Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Natural Fabrics

Caricato da

Santosh BishtDescrizione originale:

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Natural Fabrics

Caricato da

Santosh BishtCopyright:

Formati disponibili

1

Natural Fabrics Gather knowledge about the natural fibers, various end products, their characteristics and many more. y y y y y Bamboo Fabric Leather Fabric Linen Fabric Wool Fabric Canvas Fabric y y y y y Cotton Fabric Hemp Fabric Ramie Fabric Jute Fabric Satin Fabric y y y y y Silk Fabric Coir Fabric Fabric Blends Sateen Fabric Satin Fabric

Natural fabrics are those which are created from the fibers of animals coats, the cocoons of silkworms, and plants seeds, leaves and stems. It is breathable and never cause rashes apart from being soft and durable. Natural fabric is the best choice for everyone. It does not change color from UV light and there is no warming until the material looses its tensile strength. Common Natural Fabrics Cotton Fabric - It is versatile with natural comfort and durability. The use of cotton fabric dates back to 3000 B.C. It is used as garments, home furnishings, and industrial cloths. It is soft with good strength and drapes well.

Silk Fabric - If we talk about silk, we talk about softness, beauty and luxuriousness. It is a high grade fabric with weather fabric quality. It is used as expensive dresses and home furnishings. Discovered in China during 2640 B.C. and is still the leading producer in the world.

Wool Fabric - Wool means warmth, softness and strength. It is resistant to wrinkle, dirt and wear and tear. Wool as a clothing was discovered some twelve thousand years ago. Today, it is obtained from sheep, goat, angora goat and angora rabbit and camel.

Leather Fabric - The fabric which never ages. It is firm, soft, elastic and weather friendly. Commercially it is obtained from cattle, calf, goat, sheep, lamb, horse, pig, kangaroo, deer, reptile, seal, and walrus. The major exporters of goatskin leather in the world are India, China and Pakistan. In sheepskin leather, China, New Zealand, Australia and Iran are the important exporters. USA, Europe, Brazil and USSR are key players in exporting leathers obtained from bovine. Hemp Fabric - The warmth, softness and durability of hemp fabric is rarely found in any other fabric. It is very versatile with UV protective and insulative quality. It is used as apparel, accessories, shoes, furniture, and home furnishing. It is obtained from stems of plant. The finest comes from Italy and the leading producer is China . Coir Fabric - It is known for its resilience and durable quality. It is the perfect fabric for controlling soil erosion. In horticulture, coir fabric is used as a substitute for peat because it is

bacteria free and free from fungal spores. It is an environmental friendly fabric and fully biodegradable.

Jute Fabric - It is eco-friendly with good strength and durability. It is widely used as bags and sacks. Fashionable cloths, home furnishing and fashion accessories are some of the innovation of jute. India is leading jute manufacturer in the world.

Linen Fabric - It is the fabric of luxury. Lustrous, beautiful and elegant. It is antibacterial and antifungi with a property of UV protection. It is being used for more than 10,000 years. Egyptians made extensive use of linen. It is obtained from flax plant. Ramie Fabric - A summer fabric with air-permeability and moisture-absorption quality. It is obtained from ramie plant, a tall shrub grown in South-east Asia. China is the leading producer of ramie followed by Brazil, Korea and Philippines.

Fabric Blends- are one which is made up of two or more different types of fibres twisted or spun together. Blending adds to the quality of the final product. Natural Fabrics Uses Natural fabrics are much more comfortable to wear than synthetic fabrics. They drape and fit better. They help the skin to breathe properly and hence they are better for the body. They also absorb perspiration. Natural fabrics normally do not produce any allergic reactions on the skin. People with skin problems should wear clothes made of natural fabrics. They also help reduce body odor. Most important of all, natural fabrics are better for the environment because they are 100% biodegradable. Bamboo Fabric Bamboo fabric is the natural fabric that is made from pulp of bamboo grass. Bamboo fabric is more sustainable, light, anti bacterial, hypoallergenic and stronger than any other fabric. Because of these properties bamboo fabric is extensively used in almost all types of industries ranging from bedding to clothing. The properties like softness, appearance and durability make it such a widely accepted fabric in various industries. When unspun bamboo fabric closely resembles the cotton. Bamboo fabric manufacturers and companies use bleaching chemicals to whiten the bamboo fabrics but to make organic bamboo fabric no such bleaching agents are used and mostly these are kept unbleached. Strong anti bacterial and water absorbing tendency make it fit to use directly on skin. Therefore people using it does not complaint of any itching or irritation as caused by wool or hemp. It is because, bamboo fibers naturally does not have any sharp spurs like these two fibers.

Along with these properties there are many other things that make it the most favorable fabric among suppliers, exporters and bamboo fabric wholesale manufacturers. One of these is the growth of bamboo plant. If proper soil is there then bamboo plant can grow up to 60 cm in a day because of the unique rhizome dependent system. This in turn means more production. Along with this no pesticides are used to grow the bamboo plant thus making it organic. Process of Making Bamboo Fabric y y y y y y y Soft leaves and inner pith of the bamboo trunk are taken & crushed to form bamboo cellulose. Bamboo cellulose is then soaked in solution of 15-20% hydrogen peroxide for one to three hours at 20-25 degrees C. The resultant will be alkali cellulose. Then through the processing, excess of hydrogen peroxide is removed from alkali cellulose. This followed by crushing of cellulose and drying it for 24 hours. Carbon disulfide (about one third) is added to bamboo alkali cellulose to sulfurize it and to convert it in the form of jell. Then the remaining carbon disulfide is evaporated that results in sodium xanthogenate. In sodium xanthogenate, diluted solution of sodium hydroxide is added. This creates the viscose solution containing 7-15% of bamboo fiber cellulose and 5% sodium hydroxide. The viscose solution is then passed through the spinneret nozzle into a container containing diluted sulphuric acid. This results in the hardening of viscose bamboo cellulose sodium xanthogenate and reconvert it into bamboo fiber threads that are now spun to form bamboo fiber yarn. The bamboo fiber yarn is then used to make bamboo fabric. Uses of Bamboo Fabric In Various Industries Apparel Industry and Bamboo Fabric Because of unique luster and softness of bamboo fabric, it is used in apparel industry. Socks, undergarments, bathing suits, bath robes, sleepwear etc are made from bamboo fabric. Bamboo fabric are also hypoallergenic so the best for children and pregnant women. It is very comfortable because of the good absorbent property. Because of this it will not stick to your skin and you will feel cooler during summer and warm in winters. Traditionally bamboo hats were worn by the farmers in Japan and China. Even it is also used to decorate women's dress in west.

