Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Design Management Process

Caricato da

Joshua OsezuaDescrizione originale:

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Design Management Process

Caricato da

Joshua OsezuaCopyright:

Formati disponibili

Engineering Procedure Design

EPD 0001 DESIGN MANAGEMENT PROCESS

Version 2.0 Issued May 2009

Owner: Approved by:

Manager Engineering Services Mike Hogan Manager Engineering Services Authorised by: Jim Modrouvanos General Manager Engineering Standards & Services

Disclaimer This document was prepared for use on the RailCorp Network only. RailCorp makes no warranties, express or implied, that compliance with the contents of this document shall be sufficient to ensure safe systems or work or operation. It is the document users sole responsibility to ensure that the copy of the document it is viewing is the current version of the document as in use by RailCorp. RailCorp accepts no liability whatsoever in relation to the use of this document by any party, and RailCorp excludes any liability which arises in any manner by the use of this document. Copyright The information in this document is protected by Copyright and no part of this document may be reproduced, altered, stored or transmitted by any person without the prior consent of RailCorp.

UNCONTROLLED WHEN PRINTED

Page 1 of 20

Engineering Procedure

Engineering Procedure Design Design management process EPD 0001

Document control

Pages All All All All All Revision 1.0 1.1 1.2 1.3 2.0 Reason for and nature of change First issue Section numbering updated, reference corrections and document control page added. Replace reference from RIC to RailCorp reference made to RailCorp Safety Management System Standardising format. Changes as listed below.

Summary of changes from previous version

The review of the previous published version involved circulation of drafts A, B and C. Draft A was provided to the document owner, Manager Engineering Services and his comments incorporated. Draft B was then circulated to stakeholders via email with comments being received from Mike Hogan, Warwick Allison, Richard Hitch, John McErlane, Jeff Byron and Jeff Stead. Draft C was then circulated through CMWeb with comments being received from John Stapleton and Jeff Byron. Change Formatting changed. Removal of document control from document numbering resulting in Introduction now being section 1 and all other sections 1 less than previous version, i.e. 2 becomes 1, 3 becomes 2 etc. NOTE all below section references relate to the new section number. Moved process owner information to front page and applied new format to document control page. Removed Distribution and change section. Reference to Rail Safety Act 2002 updated to 2008 Removal of the requirements for application of this procedure to rolling stock design by removing references to rolling stock in the body of this document as per condition imposed by Engineering CCB Move previous paragraph 2 section 2.2.1 to paragraph 2 section 2.1 Replaced sets out general policy and requirements for the engineering design management system to be adopted within RailCorp in paragraph 1 with supports the RailCorp System Procedure SMS-12-PR-0371 Managing Engineering Design Control. Replaced manual with suite of Engineering Design Management Procedures in paragraph 2. Removed section 2.2.1 except for moving paragraph 2 to 2.1 as above. Updated and reordered referenced documents. Inserted SMS-12-PR-0371. Subsequent updating of referenced documents throughout document where required. Removed list of definitions with specific importance as they are included in the Glossary. Minor rewording in paragraph 1 and reformatting of following paragraphs. Reinstated Federal and state legislation and regulations shall have precedence. Refer to EPD 0004 P. Section Ref. Whole document. Whole document

Document control Various Various 2.1 2.2

2.2 2.2.1 3 & whole document 4 5.2 5.2 para 3

Rail Corporation Issued May 2009 UNCONTROLLED WHEN PRINTED

Page 2 of 20 Version 2.0

Engineering Procedure Design Design management process EPD 0001

Removal of acting under delegation from the General Manager of the division responsible for engineering standards and authority (the engineering division). Customer specification, design approval and design acceptance were redefined Design Brief added to section heading Replaced will be an internal division/section within RailCorp with will be a RailCorp division/section. Replaced responsible discipline head and/or the engineer or design delivery manager with design delivery manager. Replaced OH&S Act with Occupational Health and Safety Act 2000. Replaced agreeing these with the customer with ensuring customer agreement Insertion of new paragraph. Removal of This will normally include documents that define the for construction standard as well as as-built documents that describe the design of the equipment actually fielded. Design records that provide traceability of design decisions shall be maintained for all design tasks. Removal of For major projects, or on other occasions determined by the manager of the responsible design unit, the final verification shall be through completion of a Physical Configuration Audit (PCA), as defined in Procedure EPD 0014. Heading changed to Design output approval / acceptance and the acceptance role described Heading changed to configuration record Paragraph one phrase essential for determining supportability replaced with essential for confirming Alignment of responsibilities with SMS-12-PR-0371 Updating definitions to align with updated referenced documents, insertion of definitions for design acceptance, rotable item, consumable, repair part, update of definitions of railway infrastructure and rolling stock to align with Rail Safety Act 2008

5.2 para 8 5.2 5.3.1 5.3.1 para 1 5.3.1 para 2 5.3.2 para 1 5.3.2 para 2 5.3.4 para 3 5.3.4 para 4

5.3.4 penultimate paragraph 5.3.5 5.3.7 6.1, 6.3 Glossary

Rail Corporation Issued May 2009 UNCONTROLLED WHEN PRINTED

Page 3 of 20 Version 2.0

Engineering Procedure Design Design management process EPD 0001

Contents

1 Introduction..........................................................................................................................................5 2 Scope and application .........................................................................................................................5 2.1 Design management documentation system...............................................................5 2.2 Application....................................................................................................................6 3 Referenced documents .......................................................................................................................6 4 Definitions and terms...........................................................................................................................6 5 Requirements ......................................................................................................................................7 5.1 Scope of design work ...................................................................................................7 5.2 Key requirements .........................................................................................................7 5.3 Design process model..................................................................................................8 5.3.1 Customer specification requirements ...........................................................9 5.3.2 Design inputs ..............................................................................................10 5.3.3 Design stages (new and altered assets).....................................................10 5.3.4 Design verification.......................................................................................10 5.3.5 Design output approval and acceptance ....................................................11 5.3.6 Design validation.........................................................................................11 5.3.7 Configuration management ........................................................................12 5.4 Related design tasks ..................................................................................................12 5.4.1 Hazard and risk analysis.............................................................................12 5.4.2 Integrated support provisions .....................................................................12 6 Responsibilities .................................................................................................................................13 6.1 General Manager Engineering Standards & Services ...............................................13 6.2 Manager Engineering Services ..................................................................................13 6.3 Discipline heads .........................................................................................................13 6.4 Design staff ................................................................................................................14 APPENDIX Glossary..........................................................................................................................15

