unatlended or when mower is not in

st

nTrNG Hrr{ts

2. Oeclutch all possible exiernal loads. 3. Sel speed convol al part-lhrottle posilion. 4. A sllghtly .ichr lul mixture. obleind by luming

carburelor n66dl valv 1 /8 lurn counlrclockwis, will usually improve cold starling.

transporled to preventluel leakage lrom carburetor.

NOTE: Close luel shut-oll valve when onqine is

cAUTloN: TO PREVENT

AGCIDENTAL STARTING when servicing the engin or equipment, always removo th spark plug or wke lrom lhe spark plug and insert in holding

tab shown on page 3. Disconnectneoalive wire

Remove oil drain plug and drain oil while engine is wann- Replace drain plug. Remove oil lill plug, oilminde.. or cap and dipslick and relill with new oil ol proper gred. Roplaco oil lill plug, oil-minder or cap

and dipstick.

lrom batlery terminal it equipped wilh 12 volt

starting syslem.

gEEgIlllLtEyE!

CHA GE OIL (GEAR REDUCTION optional). Remove oillev6lplug and oiltill plug. Orain oilevery 100 hourc

rgularly stlr each live hours ol opTaIion. BE SUBE OIL LEVEL IS MAINTAINED,

CHANGE OIL aller tirsl live hours oloperalion. Thereafter change engine oil every 5() hours ol operalion, under normal operating condilions- Change eng ine oil every 25 hours of operation il the engine is operated

ol operatlon. To reJill, pour '10W-30 oil into liller hole untilil runs oul levelcheck hole. Replace bolh pl!gs. Oillillplug hasavenl holeand muslbe installed on lop

under heavy lo6d, or in high ambienl temperalures.

TO SERVICE AIR CLEAIIERS CARTAIDGE AIR CLEAI'IER Bemove and clean canridge yearly or after every 25

1.

Bemove wing nut and cover

2 Remove air cleaner carelully lo prevenl dirt trom

entering carburelor.

3. Take air cleaner aparland clean. a. WASH loam elemenl in keroseneorliquid doter-

hours- whichever occurs lirsl. Service more ollen il necessary. clean by lapping genlly on llal su ac6, lf very dirty, replace carlridge, or wash in a low or non-

sudsing delergenl and warm waler solulion. Rinse lhoroughly with llowing water lrom inside out unlil

waler is clear. Cartridge musl be allowed lo sland and air dry !!919!9[! belore usins.

genl6nd wal6r to remove dirt. b, Wrap ,oam in clolh and squeeze dry. c. Saturate loam with enoine oil. Squeeze to

remove excess oil.

cAuTloNr Petroleum solvents, such as kerosene, are nol io be used to clean cartridge- They may cause delerioralion ol lhe cartridge. DO NOT OIL CARTRIDGE. DO NOT USE PRESSURIZEDAIR TO CLEAN OR ORY CARTRIDGE.

4. Reassemble parts and lasten lo carburelor.

ruPtEBr

_ .dvFA --4_

-*a, z-:_-\

t

*"'ffi

OUAL ELEMENT AIA CLEAIIEF

*-.11?I*"\-2

lt

)-a-r

*--)

W'

FEMOVE COMaUsrloN oEPOSITS eve.y 100-300 hours ol operalion. Remove cylinde. head and cylinder head shield. Scrape and wire brush the combuslion deposils lrom cylinde., cylinder head, lop ol piston and around valves. use a soll brush to remove deposilsRe-assemble gaskel, cylinder head and cylinder had shield. Turn screws down linger lighl. wilh the three longer scrws a.ound lhe rhausl valve, il so qurp. p6d, Torque cylinder had scrows in a slaggred sequence to 140 inch pounds (15.82 Nm). Remove dirt and debriswilh a clolh CLEAN El{Gll{E or brush. Cleaning wilh a torcetu I spray of waler is nol

DUAL EIEI{ENT AN CIEANN (oPTtot{AL ox soME ooEls) Clean and re-oil toam pre-cleaner al lhree month intervals or every 25 hours, whichever occurs first

NOTE:Sewice more ollen under dusty conditions.

recommended as water could contaminate lhe luel

CLEAN COOLII{G SYSTEiI

1. Remove knob and cover. 2. Remove loam pre-cleanerbysliding itotflhe paper

carlridge.

