Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Pre Insulated Orascom Egypt

Caricato da

Muhammad FarhanDescrizione originale:

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Pre Insulated Orascom Egypt

Caricato da

Muhammad FarhanCopyright:

Formati disponibili

Main Office : Jeddah Industrial Zone 4, P.O.

O. Box : 34572, Jeddah: 21478 Saudi Arabia, Tel +966-2-6370999 / 6081100 Fax +966-2-6365925 / 6379439 Email : spsvalve@sps.net.sa, Web Site: www.saudivalve.com

1. ITEM REFERENCE LIST 2. COMPLIANCE STATEMENT 3. PRODUCT/S DATA SHEETS AND TECHNICAL CATALOGUES 4. CERTIFICATES 4.1 ISO CERTIFICATE 4.2 TESTING CERTIFICATES

Main Office : Jeddah Industrial Zone Phase 4, P. O. Box: 34572, Jeddah: 21478 Saudi Arabia Tel +966 2 6370999 / 6081100 Fax +966 2 6365925 / 6379439 Email: spsvalve@sps.net.sa : www.saudivalve.com

Main Office : Jeddah Industrial Zone Phase 4, P. O. Box: 34572, Jeddah: 21478 Saudi Arabia Tel +966 2 6370999 / 6081100 Fax +966 2 6365925 / 6379439 Email: spsvalve@sps.net.sa : www.saudivalve.com

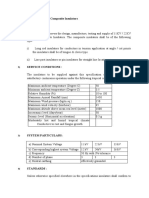

PROPOSED PRODUCT SPECIFICATION

CORE PIPE: Carbon Steel Pipe, Seamless, conforming to ASTM A53, Grade B, Shedule 40, Beveled Ends. For pipe diameter DN300mm and below. Carbon Steel Pipe, ERW (Electric Resistance Welded), conforming to ASTM A53, Grade B, Beveled Ends. For pipe diameter DN400 to DN500mm. Carbon Steel Pipe, SSAW (Spirally Submerged Arc Welded), conforming to API 5L, Grade B, XS, Beveled Ends. For pipe diameter DN850mm and above. BRAND & ORIGIN OF PIPES: ERW & SSAW PIPE IS FROM TURKEY OR HYUNDAI-KOREA. FOR SEAMLESS PIPE IS FROM INTERPIPE-UKRANE. FITTINGS: Butt-Welded Black Carbon Steel, Conforming to ASME B16.5 / ASTM A234 WPB, dimension according to ANSI B16.9 PIPE & FITTINGS SURFACE PREPARATION ( TO BS EN 253: 2009 ): Prior to spray the insulation foam all external surface of pipes & fittings shall be Grit Blasted to ASTM SA 21/2 near white metal finish, free from dust, mill scale, oil, grease dust, paint moisture and other contaminants. INSULATION: The Insulation shall be rigid cellular CFC-Free polyurethane (PUR) foam, Having Density of 77 kg/m3. Insulation Thickness shall be minimum 75mm. Directly sprayed to the core pipe for size 400mm and above. Injection for size 300mm and below. OUTER CASING / JACKETING: The Outer casing / Jacketing shall HDPE pipe, 3 10mm wall thickness. ALTERNATIVE PROPOSAL FOR OUTER CASING / JACKETING: Straight Section of insulated pipe system shall be jacketed with GRP pipe resin with fiber glass reinforcement, directly applied on the insulating foam with 5 -10mm. Wall thickness: LEAK DETECTION SYSTEM : included Leak Detection system shall be an integral part of the piping system, utilizing 2-4 monitoring wires embedded in the foam insulation. The measuring method called Time Domain Reflectometry (TDR) or Pulseechometer.

FIELD JOINT INSULATION KITS. The field joint insulation kits shall be SPS standard two half Pre-molded cladding type insulation kits. SERVICES. SPS shall provide training and demonstration for field joint insulation to your staff. Site supervision / Technical assistance will be provided as required. Welding Machines by the contractor. Material shop drawings will be submitted at due time.

Main Office : Jeddah Industrial Zone Phase 4, P. O. Box: 34572, Jeddah: 21478 Saudi Arabia Tel +966 2 6370999 / 6081100 Fax +966 2 6365925 / 6379439 Email: spsvalve@sps.net.sa : www.saudivalve.com

Main Office : Jeddah Industrial Zone Phase 4 P. O. Box: 34572 Jeddah: 21478 Saudi Arabia Tel +966 2 6370999 / 6081100 Fax +966 2 6365925 / 6379439 Email: spsvalve@sps.net.sa : www.saudivalve.com

SAUDI PIPE SYSTEMS COMPANY is one of the biggest manufacturers of pre-insulated piping systems in the Kingdom of Saudi Arabia. We provide superior quality products and services to a large-scale clientele base. Our products are fully engineered to job specifications based on the clients requirement thereby reducing costs by providing custom-made and fabricated fittings which reduce the number of field connections. We also provide onsite technical service team to monitor and resolve critical issues involving installation, usage and application. We have top of the line electronic detection system and technical equipments for monitoring and safety standards. We have competent, well-experienced, qualified and expert professionals who painstakingly oversee to ensure that quality is never compromised. We offer our best pre-insulated piping system with the following types of pipes; ERW, SAW and seamless steel pipes, GRP/FRP pipes and HDPE pipes. The insulation material is fine-celled polyurethane foam applies onto inner pipe by means of injection or spray. This insulated piping system is suitable for both above and underground application which minimizes the heat transfer in the following medium; chilled water system, heating system, steam application, gas, oil and industrial application. We have excellent Quality Control procedures and monitoring system making sure every product conforms to a specific requirements and highest standards. We therefore assure you that all our products are of 100% free from defects, deficiencies and flaws. We are promoting pre-insulated piping system as most suited for efficient and effective ways to distribute toxic wastes in industrial applications. This has been proven to be efficient, durable and environmentally safe. We had successfully established a reputable name in the business industry and our products have been proven of world-class quality and marketability. We continue to receive commendable feedbacks from our customers (in local and international markets) engaged in projects including aviations/airports, school/universities, housing/mosques, petro-chemical plants and Royal Commission. We have been very serious in our commitment of providing our customers a superior quality products and services, and giving them full satisfaction to the utmost level.

