Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Rack Fundamentals

Caricato da

Mazuni Zuni MazuniDescrizione originale:

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Rack Fundamentals

Caricato da

Mazuni Zuni MazuniCopyright:

Formati disponibili

Rack Fundamentals

Description: 2-post, 4-post, U's, cable entry, seismic ratings, placement, service access,

power and cooling integration. When did Racks become so complicated and how have they evolved to meet the changing needs of Data Centers? This course covers rack standards, rack types, and rack enclosures. It discusses best practices for rack system selection, and explores the physical considerations for rack layout. If this is your first time participating in a Data Center University course, please note some of the screen controls. For best viewing results, we recommend that you maximize your browser window now. The Pause/ Play icon lets you pause and play the course. Use the Previous and Next slide icons to move back or ahead. Using your browser controls may disrupt the normal play of the course. Finally, click the Notes tab to read a transcript of the narration. Contenet The agenda for this course is as follows. We will have a brief introduction and then we will cover the following topics: Rack Standards, Rack Types, and Rack Enclosures Best Practices for Rack System Selection Physical Considerations for Rack Layout Summary

As technology compaction has evolved from mainframes to blade servers the need for power, cooling and space optimization has dramatically increased. In their simplest form, racks and enclosures are the building blocks of a data center. Cutting edge rack technology streamlines the cable management and affords the vertical stacking of IT equipment, reducing server sprawl and maximizing IT real estate. Therefore, the role of the rack has become strategic to the availability of a given network. How these racks and enclosures are selected and configured affects a data centers availability and agility for years after an installation is completed. This course will put you one step closer to understanding the importance and the impact racks have on a data center.

Two types of standards for racks and enclosures are: The 19 inch standard Earthquake standards

The Electronics Industries Association (EIA) established the EIA-310 standard to ensure physical compatibility between racks, enclosures, and rack mounted equipment. The intent of the standard is to ensure compatibility and flexibility within the Data Center. EIA-310 is used world-wide for 19-Inch Rack-Mounted equipment.

EIA-310 defines the Rack Unit (U) to be the usable vertical space for a piece of rack mounted equipment. The U is equal to 1.75 inches. If a rack is described to be 10U, it means that there is a physical interior vertical space of 17.5 inches available for equipment mounting.

There are several types of vertical mounting rails for standard equipment. These include square holes for cage (captive) nuts and clip nuts, or round holes, with or without threads. The 19 Inch Standard defines important dimensions for racks, enclosures, and rack mounted equipment. For example, EIA-310 defines minimum enclosure opening between rails to be 450 mm (17.72 inches), to provide clearance for equipment chassis widths. The width between the centers of the equipment mounting holes is 465 1.6 mm (18.31 inches 0.063 inches). The minimum enclosure width to provide clearance for equipment front panels/ bezels/ faceplates is 483.4 mm (19 inches).

Most enclosures now use square holes and cage nuts, although some customers require threaded holes or non-threaded through holes. The more common square holes with cage nuts support several thread sizes and types. If a cage nuts threads get damaged, the repair is as easy as replacing the cage nut. Because the cage nut floats in its mount, the nut has some freedom to move, which makes nut and bolt alignment easier. The trend for open frame racks is to have threaded holes. There are many thread sizes, but #12-24 is the most common thread size. The main advantage of threaded holes placed directly into the rack is that deployment is fast, since there are no cage nuts to install.

Uniform Building Code (UBC) and Eurocode specify how enclosures should be bolted to the floor in geographies where there is a high risk for earthquakes. The Network Equipment Building System (NEBS) and the European Technical Standards Institute (ETSI) standards have more stringent requirements than the UBC and Eurocode, and specify floor anchoring and reinforced frame structures for enclosures.

The Open Frame Rack comes in two basic types: Two Post and Four Post.

The Two Post frame also known as a relay rack holds equipment that can be front or center mounted. It is typically used for lightweight applications in IT environments. Although the two post frame has a relatively low price, it offers no security, no airflow control, low weight capacity and low stability. Depending upon the manufacturer, common rack accessories may include shelving, vertical cable organizers, brackets for power distribution, and baying kits which permit several racks to be joined together.