clog lhe rotaling scr6n and the air cooling system,

Grass, chall or dirl may

3, a. Wash loam pre-cleaner

detergenl and waler.

especially etter prolonged service culling dry grass.

an

kerosene or liquid

Yearly or every 100 hours, whichevff occurs first,

remove th6 blower housing and clean lhe areas shown lo avoid ovrcpeeding. overhealing and engine demage- clean more often it necessary.

b. Wrap toam pre-cleaner in cloth and squeez

c. gelqets&erurg:glc3lslllrglcgLsqueeze

to remove excess oil.

4. lnstall loam pre-cleaner over paper carlridge. Reassemble cover and screw down tighl.

NOTE: Replace or clean carlridge included wilh DUA L ELEI\,{ENTAIF CLEANER yearlyorevery 100 hourses

!t

\-

described

in

CARTRIDGE AIA CLEANER. Service

WABNINGT Periodically clean mufller area to remove allgrass, dirtand combustible debris.

more ollen il neces$ry. TO SERVICE AIR CLEA}IER .OIL FOAM" AIR CLEANER Clean and re-oilloamelemenlorloampre-cleaneral

three monlh inlervals or every 25 hou.s, whichever

NOTE: Service more ollen under dusty condilions,

llengine SpARX ARRESTER EOUIPPEO UFFLER muffler isquipped with spa* arrslr screen assembly, remov very 50 hours lor cleaning and inspection. Feplac il damaged.

SPAnK pLUG

100 hours ol operation,

Cleen end rsetgap al.030" every

cauTtoNr Spa*ing can occur il wireterminal does nol lil lirmly on spark plug, or il stop switch vibEles againsl spark plug. Belorm lerminalor repair su,ilch il necessaryFUEL FILTER

screen and bowl every season.

Replace IN-LINE lilter

or

clean

NOTE: Oo nol blasl clsan spark plug. Spark plug should be cleaned by scraping or wire brushing end washing with a cornmercial solvent

CARBURETOR AOJUSTIIENTS Min or carburelor adjuslmenl may berequiredlo compensale lor dillerences in luel, lempe16lurg, allilud or

will nol accelerale properly,lh carburelor should bs

re-adjusled, usually to a slightly richer mixture. CO]{TROL AOJUSTMENTS Properchoke and stop swilch operation isdependent upon proper adjuslmenl of controls on the powered equipment.

load, NOTE| The air cleanr musl b assombled lo carburetorwhen running ongine,

Gently lurn valves clockwise onlil they j!9!close- Valves may be damaged by lurning them too far.

TO ADJUST CARBURETOR

Now open needlevalve

-1

/2 turnscounterclockwise

and idle valve one lurn. This initial adjuslment will permiilheengine to be started and warmed up priorto linal adiushenl.

IDTE SPEEO AOJUSIING SCREW

CO TROLS: Place lever on equipmenl in CHOKE (high speed) posilion. Loosen casing clamp screw B. [,4ovecasing ''a' and wire until lever "D" touches choke operating link al "C." Tighlen casing clamp scrw "8." Move lever to "STOP" position. Lever must make good conlacl with slop switch il so quippd.

TO ADJUST CHOKE.A.MATIC

NEEDLEVALVE (HGHSPEED)

FINAL AOJUST ET{T

Place speed control lever in "FAST" posilion. Turn needle valve in unlil engine slows (clockwise - lean mixture). Then lurn it out past smoolh operating point (rich maxture). Now turn needle valve to midpoint blween rich and lean. Next, adjusl idle RPM. Rolale lh rotlle counlerclockwise and hold againslstop while adiusting idle sped adjusling scre$/ lo oblain 175O RPl,{. Holding throtlle againsl idleslop,lurn idlevalve in (lean) and oul (rich). Sel at midpoint belween rich and ean. Recheck idle FPM. Release lhroltle. ll engine

SPEEO CO]ITROL ADJUSTiIENT The acceptableoperaling speed renge is 1800to 3600 RPM.ldlespeed is 1750 RPM-Tho manulacluret olths equipment on which the engine is used, specifies the top governed no load speed at which lhe engine may be operaled. DO NOT EXCEED this speed.

t,." t.

