Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Civil Aviation Requirements Section 2 - Airworthiness Series I' Part I Issue Ii, 15Th March, 1976 Effective: Forthwith

Caricato da

Manish MishraDescrizione originale:

Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Civil Aviation Requirements Section 2 - Airworthiness Series I' Part I Issue Ii, 15Th March, 1976 Effective: Forthwith

Caricato da

Manish MishraCopyright:

Formati disponibili

GOVERNMENT OF INDIA

OFFICE OF THE DIRECTOR GENERAL OF CIVIL AVIATION

TECHNICAL CENTRE, OPP. SAFDARJUNG AIRPORT, NEW DELHI-110 003

CIVIL AVIATION REQUIREMENTS SECTION 2 AIRWORTHINESS SERIES I PART I ISSUE II, 15TH MARCH, 1976 Subject: Aircraft Instruments Inspections.

EFFECTIVE: FORTHWITH Overhaul and Periodical

1. GENERAL : 1.1 Aircraft instruments shall be overhauled and inspected in accordance with the requirements of this part of CAR Section 2 Series I except where different requirements have been specified by makers of an aircraft of in an operator's approved Maintenance System Manual or in other documents approved or issued by the Director General. 1.2 The periodical inspection checks for ascertaining instruments may be made "in-situ" if possible. the accuracy of

1.3 Instruments which on test are found defective and do not conform with the maker's/Director General of Civil Aviation's requirements shall be required to be maintained/inspected as per maker's Director General of Civil Aviation's requirements by persons approved for the purpose or shall be replaced with serviceable instruments. 1.4 Instruments shall be inspected prior to installation to ensure that (a) The instruments are approved for the type aircraft; (b) The range of the dial marking is adequate to reflect correct operation of the aircraft, power plant or equipment and to precisely indicate the appropriate operating limitations;

Rev 1, 5th June 2009

CIVIL AVIATION REQUIREMENTS SERIES I PART I

SECTION 2 AIRWORTHINESS 15TH MARCH 1976

(c) The range of any coloured sectors marked on instrument dials corresponds with the ranges specified in the aircraft flight manual or aircraft/engine manufacturer's manuals as applicable. 1.5 At times aircraft manufacturers recommend "on-condition" maintenance programme for some of the aircraft components, including aircraft instruments. This type of maintenance means specifying intervals or inspecting/testing the concerned units of aircraft to determine reduction in failure resistance before the failure occurs of becomes critical. These inspections/testing may be on the aircraft or at a maintenance facility. Before operators adopt this type of maintenance in preference to "Hard time limits", as far as periodical servicing of aircraft components is concerned, they shall submit to DGCA details of programme of repetitive inspections/tests for approval and include in Quality Control cum Maintenance System Manual. However the inspection/test intervals achieved by an operator may be followed with prior concurrence of DGCA, by other operators, operating similar equipment, provided operating and environmental conditions are similar. 1.6 All maintenance (including overhaul) shall be performed and certified in accordance with the manufacturer's and/or DGCA's requirements. 2. MAGNETIC COMPASSES : Magnetic compasses shall be inspected at the time of installation to ensure that (a) there are no signs of leakage of the liquid; (b) bubbles, excessive sediment and discolouration are not present in the liquid; (c) the pivot friction does not exceed the manufacturer's tolerances. Where such tolerances are unknown the pivot friction shall be determined by deflecting the compass needle 10 degrees and allowing it to return to the magnetic meridian. The change in indication from the original heading shall not exceed two degrees ; (d) the compass is swung and correction card is in place in the aircraft ; and (e) the compass mounting is satisfactory.