Main Office : Jeddah Industrial Zone Phase 4, P. O. Box: 34572, Jeddah: 21478 Saudi Arabia Tel +966 2 6370999 / 6081100 Fax +966 2 6365925 / 6379439 Email: spsvalve@sps.net.sa : www.saudivalve.com

LIMITED WARRANTY

Saudi Pipe System Co., warrants only to the original purchaser of its products, and that those products will be free from defects in material and workmanship under normal use for one year after the date of purchase. SPS reserves the right, before having any obligation under this limited warranty, to inspect the damaged SPS product, and all costs of shipping the SPS product to SPS for inspection shall be borne solely by the purchaser. In order to recover under this limited warranty, Purchaser must present acceptable proof of original ownership (such as original receipt, delivery note, warranty or other documents (SPS deems acceptable) for the product. SPS, at its option, shall repair or replace the defective unit covered by this warranty. In order to keep this limited warranty in effect, the product must have been handled, used, or installed in accordance within application. This limited warranty does not cover any damage due to accident, misuse, abuse or negligence.

Main Office : Jeddah Industrial Zone Phase 4, P. O. Box: 34572, Jeddah: 21478 Saudi Arabia Tel +966 2 6370999 / 6081100 Fax +966 2 6365925 / 6379439 Email: spsvalve@sps.net.sa : www.saudivalve.com

PRE-INSULATED PIPE Is a piping system comprising of a primary pipe and a secondary pipe. The primary pipe which is the inner pipes also called the CORE PIPE and it is the one conveying the fluid medium. The foam that is filling the space between the primary pipe and the secondary pipe is the INSULATION. The secondary pipe which is the outer pipe is also called the JACKET. The jacketing pipe is the one protecting and holding together the core pipe and the insulation.

A. CORE PIPE

The inner pipe may be any material suited to convey the fluid media. SPS PROVIDES THE FOLLOWING CARRIER/CORE PIPES:

C. JACKET The outer pipe protects the insulation from mechanical damage and water intrusion. SPS PROVIDES THE FOLLOWING CASING/JACKET ING PIPES: 1. GRP/FRP Pipes made from filament and continuous winding.

1. Steel Pipes Consist of ERW, SAW and Seamless Black Steel Pipes.

2. GRP/FRP Pipes made from filament and continuous winding. 3. Extruded High Density Polyethylene Pipe (HDPE). B. INSULATION The insulation material is a fine celled polyurethane foam. It is applied onto the inner pipe by means of injection and spray.

2. Extruded High Density Polyethylene Pipe (HDPE)

Main Office : Jeddah Industrial Zone Phase 4, P. O. Box: 34572, Jeddah: 21478 Saudi Arabia Tel +966 2 6370999 / 6081100 Fax +966 2 6365925 / 6379439 Email: spsvalve@sps.net.sa : www.saudivalve.com

APPLICATION Pre-insulated pipe are utilized to minimize the heat transfer of the following mediums:. Chilled Water System Heating System Steam Application Gas and Oil Industrial Application

The systems are comprised of a specified carrier pipe insulated with polyurethane insulation and jacketed by either a HDPE or FRP/GRP pipe.

STEAM APPLICATION

CHILLED WATER APPLICATION

ADVANTAGES OF USING PRE-INSULATED PIPES: 100% Water Tight 100% Corrosion Protected Energy Saving No Maintenance Costs UV Resistant Increase Surface Strength

Main Office : Jeddah Industrial Zone Phase 4, P. O. Box: 34572, Jeddah: 21478 Saudi Arabia Tel +966 2 6370999 / 6081100 Fax +966 2 6365925 / 6379439 Email: spsvalve@sps.net.sa : www.saudivalve.com

76

Pre-insulated Pipe Core: GRP Pipe Filament Wound Insulation: Polyurethane Foam Jacket: GRP Pipe Filament Wound

Pre-insulated Pipe Core: Black Steel Pipe Insulation: Polyurethane Foam Jacket: GRP Pipe Filament Wound

Pre-insulated Pipe Core: HDPE Pipe Insulation: Polyurethane Foam Jacket: HDPE Pipe

Pre-insulated Pipe Core: Black Steel Pipe Insulation: Polyurethane Foam Jacket: HDPE Pipe

Main Office : Jeddah Industrial Zone Phase 4, P. O. Box: 34572, Jeddah: 21478 Saudi Arabia Tel +966 2 6370999 / 6081100 Fax +966 2 6365925 / 6379439 Email: spsvalve@sps.net.sa : www.saudivalve.com

79

PREINSULATED PIPE Core: Black Steel Pipe Insulation: Polyurethane Foam Casing: GRP Pipe

PREINSULATED PIPE Core: Black Steel Pipe Insulation: Polyurethane Foam Casing: HDPE Pipe

Main Office : Jeddah Industrial Zone Phase 4, P. O. Box: 34572, Jeddah: 21478 Saudi Arabia Tel +966 2 6370999 / 6081100 Fax +966 2 6365925 / 6379439 Email: spsvalve@sps.net.sa : www.saudivalve.com

Main Office : Jeddah Industrial Zone Phase 4, P. O. Box: 34572, Jeddah: 21478 Saudi Arabia Tel +966 2 6370999 / 6081100 Fax +966 2 6365925 / 6379439 Email: spsvalve@sps.net.sa : www.saudivalve.com