Potrebbero piacerti anche

- 2009 Commercial Truck BrochureDocumento17 pagine2009 Commercial Truck BrochureGateway Chevrolet Cadillac100% (1)

- S08337 PDFDocumento396 pagineS08337 PDFJhony KizeNessuna valutazione finora

- 6 Speed RWD (Electronic Control) 2007-: Revision 10/2009Documento3 pagine6 Speed RWD (Electronic Control) 2007-: Revision 10/2009krzysiek1975Nessuna valutazione finora

- Reliability. The Single Integrated and Engine Mounted Control Module Replaces TheDocumento2 pagineReliability. The Single Integrated and Engine Mounted Control Module Replaces TheJaafar Fadhil.AbboodNessuna valutazione finora

- Aries F450 F550 ManualDocumento19 pagineAries F450 F550 Manualedbodie33% (3)

- Axsm 0041Documento98 pagineAxsm 0041Walter ╰⏝╯ MaonesNessuna valutazione finora

- Perator S Anual: Hydrostatic Garden Tractor, 900 SeriesDocumento36 paginePerator S Anual: Hydrostatic Garden Tractor, 900 SeriesThomas SwinneyNessuna valutazione finora

- Service Manual: International® VT 365 Diesel EngineDocumento25 pagineService Manual: International® VT 365 Diesel EngineMeilis Ariza100% (1)

- M46 PUMPS HYDRAULIC SCHEMATICDocumento3 pagineM46 PUMPS HYDRAULIC SCHEMATICPepe AlNessuna valutazione finora

- Reyco Manual Axle Model 21B & 21-Y MediaDocumento36 pagineReyco Manual Axle Model 21B & 21-Y Mediahebert perezNessuna valutazione finora

- Spring 2020Documento45 pagineSpring 2020Jeff AllisonNessuna valutazione finora

- Motor E15 para Wood MizerDocumento40 pagineMotor E15 para Wood MizerCesar Edgardo Lopez PortilloNessuna valutazione finora

- AXSM0034-In Axle Speed SensorDocumento34 pagineAXSM0034-In Axle Speed Sensorwadalla100100% (1)

- Eaton Transmission Specifications Catalog en UsDocumento23 pagineEaton Transmission Specifications Catalog en UsservitronicjleNessuna valutazione finora

- Fabco PTO 180 PTO 180 23 Parts ManualDocumento27 pagineFabco PTO 180 PTO 180 23 Parts Manualeliseo cardosoNessuna valutazione finora

- VT275 Diagnostico 3Documento66 pagineVT275 Diagnostico 3emmanuelNessuna valutazione finora

- 27 1745 Chevy Silverado Installation Instructions CaridDocumento4 pagine27 1745 Chevy Silverado Installation Instructions CaridenthonytopmakNessuna valutazione finora

- Bobcat 974/975 Service Manual Skid Steer Loader Attachment GuideDocumento10 pagineBobcat 974/975 Service Manual Skid Steer Loader Attachment GuideGustavo Ramon Morinigo Ortigoza0% (1)

- Owner's ManualDocumento56 pagineOwner's ManualAlexis BriseñoNessuna valutazione finora

- Navistar, Inc.: 2701 Navistar Drive, Lisle, IL 60532 USADocumento1.135 pagineNavistar, Inc.: 2701 Navistar Drive, Lisle, IL 60532 USAMinh VũNessuna valutazione finora

- Re6 Relay Emergency ValveDocumento12 pagineRe6 Relay Emergency ValveVicente TanNessuna valutazione finora

- 02b2462c f0d8 41f7 8c8c D6ce304e67cc Sterling Acterra Driver's ManualDocumento148 pagine02b2462c f0d8 41f7 8c8c D6ce304e67cc Sterling Acterra Driver's ManualEnrique GiesbrechtNessuna valutazione finora

- SAP Catalog HeavyDutyDivision LDocumento176 pagineSAP Catalog HeavyDutyDivision LUrias SanchezNessuna valutazione finora

- Manual de Partesz225 PDFDocumento209 pagineManual de Partesz225 PDFManuel GuevaraNessuna valutazione finora

- EGES2651 ADocumento70 pagineEGES2651 ARonald BetancourtNessuna valutazione finora