The Four Post frame allows equipment to be supported from the front and back, making it a more versatile option than the two post frame. It is typically used for server, networking, and telecom applications in IT environments. The obvious advantage to the Four Post frame is that it is physically stronger than the Two Post frame and can support heavier equipment. Depending upon the manufacturer, common rack accessories may include light and heavy-duty shelves, vertical cable organizers, brackets for power distribution, and baying kits.

Open frames have the advantage of allowing easy access to equipment, and they can be easily assembled by the owner. They are also a low cost, economical solution. Significant disadvantages of open frames are:

They do not provide physical security/ protection The equipment is exposed They do not allow for optimized airflow in densely packed or high-heat-producing configurations

The Open Frame rack typically relies on natural convection to dissipate heat from equipment. As the density of rack mounted equipment increases, natural convection has a limited ability to remove the heat that needs to be dissipated. Enclosures, discussed in the next section of this course, provide an improved means to control and manage airflow.

Enclosures are advanced rack containment systems. As these illustration show, there are several varieties of basic enclosure designs. However, most enclosures include front and rear doors, side panels, and a roof. Within an enclosure, channels are created for forced air to move through rack-mounted equipment. These channels provide enhanced air cooling capability over open racks.

Depending upon the manufacturer, enclosures may also have cable management options, power distribution units, power protection devices, cooling devices, environmental management systems, and other accessories.

Compared to open frame racks, enclosures offer improved static load capacity, cooling, security, and multi-vendor compatibility for rack mounted equipment.

Next , we will discuss some common enclosure types.

This slide shows an example of a server enclosure. There are different enclosure sizes for different applications.

Server applications most commonly use 42U high x 600mm wide x 1070 mm deep. Server enclosures have been getting deeper to support the higher densities of power and cabling. Some applications that have high cable density, combine network switches with server equipment, or use side-to-side cooling instead of front-to-back cooling. Those applications will require enclosures that are wider than 600mm.

Some rooms that have high ceilings may permit enclosures to be as tall as 47 U. Some 47U applications may also require wide enclosures. When using tall enclosures, be cautious about safety regulations and overhead fire suppression sprinklers.

This slide shows an example of a network enclosure. High-density cabling or networking applications typically require 42U x 750mm wide .

As shown in this illustration from behind the networking enclosure, networking applications require wider racks than server applications, to give room for cabling. A fully loaded networking enclosure can require up to 2000 Category 5 or Category 6 network cables.

Here is an example of a seismic enclosure. Seismic enclosures, are specially reinforced to protect equipment from earthquakes. To ensure equipment and personnel safety, seismic enclosure installations should conform to regional standards, such as NEBS or ETSI for Zone 4. Most commercial data centers and telecom central offices that are not in high risk zones, utilize less stringent standards like the UBC or Eurocode, rather than the stricter NEBS or ETSI standards.

Here is an example of a wall mount enclosure. Wall mount enclosures are useful when only a couple of pieces of rack equipment need to be enclosed. One of the key features of the wall mount enclosure is its double-hinged frame construction, which allows easy access to the rear of the rack mounted equipment.

Wall mount enclosures conserve floor space and provide a neat, clean installation for wiring closets.

APC recently conducted a worldwide survey of CIOs, Facility Managers, and IT managers. Based on survey findings, 5 areas have been identified for optimization with regard to rack system selection. They are:

1. Lifecycle Costs 2. Availability 3. Maintenance and Serviceability 4. Adaptability and Scalability (Flexibility) 5. Manageability

he survey found that optimizing lifecycle costs was the most important requirement to most organizations.