Rail Corporation Issued May 2009 UNCONTROLLED WHEN PRINTED

Page 4 of 20 Version 2.0

Engineering Procedure Design Design management process EPD 0001

Introduction

RailCorp has a primary responsibility as an owner and operator under the New South Wales Rail Safety Act 2008 (Rail Safety Act) for the safe construction, operation and maintenance of railway infrastructure. RailCorp also has a range of additional obligations under the New South Wales Occupational Health and Safety Regulation 2001 (OH&S Regulation). Design management processes implemented by RailCorp represent a key component of the systems necessary for RailCorp to maintain the safety and integrity of railway infrastructure to: comply with the set of statutory obligations placed on RailCorp maintain the accreditation as a rail transport operator within the terms of the Rail Safety Act maintain RailCorp accreditation to AS/NZS ISO 9001 and other standards

2

2.1

Scope and application

Design management documentation system

This system comprises of a set of Engineering Design Procedures that establish the framework to be adopted for all engineering design tasks. These procedures reflect high level policies, processes and requirements for the management of design and integrated support tasks within a systems engineering context, and are intended to provide a stable basis for RailCorp business processes. The procedures incorporate key statutory and management requirements as shown in Figure 1. Specific requirements are included in individual procedures.

Australian and international standards

RailCorp Management Policies

Federal and state legislation and regulations

ENGINEERING DESIGN PROCEDURES

RailCorp design standards, instructions and manuals (each discipline)

RailCorp design data and configuration records

RailCorp support data

Figure 1 - Design management documentation structure

Rail Corporation Issued May 2009 UNCONTROLLED WHEN PRINTED

Page 5 of 20 Version 2.0

Engineering Procedure Design Design management process EPD 0001

2.2

Application

This procedure supports the RailCorp Safety Management System Requirements SMS09-SR-0151 - Configuration Management, SMS-12-SR-0128 - Engineering and Operating Standards and Procedure SMS-12-PR-0371 - Managing Engineering Design Control. The requirements of this procedure and of other procedures within the suite of Engineering Design Procedures shall apply to all engineering design work performed by or for RailCorp as defined in Paragraph 5.1.

Referenced documents

New South Wales Rail Safety Act 2008 New South Wales Occupational Health and Safety Act 2000 New South Wales Occupational Health and Safety Regulation 2001(OH&S Regulation) AS/NZS 3931:1998 - Risk analysis of technological systems - Application guide AS 4292 - 2006: Railway safety management AS/NZS 4804:2001 - Occupational health and safety management systems - General guidelines on principles, systems and supporting techniques AS/NZS ISO 9001:2000: Quality management systems - Requirements AS ISO 10007-2003: Quality management systems - Guidelines for configuration management AS/NZS 15288:2003 (ISO/IEC 15288-2002) Systems engineering - System life cycle processes HB 90.3 - 2000: The Construction Industry - Guide to ISO 9001:2000 SMS-09-SR-0151 - Configuration Management SMS-12-SR-0128 - Engineering and Operating Standards RailCorp SMS-12-PR-0371 - Managing Engineering Design Control Note: Engineering Design Procedures are referred to herein adopting the new numbering system as per TMA 400 - Engineering Publications Manual. The document number changes will be effected from the time revisions to procedures numbered in the ED XXXX P format are published. In the interim some Engineering Design Procedures referred herein by the new number format EPD XXXX may still be in the ED XXXX P format.

Definitions and terms

A glossary of terms and definitions used within RailCorp Engineering Design Procedures is contained in the Appendix to this procedure. The Appendix also includes a list of acronyms and abbreviations used within the procedures.

Rail Corporation Issued May 2009 UNCONTROLLED WHEN PRINTED

Page 6 of 20 Version 2.0

Engineering Procedure Design Design management process EPD 0001

5

5.1

Requirements

Scope of design work

Design work performed by RailCorp is not confined to major projects. It includes all tasks that may alter the physical configuration, functional performance or the conditions of use of any item of railway infrastructure including associated hardware and software elements. Design tasks include, but are not limited to: Development of new designs. Modification or alteration of existing designs. Development of repair methods for any item, particularly where the repair would alter strength, durability or functional performance or limitations. Identification, development and type testing/approval of new standard designs and equipment for use in specified applications including standard repairs. Review and approval of changes in the conditions of use for any item including definition of restrictions or additional inspection requirements where the proposed usage would result in the item being used outside of its original design basis. These include changes to usage parameters such as speed, loading, operating and environmental conditions. Local development and/or modification of tools, test equipment, workshop aids or other plant and equipment. Review and approval of substitute or replacement spares for any hardware item.

5.2

Key requirements

Certain key requirements shall apply for all design work performed within RailCorp. Specific requirements are further described in Section 5.3 of this procedure and are defined in detail in individual Engineering Design Procedures. The key requirements are: engineering authority all design tasks shall be undertaken by competent persons who have been allocated Engineering Authority to undertake those tasks. Refer to EM 0241. customer specification / design brief design work shall not commence without an agreed brief or a customer specification. Refer to EPD 0004. design standards all design work shall be performed to the relevant federal and state legislation and regulations and to standards approved by RailCorp. Federal and state legislation and regulations shall have precedence. Refer to EPD 0004. documentation all design outputs shall be fully and properly documented. Refer to EPD 0017. verification design stage output shall be verified to ensure consistency with design stage inputs. Refer to EPD 0011. validation design output shall be validated to ensure that customer requirements have been met. Refer to EPD 0012. risks and hazards an evaluation of risks and hazards is to be performed and documented as part of every design task. Refer to EPD 0008.

Rail Corporation Issued May 2009 UNCONTROLLED WHEN PRINTED

Page 7 of 20 Version 2.0

Engineering Procedure Design Design management process EPD 0001

integrated support requirements (i.e. maintenance plans and specifications) shall be considered both as part of the detail design effort and prior to release of new or altered assets to the field. Refer to EPD 0018. design approval all design output shall be approved by an authorised person prior to release for construction. Refer to EPD 0010. design acceptance all design output shall be accepted by the relevant discipline head for use by RailCorp prior to release for construction. Refer to EP 0280. design and configuration records design and supporting documentation that fully describe the as-built configuration of railway infrastructure shall be maintained. Refer to EPD 0014.