- 2019 Kawasaki Brute Force 750 4x4i 1Documento197 pagine2019 Kawasaki Brute Force 750 4x4i 1Cristhian De La Barra100% (1)

- NEHS0708Documento9 pagineNEHS0708Victor Nunez100% (1)

- Clutch Selection Guidelines C102Documento24 pagineClutch Selection Guidelines C102Diego Alejandro Quintero100% (3)

- Product Technical Bulletin: BackgroundDocumento2 pagineProduct Technical Bulletin: BackgroundYolian Andres Aricapa CastañoNessuna valutazione finora

- Bezares PTO Application CatalogDocumento454 pagineBezares PTO Application CatalogTim WorkmanNessuna valutazione finora

- EPA07 MBE 4000 Standard Grid Heater Relay Installation InstructionsDocumento6 pagineEPA07 MBE 4000 Standard Grid Heater Relay Installation InstructionsАндрейNessuna valutazione finora

- SPX Power Team Pt1403bDocumento240 pagineSPX Power Team Pt1403bjeedanNessuna valutazione finora

- Atkinson Tractor Service Shop Manual Unit 1 - Engine and Ancilliary EquipmentDocumento26 pagineAtkinson Tractor Service Shop Manual Unit 1 - Engine and Ancilliary EquipmentDavid Kelly100% (1)

- John Deere Z225 EZTrak Mower (North American Version) Service Repair Manual (Tm1477)Documento15 pagineJohn Deere Z225 EZTrak Mower (North American Version) Service Repair Manual (Tm1477)zhuangfuqian31Nessuna valutazione finora

- GXV160H213Z1V402VerV PDFDocumento92 pagineGXV160H213Z1V402VerV PDFLupin GonzalezNessuna valutazione finora

- Technical Service Bulletin: ISB4.5 CM2150 SN and ISB6.7 CM2150 SN Engine IntroductionDocumento3 pagineTechnical Service Bulletin: ISB4.5 CM2150 SN and ISB6.7 CM2150 SN Engine IntroductionIan WoodsNessuna valutazione finora

- TRIG0082 - 1007-Modified Cover PDFDocumento80 pagineTRIG0082 - 1007-Modified Cover PDFLuis AlcalaNessuna valutazione finora

- Cf500 Circuit DiagramsDocumento197 pagineCf500 Circuit DiagramsARY TOGINHO0% (1)

- Parts Manual: 60 HZ Homesite Power Portable Generator SetDocumento32 pagineParts Manual: 60 HZ Homesite Power Portable Generator SetKoalla WarNessuna valutazione finora

- Codigos y Partes de CoronaDocumento56 pagineCodigos y Partes de CoronaAntony Moreno0% (1)

- Serial Number Range: From SN 4551Documento250 pagineSerial Number Range: From SN 4551Святослав ВороновNessuna valutazione finora

- Caja 8908LL EspDocumento2 pagineCaja 8908LL EspDanny M Hurtado TaypeNessuna valutazione finora

- Windsor Saber Service ManualDocumento104 pagineWindsor Saber Service Manualsully1974Nessuna valutazione finora

- Tecumseh Model Tvs90 43000b Parts ListDocumento9 pagineTecumseh Model Tvs90 43000b Parts ListSandra SpeedNessuna valutazione finora

- Illustrated Parts List: RTO-14908LL November 2008Documento34 pagineIllustrated Parts List: RTO-14908LL November 2008Agustin FigueroaNessuna valutazione finora

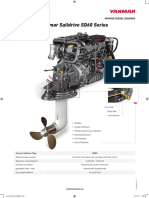

- Yanmar Saildrive SD50 & SD60 Series Marine Diesel EnginesDocumento4 pagineYanmar Saildrive SD50 & SD60 Series Marine Diesel EngineshastaNessuna valutazione finora

- MBE900 Fuel Filter HousingDocumento3 pagineMBE900 Fuel Filter HousingJosue Alvarez VegaNessuna valutazione finora

- 2000 Series Genset Circuit DiagramDocumento5 pagine2000 Series Genset Circuit Diagramaung minhtetNessuna valutazione finora

- Standard Clutch PDFDocumento136 pagineStandard Clutch PDFEduar Drink Lozano100% (1)