Rev 1, 5th June 2009

CIVIL AVIATION REQUIREMENTS SERIES I PART I 2.1 Calibration and compensation :

SECTION 2 AIRWORTHINESS 15TH MARCH 1976

Following are the circumstances under which direct reading aircraft magnetic compasses, as installed in aircraft, shall be calibrated and compensated : (a) At the time of initial installation of a compass; (b) At periods as specified by the manufacturer; (c) After major repair of the aircraft, replacement of an engine mounted in the forward fuselage, or on installation/ removal/ replacement of any magnetic material in the vicinity of the compasses; (d) After installation of a new electrical system or major modification of the existing electrical system in the vicinity of compass, in which case the calibration shall be made with the electrical and radio service operating in straight and level flights; (e) After installation of geophysical survey equipment or other likely to have a strong external magnetic field; equipment

(f) Whenever a direct reading compass or a magnetic sensing element is changed or relocated; (g) Whenever the correct functioning of a compass is in doubt, or excessive deviations have been found in flight observations; (h) after an aircraft has passed through an electrical storm; (i) Whenever a physical damage, discoloration of fluid or presence of bubbles in the fluid is observed; (j) After an aircraft is subjected to a serve shock as in the case of a heavy landing.

Rev 1, 5th June 2009

2A

CIVIL AVIATION REQUIREMENTS SERIES I PART I

SECTION 2 AIRWORTHINESS 15TH MARCH 1976

Note :- Compass compensation shall be conducted in accordance with the General Rules of Compensation in vogue and whenever compasses are calibrated and/or compensated appropriate entry shall be made in the aircraft log book. 3. OVERHAUL AND PERIODICAL INSPECTION PERIODS : 3.1 The overhaul and periodical inspection periods specified in this part of the CAR Series shall be calculated : (a) (b) from the date of the last overhaul; or from the date of installation in the aircraft if, prior to installation and following overhaul the instrument had been stored in accordance with accepted practices for the storage of instruments ; or in the case of imported aircraft when neither of the dates specified in sub-paragraph (a) and (b) above is known, from the date of issue or last renewal of the aircraft's Certificate of Airworthiness

(c)

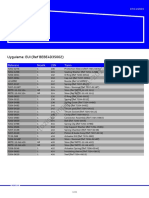

3.2 Where the manufacturer/ vendor's recommendations are not available with regard to the overhaul and inspection periods of instruments, the periods as specified in the following table shall be followed: ________________________________________________________________ Instrument Maximum overhaul Periodical Period Inspection Period ________________________________________________________________ 1. Gyrohorizon indicators, 2 years/1000 hrs. Directional gyro (whichever is earlier.) indicators, Automatic pilots (gyro units only) 2. Automatic pilot (except gyro units) Airspeed indicators and pitot static system. Turn & bank indicators. 3 years/2000 hrs. (which ever is earlier).

Vertical speed indicators 3 years/2000 hrs. (which (Rate of Climb ever is earlier). indicators), Tachometers (RPM indicators). Fuel contents gauges and fuel flow gauge. Manifold pressure gauges in piston engine and such pressure gauges of jet engines utilised for engine power output indication, Engine Oil pressure gauges, Magnetic compasses, Watches. 3. Altimeters 2 years.

CIVIL AVIATION REQUIREMENTS SERIES I PART I

SECTION 2 AIRWORTHINESS 15TH MARCH 1976

4. Thermometers, pressure To be decided Bench Check every and vacuum gauges by individual two years. (except the pressure operator. gauges mentioned in the preceding column), Ammeter and voltmeters and position indicators. ________________________________________________________________ Note :- Overhaul/periodical inspection periods in respect of instruments other than those indicated above, will be notified by the Director General of Civil Aviation on specific request. 3.3 3.3.1 Inspection Procedure : At the periodical inspection period of the instruments specified in paragraph 3.2 of this series :the accuracy of instruments shall be checked against an appropriate test instrument to ensure that the instrument operators correctly in accordance with the manufacturer;s requirements.

(a)

Note:- Test instruments shall conform to Director General of Civil Aviation. (b)

the requirements

of the manufacturer and/or

Magnetic compasses shall be inspected to ensure compliance with the requirements of Paragraph 2 of this series. The instruments shall be overhauled/bench checked by an approved agency and certified by an appropriately licensed Aircraft Maintenance Engineer or persons approved for the purpose. However, time pieces (clocks, watches) installed on aircraft having all up weight below 3000 Kgs. can be overhauled/repaired by any of the reputed commercial watch makers/watch repairing agencies.

