Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Lab Manual 1

Caricato da

Hallowfied KawsarDescrizione originale:

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Lab Manual 1

Caricato da

Hallowfied KawsarCopyright:

Formati disponibili

UNIVERSITY OF WINDSOR Faculty of Engineering

Mechanics of Deformable Bodies 85-218

Winter 2012

Experiment 1 Tension Test

Objectives: 1. 2. 3. 4. To carry out quasi-static tension tests on ductile and brittle materials. To determine the mechanical properties of ferrous and non-ferrous materials. To study the behaviour of materials under load. To observe the fracture of specimen.

Equipment: 1. 2. 3. 4. 5. Universal Testing Machine Tinius Olsen Extensometer Tinius Olsen Datascan Analog Measurement Processor Dalite Datascan Configurator Micrometer, scales, dividers, etc.

Specimens: Specimens of ferrous and non-ferrous materials (steel, aluminum and cast iron). Each group should test one specimen of cast iron, one specimen of steel and one specimen of aluminum. Procedure: 1. Measure the diameter of the specimen to be tested at several places along the gauge with a micrometer. Use the average diameter to calculate the cross-sectional area. 2. Examine the punch marks on the specimen to establish the gauge length. 3. Examine the grips in the Universal Testing Machine. Zero the machine for all load ranges to be used. 4. Place the specimen in the grips so that the punch marks face the operator and the grips are properly aligned.

5. Examine the extensometer and attach it to the specimen. Observe the precautions as pointed out by the instructor to avoid damaging the extensometer. 6. Open the Dalite Datascan Configurator. Open defbod1.ovl file and click on the monitor every second window. Check if the load and extend readings are zero. 7. Apply a load of approximately 2 kN to ensure that the extensometer is working properly. If it is working properly reduce the load to zero. 8. Begin to load the specimen slowly. Take readings of elongation in the monitor window at the following load increments: 2 kN increments for cast iron, 4 kN increments for aluminum and steel. In the inelastic range, use elongation increments as the basis of when to take readings. 9. Continue taking readings until the limit of extensometer has been reached, or when rapid increases in elongation are observed. To protect the extensometer from being damaged, the extensometer will be removed at a load of 32 kN for the aluminum specimen, 52 kN for the steel specimen and 20 kN for the cast iron specimen. 10. Observe and record the maximum load and the load at failure on the load window of the Dalite Datascan Configurator. 11. Place the two parts of the specimen together after rupture and measure the total elongation of the gauge. For ductile materials, measure the smallest neck diameter with the micrometer. Observe the appearance of the specimen after failure. 12. Repeat this same procedure for the other specimens to be tested.

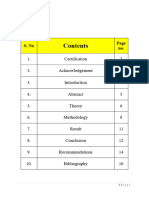

Report: Prepare the Lab report according to the outline provided in the course syllabus. This is a formal report that should be written using a word processor; the only hand writing allowed is for the sample calculations. Include the following results in the report: 1. Prepare a table (identical to Data Sheet No.2) for each specimen tested showing the load, elongation, stress and strain. Note that the original cross-sectional area and gauge length are used in these calculations. 2. Plot a graph of the complete stress-strain curve for each specimen. Indicate significant points on the graph. (Stress on the y-axis and strain on the x-axis). It will be necessary to estimate the shape of the curve for portions where the strain was not recorded. 3. For the material which exhibits a yield point, plot a graph showing the elastic portion of the curve, including the yield point, to an enlarged strain scale. 4. Complete Data Sheet No.1. 5. Provide one sample calculation for each mechanical property in Data Sheet No.1 6. Sketch the fracture surface by hand, describe the characteristics of the fracture and comment on the reasons for the fracture, for each specimen tested.

Hints for completing data sheets load original cross - sectional area change in length original length 3. Reduction of area at fracture (%) (original cross = sectional area - final cross - sectional area) original cross 100 - sectional area (final gauge length - original gauge length) original 100 gauge length

1. Stress =

2. Strain =

4. Elongation (%) =

5. Proportional limit is to be obtained from the stress-strain curve. It is the stress at which the stressstain curve is no longer linear. stress

6. Modulus of elasticity = proportional limit.

; it is the slope of the stress-strain curve below the strain

7. Yield stress at 0.2% offset: (see figure)

STRESS (MPa)

Yield stress 3

0 STRAIN 0.002

8. Ultimate Stress (tensile strength) =

maximum load original cross - sectional area

9. Fracture Stress (rupture stress) = 10. Modulus of Resilience

load at fracture original cross sectional area

= energy stored per unit volume at the elastic limit = triangular area under the stress-strain diagram up to the elastic limit 1/2 (proportional limit) (strain at proportional limit) 11. Modulus of Toughness = energy stored per unit volume required to rupture the material = total area under the stress-strain diagram overall average stress strain at rupture