Main Office : Jeddah Industrial Zone Phase 4, P. O. Box: 34572, Jeddah: 21478 Saudi Arabia Tel +966 2 6370999 / 6081100 Fax +966 2 6365925 / 6379439 Email: spsvalve@sps.net.sa : www.saudivalve.com

Main Office : Jeddah Industrial Zone Phase 4, P. O. Box: 34572, Jeddah: 21478 Saudi Arabia Tel +966 2 6370999 / 6081100 Fax +966 2 6365925 / 6379439 Email: spsvalve@sps.net.sa : www.saudivalve.com

77

Pre-insulated Fittings Core: Black Steel Insulation: Polyurethane Foam Jacket: GRP

Pre-insulated Jacket for Fittings Insulation: Polyurethane Foam Jacket: GRP

Pre-insulated Jacket for Pipe Insulation: Polyurethane Foam Jacket: GRP

Main Office : Jeddah Industrial Zone Phase 4, P. O. Box: 34572, Jeddah: 21478 Saudi Arabia Tel +966 2 6370999 / 6081100 Fax +966 2 6365925 / 6379439 Email: spsvalve@sps.net.sa : www.saudivalve.com

83

PREINSULATED ELBOW Core: Black Steel Casing: GRP Insulation: Polyurethane Foam

PREINSULATED ELBOW Core: Black Steel Casing: HDPE Insulation: Polyurethane Foam

Main Office : Jeddah Industrial Zone Phase 4, P. O. Box: 34572, Jeddah: 21478 Saudi Arabia Tel +966 2 6370999 / 6081100 Fax +966 2 6365925 / 6379439 Email: spsvalve@sps.net.sa : www.saudivalve.com

87

PREINSULATED REDUCER Core: Black Steel Casing: GRP Insulation: Polyurethane Foam

L

PREINSULATED REDUCER Core: Black Steel Casing: HDPE Insulation: Polyurethane Foam

L

Main Office : Jeddah Industrial Zone Phase 4, P. O. Box: 34572, Jeddah: 21478 Saudi Arabia Tel +966 2 6370999 / 6081100 Fax +966 2 6365925 / 6379439 Email: spsvalve@sps.net.sa : www.saudivalve.com

96

PREINSULATED TEE Core: Black Steel Casing: GRP Insulation: Polyurethane Foam

PREINSULATED TEE Core: Black Steel Casing: HDPE Insulation: Polyurethane Foam

Main Office : Jeddah Industrial Zone Phase 4, P. O. Box: 34572, Jeddah: 21478 Saudi Arabia Tel +966 2 6370999 / 6081100 Fax +966 2 6365925 / 6379439 Email: spsvalve@sps.net.sa : www.saudivalve.com

Main Office : Jeddah Industrial Zone Phase 4, P. O. Box: 34572, Jeddah: 21478 Saudi Arabia Tel +966 2 6370999 / 6081100 Fax +966 2 6365925 / 6379439 Email: spsvalve@sps.net.sa : www.saudivalve.com

12

Service pipe insulation shall be sprayed layer by layer directly to the core pipe with nominal 77 kg/m density. After sprayed of foam completed it shall be machined to the rectifying machine to ensure smooth surface, fully concentric and precise thickness of the foam. To ensure no voids are present, all insulation shall be visually inspected prior to apply the outer GRP or HDPE jacketing. All polyurethane foam insulation shall be minimum 90% closed cell. Open foams will not be allowed. GENERAL

PIPE SIZE

mm 25 ~ 150 200 ~ 350 400 ~ 600 700 ~ 900 1000 ~ GREATER

INSULATION THICKNESS (mm)

CHILLED WATER 75 75 75 75 75 - 100 HOT WATER 75 75 75 75 75 -100

Polyol rigid polyurethane systems are of two components. Blended Polyol and polymeric MDI are available in various nominal density grades; 32, 40, 48 and 55 kg/m. The systems have 1:1 volume ratio.

APPLICATION Polyol resin components is a lowmedium viscosity blend of Polyols, fire retardants, HCFC 141b as blowing agent, surfactants and catalysts. The Polyol offers increase resistance to burning and spread of flames, specially developed for Spray Insulation with the use of a spray machine. TYPE OF SPRAY SYSTEMS The systems modified with catalyst for improved performance during the cold winter weather (below 25C) and the hot summer (above 25C). The choice of grade is not mandatory where the type of substrate, equipment and the other factors influence the choice of systems used.

Main Office : Jeddah Industrial Zone Phase 4, P. O. Box: 34572, Jeddah: 21478 Saudi Arabia Tel +966 2 6370999 / 6081100 Fax +966 2 6365925 / 6379439 Email: spsvalve@sps.net.sa : www.saudivalve.com

11

SPS insulation material is fine celled polyurethane foam (PUR). It is applied onto the inner pipe by injection or spraying. The foam expands using cyclopenthane as a blowing agent and is completely free from water.

FOAM SPRAYER MACHINE

FOAM INJECTION MACHINE

Main Office : Jeddah Industrial Zone Phase 4, P. O. Box: 34572, Jeddah: 21478 Saudi Arabia Tel +966 2 6370999 / 6081100 Fax +966 2 6365925 / 6379439 Email: spsvalve@sps.net.sa : www.saudivalve.com