5.3

Design process model

RailCorp has adopted the systems engineering methodology as the basis for management of the design process. AS/NZS 15288:2003 provides additional information related to the systems engineering process. This model, which is consistent with the process of design described in AS/NZS ISO 9001:2000 and explained in more detail in HB 90.3 - 2000, establishes a systematic methodology for ensuring that customer requirements are fully identified during the concept stage and achieved within the final design. Application of the RailCorp model will also meet the requirements of the OH&S Regulation in respect of plant design, as well as the requirements of the New South Wales Rail Safety Act 2008 and associated AS 4292 Series of Standards. The top-level model adopted by RailCorp is shown in Figure 2. The paragraphs following Figure 2 provide a brief description of each element of the model.

Rail Corporation Issued May 2009 UNCONTROLLED WHEN PRINTED

Page 8 of 20 Version 2.0

Engineering Procedure Design Design management process EPD 0001

CUSTOMER/CLIENT OR USER SPECIFICATION

TRACEABILITY

TRACEABILITY

Legislation & Regulations

PROPOSED CHANGES TO CONFIGURATION

Verification of Stage Output

CONSTRUCTION CHANGES

DESIGN OUTPUT & APPROVAL

For-Construction Baseline

CONSTRUCTION

As-Built Baseline

USE & MAINTAIN

RailCorp CONFIGURATION MANAGEMENT RECORDS

Figure 2 - RailCorp design process model

5.3.1

Customer specification requirements

Every RailCorp design task will have a designated customer (client). Generally this will be a RailCorp division/section head. The customer for tasks initiated within the Engineering Division will be the section or discipline head initiating the requirement. The design delivery manager assigned to the task shall ensure that the customers requirements are specified in sufficient detail to establish clear output requirements for the task. Where the customer has not provided a specification, the engineer or design delivery manager responsible for the task shall develop a design brief for approval by the relevant discipline heads and acceptance by the client prior to commencing the task. No design shall commence without a customer specification or an approved design brief. EPD 0004 provides further guidance on preparing briefs, however, as a minimum the design brief must include: performance requirements for the item to which the task applies intended use, including maximum loads or operating condition, duty cycle, operating environment and required design life levels of maintenance, maintenance locations, maintenance windows and systems, maintenance staff skills, self testing and diagnosis and test equipment, spare / rotable warehouse locations interfaces with existing equipment

Rail Corporation Issued May 2009 UNCONTROLLED WHEN PRINTED

Page 9 of 20 Version 2.0

VALIDATION

DESIGN STAGES (New or Altered Designs)

Design & Configuration Documents

VERIFICATION

DESIGN INPUTS

Interfaces RailCorp Standards

Engineering Procedure Design Design management process EPD 0001

reliability, availability, requirements (RAMS)

maintainability

and

supportability

specifications

and

any other special requirements including alternative design standards (where these differ from RailCorp standards) or other regulatory requirements

5.3.2

Design inputs

The customer specification or agreed design brief forms the major design input. However, RailCorp design tasks are also governed by statutory requirements, particularly those relating to the design of plant within the Occupational Health and Safety Act 2000, OH&S Regulation 2001 and environmental legislation. These statutory requirements must be taken into account in establishing design inputs irrespective of whether they are specified by the customer. Determining the full set of design inputs, and ensuring customer agreement, represents an essential step for management of the design process. The set of design inputs also forms the basis for verification/validation of design output, i.e. for determining whether the final design has met the customers requirements.

5.3.3

Design stages (new and altered assets)

The stages of the design development normally are concept design, preliminary design and detailed design respectively. These three design stages are applicable to most RailCorp design tasks whether they are undertaken as part of a major project (the most complex case) or for alteration of an in-service asset. Each stage may include a number of identifiable sub-stages, particularly in major projects where the development of individual sub-systems and configuration items may proceed as separately identified work packages. In other cases, such as processing of a minor configuration change request (CCR), the stages may be combined. Detailed requirements for completion of the actual design work within each design stage are covered by RailCorp design standards, instructions and manuals applicable to each discipline. EPD 0006 and EPD 0013 provide additional details. All design work shall be executed in accordance with the agreed customer specification or design brief. Design tasks shall only proceed after detailed analysis of specification and design brief requirements. Where necessary this shall be documented in the form of a traceability record that permits traceability from the specification/design brief to the verification and validation records for the final design. EPD 0005 establishes specific requirements for requirement analysis and traceability.

5.3.4

Design verification

Verification of design output shall be accomplished through review and approval of the documentation by person(s) who has/have been granted Engineering Authority for that purpose. Verification may take place either at the completion of each design stage for major projects or at the completion of the design task for minor projects. Design verification is to ensure that the design output for each design stage is consistent with the design input for that stage. Verification is a mandatory activity and a pre-requisite for design approval. Verification of the final design is required to ensure that:

Rail Corporation Issued May 2009 UNCONTROLLED WHEN PRINTED

Page 10 of 20 Version 2.0

Engineering Procedure Design Design management process EPD 0001

the design output conforms to specified requirements the design has been completed in accordance with the appropriate procedures and standards the design has taken in to account all applicable aspects listed in the CCR, design checklists or the proceedings of a technical review, including test results where appropriate supporting calculations and decisions for defined critical systems have been independently checked and verified the requisite approvals have been obtained from regulatory authorities, and the design has been properly documented. More detailed requirements for design verification are provided in EPD 0011.

5.3.5

Design output approval and acceptance

Design output may include technical specifications, drawings, plans, test data and results, which in combination fully describe the final design. Outputs include configuration documents and design records as further explained in EPD 0014. All design outputs developed by RailCorp shall be approved by a suitably qualified and authorised person prior to release for construction or manufacture. Externally developed designs shall be approved by an authorised representative of the design company before being submitted to RailCorp. Refer to EPD 0010. All approved designs shall be accepted by the relevant discipline heads for use by RailCorp prior to release for construction or manufacture as required in EP 0280.

5.3.6

Design validation

Design validation is the process of ensuring that the final product conforms to defined user (customer) needs and/or requirements. The validation process may be accomplished through a variety of methods as defined in EPD 0012. A common method of validation is type testing which is designed to demonstrate the ability of the final design to meet the range of operating conditions included in the specification or design brief. General validation requirements and methods shall be determined and approved by the discipline head or by his delegated representative for all new design tasks before commencement of the task, and progressively defined and refined as the task proceeds. Validation results shall form part of the design record for the item or system concerned and shall be filed as part of the design data for the item. More detailed requirements for design validation are provided in EPD 0012.