Bamboo Fabric in Non Woven Industry Bamboo fabric manufacturers use the non-woven bamboo fabric extensively in making sanitary napkins, face masks for industrial and medical use and in mattress. Bamboo has high anti bacterial properties because of the bamboo kun that is a bio agent in bamboo and it is part of its molecular structure. It does not allow bacteria to incubate in bamboo.

Bamboo Fabric in Home Furnishings

Most of the home furnishing products like comforters, pillow covers, mattress pads, bed skirts,bed covers, bed sheets, towels, bath rugs, shower curtains et al are made from bamboo fabrics. Top brands are also promoting the use of bamboo fabric because of its natural and organic properties. Pottery Barn has the range of bed linen and other home furnishing products that are made from bamboo fabric along with other natural fabrics like cotton, hemp, silk, wool, hemp etc. These products are highly beneficial to use as these causes no harm to the body. They absorb moisture to a large extent keeping you free from that and thus making the furnishing comfortable to use. It is not that these Advantages of Bamboo and Bamboo Fabric y Bamboo fabric is naturally grown plant that requires no pesticide or fertilizer. If we compare it with cotton then to grow conventional cotton 25% of the total pesticides used in the world are consumed that are harmful to the environment. y y y y Bamboo fabric is extremely soft and luxurious to touch. It just feels like silk or cashmere. Bamboo is a type of grass, which means that once you cut this it will regrow from the same roots leading to no problem in growing plant each year. Bamboo is also the fastest growing plant. Moso bamboo grows up to a meter each day making it very sustainable. As compare to cotton the yield per acre is more as bamboo plant can grow very densely. Also bamboo plant absorbs 35% more carbon dioxide than the other equal trees.

Bamboo fabric absorbs 60% more water as compared to cotton. This makes it favorite among bamboo fabric manufacturers. Because of this property bathroom furnishing like bath robes, towels, bath mats are extensively made from bamboo fabric.

y y y y y

Thermo regulating property makes bamboo fabric wearable in every season. It is cool in summers and warm in winters. Bamboo fabric is also hypoallergenic and has anti bacterial properties. Natural sheen on bamboo fabric makes it excellent choice to sew fashionable clothes. Clothes made from bamboo are easy to wash and dry. Bamboo clothing is wrinkle resistant and requires less ironing and that too at low temperature. It is also prone to less shrinkage in warm water.

Cotton Fabric Cotton is a soft fibre that grows around the seeds of the cotton plant, a shrub native to the tropical and subtropical regions of both the Old World and the New World. The fibre is most often spun into thread and used to make a soft, breathable textile. Cotton Fabric is noted for its versatility and its natural comfort. Cotton cloth has been used since primitive ages dating back to about 3000 B.C. Today, the main uses of cotton is in the form of garments, home furnishings, and industrial cloths.

Cloth made of cotton is more comfortable, durable and suitable to resist all kinds of weather. The comfort quality of the cotton is due to its twisted or coiled shape. It traps air within the fabric structure and help for a thermal insulation process, resulting protection from heat in summer and cold in winter.

For the fabrics strength, absorbency quality, capacity to be washed and dyed, cotton has become the principal clothing fabric of the world. It is obtained from a bushy plant scientifically known as Gossypium. The fruit (boll) part of the plant is used to make cotton fabric. There are four main types of cotton namely American Upland, Egyptian, Sea Island and Asiatic. In the world production of cotton, China is the leading followed by United States, India, Pakistan, Brazil, Turkey and Greece. Today, production of cotton is one of the major factors in world prosperity and economic stability. Process of creating the Cotton Fabric Cotton fiber undergoes several process to reach the stage of final cloth. The processes are as mentioned below:

Ginning Ginning is the method of separating the cotton fibers from the seedpods, and sometimes with the sticky seeds. This is done in the cotton field with the help of machines. Spinning Spinning is the succeeding step to ginning. This process involves the making of yarn from the cotton fiber. The cotton yarns are made of different thickness in this stage. Weaving Weaving is the most important process in the making of cotton cloth. In this process, two yarn is placed to make warp and weft of a loom which successively turn them into a cloth.

Fabric finishes and treatments After weaving the cotton fabric passes through different processing stages till it reaches to the state of final product. The stages are mentioned below, but it is not necessary for the fabric to undergo all the process for e.g. grain bags cloth are used unbleached. y y y y y y y Singeing - This process burns off the fibers sticking in the goods. Desizing - This process involves removing the size material from warp yarns in woven fabrics. Scouring - The cleaning part of the fabrics are involved in this process. Bleaching - The fabrics are bleached here to make it more whiter and lighter. Mercerizing - In this process, the fabric is immersed in alkali to make it more strong, shining, durable, shrink free and stretch free. Dyeing - This process involves the changing of the fabric color by the treatment with a dye. Finishing - In this process, the fabric is treated with some chemicals or other useful agents to make it qualitatively more better, for e.g. cotton is made sun protected by treating it with UV protecting agent. Characteristics of Cotton Fabric y y y y y y y It is soft and comfortable. It has good strength. It is easy to handle and sew. It drapes well. It is flame retardant. It is machine-washable and dry-cleanable. It is hydrophilic, which means that cotton have excellent absorbing capabilities. Garments made of cotton absorb perspiration, thus keeping one more comfortable.

y y y y y

Cotton wrinkles easily. To resist this, cotton is being blended with many other natural or synthetic fibers. The blending of cotton also gives a bouncy and elasticity property to the cotton. 100% untreated cotton fabric has pleasant matte luster. It is hypoallergenic, which means it has a low tendency to cause allergic reactions. Cotton Apparel / Garments - Garments made of cotton are very soft, comfortable and weather friendly. They are either 100% or blended with some natural or synthetic fibers. Normally all types of garments are made of cotton fabrics; formal, casual and even industrial clothing.

Cotton Home Furnishing - Cotton home furnishing is preferred because of the fabrics strength and durability characteristics. A good example of cotton home furnishing is rugs or durries, draperies and curtains, bedding products, etc.

y y y

Cotton Handbags and Luggages - Due to strength, cotton handbags and luggages are more widely preferred. The heavier cotton fabric is used in these kind of products. Cotton Canvas - Medium to heavyweight cotton fabric is used in range of canvas products like shoes, tents, tarpaulins, etc. Apart from these, cotton fabrics are also used in medical and surgical products, bookbinding cloths and tobacco cloths.