60

HANDLING and STORAGE Spray Polyol Systems should be stored at a room temperature below 25C in sealed drums. Drums should be released immediately after use to avoid loss of blowing agent and absorption of moisture. Agitate contents before use, particularly after long standing. Consult the polyol handbook for surface preparation and proper application. Pre-cautions should be observed to avoid prolonged or repeated skin contact with the production or its introduction in or near the eyes. If skin contact occurs all contaminated clothing should be removed and the affected skin area wipe with a cloth or paper towels saturated with the ethanol or equivalent solvent followed by washing with soap and water. Goggle or eye shields should be worn when there is a danger of splashing or eye contact. Polyurethane Foam has an exceptional insulating and mechanical values characterized by very low vapor permeability resulting in long term steady dielectic and insulation properties. Its closed cell structure allows water absorption and CFC free formulation makes it more effective as thermal insulation material due to superior ageing properties. OTHER TESTED PROPERTIES OF POLYURETHANE FOAMS Higher tensile, compressive and shear strengths Ductility at both high and low strain rates give good impact Good freeze thaw characteristics Excellent bending / flexing fatigue properties Unsurpassed resistance to thermal cycling fatigue Good creep resistance Withstands abuse and rough handling CFC free material Thermal conductivity from 0.027 W/mK at 100C (283K) Good cryogenic safely factor down to - 196C (77K) Stable at temperature from - 200C to +120C (73 393K) Rot and chemical resistant

Main Office : Jeddah Industrial Zone Phase 4, P. O. Box: 34572, Jeddah: 21478 Saudi Arabia Tel +966 2 6370999 / 6081100 Fax +966 2 6365925 / 6379439 Email: spsvalve@sps.net.sa : www.saudivalve.com

Main Office : Jeddah Industrial Zone Phase 4, P. O. Box: 34572, Jeddah: 21478 Saudi Arabia Tel +966 2 6370999 / 6081100 Fax +966 2 6365925 / 6379439 Email: spsvalve@sps.net.sa : www.saudivalve.com

Main Office : Jeddah Industrial Zone Phase 4, P. O. Box: 34572, Jeddah: 21478 Saudi Arabia Tel +966 2 6370999 / 6081100 Fax +966 2 6365925 / 6379439 Email: spsvalve@sps.net.sa : www.saudivalve.com

15

The purpose of the outer jacket over the insulation is to protect the foam from mechanical damage and water intrusion. SPS has provided two jacketing processes and these are by the use of FRP/GRP Pipes and HDPE Pipes . For sizes 630mm and smaller.

The GRP jacket has a top coat inhibitors for ultra violet protection, if installed above ground for an unlimited period of time. The jacket allows the insulation to retain flexibility almost identical to that of the core pipe. This permits the jacketed pipe to conform in unstable soils. For above ground application in abusive environments, generally a heavier wall thickness is desirable.

Straight section of insulated pipes systems shall be jacketed with GRP pipe resin with fibreglass reinforcement , directly applied on the insulating foam to the minimum thickness as follows: 16 inch and smaller: 2 ~ 3m thick 18 inch and larger: 3 ~ 5mm thick The resin saturated system shall contain 60 to 70% glass by weight. The filament wound casing will be as per ASTM D 2580 : 34 SHORE, ASTM 2584 : 60 to 70 by weight. The jacket will be helically and circumferentially applied on the insulating foam.

Main Office : Jeddah Industrial Zone Phase 4, P. O. Box: 34572, Jeddah: 21478 Saudi Arabia Tel +966 2 6370999 / 6081100 Fax +966 2 6365925 / 6379439 Email: spsvalve@sps.net.sa : www.saudivalve.com

16

GRP JACKET TECHNICAL SPECIFICATION SPS GRP carrier and jacket pipes are manufactured in diameters ranging from 100mm to 2500mm. The nominal diameter of the jacketing pipe coincides with the internal diameter. Glass reinforcements and isophtalic resin are the raw materials in making GRP pipes.

Typical Properties of Liquid Resin

Viscosity Percent Styrene Specific gravity Gel Time 25C Cure Time in Hours De Mould Time 500 38 1.2 25 3

Resin properties are measured on every single batch according to SPS internal Quality Control and Inspection Plan.

Cured Resin at Room Temperature

Glass Content by Weight Flexural Strength (psi) Flexural Modulus x 10 (psi) Tensile Strength (psi) Tensile Modulus x 10 (psi) Tensile Elongation (Cast Resin) Compressive Strength (psi) Heat Distortion Temperature (resin) C HDT (Laminate) C 32% 23200 9.6 12400 11 1.9 22300 80 200

Main Office : Jeddah Industrial Zone Phase 4, P. O. Box: 34572, Jeddah: 21478 Saudi Arabia Tel +966 2 6370999 / 6081100 Fax +966 2 6365925 / 6379439 Email: spsvalve@sps.net.sa : www.saudivalve.com

17

Glass Reinforcement Glass reinforcements are made starting from two different types of glass compositions: C Glass Performs very good properties of chemical inertness versus chemical corrosion. E Glass Has very high mechanical strength. The glass reinforcement specified by SPS consist of the following: Surfacing Veils of C Glass used as reinforcement for the first ply of the laminate. Mat of chopped strands of E Glass used in hand lay up operations such as the manufacturing of fittings. Continuous roving of E Glass to be wound, used in winding operations to obtain anisotropic structures where the distribution of the mechanical strength depends upon the orientation of the continuous fibers. Woven roving used in hand lay-up operations alternating layers of woven roving to layers of mats to improve the mechanical strength of the laminate. The significant mechanical properties of fiberglass used as reinforcement are the following:

Property Ultimate Tensile Strength, Mpa Modulus of Elasticity GPA

Value 1400 70

Main Office : Jeddah Industrial Zone Phase 4, P. O. Box: 34572, Jeddah: 21478 Saudi Arabia Tel +966 2 6370999 / 6081100 Fax +966 2 6365925 / 6379439 Email: spsvalve@sps.net.sa : www.saudivalve.com

18

Properties of Laminates The following figures refer to laminates obtained by filament winding process with a winding angle of 55 degrees. The winding angle can be varied to increase properties in the axial or circumferential directions. Design Basis Properties

Property Ultimate Hoop Stress Hydrostatic Design Basis 105 Hours Hydrostatic Design Basis 105 Hours Test Method ASTM D159 ASTM D2992 Method B ASTM D2992 Method B Pipe N/sq. mm 250 172 86