Rail Corporation Issued May 2009 UNCONTROLLED WHEN PRINTED

Page 11 of 20 Version 2.0

Engineering Procedure Design Design management process EPD 0001

5.3.7

Configuration management

As-built configuration documents shall be created and maintained for all design work in an approved RailCorp repository. This provides the basis for all subsequent changes and is essential for confirming supportability requirements such as operating instructions and manuals as well as maintenance requirements, spares and training needs. More detailed requirements for configuration management and record keeping are in EPD 0014 and EPD 0017.

5.4

5.4.1

Related design tasks

Hazard and risk analysis

RailCorp has a statutory obligation under the OH&S Regulation to ensure that hazards are identified and that risks are either eliminated or controlled within the workplace and to comply with environmental legislation. This obligation extends to the design of plant and equipment for use within RailCorp or completed for a third party as well as to the specification and acquisition of standard equipment from commercial suppliers. In addition, Railcorp must demonstrate the capability and capacity to safely construct, operate and maintain railway infrastructure under the provisions of the Rail Safety Act. Hazard and risk analysis shall be completed as an integral part of all design work, to ensure compliance with relevant legislative requirements. The results of this analysis shall be documented and maintained as part of the design record. EPD 0008 provides the principles and requirements for hazard and risk analysis including the requirement for documenting the results within the corporate SMS framework.

5.4.2

Integrated support provisions

Reliability, availability, maintainability and supportability (RAMS) are essential considerations in all RailCorp design work. Assets including plant and equipment designed by RailCorp must be able to satisfy these requirements safely and efficiently, using RailCorp staff or a third party as appropriate. Integrated support requirements shall be considered as part of each and every design task, including design changes made as a result of CCR action. Integrated support requirements to be considered as part of each task shall include the following aspects, in accordance with s.96(2) of the OH&S Regulation 2001: documentation and manuals including the purpose for which the plant is designed, installation, commissioning, operation, maintenance, inspection, cleaning, transport, storage and, if the plant is capable of being dismantled, dismantling of the plant maintenance requirements, including testing or inspections to be carried out on the plant systems of work necessary for the safe use of the plant knowledge, training or skill necessary for persons operating or undertaking inspection and testing of the plant

Rail Corporation Issued May 2009 UNCONTROLLED WHEN PRINTED

Page 12 of 20 Version 2.0

Engineering Procedure Design Design management process EPD 0001

spares support requirements emergency procedures Consideration of integrated support aspects as part of a design task includes: incorporation of specific provisions within the design to achieve the specified RAMS including ease of access, inspection provisions, emergency operation and safety aspects such as isolation and guarding ensuring that the necessary documentation and support provisions are properly assessed and introduced before the newly designed equipment enters service Specific requirements for the inclusion of integrated support provisions in all design tasks are included in EPD 0008 and EPD 0018.

6

6.1

Responsibilities

General Manager Engineering Standards & Services

The GM ES&S is responsible for the overall implementation of the engineering design management system and for improvement of the system to meet RailCorp Asset Management Group obligations. The GM ES&S must: have competent personnel to undertake design ensure that engineering design procedures align with the business needs and are reviewed at regular intervals.

6.2

Manager Engineering Services

The Manager Engineering Services is responsible for: maintaining and improving Engineering Design Procedures and their review at regular intervals. implementing Engineering Design Procedures within RailCorps Asset Management Group.

6.3

Discipline heads

Discipline heads shall be responsible for ensuring that policies and processes defined within Engineering Design Procedures are incorporated into disciplinespecific design procedures within their areas of responsibility. Discipline heads must: ensure that design procedures and standards reflect legislative requirements, Codes of Practice, Australian Standards and OHS Model for Self Insurers approve design procedures and standards within their area of responsibility and allocate Engineering Authority to design staff ensure that design stage outputs have been verified prior to accepting designs for use by RailCorp.

Rail Corporation Issued May 2009 UNCONTROLLED WHEN PRINTED

Page 13 of 20 Version 2.0

Engineering Procedure Design Design management process EPD 0001

6.4

Design staff

All RailCorp staff performing or managing engineering design work including integrated support analyses in support of design are responsible for completing their tasks in accordance with the related discipline-specific design procedures. All persons holding Engineering Authority to carry out or approve design tasks within RailCorp are responsible for managing, completing or approving design tasks (as applicable) in accordance with the related discipline-specific Engineering Design Procedures

Rail Corporation Issued May 2009 UNCONTROLLED WHEN PRINTED

Page 14 of 20 Version 2.0

Engineering Procedure Design Design management process EPD 0001

APPENDIX Glossary

administrative controls are controls, which use systems of work to eliminate or reduce risks to health or safety and do not involve engineering controls or the use of personal protective equipment. approved configuration of any system, sub-system or item of railway infrastructure is the approved design plus all approved changes to the design. availability is the measure of the percentage of time that an item or system is available to perform its designated function. Refer to EPD 0009 for mathematical formulae for calculation of availability. configuration is defined in AS ISO 10007-2003 as interrelated functional and physical characteristics of a product defined in product configuration information (see definition below). configuration baseline is defined in AS ISO 10007-2003 as approved product configuration information that establishes the characteristics of a product at a point in time that serves as reference for activities throughout the life cycle of the product. Note that during the in service phase the approved configuration represents a configuration baseline. configuration change results from any action that alters the approved design basis for the infrastructure. configuration documents include specifications, drawings, plans, equipment lists and datasheets, electronic and electrical logic diagrams, software documents and code lists, approved CCRs and modification records and any other documents required to fully define the capabilities and limitations of the infrastructure design. Configuration documents may include mandatory inspection requirements and retirement lives for designs that are based on a safety-by-inspection regime. configuration item is defined in AS ISO 10007-2003 as entity within a configuration that satisfies an end use function. A configuration item is defined as an aggregation of hardware, software, processed materials, services or any of its discrete portions that is designated for configuration management and treated as a single entity in the configuration management process. configuration management (CM) is defined in AS ISO 10007-2003 as coordinated activities to direct and control configuration NOTE Configuration management generally concentrates on technical and organisational activities that establish and maintain control of a product and its product configuration information throughout the life cycle of the product. AS ISO 10007-2003 sets out general principles for CM. Key elements of the process are: documenting the approved design of plant and equipment (plant configuration) managing and controlling changes to this configuration, including documentation of each change verifying that the physical installation remains consistent with design documentation consumable items comprise materials and standard hardware items that are used in support of maintenance, servicing or repair tasks. Typically this includes oils, grease and lubricants, but may also include standard hardware such as nuts, bolts, washers, screws and minor electrical parts.