D N M a S p D i

A r e

R e d G a u

E l o P r o M o d Y i e U l t R u p M o d M o d

Data Sheet No. 2 (a) Tension Test Data for Ferrous and NonFerrous Materials Type of Material:

L o

Data Sheet No. 2 (b) Tension Test Data for Ferrous and NonFerrous Materials Type of Material:

L o

Data Sheet No. 2 (c) Tension Test Data for Ferrous and NonFerrous Materials Type of Material:

L o

Potrebbero piacerti anche

- Strength of Materials Laboratory ExperimentsDocumento20 pagineStrength of Materials Laboratory Experimentskenneth iyahenNessuna valutazione finora

- 3-Exp#03 Tensile TestDocumento7 pagine3-Exp#03 Tensile TestD7ooM_612Nessuna valutazione finora

- Experiment 1Documento7 pagineExperiment 1waseemjuttNessuna valutazione finora

- MT Lab Experiment 3Documento13 pagineMT Lab Experiment 3Himmat Singh RawatNessuna valutazione finora

- Strength of Materia Lab Manual UET, LahoreDocumento14 pagineStrength of Materia Lab Manual UET, LahoreRizwan Khurram100% (3)

- Mechanics of Solids Laboratory Manual: Tensile TestDocumento8 pagineMechanics of Solids Laboratory Manual: Tensile TestVIPAN KUMARNessuna valutazione finora

- Mos Lab Manual PDFDocumento34 pagineMos Lab Manual PDFs.rihanaNessuna valutazione finora

- Tensile Test PresentationDocumento36 pagineTensile Test PresentationalkharfaneNessuna valutazione finora

- btech3rd-CE SOM LAB MANUALDocumento21 paginebtech3rd-CE SOM LAB MANUALvkmstp2005Nessuna valutazione finora

- Som Manual-2013 RegDocumento26 pagineSom Manual-2013 RegsugunavidiyadarNessuna valutazione finora

- Tensile Testing of Metals-II (Non-Ferrous Metals) MDDocumento3 pagineTensile Testing of Metals-II (Non-Ferrous Metals) MDH S Vishwanath Shastry0% (1)

- Som ExperimentsDocumento17 pagineSom ExperimentsAnudeex ShettyNessuna valutazione finora

- Laboratory Manual of Tensile TestDocumento11 pagineLaboratory Manual of Tensile TestVIPAN KUMARNessuna valutazione finora

- Lab Manual: International Islamic University Malaysia Department of Mechanical EngineeringDocumento36 pagineLab Manual: International Islamic University Malaysia Department of Mechanical EngineeringMuhamad HilmiNessuna valutazione finora

- Strength of MaterialDocumento18 pagineStrength of MaterialMamta SinghNessuna valutazione finora

- Strength of Materials LabDocumento30 pagineStrength of Materials LabDipesh GugaleNessuna valutazione finora

- BME Mannual BT 203-1Documento41 pagineBME Mannual BT 203-1shivanshu tiwariNessuna valutazione finora

- Tensile TestDocumento6 pagineTensile Testkinwai5557100% (1)

- MEC 222 EXP-Lab-SOMDocumento69 pagineMEC 222 EXP-Lab-SOMAbhijeeth NagarajNessuna valutazione finora

- SM Lab (Tension Test)Documento15 pagineSM Lab (Tension Test)Sushilkumar MagadeNessuna valutazione finora

- Papua New Guinea University of Technology CE 261-Engineering Materials Test 2 - Tensile Test of A Steel SpecimenDocumento4 paginePapua New Guinea University of Technology CE 261-Engineering Materials Test 2 - Tensile Test of A Steel SpecimenIsrael PopeNessuna valutazione finora

- Lab 1 - Tensile-Testing-2022Documento7 pagineLab 1 - Tensile-Testing-2022sahanss2001Nessuna valutazione finora

- E1 Tensile TestDocumento13 pagineE1 Tensile TestFirzana AmiraNessuna valutazione finora

- Manual-1 (A1 To A9)Documento37 pagineManual-1 (A1 To A9)Utkarsh AgarwalNessuna valutazione finora

- Tensile TestDocumento7 pagineTensile TestDhedhe PrasetyaNessuna valutazione finora

- Tension Test ReportDocumento7 pagineTension Test ReportTomy GeorgeNessuna valutazione finora

- SOM Lab ManualDocumento32 pagineSOM Lab ManualMuhammad Junaid100% (1)