Mechanical Properties

Property Allowable Axial Tensile Stress Axial Tensile Modulus Allowable Hoop Tensile Stress Hoop Tensile Modulus

Test Method ASTM D1599 ASTM D1599 ASTM D1599 ASTM D1599

Pipe N/mm 30 13000 55 23000

Fitting N/mm 25 10000 25 10000

Other Physical Properties

Property Coeff. Of Linear Thermal Expansion 1/C Specific Gravity kg/m Pipe 1.8 x 10-5 1850 Fitting 3.0 x 10-5 1650

Glass / Resin Ratio ( by weight ) %

About 60

About 40

Main Office : Jeddah Industrial Zone Phase 4, P. O. Box: 34572, Jeddah: 21478 Saudi Arabia Tel +966 2 6370999 / 6081100 Fax +966 2 6365925 / 6379439 Email: spsvalve@sps.net.sa : www.saudivalve.com

Main Office : Jeddah Industrial Zone Phase 4, P. O. Box: 34572, Jeddah: 21478 Saudi Arabia Tel +966 2 6370999 / 6081100 Fax +966 2 6365925 / 6379439 Email: spsvalve@sps.net.sa : www.saudivalve.com

19

SPS pre-insulated pipes are also provided with a Leak Detection System. CWA sensor wire simply a bare copper wire embedded within the insulating foam 1520mm from the carrier pipe. At field joints, the installing contractor has to crimp a short jumper cable to tie the adjacent pieces together. The installed piping system will then have a continuous copper wire embedded within the foam. Since the foam is not a conductor of electricity, there will be very high resistance between the wire and the metal pipe. This electrical resistance within the copper wire can be monitored with a simple Analog Ohmmeter to determine if there is a leak at any time.

Main Office : Jeddah Industrial Zone Phase 4, P. O. Box: 34572, Jeddah: 21478 Saudi Arabia Tel +966 2 6370999 / 6081100 Fax +966 2 6365925 / 6379439 Email: spsvalve@sps.net.sa : www.saudivalve.com

Main Office : Jeddah Industrial Zone Phase 4, P. O. Box: 34572, Jeddah: 21478 Saudi Arabia Tel +966 2 6370999 / 6081100 Fax +966 2 6365925 / 6379439 Email: spsvalve@sps.net.sa : www.saudivalve.com

56

After the core pipe is site-jointed by welding or by mechanical coupling, and the joint is tested according to project specification, the joint is insulated using the same polyurethane foam used in pre-insulated pipes and fittings. WELDED JOINT An oversized HDPE sleeve is supplied with each pipe and fitting. The sleeve is sidedover the casing prior to joining the core pipe. After joining, the sleeve is moved back to cover the bare joint. The contact areas between the HDPE sleeve and the HDPE casing are wrapped with polyolefin sleeve and then heat shrunk to make both ends water tight. Two holes are drilled in the HDPE sleeve, one for pouring and the other for venting. The predetermined quantities of Polyol and MDI are mixed together and poured into the HDPE sleeve. After the PU foam stops rising, the excess foam is cleaned and the two holes are patched with polyolefin sleeve. Welded Joint Core Pipe

HDPE Roll-up (Sleeve)

Pouring Holes

Patched Holes

Casing

Main Office : Jeddah Industrial Zone Phase 4, P. O. Box: 34572, Jeddah: 21478 Saudi Arabia Tel +966 2 6370999 / 6081100 Fax +966 2 6365925 / 6379439 Email: spsvalve@sps.net.sa : www.saudivalve.com

57

MECHANICAL JOINT A sheet metal is supplied with each pipe and fitting. After jointing, the mould is fixed on top of the bare joint with plastic straps or wire. The predetermined quantities of Polyol and MDI are mixed together and poured into the mould. After the PU foam stop rising, the excess foam is to be cleaned. For water tightness, a 24 polyolefin heat shrinkable sleeve is to be wrapped around the mould and heat shrunk. Flanged Core Jacket Joint Pipe

Vent G.I. Sheet Metal Mould

Pouring Hole Insulation

Heat Shrink Sleeve

Patched Holes

Jacket

Main Office : Jeddah Industrial Zone Phase 4, P. O. Box: 34572, Jeddah: 21478 Saudi Arabia Tel +966 2 6370999 / 6081100 Fax +966 2 6365925 / 6379439 Email: spsvalve@sps.net.sa : www.saudivalve.com

58

Another means of pre-insulating the gap after welding the core pipes is by using a galvanized sheet. G.I. sheet is to be wrapped around the gap overlapping a little portion of the insulated area as seen in the drawing below.

Pre-insulated Gap

G.I. Sheet

Main Office : Jeddah Industrial Zone Phase 4, P. O. Box: 34572, Jeddah: 21478 Saudi Arabia Tel +966 2 6370999 / 6081100 Fax +966 2 6365925 / 6379439 Email: spsvalve@sps.net.sa : www.saudivalve.com

59

Self locking screw is needed to hold and lock together the ends of the G.I. wrapping the area needed to be foamed. Securing the edges of the G.I. sheets so that the foam will not leak to the sides duck tapes can be used. Two holes are needed to where we can pour the foam to insulate the gap. After foaming a rubberized membrane can also be used to cover the G.I. sheet and to isolate the controlled temperature transferred from the core pipe to the insulation.

Pouring Hole Self Screw Duck Tape

Membrane

Main Office : Jeddah Industrial Zone Phase 4, P. O. Box: 34572, Jeddah: 21478 Saudi Arabia Tel +966 2 6370999 / 6081100 Fax +966 2 6365925 / 6379439 Email: spsvalve@sps.net.sa : www.saudivalve.com

78

PRE-MOULDED CLADDING After the core pipe and fittings are site joined by welding or by mechanical joint and tested according to project specifications, Pre-moulded foam will be placed on the joint by applying an adhesive to bond together and then the outside GRP pipe and fitting jacket will be laminated to seal the gap.