Rail Corporation Issued May 2009 UNCONTROLLED WHEN PRINTED

Page 15 of 20 Version 2.0

Engineering Procedure Design Design management process EPD 0001

customer (or client) within these procedures is the organisation or position requesting or initiating a design task. Every RailCorp design task will have a designated customer. Generally a customer will be a RailCorp division/section.. The customer for tasks initiated within the engineering division will be the section or discipline head initiating the requirement. design (verb) is defined as the process of defining, synthesising, selecting, and describing solutions to requirements in terms of products and processes. design (noun) is defined as the product of the process of designing that describes the solution (conceptual, preliminary or detailed) of the system, system elements or system end items. design acceptance is the process that sets down controls to ensure that engineering design undertaken by RailCorp, or by another firm on behalf of RailCorp, is done by qualified individuals using approved procedures and equipment, under appropriate supervision. design approval is the process whereby an authorised person certifies that design outputs have been verified as meeting design input specifications and requirements and that the design has been completed in accordance with relevant regulations and standards, prior to the release of the design for construction or use. design brief as used within Engineering Design Management Procedures describes a document (or documents) that describes the required product in sufficient detail to permit the design task to proceed. A design brief is functionally equivalent to a specification but is used where a formal specification has not been prepared by the customer. design (configuration) change is any change that affects the physical or functional characteristics of the infrastructure including operating limitations and conditions of use, hardware and software (including programmable electronic systems). design records provide traceability of the evolution of the approved design (including design changes) from the specification to approved configuration documentation. Design records include, but are not limited to, assumptions and calculations, investigations and reports (such as hazard analyses or reliability models), test and commissioning records, modelling results and any other data that supports the final design solution. developed item is used to refer to an item or product (hardware or software) that will be purchased from a supplier either in the standard form offered by the supplier in the open market or with minor alterations to meet specific RailCorp requirements. In this context minor alterations include options offered by the supplier or other minor changes that will not affect the key functional or physical characteristics of the item. The terms off-theshelf or commercial-off-the-shelf (COTS) are alternative terms for developed items. drawings include but are not limited to, track, signalling and overhead wiring plans and layouts, piping layouts and isometrics, civil and structural fabrication details, electrical schematics, single line diagrams and terminations, instrument loop and hook-up diagrams and vendor drawings. Drawings include parts lists and associated schedules. engineering approval as used within Design Management Procedures describes the process of approval of a broad range of engineering decisions and documentation including maintenance, support and related decisions. Design approval is a subset of engineering approval. engineering authority is the authority to make and approve engineering decisions. The scope of Engineering Authority may extend to the preparation and approval of

Rail Corporation Issued May 2009 UNCONTROLLED WHEN PRINTED

Page 16 of 20 Version 2.0

Engineering Procedure Design Design management process EPD 0001

specifications, detail design proposals, construction and maintenance processes and standards, as well as products and systems used within the engineering support task. engineering controls use engineering measures to change the physical characteristics of plant to eliminate or reduce risk. environmental design criteria describe the range of operating conditions related to either the natural or built environment under which the item or system is designed to operate. hazard is defined in the OH&S Regulation as anything (including work practices or procedures) that has the potential to harm the health or safety of a person. AS/NZS 4804:2001 defines hazard as a source or situation with a potential for harm in terms of human injury or ill-health, damage to property, damage to the environment, or a combination of these. hazard identification is defined in AS/NZS 3931:1998 as process of recognising that a hazard exists and defining its characteristics. hazardous event is defined in AS/NZS 3931:1998 as event which can cause harm. interfaces are common boundaries or points of connection between two or more items or systems. These may include mechanical connections, electrical/electronic connections, software to software/hardware interfaces, data transfer requirements, procedural requirements or input conditions and constraints that exist between one system and another or between items within the same system. interface specification describes the essential functional, performance and design requirements and constraints at a common boundary between two or more system elements. This includes interfaces between humans and hardware or software, as well as interfaces between humans themselves. job safety analysis (JSA) is a systematic method for identifying hazards and adopting strategies to control risk associated with a given task. maintainability is a characteristic of design and is essentially a measure of the ease with which the item can be maintained. A more formal definition is maintainability is a characteristic of design and installation, expressed as the probability that an item will be restored to operating condition, within a given period of time, using prescribed procedures and resources. The most commonly used measure of maintainability is the mean time to repair (MTTR). maintenance data comprises scheduled maintenance and major periodic maintenance (MPM) requirements, operating and repair procedures, maintenance instructions, procedures and manuals as well as maintenance documentation and compliance records. Except for mandatory safety-by-inspection requirements and retirement lives, maintenance data does not form part of the configuration documentation but must accurately reflect the approved design, must be approved through a process similar to design approval, and must be maintained for compliance purposes. process control plan is instructions for performing a specific job or task so as to prevent harm to individuals, plant and the environment through control of identified hazards. product configuration information is defined in AS ISO 10007-2003 as requirements for product design, realisation, verification, operation and support. plant includes any machinery, equipment (including scaffolding), appliance, implement or tool and any component or fitting thereof or accessory thereto.