(c)

4. COLLECTION OF OPERATIONAL DATA : In their own interest operators are advised to ask instruments overhauling agencies to furnish them with serious defects (not routine wear and tear) with come to their notice during overhauling/servicing of time expired/prematurely removed instruments. This data may be called for by Director General of Civil Aviation for future life development of instruments.

5. STORAGE/SHELF LIFE : 5.1 The instruments must be stored in accordance with the accepted practices under controlled temperature (5 deg. C.-25 deg. C.) and humidity (not exceeding 70%) conditions. The storage place must be dust free. As far as possible original manufacturers/ overhauling agencies packing should be retained. Normally the storage/shelf life of instruments should be as

5.2

CIVIL AVIATION REQUIREMENTS SERIES I PART I

SECTION 2 AIRWORTHINESS 15TH MARCH 1976

per manufacturers/overhauling agencies recommendations. However in the absence of any specific guidance from the manufacturers/overhauling agency, the shelf life of instruments (other than gyro instruments) should not exceed 2 years. On completion of this period such instruments shall be subjected to overhaul in accordance with the approved Overhaul Schedules. 5.3 Instruments which require periodic lubrication must be removed from storage and lubricated by appropriately licenced/ approved personnel at periods as recommended by manufacturers and records maintained in this regard. Instruments whose storage conditions are not in accordance with accepted practices, must be considered as unserviceable requiring complete overhaul. The shelf life of gyro instruments must not exceed two years but at the end of first year in shelf, such instruments should be exercised as per approved test schedules and bearing lubricated as per makers recommendations. The shelf life for each type of instrument must be reflected in the operators approved Quality Control Manual/Maintenance System Manual. The shelf life must be also be indicated on the serviceable tag, issued by the Overhauling Agency, accompanying the instrument/equipment. Instruments installed on aircraft which has not been operated for a continuous period of six months, shall be subjected to bench check before use. This supersedes all previous instructions on the subject by DGCA.

5.4

5.5

5.6

5.7

5.8

Sd/(V. N. Kapur) Director of Airworthiness for Director General of Civil Aviation

Potrebbero piacerti anche

- Multi-Engine Oral Exam Guide: The comprehensive guide to prepare you for the FAA checkrideDa EverandMulti-Engine Oral Exam Guide: The comprehensive guide to prepare you for the FAA checkrideValutazione: 5 su 5 stelle5/5 (4)

- 737 Performance Reference Handbook - EASA EditionDa Everand737 Performance Reference Handbook - EASA EditionValutazione: 4.5 su 5 stelle4.5/5 (3)

- FAR/AIM 2021: Federal Aviation Regulations/Aeronautical Information ManualDa EverandFAR/AIM 2021: Federal Aviation Regulations/Aeronautical Information ManualNessuna valutazione finora

- Pcar Part 6Documento14 paginePcar Part 6Arleigh Jan Igot PangatunganNessuna valutazione finora

- Aircraft Rules and Regulations Full NotesDocumento240 pagineAircraft Rules and Regulations Full NotesVinay MP75% (4)

- Module 10 Imp NoteDocumento22 pagineModule 10 Imp NoteAbdulla Khan89% (9)

- 6th Central Pay Commission Salary CalculatorDocumento15 pagine6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- History of The Sergeant Weapon SystemDocumento324 pagineHistory of The Sergeant Weapon SystemVoltaireZero100% (1)

- PiperSeneca PA34 220T MaintenanceManual 100hrinspectionDocumento18 paginePiperSeneca PA34 220T MaintenanceManual 100hrinspectionR. Demmin100% (1)

- Maitenance Schedule 3Documento15 pagineMaitenance Schedule 3BookMaggot100% (1)

- Series TDocumento4 pagineSeries TAbdulla KhanNessuna valutazione finora

- FAR-AMT 2021: Federal Aviation Regulations for Aviation Maintenance TechniciansDa EverandFAR-AMT 2021: Federal Aviation Regulations for Aviation Maintenance TechniciansValutazione: 5 su 5 stelle5/5 (2)