Main Office : Jeddah Industrial Zone Phase 4, P. O. Box: 34572, Jeddah: 21478 Saudi Arabia Tel +966 2 6370999 / 6081100 Fax +966 2 6365925 / 6379439 Email: spsvalve@sps.net.sa : www.saudivalve.com

61

Finished pipes of the same dimensions must be stored on solid flat surface.

Storing of pipes must be in rectangular

or pyramid piling style Wedges must be used at the lowest layer of the pile to support from rolling or slipping. Timber planks should be used as the base surface of the pipes.

The number of timber planks should

depend on the dimensions and lengths of the pipes. Stacks must not exceed 2.50 m in height to ensure safety when storing and transporting the pipes. Piled pipes must be protected from cold, heat and direct sunlight to prevent any loss of quality. Recommended storage temperature

ranges from 18C to 29C.

Main Office : Jeddah Industrial Zone Phase 4, P. O. Box: 34572, Jeddah: 21478 Saudi Arabia Tel +966 2 6370999 / 6081100 Fax +966 2 6365925 / 6379439 Email: spsvalve@sps.net.sa : www.saudivalve.com

62

Pipes loading area must be checked to ensure that it is clean from dirt or any sharp edged parts must be removed. Caps must be placed on the pipes to protect it from external influences. Timber planks should be used as the base surface of the pipes and belts must be strapped fixed to the trailer to ensure full stability during transporting. Piling of pipes on top of the trailer for transport must not exceed three tiers high. Timber planks be must used for each pipe layers Small dimensions fittings, shaped parts and pipes can be unloaded by hand. Larger sizes should preferably be unloaded using a crane or with the appropriate lifting gears. As not to jeopardise the quality of the pipes during the unloading process, chains and ropes are unsuitable for use. Only nylon straps or similar must be used to ensure the protection of the outer casing. It is not permissible to throw down, or roll them or pull the pipes off from the cargo area.

Main Office : Jeddah Industrial Zone Phase 4, P. O. Box: 34572, Jeddah: 21478 Saudi Arabia Tel +966 2 6370999 / 6081100 Fax +966 2 6365925 / 6379439 Email: spsvalve@sps.net.sa : www.saudivalve.com

63

Before starting excavation, trench dimensions should be determined with the following considerations: Pipe size, outside diameter of jacket pipe. Anticipated traffic and surface load after backfill. Type of pipe joint; mechanical coupling joints require more space around the pipe. Field Joint Insulation Adequate space for installation Space for any other services Any local authority requirements

The base of the trench should have a sand bed of at least 100mm thick. This sand layer must be compacted and levelled to provide support for the pipe along its entire length.

After the pipes are installed and the joints are insulated, sand backfilling should be carried out manually and compacted by hand for a total thickness of 200mm above the casing pipe.

Main Office : Jeddah Industrial Zone Phase 4, P. O. Box: 34572, Jeddah: 21478 Saudi Arabia Tel +966 2 6370999 / 6081100 Fax +966 2 6365925 / 6379439 Email: spsvalve@sps.net.sa : www.saudivalve.com

113

Main Office : Jeddah Industrial Zone Phase 4, P. O. Box: 34572, Jeddah: 21478 Saudi Arabia Tel +966 2 6370999 / 6081100 Fax +966 2 6365925 / 6379439 Email: spsvalve@sps.net.sa : www.saudivalve.com

Potrebbero piacerti anche

- Saudi PipesDocumento47 pagineSaudi Pipesneels06274Nessuna valutazione finora

- aHR0cDovL3d3dy5pbnRlci1waXBlLmFlL0dsYXNzJTIwRmliZXIlMjBSZWluZm9yY2VkJTIw PDFDocumento43 pagineaHR0cDovL3d3dy5pbnRlci1waXBlLmFlL0dsYXNzJTIwRmliZXIlMjBSZWluZm9yY2VkJTIw PDFArun VaithyanathanNessuna valutazione finora

- SBN Corp Profile - 2 PDFDocumento33 pagineSBN Corp Profile - 2 PDFSyafiq KamaluddinNessuna valutazione finora

- Pipe Specification-1 PDFDocumento37 paginePipe Specification-1 PDFzamijakaNessuna valutazione finora

- HDPE Pipe Fittings Fabrication Equipment Sales Rentals TrainingDocumento113 pagineHDPE Pipe Fittings Fabrication Equipment Sales Rentals TrainingGomes TosnomosNessuna valutazione finora

- Corruge Pipe Report PDFDocumento24 pagineCorruge Pipe Report PDFyojuandaNessuna valutazione finora

- PE Technical ManualDocumento68 paginePE Technical ManualMuhammad SalmanNessuna valutazione finora

- Producing Corrugated Pipes 200-800mmDocumento24 pagineProducing Corrugated Pipes 200-800mmdirect2aakashNessuna valutazione finora

- HDPEDocumento16 pagineHDPEfirengineerNessuna valutazione finora

- Mfgil - GRP Brochure PDFDocumento24 pagineMfgil - GRP Brochure PDFmay lintoNessuna valutazione finora

- PE Yellow Gas - WebDocumento16 paginePE Yellow Gas - WebGavin KwanNessuna valutazione finora

- Hose TestingDocumento7 pagineHose Testingaan_pkppkNessuna valutazione finora

- Global Transmission Sleeve: Product Data SheetDocumento2 pagineGlobal Transmission Sleeve: Product Data SheetgoumrisalimaNessuna valutazione finora

- HDPE FittingsApril2012Documento110 pagineHDPE FittingsApril2012Carlos GutierrezNessuna valutazione finora

- Polyolefin Pipe Inuslation - AerofoamDocumento150 paginePolyolefin Pipe Inuslation - AerofoamIrshad BPNessuna valutazione finora