Silk Fabric Silk fabric is known for its softness, luster, beauty and luxurious look. It is one of the higher grade fabrics, which gives the wearer comfort in all types of weather. It keeps the body cool in summer and warm in winter. It is the strongest natural fabric in the world. It is said that silk was discovered during 2640 B.C. in China. Chinese Empress, Hsi Ling Shi studied the silkworm and learned the art of unwinding the silk from the cocoon and made silk fabric from it. This was the beginning of silk industry in China. Today it holds over 50% of the silk production in the world. Japan ranks second followed by Brazil and India. Indian silk textiles are popular worldwide because of its sheer variety of designs, weaving and quality. Thai silk is one of the most valued fabrics in the world. USA is the worlds leading manufacturer of silk products and France and Italy are the leading manufacturers of high value sophisticated silk fabrics in Europe. Luxurious and expensive dresses and home furnishings are made of silk fabric. Silk wedding gowns, sarees, kurtas, scarves, silk evening wear and suits are widely used for their elegant look,

lustrous shine and sumptuous feel. The different varieties of silk are Chiffon, Georgette, Organza, Crepe de Chine, Duponi, Noil, Pongee, Shantung, Tussar, etc. Process of creating Silk Fabric From Cocoon to Yarn Silk from cultivated silkworms is more used though silk of wild worms is also valuable. The worms feed on mulberry leaves and increases their body size by nearly 10,000 times in a short span of time. The worm ceases to eat by the end of thirty days and attach itself to a piece of straw and begins to spin its cocoon. After the spinning of cocoon and before the hatching of the worm into a moth, the cocoon is soaked in hot water unraveling and producing long size thread. This fine thread is the basic component of silk yarn and fabric. Washing and bleaching of the silk threads The natural fiber extracted from the silkworm holds some glutinous substance (gummy substance or glue) which is removed by washing and bleaching. Weaving Weaving is a process where the fabric is created by interlacing the warp yarns and the weft yarns. It is either done by machines or hand. Hand woven fabric is better than the machine woven. It can make delicate designs with different colored thread. Modern machines use lances, projectiles, a jet of compressed air to shoot the weft-yarn between the warp-yarns. It leads to greater yield and productivity. A good quality of silk begins with a warp of approximately 2,000 threads for one meter width. 1,600 threads or 1,800 threads are considered to be poor quality fabric. Loosely woven fabrics are difficult to sew.

Dyeing, Printing and Finishing There are two main types of silk fabrics. One which is yarn-dyed or dyed-woven, like taffeta, duchess satin and many pattern-woven fabrics. The other type is piece-dyed fabrics, which is carried out after weaving, like crepes, twills, etc. The dyeing process gives the silk different shades. Printing is giving pattern to the fabric. It is either done by block-printing method, roller-printing method or screen printing. Screen printing is widely used in silk fabrics. Embroidery process gives embellishment and the perfect finish to the fabric to make it look more beautiful.

All fabrics has to be finished. It is here the fabric gets the desired appearance and feel. Finishing process is either physical or chemical. It give treatments like crease-proofing, water-proofing, fire-proofing, etc. Final soaking in a chemical solution This process helps to preserve the sheen and luster of the silk fabric. It adds weight and makes the fabric soft, smooth, easy to iron and wrinkle resistant. Characteristics of Silk Fabric y y y y y y y y y y Silk is very smooth and luxurious. Wild silks are an exception. They are dull with coarse hand and texture. It is comfortable and has a very good absorbent quality. It is the strongest natural fabric. It is not a good resistant to abrasion. Impurities in the air and direct sunlight fades the color of a silk fabric. Perspiration and sunlight weakens the silk fabrics. Cloth made of silk water-spots easily. Hence it is recommended that silk garments should be dry-cleaned. Silk fabric do not resist wrinkle. Silk fabric is also used in computerized clothing to conduct electricity.

We can cater to all types of Silk Fabrics for various industries. If you have any kind of sourcing requirement in bulk please send us an enquiry and we will send you the best quotations from genuine suppliers. Uses of Silk Fabric y Apparel/Garments - The soft, luster and supple feel of silk has made it widely used as apparels. The absorbent quality is an added advantage in silk cloth which keeps the body comfortable in all types of weather. All types of garments like sarees, shirts, skirts, blouses, suits, gown, etc. are made of silk. Silk made garments are of formal use. y Home Furnishing - Silk fabric is used in different products of home furnishing which gives the room a luxurious look like sheets, pillowcases, and throws. Since silk is not a good resistant to abrasion, it should be taken extra care. y Medical Textiles - A medicated silk fabrics has been developed which keeps the body part un-affected from cuts, burns, and bedsores. These medicated silk textiles are also antibacterial.

10

Wool fabric Wool fabric gives warmth and attractive appearance. It is soft, yet strong and very durable. It wicks away perspiration from the body and keeps the wearer dry while sweating and cool when it is hot. It does not wrinkles easily and is a resistant to dirt and wear and tear. The fabric never burns over a flame but only smoulders. Wool fabric does not only come from sheep. A widely used cashmere sweaters are made from goats originated in Kashmir (India). Mohair wool fabric is obtained from angora goat and angora wool fabric from angora rabbit. The name angora has been derived from the place Angora (Ankara) in Turkey, where these animals originated. Alpaca wool fabric comes from the hair of alpaca animal, a member of the camel family. Wool, as clothing is being used for over twelve thousand years. The first wool factory was established in Winchester (England) in 50 A.D. by the Romans. In 1797, thirteen merino sheep was brought to Australia by the British to start merino sheep industry. Today, Australia is the leading producer of wool fabric. Types of Wool Fabric Chenille - It has a fur-like texture, which is created when warp threads are woven in groups. It gives a chunky feel and is used for both clothing and upholstery. Felt - It is not a woven fabric but is created by matting or bonding fibers. Hats and occasional skirts or coats are made from felt. Flannel- These are soft and are made of a plain or twilled weave which are slightly napped on one side i.e. a little fuzzy on one side. Gabardine - These fabric has a clear-surface, twill weave and a fine diagonal rib effect. A good example of gabardine is coats, suits, trousers, skirts, and dresses. Melton - These are thicker woolen fabric and is made of twill or satin weave with a smooth surface. Due to its thickness, it is used for coats. Tweed - These are heavier wool fabric with rough texture and used for suits and coats. Worsted - These woolen fabrics are hardy, made of smooth yarn and are used for suits and coats. Characteristics of Wool Fabric y y It is warm. It resists wrinkle.

11

y y y y y y y y y

It resists wear and tear. It is light-weight and durable. It absorbs moisture. It retains shape. It resists flames. It smoulders instead of burning. It is flexible and gets tailored easily. It has natural stretch and elasticity, which responds to the wearer's body movements. lored easily. It has natural stretch and elasticity, which responds to the wearer's body movements.

