Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Glove Boxes: Key Features of A Glovebox

Caricato da

Julian Andres GarciaDescrizione originale:

Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Glove Boxes: Key Features of A Glovebox

Caricato da

Julian Andres GarciaCopyright:

Formati disponibili

Glove Boxes

Key features of a glovebox The Antechamber

A glovebox is not much good if you don't have a way of getting your materials in and out. If you look at the pictures above, you'll notice that there is a sealed chamber on the right side of the glovebox. This chamber is called the antechamber (or "port" by some) and it has two doors -- one that can be opened only from the inside of the box and one that can be opened only from the outside. As you can see in the photo on the left, the outer door to the antechamber is open, ready for glassware to be placed inside. See below to see how the antechamber is used. The antechamber can be evacuated with a pump or filled with nitrogen gas. Never have both doors open at the same time!!

The Photohelic Gauge

The photohelic gauge controls the upper and lower pressure limits in a glovebox. Modern gloveboxes use a solid state controller or touch screen interface, but the function is the same. If the pressure in the box gets too high, the controller automatically opens a valve to the vacuum pump to relieve the excess pressure and prevent the gloves from blowing off. Likewise, if the pressure is too low, the controller fills the box with nitrogen. You can set these upper and lower limits by turning the two small knobs below the gauge. The two red needles on the gauge indicate the current

settings and the black one (coincident with the lower setting in this photo) indicates the current pressure. Having the glovebox at a negative pressure with respect to the atmosphere is a Bad Thing because air will be drawn into the box through any small pinholes or leaks. Therefore, one tends to operate a glovebox at a slight positive pressure (i.e. both the cutoffs should be to the left side of zero).

The Pedatrol

The pedatrol is a foot pedal that allows one to manually adjust the pressure inside the glovebox. The high and low limits set on the photohelic gauge still apply, but you can use the pedatrol to open the box to the vacuum pump or the nitrogen supply to get the pressure to a comfortable working level. Notice that the pedatrol is sort of like a two-button computer mouse. Pressing on the left side decreases the pressure in the box and pressing on the right side increases it. No, you can't press both sides at once!

The Gloves

The gloves are obviously an important component of the glovebox. The gloves on a glovebox are usually sized large so that anyone can get their hands in. This makes life a bit difficult for people with small hands, but one quickly learns how to deal with oversized gloves. The biggest threat to the atmospheric integrity of the glovebox comes from pinholes and cuts in the gloves. The most common ways of damaging the gloves involve the use of razor blades, copper wire (sharp ends), syringe needles and scissors inside the box. If you do use any of these BE EXTREMELY CAREFUL!! Gloves are rather expensive and replacement is required if there are more than three or four pinholes on either glove (depending on size).

The Drytrain

On a research grade glovebox, the atmosphere is purified to less than 1 ppm H2O and less than 5 ppm O2 by circulating it through a catalyst bed (also called a "dry train"). The catalyst bed contains Q5 catalyst to remove oxygen as well as zeolites to remove water. After a period of use, the dry train is regenerated by isolating it from the box, exposing it

to hydrogen gas and heating it. The adsorbed oxygen is converted into water and the water is easily removed in vacuo.

Schlenk Lines and Vacuum Lines

One or two manifolds?

A Schlenk or high vacuum line consists of a glass manifold that has several stopcocks, valves or openings in addition to a connection to a vacuum source (typically a mechanical and/or diffusion pump). Having several ports on the line is convenient because several different flasks or reaction vessels may be used simultaneously. For example, gases can be vacuum transferred from one flask to another or several reactions may be run at the same time.

These lines may be of a dual or single manifold design. In a single manifold design, the manifold's main purpose is for vacuum. Here is an example of a single manifold design which uses all-Teflon(tm) valves and O-ring joints to ensure a good vacuum seal. Each port has its own independent bubbler, so up to three reactions can be stirring under nitrogen at one time.

A dual manifold design provides one manifold for vacuum and another for nitrogen or a reactant gas. A connection between the two manifolds permits the nitrogen manifold to be easily evacuated. Shown below is a diagram of a dual manifold high vacuum line. Note that the lower manifold is for vacuum and the upper one is for nitrogen.