The most common problems that pose a challenge to the optimization of lifecycle costs with regard to rack systems are:

1. Non-standardized racks Non-standardized racks lead to a higher total cost of ownership, due to the unique design features dictated by the IT equipment manufacturers. These non-standard design features result in difficulty with moves and the integration of multi-vendor equipment. A much better solution is to purchase vendor-neutral racks with guaranteed universal compatibility. Vendor neutral racks allow for greater flexibility when purchasing and mounting equipment, and more standard processes for mounting and servicing equipment. 2. Slow speed of deployment. The time and work involved in the assembly of nonstandard equipment (racks) or even in migration and refreshes are costly, both in downtime and labor. Pre-engineered solutions save time and simplify planning and installation.

The survey revealed that optimizing availability was also an important requirement. The most common problems that pose a challenge to optimizing availability are:

1. Inadequate airflow to IT equipment damages hardware. This problem has increased over the last few years with the dramatic increase in heat densities. And it is important to note that there is no standard for measuring cooling effectiveness when comparing enclosures. 2. Inadequate power redundancy to the rack. The solution is to bring dual power paths to single or dual-corded IT equipment. 3. Lack of physical security. Because of the increased demands to provide ample air, power, and data to racks, the number of individuals accessing enclosures for service tasks has increased, leaving the units more vulnerable to human error. Enclosures need to be physically secured with locking doors and locking side panels to prevent unauthorized or accidental access. 4. Non-compliance with seismic requirements. The solution is to have all racks that are located in Zone-4 regions to be in compliance with seismic building standards.

The following slides offer solutions for improving airflow as a means of increasing availability.

Good front-to-back airflow door ventilation is critical to effective cooling. This slide shows examples of perforated front and rear doors that provide for maximum ventilation.

Blanking panels are covers that are placed over empty rack spaces. Keeping blanking panels snugly in place prevents heated exhaust from being recirculated and entering IT equipment intakes. The main reason why blanking panels are not commonly used, is that the benefits of blanking panels are not always understood. People often fail to realize the cooling benefits that they provide, and mistakenly think that the are for aesthetic purposes only or that they are difficult to install.

Having blanking panels that snap-in to any square-holed rack enclosure, and install without tools, significantly reduces the time and labor cost associated with installing panels. In addition, by standardizing on a panel size of 1U, racks can be populated easily, rather than dividing empty spaces into various-sized panels of 1, 2, 4, and 8U.

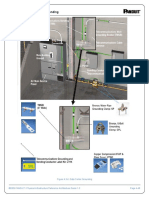

This slide shows an Air Distribution Unit (ADU) installed in a rack system. An ADU is a cooling device for raised floor applications that mounts at the bottom 2U of any EIA-310 19 inch rack that has an open base. The blue lines represent cooling airflow. The ADU connects into the raised floor and pulls supply air directly into the enclosure. This prevents the conditioned air from mixing with warmer room air before reaching the equipment. The ADU minimizes temperature differences between the top and bottom of the enclosure. It also prevents hot exhaust air from recirculating to the inlet of the enclosure.

This is a detailed view of an ADU. An ADU is only recommended as a problem-solver for heat densities of up to 3.5 kW per rack. An ADU is good for overcoming low ventilation pressure under raised floors.

\This slide shows a side ADU installed above a rack mounted device with side-toside airflow. The blue lines represent cooling airflow. The red lines represent warm airflow. The side ADU pulls air in from the cold aisle, and redirects and distributes it to the equipment inlet, located on the right side.

This slide shows the airflow for an Air Removal Unit (ARU). The ARU is a scalable cooling solution, because it can be added to an existing rack enclosure, and requires no internal rack space or raised floor connections to install. It replaces the rear door of an enclosure. This example shows a unit with a redundant fan for improved availability.

Cool air enters the rack, exhausts out the rear of the rack equipment, is pulled through the rack Air Removal Unit, and is released through the top.

The high powered fans in the Rack Air Removal Unit overcome the air resistance of cables in the rear of the rack, and prevent exhaust air re-circulation. An optional,

ducted exhaust system delivers hot air to the space above a drop-down ceiling or some other type of enclosed overhead space, and eliminates the possibility of hot air mixing with room air.