We can supply all kind of Raw Wool like: Merino Wool, Greasy Wool, Tannery Wool, Carpet Wool, Scoured Wool & Sheep Wool Fibre. Send us your sourcing requirement and receive the best quotations from genuine suppliers. Uses of Wool Fabric y Today, every wardrobe contains garment made of woolen fabric. The warmth of the fabric has made it widely used during winter or in cold areas. It is used in sweaters, dresses, coats, suits, jackets, pants, etc. y y Wool fabric is also used as blankets and carpets. Felt made of wool fabric is used as covers for piano hammers. It is also used in absorbing odors and noise in machinery and stereo speakers.

Leather Fabric Leather fabric never ages. With age, leather fabric becomes more beautiful. It becomes more comfortable and pleasant to touch, adding classic luxury. Leather fabric does not pick up surrounding temperatures, hence it is comfortable in both hot and cold condition. It is firm, soft and elastic. It retains to the original shape when stretched. It absorbs water vapour without losing the dryness. Leather fabric is commercially obtained from cattle, calf, goat, sheep, lamb, horse, pig, kangaroo, deer, reptile, seal, and walrus. The major exporters of goatskin leather in the world are India, China and Pakistan. In sheepskin leather, China, New Zealand, Australia and Iran are the important exporters. USA, Europe, Brazil and USSR are key players in exporting leathers obtained from bovine. Process of making Leather Fabric Pre-tanning y y Animal skin is cleaned and salted to prevent decay. The hide or pelt then is sent to tannery for trimming and sorting.

12

y y y y y y y

Next, it is soaked in water to restore moisture content, which is lost during salting process. It is treated mechanically with rollers and blades to remove fat/muscle and flesh (Fleshing). During liming the skin is soaked in lime solution to remove the hair, inter-fibrillary protein and epidermis. In De-liming the hide or pelt is washed in water containing ammonium chloride or ammonium sulphate to neutralise it. Bating involves treating the leather with digestive enzymes to remove non-fibrous protein. Scudding is done with a blunt knife to remove remaining hair roots, skin pigmentation, and surface fats. Lastly, it is put in sulphuric acid to lower the pH.

Tanning Tanning is the process where the leather gets the necessary feel and physical characteristics. In this process, the collagen, an insoluble fibrous protein, which carries the major property of the hide or pelt gets less susceptible to decay and are kept flexible. This is done by removing the water molecules from the gap of protein molecules and replacing it with chemicals that retain flexibility. The main tanning processes are mineral/chrome tanning, vegetable tanning and oil tanning. y y Mineral/chrome tanning is the most common and modern method, which uses chromium salts. This makes leather water proof and stretchable. Vegetable tanning, or bark tanning is the process where the hide is soaked in a solution of bark of oak/chestnut which is chopped or boiled. The leather becomes moldable and can be tooled. Moreover when dry, the leather will not stretch. y Oil tanning is a process where fish and animal oil is used. The leather becomes very soft and flexible. It cope up with wetted condition without causing damage to the leather. Chamois leather is best example of oil tanning. Lubricating, Dyeing and Finishing After tanning, the leather undergoes different processes according to the use of the final product. y y Vegetable-tanned leather which are used for shoe soles is bleached, lubricated and then run through rolling machines to make it firm and glossy. Chrome-tanned leather, for shoe uppers, is split and shaved and then placed in a rotating drum for the dyeing process using several types of coloring materials to give color fastness and durability. y Before or after dyeing, it is rolled in a fat liquor containing emulsified oils and greases. Next, the leather is pasted on glass or ceramic frames and then passed through drying tunnels with controlled heat and humidity.

13

In the finishing process, the leather is coated with grain surface which contains finishing compound. This is brushed under a revolving brush-covered cylinder. For smooth finish, the leather is treated with a mixture of waxes, shellac or emulsified synthetic resins, dyes, and pigments (to avoid painted look). Glazing is done to achieve polished surface.

Characteristics of Leather Fabric y y y y y y y y It has porosity and breathability. It is waterproof to a great extent. It is firm, soft and elastic. It retains its shape. It resists the aging process. It is durable. It is abrasion and wind resistant. It absorbs water vapour upto 30% of its weight without loss of dryness.

We can supply all types of Leather Fabrics used in products like gloves, jackets, wallets, and other apparel. If you have any kind of sourcing requirement in bulk please send us an enquiry and we will send you the best quotations from genuine suppliers. Uses of Leather Fabric y Leather fabric is very versatile. It is widely used. Soft leather is used in clothing and hard leather in products like shoe soles, machine belts, engine gaskets and harnesses. Calfskin leather, which is lighter and finer grained, is used in shoe uppers. Sheepskin leather, which is soft and supple is generally used in products like gloves, jackets, and other apparel. y Leather fabric is also used in upholstery, sofa, wallets, purses, bags, belts, rugs, tents, tepees, shields and weapon sheathes.

Hemp Fabric Hemp fabric is noted for its warmth and softness with a durability, which is rarely found in other fabrics. It is highly versatile and is used in countless number of products like apparel, accessories, shoes, furniture, and home furnishing. It is UV protected and has an insulative quality that allows clothing to be cool in summer and warm in winter. Apparel made of hemp fabric withstand harsh conditions and last longer. It has beautiful luster. The fabric accepts dyes readily and gets soft with every wash. It withstands water better than any other textile product. It blends well with cotton, silk, wool, polyester, etc. Blending with cotton improves the texture and whiteness of the fabric. Hemp fabric is obtained from the stems of the

14

plant. The stems of the plant are processed to dissolve the gum or the pectin found in it. The fiber is then separated and again processed. After the processing is over, it is woven into yarns and fabric. The finest hemp fabric is produced in Italy. China is the world's leading producer of hemp. Characteristics of Hemp Fabric y y y y y y y y y y y It is strong and durable. It has beautiful luster. It is absorbent. It readily takes dye. It gets soft with every wash. It is warm. It is a resistant to UV rays. It is a very good insulator. It blends well with other fabrics. It wrinkles easily. It has poor drapability.

We can supply all types of Hemp Fabrics like Organic Hemp Fabric, 100% Hemp, 100% Herringbone Weave Hemp, 100% Canvas Hemp Fabric, Hemp Yarn for Women Apparel or Home Furnishings Industry. If you have any kind of sourcing requirement send us an enquiry. Uses of Hemp Fabric y y Hemp Fabric is very versatile. This fabric is a great choice for comfortable work clothes, home decoration, or for anything where comfort and durability is needed. It is used as clothing, curtains, draperies, upholstery, bedspreads, table linens, sheets, dish towels, canvas, etc. Coir fabric is known for its resilience and durable quality. It is the perfect fabric for controlling soil erosion. In horticulture, coir fabric is used as a substitute for peat because it is bacteria free and free from fungal spores. It is an environmental friendly fabric and fully bio-degradable. Process of making Coir Fabric The word 'coir' is believed to be derived from the Malayalam word Kayar that means a cord (string). Coir fabric is obtained from the fibrous husk, which surrounds the coconut. Green coconuts are harvested after six to twelve months on the plant, which contain white fibers. Mature coconut contains brown fiber. The fibrous layer is separated from the fruit either manually or by machines. In case of brown fiber, the separated husks are soaked in a slow moving body of water allowing it to

15

swell and to become soft. The coir bristle fiber is put apart from the shorter one and is send for washing in clean water. Sometimes, it is also cleaned by steel combs to make the fibers straight and remove any leftover of shorter pieces. If required, it is bleached and dyed to obtain the required shades. For white fiber, the husks are put into a river or water-filled pit for approximately ten months. In these ten months, the fibers are loosen. The longer fibers are separated from the shorter one by beating with hand. It is subsequently dried and then cleaned. The cleaned fiber is send for spinning into yarn. Characteristics of Coir Fabric y y y y y It is buoyant. It is stress resistant. It is environmental friendly. It is biodegradable. It is free of bacteria.

