Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Fluidization: Chemical Engneering Practice

Caricato da

Farhan M JafrIDescrizione originale:

Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Fluidization: Chemical Engneering Practice

Caricato da

Farhan M JafrICopyright:

Formati disponibili

1

Fluidization

Chemical Engneering Practice

Due Date Feb 7, 2012 Lab #2 Farhan Jafri

To:

Rudy Jones

2 From: Date: Subject: Farhan Jafri, Group 3 Jan 31, 2012 CHG 3122, Fluidization Experiment

Fluidization has been of developed since the 1920s, but commercially it wasnt success until in 1940s, since it has played critical role in oil refineries where it was used to turn heavy petroleum products into gasoline which is used as fuel. Fluidization helped removing heavy carbon from petroleum by using fluidized catalyst particles, where the heavy carbons would be deposited on these particles and then removed. The main purpose of this lab is to study pressure drop variation as a gas is passed through when slowly increasing and decreasing the velocity of gas through bed of particles such as flexi glass and coke particles. The second part of this experiment is finding the minimum fluidization velocity and to analyze the bed expansion as a function of gas superficial velocity. Even though the procedure requires us to use both coke particles and flexolite particles in this experiment but the discussion, calculations and results will be based on just using flexolite glass as bed particles in this lab report. Other objectives of this lab would be finding pressure drops in the fixed bed and the fluidized bed will be calculated using the ergun and bed apparent weight equations. The experiment was performed by using two columns, each one was either filled with coke particles and flexolite particles, the flow is these columns was increased incrementally by factor of 2 from 0 to 60 SLPM, and there pressure drop and the

height of the column at different air flows were recorded, and pressure drop was recorded using computer software Labview.

Equipment and Procedure

The equipment used in this lab as follows, MFC which stands for mass flow controller, windbox, pyrex glass columns of 3 and 3.5 inches are used . The mass flow controller measures flow rate going into the wind box which is located beneath the columns, from here they pass through porous steel plate and into the particles in the columns. The column with 3.5 inch diameter is used for coke particle and column with 3 inch diameter is used for flexolite particles, each column was filled with approximately 6 inches of static bed height, or roughly 15 cm. As the air flow leaves the column from the top surface, there are pressure taps located on the wind box which are connected to the pressure sensors which measure the pressure and transfer the data to the computer, the labview computes the data by recording and also making a graph of it. Subsequently, the air flow rate was increased by increments of 2 SPML, and Labview was used to record data point for each increament, this was performed from range of 0 to 60 SPML. Both types of particles were subjected to the gas flow rates which passed through the bottom of columns and flow rate was increased and decreased such that it would be possible to collect data using Labview, and then be able to find the total pressure drop as well as the bed height as a function of the gas flow rate. The

4 particles were then removed from column and then they were weighed. At the end the pressure drop was recorded for the flow rates in empty column. The mean diameter of the particles also had to be determined. This was performed by doing a sieve analysis. The flexolite glass were placed into the top of the tray and placed on a shaker. By knowing the fraction of weight in each tray, the mean diameter was determined, calculation shown in appendix A. Results Summary of important results in this lab as follows, the theory and explanation is discussed in the discussion The mean diameter of flexolite glass is 185 micrometers. The theoretical pressure drop for flexolite glass in fluidized bed is 2662.84 Pa Theoretical minimum velocity required for bed to be fluidized is 0.06136 m/s, this can be determined by looking at table The experimental fluidization velocity is 0.06814 m/s by looking at figure The void fraction in the static bed is 0.1469 Minimum fluidization velocity, and bubbling velocity is Vmb=0.01723 m/s, Vmf=0.018m/s The density if flexolite glass was found out to be 1916.6 kg/m3 Discussion In order to understand this experiment clearly, one must know what is fluidization: when a static bed of particles such as flexolite glass which is the focus of this lab

5 report, are applied a strong flow of fluid such as gas in our case coming from the bottom of the bed, the weight of the particles is then supported by the drag force which is exerted by the gas on the particles, which causes them to freely suspend or in other words become fluidized, the fluidized bed characteristics are very similar to that of pure liquid. The heat and mass transfer rate are increased dramatically by the result of fluidization, this enables them to be used extensively in gas and solid reactions, for example coal combustion, solid catalysts reaction i.e. catalytic cracking of petroleum and other applications such as in bioreactors. The wet test meter is used to measure volumes and flow rates of gases, the meter consist of hollow drum which consists several compartments of known volume, as sufficient amount of gas flows through the meter causing chamber to hold maximum amount of air, and as gas leaves and enters through the meter the drum rotates, since the volume of the compartment is known, the rotation of the drum can be record to find out the total volume of gas flows through the meter. In order to find the friction pressure drop due to packed bed, first of all we had to perform experiment consisting of measuring pressure drop in the empty column, the pressure drop data was recorded using Labview, the pressure given in raw data was in torr, this converted to pressure Pa and this was plotted against superficial velocity, the graph gave a linear relationship, and using excels trendline function, the equation of line is obtained.