Rail Corporation Issued May 2009 UNCONTROLLED WHEN PRINTED

Page 17 of 20 Version 2.0

Engineering Procedure Design Design management process EPD 0001

railway infrastructure is defined in the Rail Safety Act 2008 as the facilities that are necessary to enable a railway to operate safely (other than rolling stock and any facility, or facility of a class, that is prescribed by the regulations not to be rail infrastructure) and includes, but is not limited to, the following: a) railway tracks and associated track structures, b) service roads, signalling systems, communications systems, rolling stock control systems and data management systems, c) notices and signs, d) electrical power supply and electric traction systems, e) associated buildings, workshops, depots and yards, f) plant, machinery and equipment.

reliability is a characteristic of design. It is defined as the probability that a specified item will perform a specified function within a defined environment, for a specified length of time. For complex systems the reliability requirement is normally specified in terms of the mean time between failures (MTBF) or as a failure rate, for example failures per million operating hours. repair parts are spares that are used to repair or overhaul equipment, either in the field or in the workshop, in the case of a breakdown. Repair parts are typically unique to the item that they support, but may include common, non-rotable items that are widely used within the infrastructure. risk is defined in AS/NZS 3931:1998 as combination of the frequency, or probability, of occurrence and the consequence of a specified hazardous event. NOTE - The concept of risk always has two elements; the frequency of probability with which a hazardous event occurs and the consequences of the hazardous event. risk analysis is defined in AS/NZS 3931:1998 as systematic use of available information to identify hazards and to estimate the risk to individuals or populations, property or the environment. NOTE - Risk analysis is also sometimes referred to as probabilistic safety analysis, probabilistic risk analysis, quantitative safety analysis and quantitative risk analysis. risk control is defined in AS/NZS 3931:1998 as process of decision-making for managing and/or reducing risk; its implementation, enforcement and re-evaluation from time to time, using the results of risk assessment as one input. rolling stock is defined in the Rail Safety Act 2008 as a vehicle that operates on or uses a railway and includes a locomotive, carriage, rail car, rail motor, light rail vehicle, train, tram, light inspection vehicle, self-propelled infrastructure maintenance vehicle, trolley, wagon or monorail vehicle, but does not include a vehicle designed to operate both on and off a railway when the vehicle is not operating on a railway. rotable item is one that is capable of being repaired or overhauled in a workshop environment, to return the item to a condition that is equivalent to new. specification is a document that fully describes a design element or its interfaces in terms of requirements (functional, performance, constraints, and design characteristics) and the qualification (validation) conditions and procedures for each requirement

Rail Corporation Issued May 2009 UNCONTROLLED WHEN PRINTED

Page 18 of 20 Version 2.0

Engineering Procedure Design Design management process EPD 0001

supportability is the inherent quality of a system - including design for reliability and maintainability, technical support data, and maintenance procedures - to facilitate detection, isolation, and timely repair/replacement of system anomalies. type approved product is used to refer to items or products that have previously been tested, validated and approved by RailCorp as being suitable for use in specific applications. A listing of products so validated is referred to as a Type Approved Products List. type testing is a specific form of validation carried out to demonstrate that a specific type of item (i.e. by manufacturers part or model number) is capable of meeting the full operating, performance and environmental design requirements for its intended application within the RailCorp system. validation is the process of ensuring that the final product conforms to defined user (customer) needs and/or requirements. variance (alternative terms are deviation, waiver, concession) is used to approve a departure from the approved for-construction design baseline. Variances are normally approved for a specific number of items or for a limited period. If a variance is to be permanent it must be processed as a CCR. verification is carried out to ensure that the output of a design stage (or stages) meets the design stage input requirements.

Rail Corporation Issued May 2009 UNCONTROLLED WHEN PRINTED

Page 19 of 20 Version 2.0

Engineering Procedure Design Design management process EPD 0001

Acronyms and abbreviations

Abbreviation/acronym ADR ALARP CASE CCB CCR CDR CM CMC CMP CCP COTS MoT ETA FMECA FTA ISU JSA LCC LORA MPM MRA MTBF MTTR OJT PCA PDR PES PHA PMP PPE RAMS RATM RCM RFT SCR SDR SLA SOW SVR TMP WBS Meaning activity detail register as low as reasonably practicable computer aided systems engineering configuration control board configuration change request critical design review configuration management RailCorp Configuration Management Committee. Configuration Management Plan Configuration Change Plan commercial-off-the-shelf NSW Ministry of Transport. event tree analysis failure modes, effects and criticality analysis fault tree analysis Integrated Support Unit job safety analysis life cycle cost level of repair analysis major periodic maintenance maintenance requirements analysis mean time between failures mean time to repair on-the-job training/instruction physical configuration audit preliminary design review programmable electronic system preliminary hazard analysis project management plan personal protective equipment Reliability, availability, maintainability and supportability requirements analysis, allocation and traceability matrix reliability centred maintenance request for tender system concept review . system definition review service level agreement contract statement of work system verification review technical maintenance plan work breakdown structure

Rail Corporation Issued May 2009 UNCONTROLLED WHEN PRINTED

Page 20 of 20 Version 2.0

Potrebbero piacerti anche

- L1 CHE PRO 031 Engineering Change ProcedureDocumento24 pagineL1 CHE PRO 031 Engineering Change Procedure4493464Nessuna valutazione finora

- Design Management ProcessDocumento16 pagineDesign Management ProcesssarifinNessuna valutazione finora

- 317 - Procedure - 0-Document Control and DistributionDocumento8 pagine317 - Procedure - 0-Document Control and DistributionagaricusNessuna valutazione finora

- L1-CHE-MAN-001 Engineering Management System FrameworkDocumento20 pagineL1-CHE-MAN-001 Engineering Management System FrameworkCK TangNessuna valutazione finora

- PMC-PR-001-C Drawing and Document Numbering SystemDocumento13 paginePMC-PR-001-C Drawing and Document Numbering SystemsuparnaNessuna valutazione finora

- AIPM Project Manager Professional Competency StandardsDocumento35 pagineAIPM Project Manager Professional Competency StandardsAngela VargasNessuna valutazione finora

- Testing & Commissioning Process For A Light Rail ProjectDocumento30 pagineTesting & Commissioning Process For A Light Rail ProjectФедір КовалишинNessuna valutazione finora

- Interface Management PracticesDocumento6 pagineInterface Management PracticesEdwin HarrisNessuna valutazione finora

- 240-53113685 Design Review ProcedureDocumento19 pagine240-53113685 Design Review ProcedureLegend Anbu100% (1)

- RAMS-Tender-dt 13 05 2015Documento86 pagineRAMS-Tender-dt 13 05 2015Eldho VargheseNessuna valutazione finora

- CRS Project-Management-PlanDocumento12 pagineCRS Project-Management-PlanGervie Cabang PalattaoNessuna valutazione finora

- 1H-011 RiskManagementPlanDocumento22 pagine1H-011 RiskManagementPlanAnonymous ShLi1fM3HNessuna valutazione finora

- Procedure For Design ReviewDocumento12 pagineProcedure For Design ReviewImtiyaz AkhtarNessuna valutazione finora