Maintenance and serviceability improve with practical experience. The most common problems that pose a challenge to maintenance and serviceability are:

1. Server migration delays. Limited space and deployment speed typically cause server migration delays. Enclosures that offer split doors save aisle space and make equipment access easier. Quick release doors and side panels also save time.

2. Poor cable management leads to IT equipment damage, because of airflow obstruction. Wires that form rats nests make it difficult to identify individual power and data cables. Abandoned cables get intertwined with active cables, and block airflow under raised floors. Storing power and data cables at the rear of the racks makes them easier to access. Routing data and power cables above the racks makes them more organized and accessible, and eliminates potential air dams under raised floors.

3. Non-standardized racks are a maintenance issue, because server manufacturers often state that the warrantee is void if a server is placed in a rack that does not comply with specific rack standards. Apart from aesthetics, this non-standard approach introduces complexity due to the unique characteristics of each rack. Rack vendors should guarantee compatibility with all servers. The racks should meet or exceed a server manufacturers ventilation and spatial requirements, and comply with the Electronic Industries Alliance (EIA) 310-D standard for rack mounting IT and networking equipment.

The survey found that adaptability and scalability need to be optimized. Some of the problems that hinder optimization are:

1. Frequently changing power and cooling requirements. Racks may have to support different power requirements, multiple supply voltages or several outlet types. Rack systems therefore need to provide tool-less Power Distribution Units (PDUs), and three phase power whips to support changeover capability for different voltages, power capacities, and outlets. 2. Changing room layouts cause migration and mobility problems. Rack enclosures should provide field-reversible doors, quick-release hinge pins, quick-release side panels, and castors for mobility. Racks should also adapt to new overhead power and data cabling systems.

Some of the problems that pose a challenge to optimizing manageability are:

1. Lack of environmental monitoring capability at the rack level. A lack of an environmental monitoring capability leads to difficulty identifying thermal gradients from the top to the bottom of the rack. It also causes difficulty detecting hazards such as smoke and humidity extremes. Any large thermal gradient could lead to equipment damage or shutdown. The solution is to provide environmental management devices, and a graphical user interface that allows remote monitoring, along with automatic email, pager, or telephone notification of changes in the rack level environment. 2. Lack of power monitoring capability at the rack level. Monitoring racks is critical to availability. Branch circuit logic monitoring is crucial. The solution is to provide display mechanisms that can automatically report and manage power conditions on power strips at the rack level, locally or remotely, through a digital display. 3. Lack of critical management of IT equipment. The study attributes this lack to the growing popularity of server clusters. According to Dells senior manager of product marketing for clustering, clustering is increasingly used in mission-critical

environments. IT personnel want a solution to centrally manage all equipment from one location. 4. Lack of security at the rack level. A solution is to provide rack locks as well display screens and automatic notification to report and manage rack level security breaches.

Lastly, physical considerations for rack layout is very important when designing a data center. Racks should be arranged to form alternating hot and cold aisles. When choosing a rack, it is important to select dimensions that work well with layout calculations. This illustration shows an optimal design with cold aisles that are four feet wide, and hot aisles that are three feet wide.

This course has covered Rack Standards, Rack Types, and Rack Enclosures, Best Practices for Rack System Selection, and Physical Considerations for Rack Layout.

Major points to remember include:

How racks are selected and configured has a profound and lasting impact on a data centers availability, agility, and total cost of ownership

Enclosures enhance rack system cooling by preventing hot and cold air from mixing

Enclosures should be universal, modular, organized, and scalable

Racks should be arranged to form alternating hot and cold aisles

Quiz

Time Remaining: Less than 1 hours and 1 minutes. Fundamentals of Racks

1. The Open Frame Rack comes in two basic types: Two Post and Four Post. a. True b. False 2. Significant disadvantages of open frame racks are: a. They do not provide physical security/ protection b. The equipment is exposed c. They do not allow for optimized airflow in densely packed or high-heatproducing configurations. d. All of the above 3. The most common problems that pose a challenge to optimizing availability are: a. Inadequate airflow to IT equipment b. Inadequate power redundancy to the rack c. Lack of physical security d. Non-compliance with seismic requirements e. All of the above 4. Blanking Panels are: a. Covers that are placed over empty rack spaces b. Air Distribution Units c. Devices that cool air entering a rack (1) Points (1) Points (1) Points (1) Points