6 The next part of analyzing the experimental data was to find theoretical pressure drops across the bed. The Ergun equation 3 was used to find the pressure drop when the bed height was static, and Ergun equation 2 was used to come up with pressure drops in fluidized bed. The minimum fluidization velocity occurred when the bed height changed from its static height, superficial velocity is 0.0613 m/s from theoretical point of view and the experimental minimum fluidization can be obtained from figure 2, which is 0.06814 meters per seconds. As velocity as increased beyond the point of minimum fluidization velocity results in the formation of bubbles which continue to rise through the bed, this causes the bed height to increase. As evident from figure 2, in appendix A, the friction pressure drop predicted using Ergun equation barely resembles the experimental data before and after the fluidization point, but the fluidization pressure drop data has wider range over velocity as compare to experimental, this is because as the bed starts to fluidize, but at this point Ergun equation assumes fixed bed. Also some group members decided to shake the column for some reason, which affected the fluidized bed and thus gave us inaccurate results. A graph of height versus the superficial velocity was also constructed, as seen in figure 3 in the appendix A, by visually looking at this graph, it is evident for velocity of range zero to 0.06 m/s there is no relative change in the bed height as we increase the flow rate, this process is considered to be fixed bed, thus glass particles do not move while velocity is increasing. At velocity of 0.0681 m/s, it is visually evident the bed height starts to expand experimentally but theoretically the bed expands little earlier than this; at velocity 0.06136 m/s. The rate of height change over superficial velocity is higher when the flow is increasing as it is evident by looking at the steepness of slope, the graph is more steeper when fluidization start to begin, and as

7 we go down from maximum velocity of air, the slope descends less steeper. The maximum superficial velocity applied to the bed is 0.102 m/s, from their we start to decrease the flow rate and as mentioned before the slope descending has small rate of change. Another observation that can be noted is the final bed height is higher than initial; the reason for this at the beginning the particles were tightly packed together, and when particles changing from fluidized state to static bed had more air between the particles thus giving higher height 17.4 cm compare to before of 16.63 cm. The classification of glass particles, was determined by finding density and the mean diameter. The mean diameter of glass particles was found out by; first about fifty grams were measured, and put into a sieve which distributed glass particles with respect to their diameter, and then the mean diameter was calculated using mass fractions of different diameters of glass particles which turned out to be 185 micrometers, but calculating the density was a bit trickier because not all the air bubbles in glass particles were leaving in the graduated cylinder, thus the density1916.6 kg/m3 might be greater than it is suppose to be. These two above properties help us distinguish them into classification of groups introduced by Geldart (1973), since the mean diameter fits the range 90 to 650 micrometer, thus they can be considered as group B particles. If mass of bed doubles that would double the height of the bed, but the cross sectional area of the pipe will be remain the same therefore doubling the mass of the bed means doubling the height. Both sides of equation 4 in lab handout, includes the height which can be eliminated from both sides so nothing will change. That means the fluidized bed would be in the same fluidization regime as before.

8 Conclusion and Recommendations The mean diameter of flexolite glass is 185 micrometers, and density is found to be 1916.6 kg/m3; this enables us to consider the glass particles to be in group B classification according to Geldart(1973). , this can be determined by looking at table The experimental fluidization velocity is 0.06814 m/s by looking at figure 2 in appendix A, theoretical minimum velocity required for bed to be fluidized is 0.06136 m/s. Though it was not possible in our lab, to control the air flow without manually, but using a

computer to increase or decrease air flow, could have given more consistent data, and hence better results.

Also the experiment should have been done with smaller intervals of change of air flow,

and increase range, could have given broader scope of data, thus enabling us to better relate theoretical and experimental data.

References

Geankoplis,C,N. (2003),Transport Process and Separation process principles Fourth ed., Prenice Hall, New Jesey,.

Geldart, D. (1973), Types of Gas Fluidization, Powder Tech., 7, 285-292.