- Dobdsm971 PDFDocumento25 pagineDobdsm971 PDFTecknobites VallenarNessuna valutazione finora

- 1776279Documento82 pagine1776279Tengku Nizarul AslamiNessuna valutazione finora

- Maxxforce DT, 9 and 10 Turbocharger Repair: Study Guide Tmt-121003Documento26 pagineMaxxforce DT, 9 and 10 Turbocharger Repair: Study Guide Tmt-121003Sicein Sas100% (1)

- 2008-09-01 165737 93 Rolla4Documento16 pagine2008-09-01 165737 93 Rolla4Ricard WibowoNessuna valutazione finora

- Series 60 - Section 1.9 Crankshaft Main BearingsDocumento11 pagineSeries 60 - Section 1.9 Crankshaft Main BearingsJuan RiveraNessuna valutazione finora

- Spicer AXSM 0030Documento43 pagineSpicer AXSM 0030slipsittinNessuna valutazione finora

- DJC Parts Onan Cummins PDFDocumento130 pagineDJC Parts Onan Cummins PDFStalin Paul Rodriguez LeonNessuna valutazione finora

- ETCS-I (Electronic Throttle Control System-Intelligent)Documento9 pagineETCS-I (Electronic Throttle Control System-Intelligent)ShzllNessuna valutazione finora

- Honda EM 3500 XDocumento56 pagineHonda EM 3500 XDokhtar SaidiNessuna valutazione finora

- Billy Goat Leaf Blower QB882ICDocumento8 pagineBilly Goat Leaf Blower QB882ICjmorfit3Nessuna valutazione finora

- The Mercedes-Maybach S-Class.: The Essence of LuxuryDocumento28 pagineThe Mercedes-Maybach S-Class.: The Essence of LuxuryManu0301Nessuna valutazione finora

- Waterjets Vs PropellersDocumento1 paginaWaterjets Vs Propellersaeromexpower2009Nessuna valutazione finora

- Driveline System - General Information - Driveline SystemDocumento64 pagineDriveline System - General Information - Driveline SystembledmikifrNessuna valutazione finora

- INTERSHIP Wagon Repair Shop, Kota, RajasthanDocumento18 pagineINTERSHIP Wagon Repair Shop, Kota, RajasthanDeepak Meena50% (2)

- Mazda cx5 Bodyshop Manual5 PDFDocumento1 paginaMazda cx5 Bodyshop Manual5 PDFДаниил РоманюкNessuna valutazione finora

- Ford 6.0L Fuel Injection Control Module Information (FICM)Documento2 pagineFord 6.0L Fuel Injection Control Module Information (FICM)ford62b100% (1)

- Bobcat 742b y 743bDocumento271 pagineBobcat 742b y 743bGustavo100% (5)

- Codigos de Falla Caravan 1996 PDFDocumento4 pagineCodigos de Falla Caravan 1996 PDFTizzie ContrerasNessuna valutazione finora

- NCV3 Automotive Repair and Maintenance December 2020Documento5 pagineNCV3 Automotive Repair and Maintenance December 2020SILINDOKUHLE NKUNZINessuna valutazione finora

- Electric Hydraulic Power Steering Components CatalogDocumento8 pagineElectric Hydraulic Power Steering Components CatalogLidia RaduNessuna valutazione finora

- E - Jet ChecklistDocumento1 paginaE - Jet Checklisttallie.tyeNessuna valutazione finora

- REGENERATIVE BRAKINGDocumento6 pagineREGENERATIVE BRAKINGVivek SinghNessuna valutazione finora

- Cat Sebp5922!00!01-All Mini Orugas PBDocumento377 pagineCat Sebp5922!00!01-All Mini Orugas PBWilliam RicoNessuna valutazione finora

- SUNITRAC OTR Tyre CatalogDocumento12 pagineSUNITRAC OTR Tyre CatalogCarlos Alberto Reque BardalesNessuna valutazione finora

- 4.1.1 Ex3600-5Documento276 pagine4.1.1 Ex3600-5soelist teo86% (7)

- Smittybilt2018 Catalog PDFDocumento143 pagineSmittybilt2018 Catalog PDFKotot HadisoemartoNessuna valutazione finora