d. Cable management devices 5. The Electronics Industries Association (EIA) established the EIA-310 standard to ensure physical compatibility between racks, enclosures, and rack mounted equipment a. True b. False 6. Because the cage nut _______in its mount, the nut has some freedom to move, which makes nut and bolt alignment easier. a. is fixed b. floats c. is threaded 7. Seismic, wall mount and networking are all types of: a. Disasters b. Enclosures c. Servers d. Frames 8. An ADU mounts at the bottom ____ of any EIA-310 19 inch rack that has an open base. a. 4U b. 2U c. 5U d. 8U 9. The ________ defines important dimensions for racks, enclosures and rack mounted (1) Points equipment. (1) Points (1) Points (1) Points (1) Points

a. 19 inch Standard b. EIA-310 c. Four Post Frame d. Cooling 10. Enclosures should be universal, _________, organized and scalable. a. modular b. neat c. 19 inch Standard d. 5U (1) Points

Potrebbero piacerti anche

- 3M ESD Handbook - English (v1)Documento20 pagine3M ESD Handbook - English (v1)Edwin Osogo100% (1)

- Mothership Zine Rulebook v5 PDFDocumento44 pagineMothership Zine Rulebook v5 PDFAna Luiza FernandesNessuna valutazione finora

- Datacenter KnowledgeDocumento21 pagineDatacenter KnowledgeSanto Patian100% (1)

- Iso 27001 PDFDocumento7 pagineIso 27001 PDFMonica MoreiraNessuna valutazione finora

- Nexans Cabling Best Practices v6.2Documento33 pagineNexans Cabling Best Practices v6.2Oageng Escobar Baruti100% (1)

- Tier Requirements For Power PDFDocumento1 paginaTier Requirements For Power PDFMarioyfernanda Guerra MuruaNessuna valutazione finora

- TIERSTANDARD Topology 120801 PDFDocumento12 pagineTIERSTANDARD Topology 120801 PDFSomyot Songsalee100% (1)

- Barco Control Room Display Technology Selection - v1Documento19 pagineBarco Control Room Display Technology Selection - v1Amgad M. AliNessuna valutazione finora

- Earthing and BondingDocumento18 pagineEarthing and BondingMuhammad AmjidNessuna valutazione finora

- DB-En 19 R-2-829 PDFDocumento4 pagineDB-En 19 R-2-829 PDFashokNessuna valutazione finora

- BMS Digital Building Datacentre Kotrek 13072021Documento23 pagineBMS Digital Building Datacentre Kotrek 13072021sehyong0419Nessuna valutazione finora

- Failure Analysis Report PDFDocumento2 pagineFailure Analysis Report PDFDharmaNessuna valutazione finora

- Tuvit Whitepaper Data Center Tsi En50600Documento12 pagineTuvit Whitepaper Data Center Tsi En50600saba0707Nessuna valutazione finora

- Key Design Issues For IP CCTV Security SystemsDocumento3 pagineKey Design Issues For IP CCTV Security SystemsWawan YMCI KupangNessuna valutazione finora

- Sunbird DCIM Software: Eddy Chin APAC Key Account Manager Roger Koo APAC Tech ExpertDocumento29 pagineSunbird DCIM Software: Eddy Chin APAC Key Account Manager Roger Koo APAC Tech ExpertRicca ReyesNessuna valutazione finora

- Codigos de Partes PanduitDocumento696 pagineCodigos de Partes PanduitrafcacNessuna valutazione finora

- 14 Commissioning Maintenance and TroubleshootingDocumento50 pagine14 Commissioning Maintenance and TroubleshootingAlan B100% (2)

- Data Center Site Infrastructure Tier Standard: Topology: Uptime Institute, LLCDocumento0 pagineData Center Site Infrastructure Tier Standard: Topology: Uptime Institute, LLCOrlando Ramirez MedinaNessuna valutazione finora