- EDGM-4 Project Design ProceduresDocumento41 pagineEDGM-4 Project Design ProceduresPaul CollinsNessuna valutazione finora

- MTM Design and Technical Review Procedure: ApprovalDocumento27 pagineMTM Design and Technical Review Procedure: ApprovalCK Tang100% (1)

- As Built Spatial StandardsDocumento15 pagineAs Built Spatial StandardsReza P.Nessuna valutazione finora

- Standardized Multidimensional Wbs Cbs For Hospital Construction PDFDocumento22 pagineStandardized Multidimensional Wbs Cbs For Hospital Construction PDFAndre de MontreuilNessuna valutazione finora

- Testing Commissioning Process Light Rail ProjectDocumento5 pagineTesting Commissioning Process Light Rail Projectsuraiyya begumNessuna valutazione finora

- Sample - Project Quality PlanDocumento12 pagineSample - Project Quality PlanSuraj Mani100% (1)

- L1-CHE-PRO-045 v1 - MTM Design Assurance ProcedureDocumento21 pagineL1-CHE-PRO-045 v1 - MTM Design Assurance ProcedureCK TangNessuna valutazione finora

- High-Speed Rail Projects in The United States: Identifying The Elements For Success - Part 1Documento118 pagineHigh-Speed Rail Projects in The United States: Identifying The Elements For Success - Part 1HighSpeedRail100% (3)

- Client:: Inspection & Test Plan For Excavation WorksDocumento3 pagineClient:: Inspection & Test Plan For Excavation WorksAnonymous PxHPgLNessuna valutazione finora

- EV Guidlines Network RailDocumento17 pagineEV Guidlines Network RailDa BossNessuna valutazione finora

- MSC Dissertation Project Guidelines - CE - 2014-15Documento17 pagineMSC Dissertation Project Guidelines - CE - 2014-15mohanNessuna valutazione finora

- ITP - EarthworkDocumento2 pagineITP - EarthworkManish PatilNessuna valutazione finora

- 84501-9200-9L-008 Rev-0 Technical Inspection Services Company Final Documentation RequirementsDocumento7 pagine84501-9200-9L-008 Rev-0 Technical Inspection Services Company Final Documentation RequirementsPeni M. SaptoargoNessuna valutazione finora

- Rail Infrastructure Alliance: Eastern Portal Development PlanDocumento116 pagineRail Infrastructure Alliance: Eastern Portal Development PlanSanjeev Kr. ThakurNessuna valutazione finora

- L1 PRJ Pro 009Documento39 pagineL1 PRJ Pro 009Kevin KamNessuna valutazione finora

- Assessing Integrated Project Delivery A ComparativDocumento11 pagineAssessing Integrated Project Delivery A ComparativalejandroNessuna valutazione finora

- Engineering Folder StructureDocumento1 paginaEngineering Folder StructureAashish Murali100% (1)

- S-000-5520-051 - 0 Project Quality PlanDocumento34 pagineS-000-5520-051 - 0 Project Quality PlanMahadevan Mahalingam100% (1)

- MDOT Shop Drawing Review Process 718756 7Documento15 pagineMDOT Shop Drawing Review Process 718756 7Đặng Xuân ViệtNessuna valutazione finora

- Quality Plan 2 PDF FreeDocumento21 pagineQuality Plan 2 PDF FreeEng.arifNessuna valutazione finora

- Central Corridor Design CriteriaDocumento387 pagineCentral Corridor Design CriteriaGhazala FarooqNessuna valutazione finora

- Document Controller Procedure1Documento28 pagineDocument Controller Procedure1Moosa RizwanNessuna valutazione finora

- A Good Practice Guide For Managing The Wheel-Rail Interface of Light Rail and Tramway SystemsDocumento21 pagineA Good Practice Guide For Managing The Wheel-Rail Interface of Light Rail and Tramway SystemsIbraheem Adel SheerahNessuna valutazione finora

- Quality Management PlanDocumento32 pagineQuality Management PlanJope Batiwaci100% (2)

- VD V013 ZPM Pro 1507Documento105 pagineVD V013 ZPM Pro 1507abdulNessuna valutazione finora

- Draft Methodology (G-14)Documento14 pagineDraft Methodology (G-14)Javed ParachaNessuna valutazione finora

- P A00 DC PO 003 (03) Project Documents Handover Procedure - 0Documento69 pagineP A00 DC PO 003 (03) Project Documents Handover Procedure - 0Dinesh Kumar100% (1)

- Saudi Aramco Test ReportDocumento5 pagineSaudi Aramco Test ReportzhangNessuna valutazione finora

- Project Quality Plan FormatDocumento6 pagineProject Quality Plan FormatNABEEL ABDUL GAFFARNessuna valutazione finora

- Design & Construction Phase Management-NWMODocumento34 pagineDesign & Construction Phase Management-NWMObpjindia100% (1)

- Project Management ApproachesDocumento2 pagineProject Management ApproachesAliMuzaffarNessuna valutazione finora

- Quality Metrics Project ManagementDocumento8 pagineQuality Metrics Project Managementselinasimpson1501Nessuna valutazione finora

- Project Roles and ResponsibilitiesDocumento7 pagineProject Roles and ResponsibilitiesJoseph D'souzaNessuna valutazione finora

- Quality Management Plan Jan12 RevisionDocumento11 pagineQuality Management Plan Jan12 RevisionLau Meng YongNessuna valutazione finora

- Mindalore Project Charter - Project Charter 15.09.2014Documento16 pagineMindalore Project Charter - Project Charter 15.09.2014Michael BenhuraNessuna valutazione finora

- Procedure For Control of Engineering DrawingDocumento5 pagineProcedure For Control of Engineering Drawingahmedalgalo100% (4)

- STOD OTP PMT 0804 PM PRO 0002 000 STOD Correspondence Control ProcedureDocumento8 pagineSTOD OTP PMT 0804 PM PRO 0002 000 STOD Correspondence Control Procedurejfl2096Nessuna valutazione finora

- Change Management ProcedureDocumento5 pagineChange Management Procedureautocad abdelmjidNessuna valutazione finora

- Topic 3 Construction Project OrganizationDocumento80 pagineTopic 3 Construction Project OrganizationPaul Justin MangatNessuna valutazione finora