- Bascolin CR Nozzle CatalougeDocumento64 pagineBascolin CR Nozzle CatalougeXuân TườngNessuna valutazione finora

- Catalogo de Partes Mtu Nuevo 5272010539 - enDocumento202 pagineCatalogo de Partes Mtu Nuevo 5272010539 - enDiego RodriguezNessuna valutazione finora

- Utes Flat Decks and Gullwing Boxes PDFDocumento6 pagineUtes Flat Decks and Gullwing Boxes PDFReikoMoriNessuna valutazione finora

- BULLDOZER HP 78 PDFDocumento8 pagineBULLDOZER HP 78 PDFBayu HandokoNessuna valutazione finora

- Jhon Derre 644Documento570 pagineJhon Derre 644hidraulicos100% (3)

- Model Year MG SG Illustration Restrictions UPD: Et - bt1.frmDocumento3 pagineModel Year MG SG Illustration Restrictions UPD: Et - bt1.frmStaffan FogelbergNessuna valutazione finora

- Lista de Atualizações Simplus 2022/2: Manual Sas Modelos MarcaDocumento22 pagineLista de Atualizações Simplus 2022/2: Manual Sas Modelos MarcaGabriel PortoNessuna valutazione finora

- CPP vs FPP: Controllable vs Fixed Pitch PropellersDocumento4 pagineCPP vs FPP: Controllable vs Fixed Pitch PropellersRamonValdezNessuna valutazione finora

- Joanna Langford 2019 JEEP/EAGLE COMPASS 4cyl 2.4L FI Kilometers 34057 VIN 3C4NJDBB1KT732894Documento2 pagineJoanna Langford 2019 JEEP/EAGLE COMPASS 4cyl 2.4L FI Kilometers 34057 VIN 3C4NJDBB1KT732894Joan LangfordNessuna valutazione finora

- Cub Cadet Parts Manual For Model Z Force 48 Kohler 17af3agvDocumento6 pagineCub Cadet Parts Manual For Model Z Force 48 Kohler 17af3agvirene100% (44)

- AFX Tuning Manual REV 06Documento15 pagineAFX Tuning Manual REV 06Derek KloogNessuna valutazione finora

- 9797 NXT LEGO Kit: Basic Car Building Instructions: Downloaded From Manuals Search EngineDocumento19 pagine9797 NXT LEGO Kit: Basic Car Building Instructions: Downloaded From Manuals Search EngineJohnny Romero MiliánNessuna valutazione finora

- Engine Parts Manual for SAA4D95LE-5D S/N 521394-UPDocumento157 pagineEngine Parts Manual for SAA4D95LE-5D S/N 521394-UPGustavoOliveira100% (1)

- Service Manual Trucks: WWW - Motodiesel.irDocumento128 pagineService Manual Trucks: WWW - Motodiesel.irCipitok TuaNessuna valutazione finora

- The Grid: The Fraying Wires Between Americans and Our Energy FutureDa EverandThe Grid: The Fraying Wires Between Americans and Our Energy FutureValutazione: 3.5 su 5 stelle3.5/5 (48)

- Industrial Piping and Equipment Estimating ManualDa EverandIndustrial Piping and Equipment Estimating ManualValutazione: 5 su 5 stelle5/5 (7)

- Introduction to Power System ProtectionDa EverandIntroduction to Power System ProtectionValutazione: 5 su 5 stelle5/5 (1)

- Renewable Energy: A Very Short IntroductionDa EverandRenewable Energy: A Very Short IntroductionValutazione: 4.5 su 5 stelle4.5/5 (12)

- Power of Habit: The Ultimate Guide to Forming Positive Daily Habits, Learn How to Effectively Break Your Bad Habits For Good and Start Creating Good OnesDa EverandPower of Habit: The Ultimate Guide to Forming Positive Daily Habits, Learn How to Effectively Break Your Bad Habits For Good and Start Creating Good OnesValutazione: 4.5 su 5 stelle4.5/5 (21)

- The Complete HVAC BIBLE for Beginners: The Most Practical & Updated Guide to Heating, Ventilation, and Air Conditioning Systems | Installation, Troubleshooting and Repair | Residential & CommercialDa EverandThe Complete HVAC BIBLE for Beginners: The Most Practical & Updated Guide to Heating, Ventilation, and Air Conditioning Systems | Installation, Troubleshooting and Repair | Residential & CommercialNessuna valutazione finora