Uses of Coir Fabric Brown coir fabric is used in floormats, doormats, mattresses, sack, twine, etc. White coir fabric is used as ropes. Since ages, coir fabric has been used to produce rope for ships and for making bags. Coir geotextiles is used for ground improvement of soft clays, construction of low height bunds and protection for canal banks and beaches, base separators for road construction and railway ballast protection. Linen Fabric is noted as the fabric of luxury. It symbolises comfort and elegance. It is antibacterial and antifungi and does not cause irritation or allergies when worn. It gives protection against UV radiation. The fabric carries tensile strength and is highly durable. It absorbs moisture 20 times of its weight but never gives a wet impression. After each wash, linen fabric gets stronger with better look. Since linen has low elasticity, linen cloths do not deform themselves. Linen fabric is 100% biodegradable and is waste-less . Linen fabric is being used for more than 10,000 years. It used to be called the fabric of the kings. Egyptians used it extensively. Wrapping mummies in long lengths of linen was very common. The ancient Phoenician's used to make sails from heavy weight linen fabric for their sails. In 15th century, linen fabric was used as canvas for painting. Linen fabric is obtained from the flax plant. The major producer of linen fabric is Ireland. It manufactures 20% of the European Union linen yarn. The annual production of linen fabric in Ireland is 2,000 tons per annum. Ireland also produces the world's best linen fabric. Linen is widely blended with wool. The combination of linen and wool is known as linsey-woolsey. In linsey-

16

woolsey fabric, linen is used as warp threads for strength and wool is used as weft threads to give bulk and warmth to the fabric. Characteristics of Linen Fabric y y y y y y y y y y y y It is lustrous and flexible. It is beautiful, smooth and elegant. It is strong and durable. It supports painting when wet. It has a low elasticity. It has great tensile strength. It is highly absorbent. It can absorb up to 20 times of its weight. It dries quickly. It is thermo-regulating. It is non-allergenic. It is antibacterial. It is resistant to wear and abrasion.

Uses of Linen Fabric y Linen fabric is the first choice for summer wear. It absorbs humidity and allows the skin to breathe. The fabric is suitable for daily use clothing, like shirts, because it becomes softer after each wash. Apart from this, linen fabric is also widely used as home furnishings. y y Linen fabric is also used as rugs because of its strength, durability and resistant to wear and abrasion. Linen fabric is used as canvas for painting since ages. Linen fabric when wet reacts well with the colors.

Fabric Blends Fabric Blends are one which is made up of two or more different types of fibres twisted or spun together. Blending adds to the quality of the final product. Characteristics of Fabric Blends y y y y y It is easy to care. It becomes more durable. It becomes more soft and luxurious. It becomes more resistant to wrinkles. It becomes more comfortable to wear.

17

y y

It does not shrinks. It becomes stronger to withstand lots of wear and multiple washing.

Uses of Fabric Blends Polyester/Cotton - The tough crease-resistance of polyester combines with the cool comfort of cotton. It is easily laundered, dries quickly and is ironed with lower temperature than pure cotton. Nylon/Wool - The blending of nylon with wool makes the fabric more absorbent and softer. It becomes more strong and durable. Nylon/Acetate - This combination makes the fabric more absorbant than nylon alone. Ramie/Polyester or Ramie/Acrylic - These two blends help the fabric to be easily taken care of and it is less stiff than pure ramie fabrics. Wool/Cotton - These two fabrics benefit from the inherent qualities of each other after blending. It gives better comfort, better aesthetics and better performance. Linen/Silk or Linen/Rayon - These blend helps the fabric to retain the characteristics of linen along with to make the fabric drape better and wrinkle less. Silk/Wool - The blending of silk with wool provides subtle texture to the fabric. It is generally used for ties.

Rayon/Cotton - This fabric of rayon and cotton blend wears well and is washable. It is soft and has fuzzy surface. Dresses, suits, sportswear, men's shirts, etc. are made out of this fabric. Wool/Synthetics or Rayon/Synthetics - These blends has a very clear finish and it drapes better and tailors easily. It has exceptional wearing qualities. The fabric is used for men's and women's suits and coats. Ski slacks are also made out of these blends. Cotton/Polyester - The quality of polyester helps cotton to give a permanent press property. It is extremely soft, resists wrinkling and are easy to care for. This fabric is widely used as men's dress shirts and christening apparel.

18

Sateen Fabric Sateen fabric is often confused with satin but these are two different types of fabrics. Sateen is mostly applied to cotton and rarely rayon. In most of the cases sateen is the cotton fabric whose luster resembles that of satin. Luxury sateen fabric is used for making bedsheets and apparels. Sateen is a very famous fabric that is made from cotton but it is much cheaper than the silk and satin. Sateen is very durable and machine washable. How Sateen Fabric is Made? To make luxury sateen fabric first of all the long and combed fiber of cotton are taken. These cotton fibers are then mercerized to get the sheen. In the process of mercerization the cotton fibers are soaked in sodium hydroxide and then in an acid bath. This process makes the cotton fiber very strong and gives an extra luster that is the property of sheen fabric. Sateen Weave Weaving is one of the factors that helps in recognizing the sateen fabric. In sateen weave, one vertical thread is woven for four or more threads that are horizontal. Because of this weaving, more number of threads are exposed to the surface making the sateen fabric very smooth and soft. Sateen Fabric Sateen Fabric Application y y y y Luxury sateen fabric is a very lustrous and heavy fabric so chiefly used for making bed sheets. Sateen is also used as an inner lining in jackets as it stops the air. Many vintage dresses and other types of vintage clothes are made from sateen fabric. Spun Polyester Sateen is used for making abrasion material for sand paper and for filtering liquids.