- B 757 General Familiarisation in MaintenanceDocumento167 pagineB 757 General Familiarisation in MaintenanceManish Mishra100% (8)

- Cessna 152 Electrical SystemDocumento5 pagineCessna 152 Electrical SystemManish MishraNessuna valutazione finora

- Cessna 172 SP ChecklistDocumento12 pagineCessna 172 SP ChecklistTim Morgan100% (39)

- Cessna 172 SP ChecklistDocumento12 pagineCessna 172 SP ChecklistTim Morgan100% (39)

- AC 66 - 2-11 AME Exam Avionic PDFDocumento33 pagineAC 66 - 2-11 AME Exam Avionic PDFKaung MyatToe0% (1)

- Moon Hoax Debunked-Paolo AttivissimoDocumento344 pagineMoon Hoax Debunked-Paolo Attivissimoyaswanthbond100% (2)

- Airworthiness Advisory Circular: Director General of Civil AviationDocumento6 pagineAirworthiness Advisory Circular: Director General of Civil AviationDayakar RanaNessuna valutazione finora

- Aircraft Rules and Regulations Notes (Semester-5) PDFDocumento158 pagineAircraft Rules and Regulations Notes (Semester-5) PDFsatyam singhNessuna valutazione finora

- UntitledDocumento8 pagineUntitledBhashkar chouhanNessuna valutazione finora

- CAR Series - Unit 1, 2Documento77 pagineCAR Series - Unit 1, 2sarathkumar sebastinNessuna valutazione finora

- D2B-B1 (Draft Sept2017)Documento5 pagineD2B-B1 (Draft Sept2017)Sheik AbdullahNessuna valutazione finora

- D2B B1 PDFDocumento5 pagineD2B B1 PDFHemanthNessuna valutazione finora

- PDF Aircraft Rules and Regulations Full Notes CompressDocumento92 paginePDF Aircraft Rules and Regulations Full Notes CompressDr. S. Arunvinthan Faculty, AeronauticalNessuna valutazione finora

- Series - TDocumento10 pagineSeries - TAryan LahariaNessuna valutazione finora

- Airworthiness Advisory Circular: Director General of Civil AviationDocumento7 pagineAirworthiness Advisory Circular: Director General of Civil AviationraviNessuna valutazione finora

- R Standard Maintenance Practice Issue 3Documento7 pagineR Standard Maintenance Practice Issue 3cclo138Nessuna valutazione finora

- Car D2T-T2Documento10 pagineCar D2T-T2Pravin HandeNessuna valutazione finora

- MEL DATA For A320Documento5 pagineMEL DATA For A320amitNessuna valutazione finora

- Time Limits/Maintenance Checks 1. Time Limits/Maintenance Checks - GeneralDocumento2 pagineTime Limits/Maintenance Checks 1. Time Limits/Maintenance Checks - GeneralRizqi PerdanaNessuna valutazione finora

- Subject:-Defect Recording, Reporting, Investigation, Rectification and Analysis. 1Documento13 pagineSubject:-Defect Recording, Reporting, Investigation, Rectification and Analysis. 1rashmiameNessuna valutazione finora

- Civil Aviation Requirements Section 2 - Airworthiness Series 'C', Part I Effective: ForthwithDocumento12 pagineCivil Aviation Requirements Section 2 - Airworthiness Series 'C', Part I Effective: ForthwithChalla AmarsrinuNessuna valutazione finora

- Time Limits / Maintenance Checks A. GeneralDocumento6 pagineTime Limits / Maintenance Checks A. GeneralAlexis CabreraNessuna valutazione finora

- C1-Defect Recording Reporting InvestigationDocumento13 pagineC1-Defect Recording Reporting InvestigationSingh Vineet Kumar -Nessuna valutazione finora

- Office of The Director General of Civil AviationDocumento4 pagineOffice of The Director General of Civil Aviationconfirm@Nessuna valutazione finora