- Reference Architecture Design Guide Part 3,0 PDFDocumento100 pagineReference Architecture Design Guide Part 3,0 PDFdexterNessuna valutazione finora

- Fosroc Below Ground Waterproofing BrochureDocumento8 pagineFosroc Below Ground Waterproofing Brochure15_01_1977_anandNessuna valutazione finora

- HB 187-2006 Guide To Selecting A Safe MultimeterDocumento7 pagineHB 187-2006 Guide To Selecting A Safe MultimeterSAI Global - APACNessuna valutazione finora

- Ecostruxure White PaperDocumento22 pagineEcostruxure White PaperSerion0% (1)

- Safety Health & Environment MethodologyDocumento14 pagineSafety Health & Environment MethodologymusengemNessuna valutazione finora

- Data Center Power Management 8.2 - Design GuideDocumento118 pagineData Center Power Management 8.2 - Design GuideOmar Cuervo100% (1)

- Buddhist Concept of HappinessDocumento11 pagineBuddhist Concept of HappinessTharaka Nadeeshan100% (1)

- ICT Structured Cabling GuidelinesDocumento37 pagineICT Structured Cabling GuidelinesSylvester Muzendah100% (1)

- 17 WAN TechnologiesDocumento33 pagine17 WAN TechnologiesManoj Kumar SharmaNessuna valutazione finora

- Practical Considerations For Implementing Prefabricated Data CentersDocumento14 paginePractical Considerations For Implementing Prefabricated Data CentersJesús MendivelNessuna valutazione finora

- Green Cloud ComputingDocumento9 pagineGreen Cloud ComputingJohn SinghNessuna valutazione finora

- Facilities Management - 1.7.2. Data Center Power and Cooling Requirements CalculatorDocumento31 pagineFacilities Management - 1.7.2. Data Center Power and Cooling Requirements CalculatortdubendorfNessuna valutazione finora

- ITCC in Riyadh Residential Complex J10-13300 16715-1 Voice & Data Communication CablingDocumento16 pagineITCC in Riyadh Residential Complex J10-13300 16715-1 Voice & Data Communication CablinguddinnadeemNessuna valutazione finora

- EN 50600 Data Center Standard:: What You Need To Know About The EN 50600Documento24 pagineEN 50600 Data Center Standard:: What You Need To Know About The EN 50600saba0707Nessuna valutazione finora

- Lan HandbookDocumento48 pagineLan Handbookdimlou1Nessuna valutazione finora

- StruxureWare Data Center OperationDocumento20 pagineStruxureWare Data Center OperationMuhammad Alvin Nur RamadhanNessuna valutazione finora

- ENP Energy Efficient Free Cooling For Data CentersDocumento16 pagineENP Energy Efficient Free Cooling For Data CentersKarthi KeyanNessuna valutazione finora

- Commercial Building Standard For Telecom Pathway & SpacesDocumento58 pagineCommercial Building Standard For Telecom Pathway & Spacesamhosny64Nessuna valutazione finora

- Reducing Racial and Ethnic Disparities in Jails: Recommendations For Local PracticeDocumento64 pagineReducing Racial and Ethnic Disparities in Jails: Recommendations For Local PracticeThe Brennan Center for JusticeNessuna valutazione finora

- ASHRAE and TIA-942 On Cooling SolutionDocumento4 pagineASHRAE and TIA-942 On Cooling SolutionbeanxinhNessuna valutazione finora

- NCP Risk For Bleeding Related To Decreased Platelet CountDocumento2 pagineNCP Risk For Bleeding Related To Decreased Platelet CountKC Ignacio83% (24)

- Masculine Scents SpicyDocumento2 pagineMasculine Scents SpicyGabrielle May LacsamanaNessuna valutazione finora

- Structure Ware For DC BrochureDocumento9 pagineStructure Ware For DC BrochureSargurusivaNessuna valutazione finora