- OFF-GRID PROJECTS: A Comprehensive Beginner's Guide to Learn All about OffGrid Living from A-Z and Live a Life of Self-SufficiencyDa EverandOFF-GRID PROJECTS: A Comprehensive Beginner's Guide to Learn All about OffGrid Living from A-Z and Live a Life of Self-SufficiencyNessuna valutazione finora

- Asset Integrity Management for Offshore and Onshore StructuresDa EverandAsset Integrity Management for Offshore and Onshore StructuresNessuna valutazione finora

- Handbook on Battery Energy Storage SystemDa EverandHandbook on Battery Energy Storage SystemValutazione: 4.5 su 5 stelle4.5/5 (2)

- Idaho Falls: The Untold Story of America's First Nuclear AccidentDa EverandIdaho Falls: The Untold Story of America's First Nuclear AccidentValutazione: 4.5 su 5 stelle4.5/5 (21)

- The New 3D Layout for Oil & Gas Offshore Projects: How to ensure successDa EverandThe New 3D Layout for Oil & Gas Offshore Projects: How to ensure successValutazione: 4.5 su 5 stelle4.5/5 (3)

- Shorting the Grid: The Hidden Fragility of Our Electric GridDa EverandShorting the Grid: The Hidden Fragility of Our Electric GridValutazione: 4.5 su 5 stelle4.5/5 (2)

- Flow Analysis for Hydrocarbon Pipeline EngineeringDa EverandFlow Analysis for Hydrocarbon Pipeline EngineeringNessuna valutazione finora

- Formulas and Calculations for Drilling, Production, and Workover: All the Formulas You Need to Solve Drilling and Production ProblemsDa EverandFormulas and Calculations for Drilling, Production, and Workover: All the Formulas You Need to Solve Drilling and Production ProblemsNessuna valutazione finora

- Build Your Own Electric Vehicle, Third EditionDa EverandBuild Your Own Electric Vehicle, Third EditionValutazione: 4.5 su 5 stelle4.5/5 (3)

- The Rare Metals War: the dark side of clean energy and digital technologiesDa EverandThe Rare Metals War: the dark side of clean energy and digital technologiesValutazione: 5 su 5 stelle5/5 (2)

- Transmission Pipeline Calculations and Simulations ManualDa EverandTransmission Pipeline Calculations and Simulations ManualValutazione: 4.5 su 5 stelle4.5/5 (10)

- Introduction to Power System ProtectionDa EverandIntroduction to Power System ProtectionNessuna valutazione finora

- Implementing an Integrated Management System (IMS): The strategic approachDa EverandImplementing an Integrated Management System (IMS): The strategic approachValutazione: 5 su 5 stelle5/5 (2)

- Nuclear Energy in the 21st Century: World Nuclear University PressDa EverandNuclear Energy in the 21st Century: World Nuclear University PressValutazione: 4.5 su 5 stelle4.5/5 (3)

- ISO 50001: A strategic guide to establishing an energy management systemDa EverandISO 50001: A strategic guide to establishing an energy management systemNessuna valutazione finora

- Energy, Light and Electricity - Introduction to Physics - Physics Book for 12 Year Old | Children's Physics BooksDa EverandEnergy, Light and Electricity - Introduction to Physics - Physics Book for 12 Year Old | Children's Physics BooksNessuna valutazione finora

- Operational Amplifier Circuits: Analysis and DesignDa EverandOperational Amplifier Circuits: Analysis and DesignValutazione: 4.5 su 5 stelle4.5/5 (2)

- The Boy Who Harnessed the Wind: Creating Currents of Electricity and HopeDa EverandThe Boy Who Harnessed the Wind: Creating Currents of Electricity and HopeValutazione: 4 su 5 stelle4/5 (130)

- Air-Cooled Condenser Fundamentals: Design, Operations, Troubleshooting, Maintenance, and Q&ADa EverandAir-Cooled Condenser Fundamentals: Design, Operations, Troubleshooting, Maintenance, and Q&AValutazione: 5 su 5 stelle5/5 (1)