- Tension TestDocumento7 pagineTension TestmanmathkNessuna valutazione finora

- Real O.V Tensile TestingDocumento14 pagineReal O.V Tensile TestingOshane ThomasNessuna valutazione finora

- Lab#1 - Tensile Test HandoutDocumento7 pagineLab#1 - Tensile Test Handoutgrbxjgsh59Nessuna valutazione finora

- Theory:: Experiment No. 03 Aim: Shear Test On Mild Steel and Aluminum (Single and Double Shear Tests) Apparatus UsedDocumento5 pagineTheory:: Experiment No. 03 Aim: Shear Test On Mild Steel and Aluminum (Single and Double Shear Tests) Apparatus UsedRaj TondayNessuna valutazione finora

- Experiment Name: Tensile Test of Steel: ObjectivesDocumento4 pagineExperiment Name: Tensile Test of Steel: ObjectivesKalikiri navyaNessuna valutazione finora

- Laboratory Manual of Tensile TestDocumento12 pagineLaboratory Manual of Tensile TestVIPAN KUMARNessuna valutazione finora

- SM Lab ManualsDocumento27 pagineSM Lab ManualspraveenampilliNessuna valutazione finora

- Engineering Council Certificate Level Engineering Materials C102 Tutorial 6 - Materials TestingDocumento11 pagineEngineering Council Certificate Level Engineering Materials C102 Tutorial 6 - Materials TestingcataiceNessuna valutazione finora

- Tensile Test PresentationDocumento36 pagineTensile Test Presentationssdivi100% (2)

- 85-218-Lab 2-ManualDocumento5 pagine85-218-Lab 2-Manualjoseph0% (1)

- TensileDocumento4 pagineTensileاحمد الشلمانيNessuna valutazione finora

- Tensile LabDocumento13 pagineTensile LabnevermoreNessuna valutazione finora

- Uniaxial TestDocumento6 pagineUniaxial Testanil chejaraNessuna valutazione finora

- Tensile Test Lab ReportDocumento4 pagineTensile Test Lab ReportElisha NissiNessuna valutazione finora

- Material Science and Testing LabDocumento26 pagineMaterial Science and Testing LabJitendra JangidNessuna valutazione finora

- Am LabDocumento22 pagineAm LabJayavel123Nessuna valutazione finora

- Material Testing LabDocumento79 pagineMaterial Testing LabBrijesh VermaNessuna valutazione finora

- DK. BMT Lab ManualDocumento46 pagineDK. BMT Lab ManualPaviter SinghNessuna valutazione finora

- Lab Manual: Sant Longowal Institute of Engineering & Technology Longowal-148106Documento4 pagineLab Manual: Sant Longowal Institute of Engineering & Technology Longowal-148106Vivek JhaNessuna valutazione finora

- Experiment # 2 Tension Testing of MetalsDocumento3 pagineExperiment # 2 Tension Testing of MetalsJ. Fabián MenaNessuna valutazione finora

- Unit - IIIDocumento215 pagineUnit - IIINishigandha Bansode100% (1)

- Tensile Test - UTMDocumento4 pagineTensile Test - UTMmjayrajsharma19Nessuna valutazione finora

- Ramkrishna Mahato Government Engineering College: S0Lid Mechanics LaboratoryDocumento34 pagineRamkrishna Mahato Government Engineering College: S0Lid Mechanics LaboratoryMaynak DeyNessuna valutazione finora

- Tensile and Hardness Testing LabDocumento14 pagineTensile and Hardness Testing LabaNessuna valutazione finora

- TensileTest SheetDocumento7 pagineTensileTest SheetKhubaib MalikNessuna valutazione finora

- 8-To Study The Fatigue Behavior of A Given SampleDocumento4 pagine8-To Study The Fatigue Behavior of A Given SampleShreyan DevNessuna valutazione finora

- Material Lab 9Documento1 paginaMaterial Lab 9AhmadNessuna valutazione finora

- Tensile Test: (Selection and Testing of Materials (PE-ME 701E) Continuous Assessment 2 (CA 2)Documento9 pagineTensile Test: (Selection and Testing of Materials (PE-ME 701E) Continuous Assessment 2 (CA 2)Prabhat RoutNessuna valutazione finora

- Compression Test - Lab Module 2023 StudentDocumento8 pagineCompression Test - Lab Module 2023 Students221320994Nessuna valutazione finora

- Advanced Opensees Algorithms, Volume 1: Probability Analysis Of High Pier Cable-Stayed Bridge Under Multiple-Support Excitations, And LiquefactionDa EverandAdvanced Opensees Algorithms, Volume 1: Probability Analysis Of High Pier Cable-Stayed Bridge Under Multiple-Support Excitations, And LiquefactionNessuna valutazione finora