- Al Bilad Factory for HDPE and PP PipesDocumento53 pagineAl Bilad Factory for HDPE and PP PipesQuerubin R Yolando Jr.Nessuna valutazione finora

- HDPE SubmittalDocumento32 pagineHDPE SubmittalmostafaNessuna valutazione finora

- Protective Epoxy Primer for Steel and Non-Ferrous MetalsDocumento6 pagineProtective Epoxy Primer for Steel and Non-Ferrous MetalsdianaR339900Nessuna valutazione finora

- Bauder Thermofolbrochure May2010Documento12 pagineBauder Thermofolbrochure May2010Deana WhiteNessuna valutazione finora

- RLADocumento3 pagineRLAgopalakrishnannrm1202Nessuna valutazione finora

- VEM CatalogueDocumento6 pagineVEM CatalogueMeriam KetataNessuna valutazione finora

- E40000 Aquatherm Red Pipe 02Documento74 pagineE40000 Aquatherm Red Pipe 02Akram FerchichiNessuna valutazione finora

- ISC2 Series Broch A4Documento6 pagineISC2 Series Broch A4isosicaNessuna valutazione finora

- Qatar Pipeline & Fittings HDPE CatalogueDocumento10 pagineQatar Pipeline & Fittings HDPE CatalogueJayakrishnan RadhakrishnanNessuna valutazione finora

- PFI-ES-05 (Cleaning 2006) PDFDocumento2 paginePFI-ES-05 (Cleaning 2006) PDFRamesh Kumar RamisettiNessuna valutazione finora

- HDPEDrainage07OCT2021 05 04 2022Documento48 pagineHDPEDrainage07OCT2021 05 04 2022NoorudheenEVNessuna valutazione finora

- Upload Items Files 1570559467Documento19 pagineUpload Items Files 1570559467tajman90Nessuna valutazione finora

- Cellular Glass DatasheetDocumento2 pagineCellular Glass DatasheetNhat Thanh DangNessuna valutazione finora

- GRP Product GuideDocumento20 pagineGRP Product Guidedp75Nessuna valutazione finora

- Borusan-Mannesmann Pipe Industry LeadershipDocumento32 pagineBorusan-Mannesmann Pipe Industry LeadershipCarlos Torres Oliveros100% (1)

- Ves 5145 R3Documento10 pagineVes 5145 R3danikakaNessuna valutazione finora

- Waterproofing, Lining, Tunnel, Geomembrane Manual: Carlisle'SDocumento91 pagineWaterproofing, Lining, Tunnel, Geomembrane Manual: Carlisle'SGirdan BogdanNessuna valutazione finora

- PPSA Special Section Pipeline DevelopmentsDocumento6 paginePPSA Special Section Pipeline DevelopmentsJuan Roberto López BetanzosNessuna valutazione finora

- #1027 Primer CoatingDocumento6 pagine#1027 Primer CoatingChairul AnwarNessuna valutazione finora

- Delphi Liquid Silicone and Elastomer TechnologiesDocumento6 pagineDelphi Liquid Silicone and Elastomer Technologiesmirco1Nessuna valutazione finora

- Ameron CatalogDocumento719 pagineAmeron CatalogLeianne050610100% (5)

- Sigmacover 630 March 13Documento6 pagineSigmacover 630 March 13leonciomavarezNessuna valutazione finora

- Style 997 Transition Coupling HDPE Plastic To Steel: Product DescriptionDocumento2 pagineStyle 997 Transition Coupling HDPE Plastic To Steel: Product DescriptionJason MillerNessuna valutazione finora

- Sikagard-670 WMYDocumento3 pagineSikagard-670 WMYNARUdaARCNessuna valutazione finora

- GRP Non Circular Pipe SystemsDocumento16 pagineGRP Non Circular Pipe Systemsseby_77Nessuna valutazione finora

- Introduction to Gulf Cable & Electrical Industries Co. KSC (less than 40 charsDocumento164 pagineIntroduction to Gulf Cable & Electrical Industries Co. KSC (less than 40 charsRafat OsmanNessuna valutazione finora

- Sika PDS - E - Sarnafil G 476 PDFDocumento3 pagineSika PDS - E - Sarnafil G 476 PDFlwin_oo2435Nessuna valutazione finora

- E 9114 - Sika Unitherm 7854Documento3 pagineE 9114 - Sika Unitherm 7854didapopescuNessuna valutazione finora

- Semi Conductive Heat Shrink TubeDocumento2 pagineSemi Conductive Heat Shrink Tubesales3167Nessuna valutazione finora

- Wrapid BondDocumento2 pagineWrapid BondgrtunaNessuna valutazione finora

- JOHN GUEST Speedfit PlumbingDocumento80 pagineJOHN GUEST Speedfit PlumbingRui Miguel SilvaNessuna valutazione finora

- Cellular Glass DatasheetDocumento2 pagineCellular Glass DatasheetmishraenggNessuna valutazione finora

- Sigma PrimeDocumento7 pagineSigma Primegstketut0% (1)

- Viega ProPress Submittal PackageDocumento35 pagineViega ProPress Submittal PackageJeremy YostNessuna valutazione finora

- BSL e CatalogueDocumento372 pagineBSL e CatalogueSyed Kareem IqbalNessuna valutazione finora

- Duke Plasto Technique PVTDocumento25 pagineDuke Plasto Technique PVTVishnu Suthar100% (1)

- Introduction. Registration LetterDocumento3 pagineIntroduction. Registration LetterAnonymous p77pedOhPMNessuna valutazione finora

- Info On HDPE PipesDocumento49 pagineInfo On HDPE PipesH.V. Patil100% (1)

- Thermal Insulation Handbook for the Oil, Gas, and Petrochemical IndustriesDa EverandThermal Insulation Handbook for the Oil, Gas, and Petrochemical IndustriesValutazione: 3.5 su 5 stelle3.5/5 (3)