Grace, J.R. (1982), Fluidized Bed Hydrodynamics, Chapter 8.1 in Handbook of Multiphase Systems, ed. G. Hetsroni, Washington D.C., Hemisphere Publishing.

Fluidization Experiment Handout

Appendix A

Table 1- Pressure and temperature of room where experiment was conducted Pressure (psi) Pressure (Pa) Room temp.(C) 14.69 101283.6 23

10

Temperature (K)

296.15

Table 2 - The air velocity in the fluidized bed and the pressure drop due to friction. Column filled with flexilite Pressure (torr) 0 1.8 3.7 5.7 7.7 9.8 11.9 14.1 16.5 18.7 20.8 21.2 21.5 21.8 21.9 22.4 21.5 20.9 20.3 18.7 17 Flow (SLPM) 0 2.1 4.1 6.1 8 10.2 12 14.1 16.1 18.1 20.1 22.1 24.1 26.1 28.1 30.1 28.1 26 24 22 20 Packed Bed Height (cm) 15.33 15.33 15.33 15.33 15.33 15.33 15.33 15.33 15.33 15.43 15.4 15.73 16.13 16.33 16.63 16.83 16.63 16.43 16.33 16.23 16.2 Empty Column Pressure (torr) 0 0.1 0.2 0.4 0.5 0.7 0.8 0.9 1.1 1.2 1.3 1.5 1.6 1.8 1.9 2.1 1.9 1.8 1.6 1.5 1.3

11 15.3 13.4 11.8 10.2 8.4 6.8 5 3.3 1.7 0.2 18 15.9 14 12 10.2 8.3 6.1 4.2 2 0.1 16.13 16.13 16.1 16.13 16.13 16.1 16.1 16.1 16.1 16.1 1.2 1.1 0.9 0.8 0.7 0.5 0.4 0.2 0.1 0

Table 3 Data of flexilite glass particles in SI units.

Column filled with flexilite Pressure (Pa) 0 239.994 493.321 759.981 1026.641 1306.634 1586.627 1879.953 2199.945 Flow (m^3/s) 0 0.0000324 66 0.0000633 86 0.0000943 06 0.0001236 8 0.0001576 92 0.0001855 2 0.0002179 86 0.0002489 Packed Bed Height (cm) 16.63 16.63 16.63 16.63 16.63 16.63 16.63 16.63 16.63 Packed Bed Height (m) 0.1663 0.1663 0.1663 0.1663 0.1663 0.1663 0.1663 0.1663 0.1663 Empty Column Pressure (Pa) 0 13.333 26.666 53.332 66.665 93.331 106.664 119.997 146.663

12 06 2493.271 2773.264 2826.596 2866.595 2906.594 2919.927 2986.592 2866.595 2786.597 2706.599 2493.271 2266.61 2039.949 1786.622 1573.294 1359.966 1119.972 0.0002798 26 0.0003107 46 0.0003416 66 0.0003725 86 0.0004035 06 0.0004344 26 0.0004653 46 0.0004344 26 0.0004019 6 0.0003710 4 0.0003401 2 0.0003092 0.0002782 8 0.0002458 14 0.0002164 4 0.0001855 2 0.0001576 92 16.73 16.7 17.03 17.43 17.63 17.93 18.13 17.93 17.73 17.63 17.53 17.5 17.43 17.43 17.4 17.43 17.43 0.1673 0.167 0.1703 0.1743 0.1763 0.1793 0.1813 0.1793 0.1773 0.1763 0.1753 0.175 0.1743 0.1743 0.174 0.1743 0.1743 159.996 173.329 199.995 213.328 239.994 253.327 279.993 253.327 239.994 213.328 199.995 173.329 159.996 146.663 119.997 106.664 93.331

13 906.644 666.65 439.989 226.661 26.666 0.0001283 18 0.0000943 06 0.0000649 32 0.0000309 2 0.0000015 46 17.4 17.4 17.4 17.4 17.4 0.174 0.174 0.174 0.174 0.174 66.665 53.332 26.666 13.333 0

Table 4- Calculated values of for each air velocity, from increase of flow, to decrease.

