Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Transducers #2

Caricato da

Asim ShahzadDescrizione originale:

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Transducers #2

Caricato da

Asim ShahzadCopyright:

Formati disponibili

1

Assignment # 01

Title Transducers,types,working principle,diagrams and applications Submitted to Sir Tahir Ashfaq Submitted by M,Naeem Rizwan Roll # 08-ch-39

nfc institute of engg. And fertilizer research fsd

1-What are transducers

1.1 -Sensor 1.2 -Actuator

2-Efficiency 3-Classification of transducer

3.1- Based on the physical phenomeno 3.1.1-Primary transducer 3.1,2-Secondary transducer: 3.2- Based on the power type Classification, 3.2.1-Active transducer 3.2.2 Digital transducer 3.3 Based on the type of output the classification of transducers are made, 3.3.1-Analog transducer 3.3,2-Digital transducer

3.4-Based on the electrical phenomenon is a best Classification of Trasnducer,

3,4.1-Resistive transducer 3.4.2-Capacitive transducer 3.4.3-Inductive transducer 3.4.4-Photoelectric transducer 3.4.5-Photovoltaic transducer 3.5-Based on the non-electrical phenomenon Classification of transducer, 3.5.1-Linear displacement

3.5.2-Rotary displacement

4-Principle of the Transducer 5-Transducer Circuit Diagram

5.1- Easy LED Photo Sensor Circuit 5.2- Dog Repellent Circuit 5.3-Proximity Alarm Circuit

6-Applications of transducer

6,1-Pressure sensing in the Water industry 6.2-CC Cylindrical force transducer for industrial applications 6.3-Wireless sensors and smart transducers 6.4-Pressure Transducer Usage for Load Moment Indication in Cranes in Fluid Power and Mobile Hydraulics Applications 6.5-What makes a machine a robot? 6.6-Temperature Transducer 6.7-Steam Pressure Transducers

7-Refrences 1-(1)What are transducers

A transducer is a device that converts one form of energy to another. Energy types include (but are not limited to) electrical, mechanical, electromagnetic (including light), chemical, acoustic or thermal energy. While the term transducer commonly implies the use of a sensor/detector, any device which converts energy can be considered a transducer. Transducers are widely used in measuring instruments.

1.1-Sensor (e.g., thermometer)

a device that detects/measures a signal or stimulus acquires information from the real world a device that generates a signal or stimulus

1.2-Actuator (e.g., heater)

real world

sensor actuator

intelligent feedback system

2-(2)Efficiency

As in all energy conversions, some energy is lost when transducers operate. The efficiency of a transducer is found by comparing the total energy put into it to the total energy coming out of the system. Some transducers are very efficient, and others are extraordinarily inefficient.

3-(3)Classification of transducers:

3.1. Based on the physical phenomenon,

3.1.1-Primary transducer 3.1.2-Secondary transducer:

Primary transducer:The Mechanical device which converts physical quantity to be measured into a mechanical signal.

5 Secondary tranducer:The Electrical device which converts this mechanical signal to the electrical signal.

3.2. Based on the power type Classification,

3.2.1-Active transducer 3.2.2-Passive transducer

Passive transducers - require an external power to operate, and the output is a measure of some variation in passive components (e.g. resistance or capacitance) Examples of passive transducer : -Slide-wire resistor Resistance strain gauge Differential transformer Active Transducers - Self generating type - do not require an external power, and produce an analog voltage or current when stimulated by some physical form of energy. Thermocouple Photovoltaic cell Moving coil generator

3.3. Based on the type of output the classification of transducers are made,

3.3.1Analog transducer 3.3.2Digital transducer

Analog transducers convert the input quantity into an analog output which is a continuous function of time. E.g.-L.V.D.T,Thermocouple, Strain guage . Digital transducers convert the input quantity into an electrical output which is in the form of pulses.

3.4. Based on the electrical phenomenon is a best Classification of Trasnducer,

3.4.1-Resistive transducer 3.4.2-Capacitive transducer 3.4.3-Inductive transducer 3.4.4-Photoelectric transducer 3.4.5-Photovoltaic transducer

6 Variable resistance transducers are one of the most commonly used types of transducers. The variable resistance transducers are also called as resistive transducers or resistive sensors. They can be used for measuring various physical quantities like temperature, pressure, displacement, force, vibrations etc. These transducers are usually used as the secondary transducers, where the output from the primary mechanical transducer acts as the input for the variable resistance transducer. The output obtained from it is calibrated against the input quantity and it directly gives the value of the input. Capacitive transducer is a device that will sense the environment in a form of capacitor changes. Usually an oscillator will sense this change and change frequency accordingly. Inductive sensors are used for non-contact detection of metallic objects. Their operating principle is based on a coil and oscillator that creates an electromagnetic field in the close surroundings of the sensing surface. The presence of a metallic object (actuator) in the operating area causes a dampening of the oscillation amplitude Photoelectric transducers are Calorimetric Flow Sensors for gas & liquid applications, A photovoltaic transducer is simply another name for a solar panel. A transducer changes one energy to another in this case light energy to electrical energy. The two most common type of photovoltaic transducers are silicon and selenium.