Canvas Fabric Canvas fabric is a thick and plain weave fabric that is made from cotton, jute, linen, hemp and even from polyester. Canvas fabric has basically two main kinds i.e. Plain and duck. In duck canvas fabric, threads are tightly woven. Canvas fabric can be classified in two ways i.e. by weight and by graded number system. Higher the number lower will be the weight of the canvas.

19

Types of Canvas Fabric The type depends upon how it has been made. It can be bought as untreated fabric and as flame resistant, water resistant or both. Basically it can be

y y y y y

Waterproof canvas and water resistant canvas Fire Proof Canvas Dyed Canvas Stripe Canvas Printed Canvas

Canvas Fabric Applications In all the applications that require rough and thick fabric use the canvas fabric. Because of this it is extensively used as canvas tent, tarpaulins, umbrellas, embossed wall covering, bags and covers. Apart from this canvas fabric is also used for oil painting and to do embroidery or needlework as a mesh fabric. The duck kind of canvas fabric is used for making special garments for the sailors. Canvas fabric manufacturers depending upon the need make all kinds of canvas fabrics that are used in number of different applications.

Canvas Fabric Bag Canvas Fabric for Oil Painting Canvas is extensively used as a painting fabric especially for oil painting. The oil painting canvas fabric is made from linen as linen is suitable for oil painting. Although you may also find the cotton

20

canvas for this purpose but still linen is the most popular one. It also called artist's canvas and needs wooden support to be used for oil painting. It is basically the loomstate canvas that is stretched during weaving process. Which canvas fabric to pick depends upon number of factors Like the size of the painting, type of paints you are going to use along with paint and application techniques. Canvas Fabric for Canoes and Sailmaking Canvas fabric is fastened to wooden hull that is made from the cedar planks and ribs. Canvas since ages has been one of the most promising fabrics for sailmaking. Although there are now many new and light weight fabrics to be used as sailmaking yet the canvas is predominantly used for this purpose. Waterproof canvas fabric has the ability to withstand water. Needlework Canvas Fabric Canvas is also used for embroidery and other needlework. Now the type of canvas depends upon the requirement of design. Here you can consider the fiber, type of canvas and thickness of the hole. The needlework canvas fabric is measured as number of mesh per inch. Canvas for Shelter Another popular usage of canvas fabric is the outdoor shelter. Canvas is heavier than other material like nylon and at the same time quiet a breathable fabric. You can also make a good summer house out of this fabric. Canvas as Clothes Apart from all these usage, the cotton canvas fabric is also used for making human clothes for warm weather. The stiffness of canvas fabric will not allow the cotton to sag as it normally does. Also The canvas shoes are well known. Canvas is one of the most versatile fabrics. You can meet your bulk requirement by purchasing it from canvas fabric wholesale suppliers.

Potrebbero piacerti anche

- Properties Natural FibresDocumento46 pagineProperties Natural FibresanishaNessuna valutazione finora

- Synthetic FibreDocumento6 pagineSynthetic FibreswaroophoppyNessuna valutazione finora

- Polymer Blends and Composites: Chemistry and TechnologyDa EverandPolymer Blends and Composites: Chemistry and TechnologyNessuna valutazione finora

- Textile Fibre Yarn CountDocumento30 pagineTextile Fibre Yarn CountSujit GulhaneNessuna valutazione finora

- Modern Cotton Spinning Machinery, Its Principles and ConstructionDa EverandModern Cotton Spinning Machinery, Its Principles and ConstructionNessuna valutazione finora

- Presentation by MR Shishir Jaipuria On MeditechDocumento20 paginePresentation by MR Shishir Jaipuria On Meditechsathish_20102010Nessuna valutazione finora

- Medical Nonwoven ApplicationsDocumento17 pagineMedical Nonwoven ApplicationsDipesh JainNessuna valutazione finora

- Antibacterial Agents in Textile Industry PDFDocumento20 pagineAntibacterial Agents in Textile Industry PDFimran24Nessuna valutazione finora

- Note Polyster FiberDocumento16 pagineNote Polyster FiberMohammed Atiqul Hoque ChowdhuryNessuna valutazione finora

- Understanding Textile Fibres: A Guide to Properties and ApplicationsDocumento17 pagineUnderstanding Textile Fibres: A Guide to Properties and ApplicationsRezaul Karim TutulNessuna valutazione finora

- Yarn Count Thread Numbering System Count Conversion LawsDocumento3 pagineYarn Count Thread Numbering System Count Conversion LawsMohammed Atiqul Hoque ChowdhuryNessuna valutazione finora

- Textile Fibres and Their Properties ExplainedDocumento82 pagineTextile Fibres and Their Properties ExplainedAnand ShrivastavaNessuna valutazione finora

- Lecture Three Natural Bast FiberDocumento46 pagineLecture Three Natural Bast FiberGemeda GebinoNessuna valutazione finora

- Gross & Fine Structure of Cotton Fiber - Textile Learner 1Documento3 pagineGross & Fine Structure of Cotton Fiber - Textile Learner 1RAFIAHAMMEDNessuna valutazione finora

- Fabric FinishesDocumento31 pagineFabric FinishesDeepthi SonuNessuna valutazione finora

- Fiber and YarnDocumento38 pagineFiber and YarnPutri Mayangsari100% (1)

- Shanti Kumari: Presented byDocumento21 pagineShanti Kumari: Presented byDr-Eng Amir ElsafraweyNessuna valutazione finora

- Textile Vocabulary 2Documento10 pagineTextile Vocabulary 2scribd101Nessuna valutazione finora

- Regenerated Fibres: ViscoseDocumento16 pagineRegenerated Fibres: ViscoseAshfaque AhmedNessuna valutazione finora

- Textile ScienceDocumento22 pagineTextile ScienceAbhinav VermaNessuna valutazione finora

- Textile Testing and Product EvaluationDocumento64 pagineTextile Testing and Product EvaluationBhaswati PandaNessuna valutazione finora

- Primeasia UniversityDocumento206 paginePrimeasia UniversityAtik Nayon100% (2)

- 1 # Introduction: Principles of Fashion Marketing - Yarn SectorDocumento22 pagine1 # Introduction: Principles of Fashion Marketing - Yarn SectorSeveshNessuna valutazione finora

- Fabric Studies - 2nd SetDocumento32 pagineFabric Studies - 2nd SetP. Lakshmanakanth100% (3)

- Phenolic Yellowing of TextileDocumento2 paginePhenolic Yellowing of Textilekingson007Nessuna valutazione finora

- Textile Manufacturing Process Textile Manufacturing Process Is Done Some Regular ProcessesDocumento5 pagineTextile Manufacturing Process Textile Manufacturing Process Is Done Some Regular Processesananthakumar100% (1)