Air velocit y (m/s) 0 Void Fractio n 0.147 Experiment al (Pa) Theoretic al (Pa) Sphericit y () Fluid Viscosit y (Pa*s) 0.00001 8 Mean Diamete r dv (m) 0.00018 5 Fluid Density (kg/m^3 ) 1.2 1-

0 (fixed bed)

0.82

0.85 3

0.0071 0.0139 0.0207 0.0271 0.0346 0.0407 0.0478

0.147 0.147 0.147 0.147 0.147 0.147 0.147

226.661 466.655 706.649 959.976 1213.303 1479.963 1759.956

37.0792 72 140.741 89 311.086 49 534.678 05 868.757 46 1202.10 89 1659.28 47

0.82 0.82 0.82 0.82 0.82 0.82 0.82

0.00001 8 0.00001 8 0.00001 8 0.00001 8 0.00001 8 0.00001 8 0.00001 8

0.00018 5 0.00018 5 0.00018 5 0.00018 5 0.00018 5 0.00018 5 0.00018 5

1.2 1.2 1.2 1.2 1.2 1.2 1.2

0.85 3 0.85 3 0.85 3 0.85 3 0.85 3 0.85 3 0.85 3

14 0.0546 0.147 2053.282 2163.03 92 (fixed bed) 2662.84 27 (fluidize d bed) 0.0681 0.0749 0.0817 0.0885 0.0953 0.102 0.0953 0.0881 0.0814 0.0746 0.0678 0.151 0.167 0.186 0.195 0.209 0.218 0.209 0.2 0.195 0.191 0.189 2599.935 2626.601 2653.267 2666.6 2666.6 2706.599 2613.268 2546.603 2493.271 2293.276 2093.281 2662.84 27 2662.84 27 2662.84 27 2662.84 27 2662.84 27 2662.84 27 2662.84 27 2662.84 27 2662.84 27 2662.84 27 2662.84 27 (fluidize d bed 0.061 0.186 1879.953 1398.95 15 (fixed 0.82 0.00001 8 0.00018 5 1.2 0.81 4 0.82 0.82 0.82 0.82 0.82 0.82 0.82 0.82 0.82 0.82 0.82 0.00001 8 0.00001 8 0.00001 8 0.00001 8 0.00001 8 0.00001 8 0.00001 8 0.00001 8 0.00001 8 0.00001 8 0.00001 8 0.00018 5 0.00018 5 0.00018 5 0.00018 5 0.00018 5 0.00018 5 0.00018 5 0.00018 5 0.00018 5 0.00018 5 0.00018 5 1.2 1.2 1.2 1.2 1.2 1.2 1.2 1.2 1.2 1.2 1.2 0.84 9 0.83 3 0.81 4 0.80 5 0.79 1 0.78 2 0.79 1 0.8 0.80 5 0.80 9 0.81 1 0.82 0.00001 8 0.00018 5 1.2 0.85 3

0.0614

0.152

2333.275

0.82

0.00001 8

0.00018 5

1.2

0.84 8

15 bed) 0.0539 0.0475 0.0407 0.0346 0.0281 0.0207 0.0142 0.0068 0.0003 0.186 0.185 0.186 0.186 0.185 0.185 0.185 0.185 0.185 1639.959 1453.297 1253.302 1026.641 839.979 613.318 413.323 213.328 26.666 1092.11 99 864.990 14 622.940 43 450.527 43 305.006 07 165.213 64 78.7014 48 18.1498 48 0.07291 6 (fixed bed) 0.82 0.82 0.82 0.82 0.82 0.82 0.82 0.82 0.82 0.00001 8 0.00001 8 0.00001 8 0.00001 8 0.00001 8 0.00001 8 0.00001 8 0.00001 8 0.00001 8 0.00018 5 0.00018 5 0.00018 5 0.00018 5 0.00018 5 0.00018 5 0.00018 5 0.00018 5 0.00018 5 1.2 1.2 1.2 1.2 1.2 1.2 1.2 1.2 1.2 0.81 4 0.81 5 0.81 4 0.81 4 0.81 5 0.81 5 0.81 5 0.81 5 0.81 5

Table 5 - Properties of two different particles.

Flexolite Particles Diameter of the bed (cm) Height of Static Bed (cm) Weight of Particles (Kg) 7.8 16.63 1.24 Coke particles 9.2 15.24 1.12

16

Figure 1 The pressure drop in the empty column used in the fluidization bed experiment versus air velocity. Using excel trendline function it can be found that it follows the equation delta P =y = 2730x -5.576. Figure 2 A comparison between the experiments results for the pressure drop due to friction and those would be obtained using Ergun equation for fixed, and fluidized bed.

Figure 3 The change in height of the fluidized bed versus the air velocity for flexi glass particles.