Two features worth noting in this drawing are:

1. Main Trap. When the line is running, this trap is immersed in a liquid nitrogen dewar. This stops volatile or corrosive vapors that have escaped the pre-trap and prevents them from entering the pump. New pumps can cost one to two thousand dollars, so protecting the pump is its ONLY role. NEVER PULL SOLVENTS INTO THE MAIN TRAP! 2. Pre-Trap. This is an additional liquid nitrogen trap to condense vapors or gases from the vacuum line. It is also used to collect solvents that are removed from reaction flasks. If you are removing a lot of solvent from a reaction the nitrogen level will drop quickly, so be sure to keep an eye on it. Click on any of these manifolds for more information or to order:

Dual Manifold Line

Single Manifold Line

Dual Manifold, Souza Design

Single Bank Manifold

Double Bank Manifold 4-port Vacuum/Inert Line

Potrebbero piacerti anche

- Concentration of Solutions DLPDocumento3 pagineConcentration of Solutions DLPLouise Meara Severo70% (10)

- Peugeot HyrdrovacDocumento45 paginePeugeot HyrdrovacKarni100% (1)

- A Beginner's Guide To The Rotary EvaporatorDocumento4 pagineA Beginner's Guide To The Rotary EvaporatordominicbelawingNessuna valutazione finora

- Plastic Injection Mold Design for Toolmakers - Volume I: Plastic Injection Mold Design for Toolmakers, #1Da EverandPlastic Injection Mold Design for Toolmakers - Volume I: Plastic Injection Mold Design for Toolmakers, #1Valutazione: 5 su 5 stelle5/5 (2)

- Technical Textiles Application in DifferentDocumento149 pagineTechnical Textiles Application in DifferentAredaNessuna valutazione finora

- Fan Lub CFM56-7 - HandbookDocumento44 pagineFan Lub CFM56-7 - HandbookANDRANessuna valutazione finora

- Reactor Startup ProcedureDocumento3 pagineReactor Startup ProcedureAjgaj1Nessuna valutazione finora

- Bag FiltersDocumento18 pagineBag FiltersMehmet C100% (2)

- Hersill - KAV-1 - CO2 Absorber - UserManualDocumento12 pagineHersill - KAV-1 - CO2 Absorber - UserManualAnniel Mendez Broche100% (1)

- Vacuum DistillationDocumento1 paginaVacuum Distillationzephyr_2090Nessuna valutazione finora

- Chem 1140 Techniques For Handling Air-Sensitive CompoundsDocumento28 pagineChem 1140 Techniques For Handling Air-Sensitive Compoundsadee13100% (1)

- M-Braun Glovebox System Operation ProcedureDocumento5 pagineM-Braun Glovebox System Operation ProcedureharNessuna valutazione finora

- Operation Manual For Anaesthesia Machine NarkovetDocumento6 pagineOperation Manual For Anaesthesia Machine NarkovetliputariNessuna valutazione finora

- SopDocumento8 pagineSopSean PassinoNessuna valutazione finora

- Purpose of Vaccum DistilationDocumento5 paginePurpose of Vaccum DistilationChad RedwoodNessuna valutazione finora

- Equipment Used During VentingDocumento9 pagineEquipment Used During VentingRahulChoudharyNessuna valutazione finora

- Vacuumpump TroubleshootingDocumento5 pagineVacuumpump TroubleshootingKelly RobertsNessuna valutazione finora

- Manual Pump Down On An Air ConditioningDocumento7 pagineManual Pump Down On An Air ConditioningRay Ravel100% (1)

- Coleman Vacu PrintDocumento2 pagineColeman Vacu PrintAlejandra Vera LopezNessuna valutazione finora

- Tank BlanketingDocumento5 pagineTank BlanketingRahul LavandNessuna valutazione finora

- App GCFIDAirDocumento6 pagineApp GCFIDAirHamidNessuna valutazione finora

- Vacuum TechDocumento4 pagineVacuum TechCesar AugustoNessuna valutazione finora

- KORALLIN Kalkreaktor Check List: Incl. Lid, Tubing, White Pad, Sieve, Screws, Integrated O-Ring, EtcDocumento5 pagineKORALLIN Kalkreaktor Check List: Incl. Lid, Tubing, White Pad, Sieve, Screws, Integrated O-Ring, EtcHumberto DTNessuna valutazione finora

- Operating Instructions: 14.35 Soil Oxygen Analysis SystemDocumento4 pagineOperating Instructions: 14.35 Soil Oxygen Analysis SystemMadalin ApNessuna valutazione finora

- Manual Pump Down On An Air ConditioningDocumento5 pagineManual Pump Down On An Air ConditioningRay RavelNessuna valutazione finora

- Distillation ColumnDocumento192 pagineDistillation ColumnUbaid176100% (1)

- Maintenance of Oxygen FlowmeterDocumento14 pagineMaintenance of Oxygen Flowmeterver_at_work100% (2)

- Tank Blanketing BasicsDocumento4 pagineTank Blanketing BasicsOmkar VazeNessuna valutazione finora

- Valves ArticuloDocumento5 pagineValves ArticuloJohanna SanabriaNessuna valutazione finora

- Vehicle Rescue Equipment: Air BagsDocumento35 pagineVehicle Rescue Equipment: Air BagsTaqveem Mushahid AliNessuna valutazione finora