- Medical Textiles: Kavitha Rajan Lecturer in Textile TechnologyDocumento44 pagineMedical Textiles: Kavitha Rajan Lecturer in Textile TechnologyBebi WakaNessuna valutazione finora

- Mosquito Repellent Finish of Cotton Fabric by Extracting Castor OilDocumento6 pagineMosquito Repellent Finish of Cotton Fabric by Extracting Castor OilTRUSHA PITHADIYANessuna valutazione finora

- Textile Industry Pollution Hazards and SolutionsDocumento10 pagineTextile Industry Pollution Hazards and SolutionsSUBRATA DAS100% (1)

- Medica L Textile S: Click To Edit Master Subtitle StyleDocumento24 pagineMedica L Textile S: Click To Edit Master Subtitle StyleShazzad HossaIn100% (1)

- Innovation in YarnDocumento6 pagineInnovation in YarnDevendra VashisthNessuna valutazione finora

- Effect of Yarn CountDocumento12 pagineEffect of Yarn CountSyed Salahuddin MunnaNessuna valutazione finora

- Denim Washing DetailDocumento108 pagineDenim Washing DetailMudassar AliNessuna valutazione finora

- Textile Raw Material-II Course Code: Tex2101: Basic Concept On Textile FibreDocumento63 pagineTextile Raw Material-II Course Code: Tex2101: Basic Concept On Textile FibreHrs ShihabNessuna valutazione finora

- Determination of Loop Length, Tightness Factor and Porosity of Single Jersey Knitted FabricDocumento6 pagineDetermination of Loop Length, Tightness Factor and Porosity of Single Jersey Knitted FabrictanveerhusseinNessuna valutazione finora

- Water - Proof Breathable FabricDocumento29 pagineWater - Proof Breathable FabricKryptonNessuna valutazione finora

- Technical Textile A Promising FutureDocumento22 pagineTechnical Textile A Promising FutureDr Muhammad Mushtaq Mangat100% (1)

- Properties of Textile Fibres-LibreDocumento31 pagineProperties of Textile Fibres-LibreJunaid AhmedNessuna valutazione finora

- Build TechDocumento13 pagineBuild Techila030% (1)

- Introduction To Textiles 1Documento217 pagineIntroduction To Textiles 1Md NurunnabiNessuna valutazione finora

- Medical Textiles For Health and Hygiene - StandardsDocumento48 pagineMedical Textiles For Health and Hygiene - StandardsJuanNessuna valutazione finora

- Lyocell: Lyocell Is A Regenerated Cellulose Fiber Made From Dissolving PulpDocumento3 pagineLyocell: Lyocell Is A Regenerated Cellulose Fiber Made From Dissolving PulpMiraz HossainNessuna valutazione finora

- Medical TextilesDocumento31 pagineMedical TextilesSagarika AdityaNessuna valutazione finora

- Special Finishes of TextilesDocumento19 pagineSpecial Finishes of Textilespronoy34Nessuna valutazione finora

- Impact of Textiles in the Medical Field (IJLTETDocumento4 pagineImpact of Textiles in the Medical Field (IJLTETpa_ashokNessuna valutazione finora

- Stitch TypesDocumento3 pagineStitch TypesbawaneatulNessuna valutazione finora

- Wet II Presentation Group 3 Antimicrobial FinishDocumento29 pagineWet II Presentation Group 3 Antimicrobial FinishZillur Rahman SaykatNessuna valutazione finora

- Textile FinishesDocumento12 pagineTextile FinishesFakrul Hasan KhanNessuna valutazione finora

- Mechanical ComfortDocumento36 pagineMechanical ComfortDr Muhammad Mushtaq MangatNessuna valutazione finora

- Investigation of Air Permeability of Cotton & Modal Knitted FabricsDocumento6 pagineInvestigation of Air Permeability of Cotton & Modal Knitted FabricsAhmad SamerNessuna valutazione finora

- FiberDocumento9 pagineFiberAryan PatelNessuna valutazione finora

- Quality Assessment System For TextilesDocumento93 pagineQuality Assessment System For TextilesSahil SharmaNessuna valutazione finora

- Textile StructureDocumento1 paginaTextile StructureBrooks OrtizNessuna valutazione finora

- Textile Science - Session 3Documento35 pagineTextile Science - Session 3ALOK KUMARNessuna valutazione finora

- Technical TextilesDocumento13 pagineTechnical TextilesAchal Kanodia0% (2)

- Wound Care ManagementDocumento6 pagineWound Care ManagementSuparna DasNessuna valutazione finora

- Use of Enzymes in Textile Wet ProcessingDocumento6 pagineUse of Enzymes in Textile Wet ProcessingMohammed Atiqul Hoque ChowdhuryNessuna valutazione finora

- Portrait Painting Workshop Materials ListDocumento2 paginePortrait Painting Workshop Materials Listchristhianf77Nessuna valutazione finora

- Creating Classical Oil Portrait:Cesar SantosDocumento3 pagineCreating Classical Oil Portrait:Cesar Santosc cNessuna valutazione finora

- Ruby Red/ Special EditionDocumento54 pagineRuby Red/ Special EditionCollect ArtNessuna valutazione finora

- E-Book For Puzzles and Seating ArrangementDocumento97 pagineE-Book For Puzzles and Seating ArrangementSayan GhoshNessuna valutazione finora

- BSMA 3 - Art Appreciation Task on Stained Glass, Canvas Art, and Beauty StandardsDocumento40 pagineBSMA 3 - Art Appreciation Task on Stained Glass, Canvas Art, and Beauty StandardsRhea Anne N. OcceñaNessuna valutazione finora

- CORE 12-Contemporary Philippine Arts From The Region: Tel. No. (082) 300-71-73Documento4 pagineCORE 12-Contemporary Philippine Arts From The Region: Tel. No. (082) 300-71-73Dave II CosteloNessuna valutazione finora

- Notice: Antidumping: Artist Canvas From— ChinaDocumento3 pagineNotice: Antidumping: Artist Canvas From— ChinaJustia.comNessuna valutazione finora

- Classical Oil Painting TechniqueDocumento124 pagineClassical Oil Painting Techniquefakamada6044100% (15)

- Systemic Painting: An Alternative Tradition from the 1950sDocumento72 pagineSystemic Painting: An Alternative Tradition from the 1950sPa To N'Co50% (2)

- Chapter - 1 Four Year B.F.A. Course (Painting, Textile Design, Plastic Arts, Pottery - Ceramics and Applied Arts)Documento39 pagineChapter - 1 Four Year B.F.A. Course (Painting, Textile Design, Plastic Arts, Pottery - Ceramics and Applied Arts)rendez_sksNessuna valutazione finora

- Cpa RRRRDocumento106 pagineCpa RRRRChristian Paul Chungtuyco73% (11)