Appendix B Sample Calculations:

The mean diameter is defined in this experiment as the surface-to-volume mean diameter, approximated from sieve analysis as:

Obj100

Obj101

17

where, dsv: The mean diameter. It could be defined as dsv=dv, it is in m.

: The sphericity of the particles. xi: The mass fraction collected between two trays. dpi: The mean diameter between two trays of the sieve anlalysis in m.

The flexolite Density is given by:

Obj102

m is the mass of particles And V is the volume of particles The mass of the particles is: 9.584 g The volume of the particles is:

Obj103

Therefore:

18

Obj104

In order to carry out this experimental calculations; the air velocity should be found. The devices measured the air flow in SLPM. That should be changed to velocity unites for calculation required. It is known:

Obj105

Where; P Q T is the pressure in Pa. is the volumetric flow rate in LPM. is the temperature in K.

Subscripts 1&2 indicate Standard and Lab conditions respectively.

After finding the volumetric flow rate of air with respect to lab conditions; the air velocity will be found. That could be obtained easily by dividing the air flow rate by the cross-sectional area of the pipe.

19

Obj106

The pressure drop across the bed is due to two main factors. The hydrostatic pressure drop and the friction pressure drop which is due to the fluidized solid. The Labview reads the total pressure drop. In order for us to find which fraction of the pressure is due to which factor; we carried out the experiment in an empty column with various air velocities Figure (1), where x is the superficial velocity 2730.x -5.576.

Obj107

where;

Obj108

: Is the pressure drop due to connections and taps. (Pa)

Obj109

20 Is the pressure drop due to packing material. (Pa)

Obj110

Is the total pressure drop. (Pa)

The void fraction can be calculated by simply ignoring the mass of air in the packing solid: thus static bed porosity is

Obj111

where; m: p: A: x: : The total mass of the packing (g) The density of the packing particles=2.5g/cm3 The cross-sectional area of the bed = 45.6 cm2 The height of the bed at the flow of interest. (cm) The void fraction.

21 In a fluidized bed, the friction force would be equal to the buoyant weight. That will tell equation (2) in the class handout which is:

Obj112

where; g: f : The gravitational constant = 9.8 m/s2 The density of air = 1.2 kg/m3 Equation 3 in the handout is called Ergun equation. It describes the frictional pressure drop in a fixed bed.

Obj113

Obj114

Obj115

where;

22 : The air viscosity=1.8x10-5 Pa.s

Obj116

To calculate the minimum fluidization velocity, equation (4) in the handout becomes under dimensionless form:

Obj117

Obj118

is the Reynolds number at the minimum fluidization velocity Coefficients according to Grace: C1 = 27.2 and C2 = 0.0408

Obj119

is the Archimedes number Archimedes number is given by Eq. (7) in the lab manual:

Obj120

Obj121

Substitute into Eq. (4)

Obj122

23

Obj123

Rearrange Reynold number equation to solve for Vmf:

Obj124

Thus minimum fluidization velocity:

Obj125

Obj126

The minimum bubbling velocity is given by eq 10 in the lab manual

Obj127

Obj128

is the mass fraction of coke less than 45m in diameter.

Obj129

is the diameter of the particles

Obj130

is the density of the air

Obj131

is the viscosity of the air

24

Obj132

Since sieve analysis was used, we will assumeto be 1% the mass fraction

Obj133

Potrebbero piacerti anche

- Liquid Membranes: Principles and Applications in Chemical Separations and Wastewater TreatmentDa EverandLiquid Membranes: Principles and Applications in Chemical Separations and Wastewater TreatmentNessuna valutazione finora

- Fluidisation ReportDocumento29 pagineFluidisation ReportBenjamin Jie100% (2)

- Flow Through Packed Fixed and Fluidized Beds PDFDocumento7 pagineFlow Through Packed Fixed and Fluidized Beds PDFelisya diantyNessuna valutazione finora

- Fludized BedDocumento11 pagineFludized BedHaiqal AzizNessuna valutazione finora

- Series and Parallel PumpsDocumento11 pagineSeries and Parallel PumpsKevin Devastian100% (1)

- Investigation of Liquid-Solid and Gas-Solid Fluidized BedDocumento18 pagineInvestigation of Liquid-Solid and Gas-Solid Fluidized Bedmahbub1332100% (1)

- Gas Diffusion ExperimentDocumento18 pagineGas Diffusion ExperimentMuhammad NasrulNessuna valutazione finora