- Deep Vacuum PrinciplesDocumento4 pagineDeep Vacuum PrinciplesJohnMerrNessuna valutazione finora

- User Manual Thetford Cassette C200Documento36 pagineUser Manual Thetford Cassette C200Robert MillsNessuna valutazione finora

- 11mm ColumnDocumento3 pagine11mm Columnpepecolon123Nessuna valutazione finora

- Research Question Exp 1 ME LAB 2 Other AnswerDocumento21 pagineResearch Question Exp 1 ME LAB 2 Other Answerlittaua019Nessuna valutazione finora

- Hanshin 2519-3241VHDocumento7 pagineHanshin 2519-3241VHnotaden1849Nessuna valutazione finora

- Various Type of Steam TrapsDocumento46 pagineVarious Type of Steam TrapsRamesh VenugopalNessuna valutazione finora

- CtdrinssDocumento10 pagineCtdrinssAlejandra Cale RadowitzNessuna valutazione finora

- Low Vacuum Levels PDFDocumento2 pagineLow Vacuum Levels PDFbalaNessuna valutazione finora

- HORIZONTAL AUTOCLAVE USER MANUAL With Vacuum PumpDocumento8 pagineHORIZONTAL AUTOCLAVE USER MANUAL With Vacuum Pumpmaruti jadhavNessuna valutazione finora

- Technical PapersDocumento4 pagineTechnical PapersKanishk PandeyNessuna valutazione finora

- Chapter 7: Oil Vapor Diffusion Pumps: Theory of OperationDocumento9 pagineChapter 7: Oil Vapor Diffusion Pumps: Theory of OperationGyu BotNessuna valutazione finora

- Drawover Anaesthesia: Supplemental OxygenDocumento7 pagineDrawover Anaesthesia: Supplemental Oxygenapi-142637023Nessuna valutazione finora

- PBR 1000L - Instruction Manual 1.92Documento23 paginePBR 1000L - Instruction Manual 1.92Zoran ConstantinescuNessuna valutazione finora

- Continuous Blending System (Zelfbouwverhaal)Documento4 pagineContinuous Blending System (Zelfbouwverhaal)miguek clementsNessuna valutazione finora

- Cavitation TheoryDocumento6 pagineCavitation TheoryRahimd FoxNessuna valutazione finora

- Coin Box Based Automatic WheelDocumento52 pagineCoin Box Based Automatic WheelAakash DindigulNessuna valutazione finora

- Solenoid Valve TypesDocumento6 pagineSolenoid Valve Typeschdi0% (1)

- O2 PSA Design NotesDocumento3 pagineO2 PSA Design NotesTushar AgarwalNessuna valutazione finora

- Steam TrapsDocumento5 pagineSteam TrapsAdel Suker100% (1)

- Full Paper: Industrial Filters and Fabrics (P) LTDDocumento8 pagineFull Paper: Industrial Filters and Fabrics (P) LTDKenny RuizNessuna valutazione finora

- Control Valve - Theory & SizingDocumento29 pagineControl Valve - Theory & SizingSandeep KulathapallilNessuna valutazione finora

- Boom ScenarioDocumento2 pagineBoom ScenarioColin MurrayNessuna valutazione finora

- Venturi Nozzle Systems Questions and AnswersDocumento1 paginaVenturi Nozzle Systems Questions and Answersbalaji12031988Nessuna valutazione finora

- HAMMER Modeling Reference - Air Valves - Haestad - Hydraulics and Hydrology Wiki - Haestad - Hydraulics and Hydrology - Bentley CommunitiesDocumento18 pagineHAMMER Modeling Reference - Air Valves - Haestad - Hydraulics and Hydrology Wiki - Haestad - Hydraulics and Hydrology - Bentley CommunitiesSalaheddine OURNessuna valutazione finora

- Refrigerant Charging Procedure in Automotive ADocumento3 pagineRefrigerant Charging Procedure in Automotive AAnnalyn MendozaNessuna valutazione finora

- CDB Filters CatalogDocumento47 pagineCDB Filters CatalogjasonlaiymNessuna valutazione finora

- Introduction To Practical PneumaticsDocumento28 pagineIntroduction To Practical PneumaticsAjay PesadoNessuna valutazione finora

- Quick Easy Fixes RepairsDocumento57 pagineQuick Easy Fixes RepairsCaleb Garrett100% (2)

- Blow Down ProcedureDocumento7 pagineBlow Down ProcedureAayush AgrawalNessuna valutazione finora

- Autotrol 255-268 742-762Documento84 pagineAutotrol 255-268 742-762doctorstrambalemneNessuna valutazione finora