- Maintenance Manual: Poplar Farm Prolley Moor Wentnor Bishops Castle Sy9 5ejDocumento66 pagineMaintenance Manual: Poplar Farm Prolley Moor Wentnor Bishops Castle Sy9 5ejCristhian342100% (1)

- Blanik l13 - Gfa Ad-369Documento11 pagineBlanik l13 - Gfa Ad-369mersoigNessuna valutazione finora

- Dgca Ame Question Bank Paper1Documento6 pagineDgca Ame Question Bank Paper1Kevin Alexander100% (2)

- Aircraft, Engine, Propeller and Radio LogbooksDocumento4 pagineAircraft, Engine, Propeller and Radio LogbooksShrawan ShresthaNessuna valutazione finora

- Car Section - 2 NotesDocumento144 pagineCar Section - 2 NotesKshitiz Rastogi100% (1)

- Office of The Director General of Civil AviationDocumento4 pagineOffice of The Director General of Civil AviationMaulana SidikNessuna valutazione finora

- Car - M: Subpart A - GenearalDocumento10 pagineCar - M: Subpart A - GenearalChalla AmarsrinuNessuna valutazione finora

- CAR & MOE, TPM NotesDocumento75 pagineCAR & MOE, TPM Notesbirendra67% (3)

- D2T T2 PDFDocumento11 pagineD2T T2 PDFaadhya guptaNessuna valutazione finora

- CAR M NotesDocumento9 pagineCAR M NotesAnoop singh0% (1)

- EASA Changes To The Requirements For Continuing Airworthiness Records CAWDocumento7 pagineEASA Changes To The Requirements For Continuing Airworthiness Records CAWrubenarisNessuna valutazione finora

- Prescribing Airworthiness Directive in CMMDocumento3 paginePrescribing Airworthiness Directive in CMMprasetyoNessuna valutazione finora

- Chapter 14Documento6 pagineChapter 14ZamhureenNessuna valutazione finora

- Mini-QCAR 1003-2006Documento13 pagineMini-QCAR 1003-2006qureshihakeem2005Nessuna valutazione finora

- Series CDocumento11 pagineSeries CAryan LahariaNessuna valutazione finora

- C Part 1Documento11 pagineC Part 1Prathmesh DixitNessuna valutazione finora

- Airworthiness HandbookDocumento15 pagineAirworthiness HandbookSmrti Sattana100% (1)

- Cockpit Check List.Documento2 pagineCockpit Check List.james_008Nessuna valutazione finora

- Suspension or Cancellation of Certificate of AirworthinessDocumento12 pagineSuspension or Cancellation of Certificate of Airworthinesssajid93Nessuna valutazione finora

- A320 PreambleDocumento6 pagineA320 PreambleNasirNessuna valutazione finora

- 05 20 00 SchedchkDocumento31 pagine05 20 00 SchedchkSaid AdingniNessuna valutazione finora

- ANO Part B - Maintenance DirectionsDocumento181 pagineANO Part B - Maintenance DirectionsDade SobarnaNessuna valutazione finora

- D8D-D2 Subject Preparation and Use of Cockpit and Emergency Check ListDocumento2 pagineD8D-D2 Subject Preparation and Use of Cockpit and Emergency Check Listjames_008Nessuna valutazione finora

- Car MDocumento38 pagineCar MAbdulla Khan100% (1)

- A0 307 Aircraft Engine MaintenanceDocumento50 pagineA0 307 Aircraft Engine MaintenanceBigbearBigbearNessuna valutazione finora

- M10Documento20 pagineM10Gaurav Singh100% (1)

- Npa 09-2013 - Caap 71 Helidecks (Off-Shore)Documento32 pagineNpa 09-2013 - Caap 71 Helidecks (Off-Shore)Legend AnbuNessuna valutazione finora

- Rajesh M10 Online Note UPDATEDDocumento20 pagineRajesh M10 Online Note UPDATEDMilan Pj100% (1)

- Company Procedure Checpoint MNSDocumento7 pagineCompany Procedure Checpoint MNSمحمد هافيزيNessuna valutazione finora