- Suspension Od Solid Particles (Revised Report)Documento7 pagineSuspension Od Solid Particles (Revised Report)michsantosNessuna valutazione finora

- Exp 4-Fuid MixingDocumento26 pagineExp 4-Fuid MixingNawal DaBomb100% (1)

- Fluidised Bed - ReportDocumento28 pagineFluidised Bed - ReportAidan ThomsonNessuna valutazione finora

- Heat Transfer Lab - Experiment 7 - Heat Transfer From A FinDocumento11 pagineHeat Transfer Lab - Experiment 7 - Heat Transfer From A FinJordan Hines75% (4)

- SedimentationDocumento7 pagineSedimentationgrkhari1100% (2)

- Plate and Frame Filter Press PDFDocumento8 paginePlate and Frame Filter Press PDFjamaiiicaNessuna valutazione finora

- Diffusivity of Liquid Into LiquidDocumento8 pagineDiffusivity of Liquid Into LiquidZahraa GhanemNessuna valutazione finora

- FluidisationDocumento14 pagineFluidisationJuno LowNessuna valutazione finora

- Isothermal Semi-Batch Reactor PPT RJC SirDocumento16 pagineIsothermal Semi-Batch Reactor PPT RJC Sirsdjdsf100% (1)

- Exp1 - Fixed and Fluidized BedDocumento3 pagineExp1 - Fixed and Fluidized BedAhmedNessuna valutazione finora

- Fluidized Bed A14Documento8 pagineFluidized Bed A14lovelygirl_256Nessuna valutazione finora

- Fluidization Post Laboratory ReportDocumento25 pagineFluidization Post Laboratory ReportGail100% (1)

- Fixed and Fluidized Bed ExperimentDocumento9 pagineFixed and Fluidized Bed Experimentsunlias50% (2)

- Final Lab Report Group 1 Flow Through Fluidized BedsDocumento47 pagineFinal Lab Report Group 1 Flow Through Fluidized BedsCharlie CB Portner100% (2)

- Experiment On Performance of Centrifugal PumpDocumento7 pagineExperiment On Performance of Centrifugal PumpSyfNessuna valutazione finora

- Fixed Bed and Fluidized BedDocumento33 pagineFixed Bed and Fluidized Bedشاكر العاقلNessuna valutazione finora

- Experiment 2 - Study of Packed Column DistillationDocumento7 pagineExperiment 2 - Study of Packed Column DistillationAdawiyah Az-zahra100% (1)

- Study of Mass Transfer Coefficient in A Wetted Wall Column: ICCPGE 2016, 1, 201 - 209Documento9 pagineStudy of Mass Transfer Coefficient in A Wetted Wall Column: ICCPGE 2016, 1, 201 - 209Siraj AL sharifNessuna valutazione finora

- Prelab 2 Gas AbsorptionDocumento5 paginePrelab 2 Gas AbsorptionDean Joyce AlborotoNessuna valutazione finora

- Experiment 3 - Fixed and Fluidized BedDocumento12 pagineExperiment 3 - Fixed and Fluidized BedNajmul Puda PappadamNessuna valutazione finora

- Packed Bed Distillation Column Lab ReportDocumento13 paginePacked Bed Distillation Column Lab ReportShamini Sathivel100% (6)

- My Diffusion of A Gas ReportDocumento22 pagineMy Diffusion of A Gas ReportEmonbeifo Efosasere100% (3)

- Characterization of Solid ParticlesDocumento8 pagineCharacterization of Solid ParticlesShary Mosquera50% (2)

- GAS ABSORPTION - ReportDocumento6 pagineGAS ABSORPTION - Reportgzairene8762Nessuna valutazione finora

- Climbing FilmDocumento34 pagineClimbing FilmTunji Aminu100% (1)

- Chemical Engineering Laboratory For Unit Operations 2 (Adamson University and de La Salle University)Documento91 pagineChemical Engineering Laboratory For Unit Operations 2 (Adamson University and de La Salle University)Micahmae Morbs100% (1)

- Tray Distillation Column With RefluxDocumento26 pagineTray Distillation Column With RefluxMelvin MoorNessuna valutazione finora

- Exp. 8 Diffusion of Sodium Chloride in WaterDocumento6 pagineExp. 8 Diffusion of Sodium Chloride in WaterElaine Pui100% (1)

- Sample Problems On Gas AbsorptionDocumento2 pagineSample Problems On Gas AbsorptionKevin Laganao67% (3)