- Crap, The Shitter Is Broke! -Or- How To Fix Common Problems With Your ToiletDa EverandCrap, The Shitter Is Broke! -Or- How To Fix Common Problems With Your ToiletNessuna valutazione finora

- Contemporary Anaesthetic Equipments.: An Aid for Healthcare ProfessionalsDa EverandContemporary Anaesthetic Equipments.: An Aid for Healthcare ProfessionalsNessuna valutazione finora

- Popular Mechanics: How to Fix Anything: Essential Home Repairs Anyone Can DoDa EverandPopular Mechanics: How to Fix Anything: Essential Home Repairs Anyone Can DoValutazione: 4 su 5 stelle4/5 (2)

- Langbeinite ProcessingDocumento5 pagineLangbeinite ProcessingPınar EroğluNessuna valutazione finora

- Using An Automatic PipetteDocumento6 pagineUsing An Automatic PipetteMaria Jayiera Alkiela Pe�alesNessuna valutazione finora

- Surface Chemistry of Solid and Liquid Interfaces PDFDocumento365 pagineSurface Chemistry of Solid and Liquid Interfaces PDFSuchat KotcheapNessuna valutazione finora

- Pool Operator HandbookDocumento87 paginePool Operator Handbooktonyeld100% (2)

- Food Chemistry: M.S. Altaki, F.J. Santos, M.T. GalceranDocumento6 pagineFood Chemistry: M.S. Altaki, F.J. Santos, M.T. GalceranAberuNessuna valutazione finora

- A Modified UNIFAC ModelDocumento16 pagineA Modified UNIFAC Modelmappemaq100% (1)

- Eb587 PDFDocumento12 pagineEb587 PDFAuroraNessuna valutazione finora

- PG Mod Al Test PaperDocumento24 paginePG Mod Al Test PaperChiWoTangNessuna valutazione finora

- Exotic TarantulasDocumento82 pagineExotic TarantulasThiago MartinsNessuna valutazione finora

- MP Filtri Accessories HydraulicsDocumento12 pagineMP Filtri Accessories HydraulicsDaniel MarNessuna valutazione finora

- What Is DrugDocumento9 pagineWhat Is DrugFebz CanutabNessuna valutazione finora

- Chemistry 12 - Reaction KineticsDocumento16 pagineChemistry 12 - Reaction Kineticscharanbagh6402Nessuna valutazione finora

- Concentration Term Jee Main Selected 2Documento3 pagineConcentration Term Jee Main Selected 2aebafbigiNessuna valutazione finora

- Articol Excelent ZerDocumento20 pagineArticol Excelent Zerlylya_bejenaruNessuna valutazione finora

- Axis TurbineDocumento7 pagineAxis TurbineBhertrand GomesNessuna valutazione finora

- Khairat Al-Emar Co. For Oil Services: Material Safety Data SheetDocumento6 pagineKhairat Al-Emar Co. For Oil Services: Material Safety Data SheetqwaszxcdeNessuna valutazione finora

- Clinical Restorative Dental Materials Guide: University of California Los Angeles School of DentistryDocumento43 pagineClinical Restorative Dental Materials Guide: University of California Los Angeles School of DentistrySergioPachecoSerranoNessuna valutazione finora

- Chemical and MSDS RegisterDocumento5 pagineChemical and MSDS RegisterRhen HalfferzrheinsNessuna valutazione finora

- NTK O2 Sensor HistoryDocumento9 pagineNTK O2 Sensor Historyonukvedat7219Nessuna valutazione finora

- 13 - Chapter 3Documento32 pagine13 - Chapter 3Wahab Al-QaisiNessuna valutazione finora

- Cambridge International AS & A Level: Chemistry 9701/12Documento16 pagineCambridge International AS & A Level: Chemistry 9701/12O and A Level TutorNessuna valutazione finora

- Lied Mann 2017Documento8 pagineLied Mann 2017Chandra SekarNessuna valutazione finora

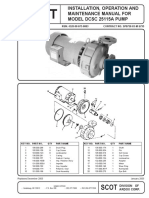

- Manual Maintenance Scot PumpDocumento4 pagineManual Maintenance Scot Pumpadrian suicaNessuna valutazione finora

- Diphenylamine and Derivatives in The Environment: A Review: Chemosphere January 2004Documento11 pagineDiphenylamine and Derivatives in The Environment: A Review: Chemosphere January 2004Muhammad Taufik MahadikaNessuna valutazione finora

- 110 WS Gas Stoichiometry KeyDocumento2 pagine110 WS Gas Stoichiometry Keyエルミタ ジョイ ファティマ100% (1)

- Expt 7 - Unit Cells (Virtual Lab)Documento9 pagineExpt 7 - Unit Cells (Virtual Lab)Angel De LoyolaNessuna valutazione finora