- Standard 625 Appendix CDocumento7 pagineStandard 625 Appendix CBakerviewNessuna valutazione finora

- Government of India Technical Centre, Opp Safdurjung Airport, New DelhiDocumento11 pagineGovernment of India Technical Centre, Opp Safdurjung Airport, New DelhiHemanthNessuna valutazione finora

- 9 9.4 Aoc Maintenance Requirements 9.4.1.1 ApplicabilityDocumento12 pagine9 9.4 Aoc Maintenance Requirements 9.4.1.1 ApplicabilityJoshua BarteNessuna valutazione finora

- 15) Trasreceiver PP-4ADocumento5 pagine15) Trasreceiver PP-4AManish MishraNessuna valutazione finora

- HAND TOOL For EASA/CAR - 66 EXAMINATIONDocumento201 pagineHAND TOOL For EASA/CAR - 66 EXAMINATIONManish Mishra100% (1)

- Lab SampleDocumento18 pagineLab SampleManish MishraNessuna valutazione finora

- Dgca Feb 2014 - Paper 2Documento8 pagineDgca Feb 2014 - Paper 2Manish MishraNessuna valutazione finora

- 021 C 99 S 2 C 13Documento10 pagine021 C 99 S 2 C 13Manish MishraNessuna valutazione finora

- M Tech in NDTDocumento17 pagineM Tech in NDTjaimin100Nessuna valutazione finora

- Sbi Assistant Clerk Notification 2014Documento5 pagineSbi Assistant Clerk Notification 2014Telugu VaahiniNessuna valutazione finora

- Airbussafetylib Maint Hum Per Seq01Documento15 pagineAirbussafetylib Maint Hum Per Seq01Manish MishraNessuna valutazione finora

- ADFDocumento11 pagineADFManish MishraNessuna valutazione finora

- Aviaftion FDocumento13 pagineAviaftion FManish MishraNessuna valutazione finora

- Airframe Answer KeyDocumento14 pagineAirframe Answer KeyDiwosh Sh100% (1)

- SBI Associates Clerks Previous Paper Completely SolvedDocumento49 pagineSBI Associates Clerks Previous Paper Completely Solvedradhika1991Nessuna valutazione finora

- VorDocumento11 pagineVorManish MishraNessuna valutazione finora

- DG ShippingDocumento76 pagineDG ShippingManish MishraNessuna valutazione finora

- Aircraft and Systems, DescriptionsDocumento17 pagineAircraft and Systems, DescriptionsManish MishraNessuna valutazione finora

- Engine Operation and MalfunctionsDocumento38 pagineEngine Operation and Malfunctionsiceman737Nessuna valutazione finora

- Engine Operation and MalfunctionsDocumento38 pagineEngine Operation and Malfunctionsiceman737Nessuna valutazione finora

- C152 Training Manual SAMPLE 16aug2011Documento34 pagineC152 Training Manual SAMPLE 16aug2011Arturo Canalda100% (1)

- Radio Naviagation Lession PlanDocumento36 pagineRadio Naviagation Lession PlanManish MishraNessuna valutazione finora

- Amecn0713 2Documento139 pagineAmecn0713 2Manish MishraNessuna valutazione finora

- Chemistry Su 2012Documento118 pagineChemistry Su 2012Manan BelaniNessuna valutazione finora

- 4.49 Aeranautics Avionics 2Documento15 pagine4.49 Aeranautics Avionics 2Manish MishraNessuna valutazione finora

- 15) Trasreceiver PP-4ADocumento5 pagine15) Trasreceiver PP-4AManish MishraNessuna valutazione finora

- AME0613 Rej1Documento39 pagineAME0613 Rej1Manish MishraNessuna valutazione finora

- Sumit VermaDocumento4 pagineSumit VermaMohan PatnaikNessuna valutazione finora

- China Tests New Space Capability With Hypersonic Missile - Financial TimesDocumento4 pagineChina Tests New Space Capability With Hypersonic Missile - Financial TimesAleksandar SpasojevicNessuna valutazione finora