- Practice Problems in Absorption and HumidificationDocumento4 paginePractice Problems in Absorption and HumidificationJenna BraszNessuna valutazione finora

- Climbing Film EvaporatorDocumento8 pagineClimbing Film EvaporatorPelin Yazgan BirgiNessuna valutazione finora

- Fluid Flow PracticalDocumento24 pagineFluid Flow PracticalRichardt Loots40% (5)

- Gaseous Diffusion CoefficientDocumento17 pagineGaseous Diffusion CoefficientAddiaAzizan93% (14)

- Fluid Mixing ExpDocumento9 pagineFluid Mixing ExpNawal DaBombNessuna valutazione finora

- APT300S Tutorial - RefrigerationDocumento2 pagineAPT300S Tutorial - Refrigerationcarleston thurgood0% (1)

- CONTINUOUS DistillationDocumento5 pagineCONTINUOUS DistillationNaseer SattarNessuna valutazione finora

- Gas Diffusion UnitDocumento20 pagineGas Diffusion Unitsolehah misniNessuna valutazione finora

- Gas AbsorptionDocumento19 pagineGas AbsorptionAnonymous NyvKBW100% (3)

- Al Duri Tutorial1 AbsorptionDocumento2 pagineAl Duri Tutorial1 AbsorptionJia YiNessuna valutazione finora

- Experiment 8: Fixed and Fluidized BedDocumento6 pagineExperiment 8: Fixed and Fluidized BedTuğbaNessuna valutazione finora

- Single Effect Evaporator 2Documento22 pagineSingle Effect Evaporator 2Shailesh Lohare100% (1)

- Experiment 4: Gas Diffusion Coefficient: KeywordsDocumento9 pagineExperiment 4: Gas Diffusion Coefficient: KeywordsMuhd Mukhrizan100% (3)

- Lab Report 1 Tray DrierDocumento7 pagineLab Report 1 Tray Drier_never_mind_100% (1)

- Absorption in Packed Bed Lab ManualDocumento5 pagineAbsorption in Packed Bed Lab ManualAshish Verma100% (1)

- Modeling in Transport Phenomena: A Conceptual ApproachDa EverandModeling in Transport Phenomena: A Conceptual ApproachValutazione: 3 su 5 stelle3/5 (2)

- Chemical Engineering in Practise 3: Fluidised BedsDocumento12 pagineChemical Engineering in Practise 3: Fluidised BedsYaz SwedanNessuna valutazione finora

- Flow Through Packed Beds: Group 11 Yuan Jia, Yan Li, David Hlavka April 29, 2009Documento23 pagineFlow Through Packed Beds: Group 11 Yuan Jia, Yan Li, David Hlavka April 29, 2009briankuletNessuna valutazione finora

- Ergun Equation ValidationDocumento18 pagineErgun Equation ValidationAtikur Rahman100% (1)

- Lab 2Documento12 pagineLab 2Carlos DiazNessuna valutazione finora

- Gas Flow and Pressure Drop Through Moving BedsDocumento7 pagineGas Flow and Pressure Drop Through Moving BedsGiovanny MateusNessuna valutazione finora

- Disscussion - Conclusion SoilDocumento3 pagineDisscussion - Conclusion SoilSyed Zulfaizzuan AljufriNessuna valutazione finora

- Lab Report 1Documento26 pagineLab Report 1ParvinNessuna valutazione finora

- Experimental Thermal and Fluid Science: Szu Hsien Liu, Rong Fung Huang, Chuang An LinDocumento11 pagineExperimental Thermal and Fluid Science: Szu Hsien Liu, Rong Fung Huang, Chuang An LinAli HusseiniNessuna valutazione finora

- Ds Vortex SwirlDocumento37 pagineDs Vortex Swirlabhishek dubeyNessuna valutazione finora

- Pipeline GRWM Design-400.Documento134 paginePipeline GRWM Design-400.aberraNessuna valutazione finora

- Seawater Intake Optimization Study - MWWD2016Documento6 pagineSeawater Intake Optimization Study - MWWD2016MVNessuna valutazione finora

- HeatDocumento12 pagineHeatmohamedNessuna valutazione finora

- Aset WTP HarapanDocumento7 pagineAset WTP HarapanReinhard SimbolonNessuna valutazione finora