- Cls Jeead-18-19 Xii Che Target-7 Set-2 Chapter-12Documento47 pagineCls Jeead-18-19 Xii Che Target-7 Set-2 Chapter-12DxNessuna valutazione finora

- Module 2: Infrared SpectrosDocumento5 pagineModule 2: Infrared SpectrosAngela ReyesNessuna valutazione finora

- Intensive Revision Program of Physical Chemistry: By: Brijesh Jindal SirDocumento11 pagineIntensive Revision Program of Physical Chemistry: By: Brijesh Jindal SirHudsun HornetNessuna valutazione finora

- Sika Igasol - 17: High Build, Bituminous Emulsion CoatingDocumento3 pagineSika Igasol - 17: High Build, Bituminous Emulsion CoatingAhmed AbdallahNessuna valutazione finora

- Organometallic Compounds NotesDocumento12 pagineOrganometallic Compounds Notesjyothi sai sriNessuna valutazione finora

- Underground Tank - 500-002Documento32 pagineUnderground Tank - 500-002meganemesisNessuna valutazione finora

- Chemistry Project PDFDocumento16 pagineChemistry Project PDFAshwin 777Nessuna valutazione finora

- مستند بلا عنوانDocumento4 pagineمستند بلا عنوانHamzah A. LaftaNessuna valutazione finora

- Astm A449Documento1 paginaAstm A449Vitor Rigueira de GodoyNessuna valutazione finora

- CB-8491 Heat Recovery BrochureDocumento8 pagineCB-8491 Heat Recovery Brochurekats2404Nessuna valutazione finora

- M SC Entrance (Environmental Science) - Panjab University 2013 (Key)Documento13 pagineM SC Entrance (Environmental Science) - Panjab University 2013 (Key)RavikanthNessuna valutazione finora

- PH Calculation With CO2 AdditionDocumento12 paginePH Calculation With CO2 AdditionPraveen KhatriNessuna valutazione finora

- Mechanical Properties of MaterialsDocumento3 pagineMechanical Properties of MaterialsTiras Ngugi0% (1)

- Lab 12 - Bunsen Burner Flame PDDocumento2 pagineLab 12 - Bunsen Burner Flame PDvictoria kairoo50% (2)

- Polymer Repair PDFDocumento3 paginePolymer Repair PDFamirouche15Nessuna valutazione finora

- TSO C72cDocumento6 pagineTSO C72cRobert FlorezNessuna valutazione finora

- Unit 1 TestDocumento5 pagineUnit 1 Testapi-485795043Nessuna valutazione finora

- 025welding Engineering An Introduction - (2.5 Plasma Arc Welding)Documento3 pagine025welding Engineering An Introduction - (2.5 Plasma Arc Welding)Kamarul NizamNessuna valutazione finora

- CoordinationDocumento3 pagineCoordinationNiteshNarukaNessuna valutazione finora

- ElemeNtS-Technical Offer 2020.5Documento36 pagineElemeNtS-Technical Offer 2020.5jawed iqbalNessuna valutazione finora

- Capsules and Its Technology An OverviewDocumento8 pagineCapsules and Its Technology An OverviewRonald Reyes LeonNessuna valutazione finora

- Desalination Technologies, 4th Level, ERE414, 2023, ChapterDocumento49 pagineDesalination Technologies, 4th Level, ERE414, 2023, ChapterMohamed HatemNessuna valutazione finora

- PH - Wikipedia, The Free EncyclopediaDocumento11 paginePH - Wikipedia, The Free EncyclopediaShikhar MahajanNessuna valutazione finora

- Reichold, Corrosion Guide 12.15.2010Documento45 pagineReichold, Corrosion Guide 12.15.2010Pradeep Srivastava100% (1)

- Solutions NumericalsDocumento3 pagineSolutions Numericalsdevesh saiNessuna valutazione finora

- Abrasive Wear Analysis Using Factorial Experiment DesignDocumento6 pagineAbrasive Wear Analysis Using Factorial Experiment DesignMislav TeskeraNessuna valutazione finora

- Chemical Content of FertilizersDocumento22 pagineChemical Content of FertilizersJohn DAcquisto, D.Sc.100% (1)

- Acros White Paper OrganosilanesDocumento16 pagineAcros White Paper OrganosilanesbbtbadalNessuna valutazione finora

- Interlab g26 User's Manual 1.2Documento61 pagineInterlab g26 User's Manual 1.2Ali AminiNessuna valutazione finora

- CFBC BoilerDocumento7 pagineCFBC Boilerkaruna346Nessuna valutazione finora