- Value Engineering (VE) in Design-Build: A Value Management ApproachDocumento16 pagineValue Engineering (VE) in Design-Build: A Value Management ApproachTAHER AMMARNessuna valutazione finora

- Technical Specs - Track Works (X0103-S02-ERT-SP-46700 - 00)Documento74 pagineTechnical Specs - Track Works (X0103-S02-ERT-SP-46700 - 00)AlexYoung100% (1)

- Weigh-in-Motion Systems - Apr 2008Documento104 pagineWeigh-in-Motion Systems - Apr 2008Mohammed100% (1)

- 03.01.04-Project Progress Reporting Contractor-GuidelineDocumento46 pagine03.01.04-Project Progress Reporting Contractor-GuidelineNithin Mathai100% (1)

- ES.0.06.0021-C - Compilation and Handover of Project DossierDocumento34 pagineES.0.06.0021-C - Compilation and Handover of Project DossierHamid Khan100% (5)

- Cpix On Line: Pre-Contract Building Information Modelling (Bim) Execution Plan (Bep)Documento11 pagineCpix On Line: Pre-Contract Building Information Modelling (Bim) Execution Plan (Bep)Himang JainNessuna valutazione finora

- 202 Procedure 0-Project Execution PlanDocumento8 pagine202 Procedure 0-Project Execution PlanagaricusNessuna valutazione finora

- Chapter 4 - Electricity Intake (2020 Edition)Documento20 pagineChapter 4 - Electricity Intake (2020 Edition)bibinbibinNessuna valutazione finora

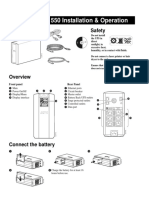

- Back-UPS RS 550 Installation & Operation: Inventory SafetyDocumento7 pagineBack-UPS RS 550 Installation & Operation: Inventory SafetyAndrej VukalovicNessuna valutazione finora

- Sample Integration MS 1 Level Seq 1Documento3 pagineSample Integration MS 1 Level Seq 1sol heimNessuna valutazione finora

- Research 2 Week 1-2 LessonsDocumento62 pagineResearch 2 Week 1-2 LessonsJenn Imperial100% (1)

- Test Certificates Repair Instructions Service Bulletins (Idms) ConversionsDocumento394 pagineTest Certificates Repair Instructions Service Bulletins (Idms) ConversionsGABRIELNessuna valutazione finora

- Section 06 Roads and Pavements PDFDocumento35 pagineSection 06 Roads and Pavements PDFlakmalperera1986Nessuna valutazione finora

- Rev17 Volume2 PDFDocumento384 pagineRev17 Volume2 PDFhjduarteNessuna valutazione finora

- Generic Fax Cover SheetDocumento10 pagineGeneric Fax Cover Sheetlashondriajohnson94Nessuna valutazione finora

- John Collier, Malcolm Collier Visual Anthropology Photography As A Research Method 1986Documento135 pagineJohn Collier, Malcolm Collier Visual Anthropology Photography As A Research Method 1986Paul Alexandru ChirilăNessuna valutazione finora

- Database Programming With PL/SQL 3-3: Practice ActivitiesDocumento2 pagineDatabase Programming With PL/SQL 3-3: Practice ActivitiesBogdan BicaNessuna valutazione finora

- OP Lifting Equipment 1006Documento1 paginaOP Lifting Equipment 1006Sinead1990Nessuna valutazione finora

- It Law Question and AnswersDocumento2 pagineIt Law Question and AnswersJb SadikNessuna valutazione finora

- Framework For Interaction Between Databases and Microservice ArchitectureDocumento7 pagineFramework For Interaction Between Databases and Microservice ArchitecturedsolisNessuna valutazione finora

- SIngle Crystal Technology and Turbines, Lecture NotesDocumento2 pagineSIngle Crystal Technology and Turbines, Lecture NotesPatrick BatemanNessuna valutazione finora

- P-CAD 2006 SP2 New Features and EnhancementsDocumento5 pagineP-CAD 2006 SP2 New Features and EnhancementsAmelco DistribuiçaoNessuna valutazione finora

- Upay Department: Frequently Asked Questions (Faqs) - CustomersDocumento13 pagineUpay Department: Frequently Asked Questions (Faqs) - CustomerstanvirNessuna valutazione finora

- Computer Memory Contingent On The Protein Bacterio RhodopsinDocumento26 pagineComputer Memory Contingent On The Protein Bacterio Rhodopsinak562192Nessuna valutazione finora

- Sample Jayant 14Documento12 pagineSample Jayant 14Shobhit PalNessuna valutazione finora

- z80.Eu-Tools For Virus AnalysisDocumento3 paginez80.Eu-Tools For Virus AnalysisVIC RODNessuna valutazione finora

- Ecology of Pa by Atty. OdilonDocumento48 pagineEcology of Pa by Atty. OdilonLeedmo ClaverNessuna valutazione finora

- Study Guide: CBCN4103 Introduction To NetworkingDocumento271 pagineStudy Guide: CBCN4103 Introduction To NetworkingHuy HANessuna valutazione finora

- Multicolumn Blast Valve PV-KKDocumento2 pagineMulticolumn Blast Valve PV-KKyousufbashaNessuna valutazione finora

- Infineon SPP - I - A15N60C3 DS v03 - 03 EN 53478Documento15 pagineInfineon SPP - I - A15N60C3 DS v03 - 03 EN 53478Jeferson TorresNessuna valutazione finora

- NVOC Advisory No. 158Documento2 pagineNVOC Advisory No. 158Pearly RederaNessuna valutazione finora

- Grade 10 Math Q2 FULL Week 1 - WatermarkDocumento28 pagineGrade 10 Math Q2 FULL Week 1 - WatermarkSophia Junelle100% (1)

- Lesson 4Documento43 pagineLesson 4Rofa Mae MedinaNessuna valutazione finora

- 3D Vision Guided Robotic Charging Station For ElecDocumento7 pagine3D Vision Guided Robotic Charging Station For ElecAnanya SinghNessuna valutazione finora

- Api 650Documento12 pagineApi 650Efrain TiradoNessuna valutazione finora

- Oxygen Forensic SQLite ViewerDocumento1 paginaOxygen Forensic SQLite ViewerkukuhNessuna valutazione finora

- Indian Telecom SectorDocumento40 pagineIndian Telecom Sectoragrawalrohit_228384Nessuna valutazione finora