- 101 Contemporary Artists and More...Documento210 pagine101 Contemporary Artists and More...Collect ArtNessuna valutazione finora

- Paintings & Sculpture - Skinner Auction 2598BDocumento252 paginePaintings & Sculpture - Skinner Auction 2598BSkinnerAuctions100% (3)

- Crushed, Crumpled, Transformed: The Work of Angela de La CruzDocumento6 pagineCrushed, Crumpled, Transformed: The Work of Angela de La CruzRuth RosengartenNessuna valutazione finora

- Acrylics WorkbookDocumento29 pagineAcrylics WorkbookEvelina Anileve88% (8)

- Canvas Stretching Machine LLC To Exhibit at West Coast Art & Frame Tradeshow in Las VegasDocumento3 pagineCanvas Stretching Machine LLC To Exhibit at West Coast Art & Frame Tradeshow in Las VegasPR.comNessuna valutazione finora

- Weaving Technical?: Do It Itema!Documento54 pagineWeaving Technical?: Do It Itema!stareq100% (1)

- Senikini#09Documento24 pagineSenikini#09senikiniNessuna valutazione finora

- The Acrylic Book - Manual y PublicidadDocumento93 pagineThe Acrylic Book - Manual y PublicidadCesar MansillaNessuna valutazione finora

- Cricut Design Studio ManualDocumento335 pagineCricut Design Studio ManualBetty Weese Holdread100% (3)

- Xia Kejun, Chinese Philosophy and Contemporary Aesthetics, Unthought of Empty, Peter Lang, 2020 PDFDocumento129 pagineXia Kejun, Chinese Philosophy and Contemporary Aesthetics, Unthought of Empty, Peter Lang, 2020 PDFAbe BillNessuna valutazione finora

- Contemporary Arts - Activity#6 - Anastacio, Atasha IvyDocumento5 pagineContemporary Arts - Activity#6 - Anastacio, Atasha IvyAtasha Ivy AnastacioNessuna valutazione finora

- Illustrated Dictionary of Art-Related TermsDocumento152 pagineIllustrated Dictionary of Art-Related Termsrgarciadgo100% (2)

- Art essayDocumento2 pagineArt essayrtrsgxp7fsNessuna valutazione finora

- Cross Sections Paint Samples PDFDocumento50 pagineCross Sections Paint Samples PDFDelia BalanNessuna valutazione finora

- Still Life ArtDocumento23 pagineStill Life ArtEvanthia BinetzisNessuna valutazione finora

- Artists For Animals Catalogue 2008Documento65 pagineArtists For Animals Catalogue 2008Kensington foundation100% (2)

- Segment: Artist Corner Heading: Thangka Painting: Iconography of Buddism SynopsisDocumento3 pagineSegment: Artist Corner Heading: Thangka Painting: Iconography of Buddism SynopsisArihant BothraNessuna valutazione finora

- The National Gallery LondonDocumento220 pagineThe National Gallery LondonArkona100% (2)

- Peralta Cbea-22-301e Final Course Requirement Ge06Documento28 paginePeralta Cbea-22-301e Final Course Requirement Ge06KRISHIA MAE PERALTANessuna valutazione finora

- Bare Bones: I'm Not Lonely If You're Reading This BookDa EverandBare Bones: I'm Not Lonely If You're Reading This BookValutazione: 4 su 5 stelle4/5 (11)

- $100M Leads: How to Get Strangers to Want to Buy Your StuffDa Everand$100M Leads: How to Get Strangers to Want to Buy Your StuffValutazione: 5 su 5 stelle5/5 (16)

- House Rules: How to Decorate for Every Home, Style, and BudgetDa EverandHouse Rules: How to Decorate for Every Home, Style, and BudgetNessuna valutazione finora

- To Pixar and Beyond: My Unlikely Journey with Steve Jobs to Make Entertainment HistoryDa EverandTo Pixar and Beyond: My Unlikely Journey with Steve Jobs to Make Entertainment HistoryValutazione: 4 su 5 stelle4/5 (26)

- Altamont: The Rolling Stones, the Hells Angels, and the Inside Story of Rock's Darkest DayDa EverandAltamont: The Rolling Stones, the Hells Angels, and the Inside Story of Rock's Darkest DayValutazione: 4 su 5 stelle4/5 (25)

- Writing Screenplays That Sell: The Complete Guide to Turning Story Concepts into Movie and Television DealsDa EverandWriting Screenplays That Sell: The Complete Guide to Turning Story Concepts into Movie and Television DealsNessuna valutazione finora

- No Lifeguard on Duty: The Accidental Life of the World's First SupermodelDa EverandNo Lifeguard on Duty: The Accidental Life of the World's First SupermodelValutazione: 3.5 su 5 stelle3.5/5 (42)

- Storyworthy: Engage, Teach, Persuade, and Change Your Life through the Power of StorytellingDa EverandStoryworthy: Engage, Teach, Persuade, and Change Your Life through the Power of StorytellingValutazione: 4.5 su 5 stelle4.5/5 (152)

- I Didn't Come Here to Make Friends: Confessions of a Reality Show VillainDa EverandI Didn't Come Here to Make Friends: Confessions of a Reality Show VillainValutazione: 3 su 5 stelle3/5 (47)

- They Can't Kill Us Until They Kill UsDa EverandThey Can't Kill Us Until They Kill UsValutazione: 4.5 su 5 stelle4.5/5 (38)

- The Hotel on Place Vendôme: Life, Death, and Betrayal at the Hotel Ritz in ParisDa EverandThe Hotel on Place Vendôme: Life, Death, and Betrayal at the Hotel Ritz in ParisValutazione: 3.5 su 5 stelle3.5/5 (49)

- The Rescue Artist: A True Story of Art, Thieves, and the Hunt for a Missing MasterpieceDa EverandThe Rescue Artist: A True Story of Art, Thieves, and the Hunt for a Missing MasterpieceValutazione: 4 su 5 stelle4/5 (1)

- The Grand Inquisitor's Manual: A History of Terror in the Name of GodDa EverandThe Grand Inquisitor's Manual: A History of Terror in the Name of GodNessuna valutazione finora

- Summary: Greenlights: by Matthew McConaughey: Key Takeaways, Summary & AnalysisDa EverandSummary: Greenlights: by Matthew McConaughey: Key Takeaways, Summary & AnalysisValutazione: 4 su 5 stelle4/5 (6)

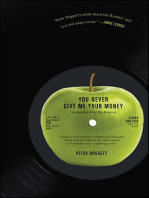

- You Never Give Me Your Money: The Beatles After the BreakupDa EverandYou Never Give Me Your Money: The Beatles After the BreakupNessuna valutazione finora