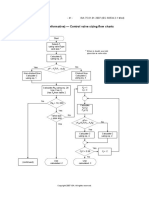

- Annex B (Informative) - Control Valve Sizing Flow Charts: - 41 - ISA-75.01.01-2007 (IEC 60534-2-1 Mod)Documento3 pagineAnnex B (Informative) - Control Valve Sizing Flow Charts: - 41 - ISA-75.01.01-2007 (IEC 60534-2-1 Mod)Abhishek Kumar SinhaNessuna valutazione finora

- Un Peu D'histoire en Mécanique Des Fluides, LPA S5 2009-2010, Daniel HuilierDocumento6 pagineUn Peu D'histoire en Mécanique Des Fluides, LPA S5 2009-2010, Daniel HuilierAbdelghafour SaidiNessuna valutazione finora

- Applied Fluid Mechanics: Viscosity of FluidsDocumento22 pagineApplied Fluid Mechanics: Viscosity of FluidsMaggie HepditchNessuna valutazione finora

- CE 137 - C - Final Exam Answers PDFDocumento9 pagineCE 137 - C - Final Exam Answers PDFMarsolito PuaNessuna valutazione finora

- Computational Fluid Dynamics Course Information: by Dr. A. Nurye Faculty of Mechanical Engineering Nurye@ump - Edu.myDocumento8 pagineComputational Fluid Dynamics Course Information: by Dr. A. Nurye Faculty of Mechanical Engineering Nurye@ump - Edu.myeldrainyNessuna valutazione finora

- Fluid Mechanics Project Search and ExperDocumento26 pagineFluid Mechanics Project Search and ExperMithileshNessuna valutazione finora

- Aerodynamics and Stability Glossary PDFDocumento14 pagineAerodynamics and Stability Glossary PDFChegrani AhmedNessuna valutazione finora

- Design and Build Dinghy Manual 2020Documento78 pagineDesign and Build Dinghy Manual 2020Joao Calinho100% (2)

- Plantwide Control of Industrial ProcesseDocumento14 paginePlantwide Control of Industrial ProcesseJose murciaNessuna valutazione finora

- Fuel Processing Technology: Roman Weber, Marco Mancini, Natalia Schaffel-Mancini, Tomasz KupkaDocumento16 pagineFuel Processing Technology: Roman Weber, Marco Mancini, Natalia Schaffel-Mancini, Tomasz KupkaJubert Angelo Ramos ParedesNessuna valutazione finora

- Pipe Flow ExpertDocumento4 paginePipe Flow Expertdchz_62Nessuna valutazione finora

- Master Thesis Final Espen Kleppa-1Documento143 pagineMaster Thesis Final Espen Kleppa-1Patrick SilvaNessuna valutazione finora

- CH 12Documento120 pagineCH 12PhimjunkieNessuna valutazione finora

- Pipe IDocumento40 paginePipe IMegelJoshuaRamiterre100% (1)

- WEEK 7 Introduction To Mechanical EngineeringDocumento42 pagineWEEK 7 Introduction To Mechanical EngineeringRahim AssaniNessuna valutazione finora

- Drag Force in Flow Over A BodyDocumento11 pagineDrag Force in Flow Over A Bodyamin67% (3)

- Twisted Tube PDFDocumento9 pagineTwisted Tube PDFsaverrNessuna valutazione finora

- Aircraft StabilityDocumento21 pagineAircraft StabilityPrasad Chamarajanagar100% (1)

- Hydro Mechanicaltransmissions Tmms10Documento10 pagineHydro Mechanicaltransmissions Tmms10Arun Raj KhannaNessuna valutazione finora

- CHE Designing Spiral Heat Exchanger - May 1970Documento10 pagineCHE Designing Spiral Heat Exchanger - May 1970John Urdaneta100% (2)

- Thesis - Rumiantcev RomanDocumento45 pagineThesis - Rumiantcev RomanPaul McNessuna valutazione finora

- Wind Load Predicting - How Could CFD Replaced Wind Tunnel TestDocumento15 pagineWind Load Predicting - How Could CFD Replaced Wind Tunnel TestadiNessuna valutazione finora

- Lab 3 Impact of Jets Virtual Lab F2020 v2Documento5 pagineLab 3 Impact of Jets Virtual Lab F2020 v2mabdoljavadiNessuna valutazione finora

- LOAD & MEMBER CALCULATION FOR PARKING AREA OnsiteDocumento7 pagineLOAD & MEMBER CALCULATION FOR PARKING AREA OnsiteCalvin SitorusNessuna valutazione finora