- Ntroduction To Structured CablingDocumento5 pagineNtroduction To Structured CablingIT TG CAPNessuna valutazione finora

- SMT Line Improvements For High Mix, Low Volume Electronics ManufacturingDocumento98 pagineSMT Line Improvements For High Mix, Low Volume Electronics ManufacturingNassim DoukhiNessuna valutazione finora

- HUAWEI IDS2000-S Small Modular Data Center Solution Brochure PDFDocumento12 pagineHUAWEI IDS2000-S Small Modular Data Center Solution Brochure PDFMaiNamThangNessuna valutazione finora

- Huawei Modular Datacenter Solution (IDS2000) : Huawei Technologies Co., LTDDocumento4 pagineHuawei Modular Datacenter Solution (IDS2000) : Huawei Technologies Co., LTDDmitriy BaybulatovNessuna valutazione finora

- LCS VDI Structured Cabling SystemDocumento164 pagineLCS VDI Structured Cabling Systemtsraj10100% (1)

- Normal ChecklistDocumento2 pagineNormal ChecklistNacho ConsolaniNessuna valutazione finora

- Certified DATA Center EngineerDocumento5 pagineCertified DATA Center EngineerSyed Haseeb RazaNessuna valutazione finora

- CCNA1 CaseStudy Structured CablingDocumento39 pagineCCNA1 CaseStudy Structured CablingsantanuengineerNessuna valutazione finora

- FTTXDocumento23 pagineFTTXBambang AdiNessuna valutazione finora

- 24.understanding Building Automation and Control SystemsDocumento4 pagine24.understanding Building Automation and Control Systemskartika100% (1)

- Data Centre Efficiency 0Documento28 pagineData Centre Efficiency 0Krishna ManandharNessuna valutazione finora

- Standards UpdateDocumento4 pagineStandards Updatescrane@Nessuna valutazione finora

- 2 Wire Remote - Signal Line Monitoring Unit CatalogDocumento40 pagine2 Wire Remote - Signal Line Monitoring Unit CatalogPiyakarn BeeNessuna valutazione finora

- Server RackDocumento10 pagineServer Rackfebruary11Nessuna valutazione finora

- Anixter Installation Pocket Reference Guide BOOK WC EN US PDFDocumento120 pagineAnixter Installation Pocket Reference Guide BOOK WC EN US PDFJose Gregorio SanchezNessuna valutazione finora

- QPViewControl Guide Form SpecificationDocumento17 pagineQPViewControl Guide Form SpecificationBala KrishnaNessuna valutazione finora

- 9 - BICSI - Bob CamerinoDocumento40 pagine9 - BICSI - Bob CamerinoecorbelliniNessuna valutazione finora

- Develop Asset Registry PDFDocumento45 pagineDevelop Asset Registry PDFZia AbbasiNessuna valutazione finora

- CLB-1000B Spec SheetDocumento1 paginaCLB-1000B Spec Sheetdiegoh_silvaNessuna valutazione finora

- 09.iec-62264 Based Quality Operations Management According The Principles of Industrial Internet of ThingsDocumento4 pagine09.iec-62264 Based Quality Operations Management According The Principles of Industrial Internet of Thingsgiorgis072Nessuna valutazione finora

- Power Distribution Unit PDUDocumento10 paginePower Distribution Unit PDUPatricio GuzmanNessuna valutazione finora

- Data Center Infrastructure Providers A Complete Guide - 2019 EditionDa EverandData Center Infrastructure Providers A Complete Guide - 2019 EditionNessuna valutazione finora

- The en 50600 Series European Data CentreDocumento14 pagineThe en 50600 Series European Data Centresaba0707100% (1)

- Anixter Ref PDFDocumento76 pagineAnixter Ref PDFDemetrios GkikasNessuna valutazione finora

- Data Center Facilities A Complete Guide - 2019 EditionDa EverandData Center Facilities A Complete Guide - 2019 EditionNessuna valutazione finora

- FO 0installation Guide PDFDocumento37 pagineFO 0installation Guide PDFErnesto MoraNessuna valutazione finora