3.5. Based on the non-electrical phenomenon Classification of transducer,

3.5.1-Linear displacement 3.5.2-Rotary displacement

Linear Displacement Transducer is a device that takes some form of input energy fed to it in a straight line, and outputs a converted signal relative to the range of displacement that has taken place The rotary capacitive displacement transducer uses a non-contact capacitance based sensor to measure shaft position.

(4)-Principle of the Transducer

In the transducer body there are four holes. Two coils at right angles to each other are wound through these holes. One coil (the primary) is supplied with an alternating current; the other (the secondary) acts as a measurement coil. Since the two are at right angles to each other, there is no magnetic coupling between the coils as long as there is no load on the transducer body.

The transductor is magnetised via the primary coil (a). A voltage proportional to the loading force is induced in the secondary coil (b). If the transducer body is loaded as shown in diagram, the field pattern changes. The permeability of the steel is reduced in the direction of the force and increases in the right angle direction to the force. The result is a change in the symmetry of the magnetic flux, so that some of the flux induces a voltage in the secondary winding. The induced voltage is proportional to the load.

(5)-Transducer Circuit Diagram

5.1-Easy LED Photo Sensor Circuit

Using a common benefit of photo voltaics LED, the circuit can recognize a different output darkness and light. This circuit is used J-FET for receive signal to buffer from LED ,About Output voltage, we used IC 1458 or LM1458 , while in the dark is about 7 volts and the drop about 2 volts in full sun. This is the figure of the circuit;

5.2-Dog Repellent Circuit

Heres circuit for dog repellent circuit that is a high output ultrasonic transmitter which is primarily intended to act as a dog and cat repeller. Heres the figure of the circuit;

5.3-Proximity Alarm Circuit

This is a design circuit for proximity circuit that can be used in alarm circuit. This is the figure of the circuit;

6-(6)Applications of transducers

6.1-Pressure sensing in the Water industry.

Pressure monitoring is widely used in the water industry to provide level measurement in reservoirs and bore boles, leak detection in distribution networks, as well as control data for a wide range of process functions.

6.2-CC Cylindrical force transducer for industrial applications

The CC force transducers have been designed for use in the plastics industry where it is required to measure the reaction force to the extrusion pressure that is present on the casing of the gearbox along the axis of the extruder screw. These models, fitted in contact with the thrust bearings, measure a force whose valve, after suitable correction, is equal to extrusion pressure multiplied by the screw area.

10

6.3-(7)Wireless sensors and smart transducers

Smart transducers are sensors or actuators equipped with microcontrollers to provide local intelligence and network capability. An obvious advantage of wireless transmission is a significant reduction and simplification in wiring and harness. It has been estimated that typical wiring cost in industrial installations is US$ 130650 per meter and adopting wireless technology would eliminate 2080% of this cost (Sensors Magazine, 2004)

6.4-(8)Pressure Transducer Usage for Load Moment Indication in Cranes in Fluid Power and Mobile Hydraulics Applications

Cranes are an everyday aspect of construction and maintenance operations. Safe operation of cranes is dependent on information about all of the forces on the crane, the cranes geometry, where loads are applied and the cranes motion. This information is combined through the use of pressure transducers and displayed to the crane operators using a load moment indicator.

6.5-What makes a machine a robot?

Sensing Planning Acting

11

6.6-(9)Temperature Transducer

\ A temperature transducer usually includes a temperature sensor such as RTD (resistance temperature detector), a thermocouple or a thermistor. Upon sensing, it converts temperature into an electrical signal proportional to the same parameter being sensed or measured. This signal will then be processed, conditioned or amplified to serve as an input voltage into a temperature controller or similarly functioning device.