- Types of SatellitesDocumento3 pagineTypes of SatellitesmadhuriNessuna valutazione finora

- CELEX:32017R0363:EN:TXTDocumento9 pagineCELEX:32017R0363:EN:TXTramchanderNessuna valutazione finora

- Bebe4d35002 21582096 7485003949 7421644598 L210PBCDocumento6 pagineBebe4d35002 21582096 7485003949 7421644598 L210PBCRasulovsNessuna valutazione finora

- Letov Š-16Documento9 pagineLetov Š-16Ivan SABONessuna valutazione finora

- Feasibilty Analysis (Modified)Documento7 pagineFeasibilty Analysis (Modified)RitvikPareekNessuna valutazione finora

- Sharklet Modificacoes MELDocumento20 pagineSharklet Modificacoes MELivofimfNessuna valutazione finora

- India Defence TechnologyDocumento82 pagineIndia Defence Technologyمحمد علىNessuna valutazione finora

- Chapter 9 - Force and Laws of Motion Revision Notes PDFDocumento13 pagineChapter 9 - Force and Laws of Motion Revision Notes PDFAbhishekNessuna valutazione finora

- Rocket ReportDocumento13 pagineRocket Reportapi-267418290Nessuna valutazione finora

- NASA Facts Rangers and Surveyors To The MoonDocumento4 pagineNASA Facts Rangers and Surveyors To The MoonBob Andrepont100% (1)

- Cpi PPT Enrollment No 10 To 13Documento32 pagineCpi PPT Enrollment No 10 To 13arshit5dobriyaNessuna valutazione finora

- Pilatus PC 6Documento9 paginePilatus PC 6Marius UrzicăNessuna valutazione finora

- Gemini 8 Voice Communications TranscriptDocumento113 pagineGemini 8 Voice Communications TranscriptBob Andrepont100% (1)

- Internship ReportDocumento25 pagineInternship Reportrealbutthole3541Nessuna valutazione finora

- Concorde144fedex PartsDocumento7 pagineConcorde144fedex PartsTommaso ScigliuzzoNessuna valutazione finora

- NASA: 83129main 1977Documento262 pagineNASA: 83129main 1977NASAdocuments100% (1)

- Rotary Wing Aircraft Handbooks and History Volume 13 Convertible AircraftDocumento82 pagineRotary Wing Aircraft Handbooks and History Volume 13 Convertible Aircraftpiolenc@archivale.com100% (2)

- Project Gemini Game ManualDocumento148 pagineProject Gemini Game ManualjeanNessuna valutazione finora

- AE6015 - Rockets and Missiles Part - A (8 X 3 24) Answer Any Eight QuestionsDocumento2 pagineAE6015 - Rockets and Missiles Part - A (8 X 3 24) Answer Any Eight QuestionspugazhNessuna valutazione finora

- Propeller SystemsDocumento2 paginePropeller SystemsSérgio PortuNessuna valutazione finora

- Air BusDocumento22 pagineAir BusChandrashekar HiremathNessuna valutazione finora

- Flights of Discovery 50 Years at The NASA Dryden Flight Research CenterDocumento213 pagineFlights of Discovery 50 Years at The NASA Dryden Flight Research CenterBob AndrepontNessuna valutazione finora

- The First-Ever Artificial Satellite, Sputnik 1, Took To The Skies On Oct. 4, 1957 As Launched by The Soviet Union.Documento4 pagineThe First-Ever Artificial Satellite, Sputnik 1, Took To The Skies On Oct. 4, 1957 As Launched by The Soviet Union.Rustom IbanezNessuna valutazione finora

- Iranian Shahab-3 Silo Complex Near TabrizDocumento33 pagineIranian Shahab-3 Silo Complex Near TabrizKn StofilNessuna valutazione finora

- Tow Target Cable Drag Mechanism (1941)Documento4 pagineTow Target Cable Drag Mechanism (1941)CAP History LibraryNessuna valutazione finora

- Gemini I Press KitDocumento18 pagineGemini I Press KitBob Andrepont100% (1)