- DCDC Exam Content Outline PDFDocumento4 pagineDCDC Exam Content Outline PDFDwitt PalacinNessuna valutazione finora

- Assessment Multiple Choice For Crowd ManagementDocumento3 pagineAssessment Multiple Choice For Crowd Managementjohnsaw ronaldoNessuna valutazione finora

- Assessment of Yalova University Campus According To LEED V.4 Certification SystemDocumento11 pagineAssessment of Yalova University Campus According To LEED V.4 Certification SystemUmitNessuna valutazione finora

- Understanding Building Construction Types - Firefighter Nation PDFDocumento3 pagineUnderstanding Building Construction Types - Firefighter Nation PDFRakeshNessuna valutazione finora

- Leica LS10 LS15 User ManualDocumento106 pagineLeica LS10 LS15 User Manualabdelghafour adjNessuna valutazione finora

- Sample - Global Pharmaceutical Contract Manufacturing Outsourcing (CMO) Market - Mordor IntelligenceDocumento54 pagineSample - Global Pharmaceutical Contract Manufacturing Outsourcing (CMO) Market - Mordor IntelligenceSilke IgemannNessuna valutazione finora

- Testing and Commissioning Procedure: 2017 EDITIONDocumento242 pagineTesting and Commissioning Procedure: 2017 EDITIONvin ssNessuna valutazione finora

- Solid Waste Management in SchoolsDocumento32 pagineSolid Waste Management in SchoolsRusty TorioNessuna valutazione finora

- 5000L Series CatalogueDocumento24 pagine5000L Series CataloguekahlaouiNessuna valutazione finora

- Vol 30 Profiles - of - Drug - Substances, - E (BookSee - Org) Vol 30Documento329 pagineVol 30 Profiles - of - Drug - Substances, - E (BookSee - Org) Vol 30Gabriel Bianco100% (1)

- 11 - Chapter 4 Muslim Law PDFDocumento87 pagine11 - Chapter 4 Muslim Law PDFAnfal BarbhuiyaNessuna valutazione finora

- 30MLD STPDocumento31 pagine30MLD STPhalavath ashokNessuna valutazione finora

- Bai Tap Cau Dieu Kien Co Dap AnDocumento19 pagineBai Tap Cau Dieu Kien Co Dap AnHồngBthNessuna valutazione finora

- All About Drilling RIGDocumento5 pagineAll About Drilling RIGSaroop JosephNessuna valutazione finora

- Plant ClassificationDocumento105 paginePlant ClassificationsjoerjenNessuna valutazione finora

- Business Ethics ANSWERSDocumento3 pagineBusiness Ethics ANSWERSMỹ HàNessuna valutazione finora

- Inspection and Repair: Inspection of Totally Enclosed Lift Bags 1.0Documento8 pagineInspection and Repair: Inspection of Totally Enclosed Lift Bags 1.0Ali KuliNessuna valutazione finora

- PETRODETAILSDocumento2 paginePETRODETAILSAlexanderNessuna valutazione finora

- Presence of Oxalative Ions in GuavaDocumento12 paginePresence of Oxalative Ions in GuavapozozgamingNessuna valutazione finora

- Toyota/Lexus U140E/F, U240E, U241E: Click On Part Numbers For Product Details or VisitDocumento1 paginaToyota/Lexus U140E/F, U240E, U241E: Click On Part Numbers For Product Details or Visitvipper king2012Nessuna valutazione finora

- Reco-Cool HD Premium-N 25% Antifreeze-Coolant v4 - MSDS - 230224 - 171528Documento7 pagineReco-Cool HD Premium-N 25% Antifreeze-Coolant v4 - MSDS - 230224 - 171528Jon HermanNessuna valutazione finora

- Pharmacist Workup of Drug Therapy in Pharmaceutical Care: Problem Oriented Pharmacist RecordDocumento20 paginePharmacist Workup of Drug Therapy in Pharmaceutical Care: Problem Oriented Pharmacist RecordNurwahidah Moh WahiNessuna valutazione finora