- Weld Like a Pro: Beginning to Advanced TechniquesDa EverandWeld Like a Pro: Beginning to Advanced TechniquesValutazione: 4.5 su 5 stelle4.5/5 (6)

- Residential Asphalt Roofing Manual Design and Application Methods 2014 EditionDa EverandResidential Asphalt Roofing Manual Design and Application Methods 2014 EditionNessuna valutazione finora

- Spot Welding Interview Success: An Introduction to Spot WeldingDa EverandSpot Welding Interview Success: An Introduction to Spot WeldingNessuna valutazione finora

- This Iz Reserved For My WifeDocumento2 pagineThis Iz Reserved For My WifeMuhammad FarhanNessuna valutazione finora

- SAP R/3 - Trainee in ABAP/4 Development As ABAP Programmer Primary & Foreign Keys, Include and Append Structure and Views, Search Objects TransactionDocumento3 pagineSAP R/3 - Trainee in ABAP/4 Development As ABAP Programmer Primary & Foreign Keys, Include and Append Structure and Views, Search Objects TransactionMuhammad Farhan0% (1)

- Cash InvoiceDocumento1 paginaCash InvoiceMuhammad FarhanNessuna valutazione finora

- KMK, LDocumento4 pagineKMK, LMuhammad FarhanNessuna valutazione finora

- Prod PrereqsDocumento8 pagineProd PrereqsMuhammad FarhanNessuna valutazione finora

- Diamond Aircraft Composite Training GuideDocumento109 pagineDiamond Aircraft Composite Training GuideWashington Masaquiza100% (1)

- Vishwakarma Entp Catalogue 2017 PDFDocumento18 pagineVishwakarma Entp Catalogue 2017 PDFAkash KulkarniNessuna valutazione finora

- Dip B1-6.3.1 - Aircraft Materials - Composite and Non-Metallic SR 2017-07-14Documento54 pagineDip B1-6.3.1 - Aircraft Materials - Composite and Non-Metallic SR 2017-07-14Fahad AlDossari100% (1)

- Grca Specification2006Documento0 pagineGrca Specification2006batteekhNessuna valutazione finora

- Boosting GRP Boatbuilding in the PhilippinesDocumento14 pagineBoosting GRP Boatbuilding in the Philippinesrafael espinosa semperNessuna valutazione finora

- Flowtite Pipe Systems Technical GuideDocumento36 pagineFlowtite Pipe Systems Technical Guide76027074Nessuna valutazione finora

- Habibi TMP assetMBWikNDocumento33 pagineHabibi TMP assetMBWikNasaad biqaiNessuna valutazione finora

- Loctite Solution GuideDocumento26 pagineLoctite Solution GuideAhmed Emad AhmedNessuna valutazione finora

- Astm D5685 PDFDocumento5 pagineAstm D5685 PDFprateekmuleNessuna valutazione finora

- Composites Strength PropertiesDocumento12 pagineComposites Strength Propertiesبلسم محمود شاكرNessuna valutazione finora

- Installation Instructions Owner'S Guide &: With ValveDocumento4 pagineInstallation Instructions Owner'S Guide &: With ValvetecnicoeemNessuna valutazione finora

- Waterproof Rooftop Balconies & DecksDocumento48 pagineWaterproof Rooftop Balconies & DeckspeterpaulwNessuna valutazione finora

- Mcgill Rocket Team Project BlancheDocumento50 pagineMcgill Rocket Team Project BlancheRitesh DubeyNessuna valutazione finora

- Koz Cable ClampsDocumento18 pagineKoz Cable ClampsshyamamolNessuna valutazione finora

- CTP Katalog WEBDocumento31 pagineCTP Katalog WEBNenad MarkovićNessuna valutazione finora

- BPI CatalogueDocumento44 pagineBPI Cataloguekate cacayNessuna valutazione finora

- Klingersil Brochure 0605Documento20 pagineKlingersil Brochure 0605tsaipeterNessuna valutazione finora

- Mbs Maintenance ManualDocumento24 pagineMbs Maintenance ManualTehreem AamirNessuna valutazione finora

- Heydar Aliyev Cultural Center BakuDocumento37 pagineHeydar Aliyev Cultural Center BakuAkshayah100% (3)

- Sassafras MKII Manual 14Documento118 pagineSassafras MKII Manual 14Rodrigo MirandaNessuna valutazione finora

- Trims and SealsDocumento44 pagineTrims and SealsboschirNessuna valutazione finora

- Smith Fibercast Green Thread Performance Plus Fiberglass Pipe Piping BrochureDocumento8 pagineSmith Fibercast Green Thread Performance Plus Fiberglass Pipe Piping BrochureWong Chung MengNessuna valutazione finora

- Fibrelogic Flowtite Engineering Guidelines DES M-004Documento122 pagineFibrelogic Flowtite Engineering Guidelines DES M-004Wilfredo GuerreroNessuna valutazione finora

- 11kV/22kV/33kV Composite Insulator SpecDocumento15 pagine11kV/22kV/33kV Composite Insulator SpecSandip AhireNessuna valutazione finora

- FRP Tank InspectionDocumento4 pagineFRP Tank InspectionDevin HardyNessuna valutazione finora

- Composite Materials: Nurul Farahin BT MusaDocumento30 pagineComposite Materials: Nurul Farahin BT MusaAhmad Faiz ShahidinNessuna valutazione finora

- BrochureDocumento11 pagineBrochureDieguitoOmarMoralesNessuna valutazione finora

- Composite Material NotesDocumento19 pagineComposite Material NotesManjunath ShettarNessuna valutazione finora

- BTT EB Specification Double Wall 08-07Documento13 pagineBTT EB Specification Double Wall 08-07Alonso VillaNessuna valutazione finora

- PASS START Prof DescriptionDocumento3 paginePASS START Prof DescriptionsrashmiiiscNessuna valutazione finora