6.7-(10)Steam Pressure Transducers

Amplified output transducers for use in applications where the transducer will be in contact with high temperature steam in aplications such as sterilizing autoclaves, food and beverage processing and power generation. These transducers include integral cooling features for protecting the transducer electronics from steam temperatures which would otherwise cause damage to standard industrial pressure transducers

7-Refrences

(1)-http://en.wikipedia.org (2)-www.wisegeek.com (3)-instrumentationandcontrollers.blogspot.com (4)-www.abb.com (5)-transducercircuit.blogspot.com/ (6)-www.sensorland.com (7)-www.sciencedirect.com (8)-http://www.wika.us

12

(9)-www.transducer-the-essential-device.com (10)-www.sensorsone.co.uk

Potrebbero piacerti anche

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (344)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (399)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (73)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (120)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- Lecture 3 Fluid Dynamics BasicsDocumento23 pagineLecture 3 Fluid Dynamics BasicsLawrence Trust MunyatiNessuna valutazione finora

- Combustion and FlameDocumento7 pagineCombustion and Flamedattatray deshmukhNessuna valutazione finora

- Unserved Legacy PR (Filtered)Documento2 pagineUnserved Legacy PR (Filtered)Francis DedumoNessuna valutazione finora

- 191 Field Level Storage Data (Annual)Documento27 pagine191 Field Level Storage Data (Annual)venu narlaNessuna valutazione finora

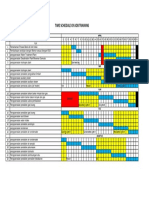

- Time Schedule On Job Training: Elemen Kompetensi AprilDocumento1 paginaTime Schedule On Job Training: Elemen Kompetensi AprilEastor Rainhard Dogma TambunanNessuna valutazione finora

- Attom Mission Critical Power System BrochureDocumento20 pagineAttom Mission Critical Power System BrochurejuancanicNessuna valutazione finora

- Basic Electrical EngineeringDocumento2 pagineBasic Electrical EngineeringsanththaNessuna valutazione finora

- Canada: American EnglishDocumento31 pagineCanada: American EnglishmuhammadizharNessuna valutazione finora

- APS's ProposalDocumento373 pagineAPS's ProposalJonathan AllredNessuna valutazione finora

- 1492sp pp001 - en PDocumento4 pagine1492sp pp001 - en PyubaileNessuna valutazione finora

- Control Concept For Centrifugal CompressorDocumento10 pagineControl Concept For Centrifugal CompressorSarizal Abu BakarNessuna valutazione finora

- Notes - TransformerDocumento6 pagineNotes - TransformerRahul BhumkarNessuna valutazione finora

- Burkert - Solenoid Valve For Gas Applications PDFDocumento27 pagineBurkert - Solenoid Valve For Gas Applications PDFBurkert IndiaNessuna valutazione finora

- Conserv Energy MetersDocumento7 pagineConserv Energy MetersmohanNessuna valutazione finora

- 07 EnergeticWellness - Ebook - 23sep2014Documento20 pagine07 EnergeticWellness - Ebook - 23sep2014sbivekNessuna valutazione finora

- Electricity Metering Equipment (A.C.) - Particular Requirements - Part 22: Static Meters For Active Energy (Classes 0,2 S and 0,5 S)Documento19 pagineElectricity Metering Equipment (A.C.) - Particular Requirements - Part 22: Static Meters For Active Energy (Classes 0,2 S and 0,5 S)Tayyab ZubairNessuna valutazione finora

- Turbine Manual Bhel4Documento2 pagineTurbine Manual Bhel4parthibanemails5779Nessuna valutazione finora

- Analysis of Reactive Power Compensation by Using Capacitor BankDocumento5 pagineAnalysis of Reactive Power Compensation by Using Capacitor BankThet TinNessuna valutazione finora

- EldaDocumento15 pagineEldaandhika swNessuna valutazione finora

- Neutral Earthing in An Industrial HV Network: BackDocumento12 pagineNeutral Earthing in An Industrial HV Network: Backmiksa samuNessuna valutazione finora

- Selectividad Eaton NEMADocumento20 pagineSelectividad Eaton NEMASantiago FarfanNessuna valutazione finora

- Internship ReportDocumento81 pagineInternship Reportyuva raj80% (5)

- IFC Harnessing+Energy+From+The+Sun - FinalDocumento132 pagineIFC Harnessing+Energy+From+The+Sun - FinalHariprasad gantyalaNessuna valutazione finora

- Introto OptimizationDocumento255 pagineIntroto OptimizationSyed QudratullahNessuna valutazione finora

- PX4211 4Documento2 paginePX4211 4kalpanaNessuna valutazione finora

- Protective Relaying QuizDocumento3 pagineProtective Relaying QuizCattleya Tabor PeñalosaNessuna valutazione finora

- Lab Manual Grade 10 - 2020-2021Documento10 pagineLab Manual Grade 10 - 2020-2021Analyah GordonNessuna valutazione finora

- 02 PHY ICSE X Work Energy PowerDocumento11 pagine02 PHY ICSE X Work Energy Power8c-1-Aditya raj BehuraNessuna valutazione finora

- Schmidt Hartmann Boiler 1Documento24 pagineSchmidt Hartmann Boiler 1Varun KarriNessuna valutazione finora

- Bitumen Rate From 01-07-2017Documento3 pagineBitumen Rate From 01-07-2017karunamoorthi_p2209Nessuna valutazione finora