Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

C75C - Ck75 Steel Data

Caricato da

vinibeDescrizione originale:

Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

C75C - Ck75 Steel Data

Caricato da

vinibeCopyright:

Formati disponibili

Steel CK75 (Mat.No. 1.

1248, DIN Ck75, AISI 1075)

Page 1 of 2

Steel Data

CK75

Identification

Designation by Standards Ravne No. Mat. No. 624 1.1248

Brand Name CK75

DIN Ck75

EN -

AISI 1075

Chemical Composition

Chemical Composition in Weight % Mn Cr Mo Ni 0.70 -

C 0.75

Si 0.25

V -

W -

Others -

General Information

Description This is one of the higher carbon steels used for high hardness in the fully hardened condition. In such condition the steel is more brittle than the lower carbon steels. Applications Quenched and subsequently tempered steel for cold rolled springs strips, wire, forgings, cutting tools, etc.

Properties

Physical properties (avarage values) at ambient temperature: Modulus of elasticity [103 x N/mm2]: 210 Density [g/cm3]: 7.85

Heat Treatment

Soft Annealing Anneal at 926?C and slow furnace cool. Hardening Hardens by cold working and heating and quenching. Tempering Temper, after heating and quenching, at 350-700?C. However this steel is most often used in the fully hardened condition (not tempered) of Rockwell C 55 or so.

Workability

Forging Hot forming temperature: 1050-850?C. Machinability The machinability of this steel suffers because of the high carbon content. It rates at 50% that of the AISI 1112 steel that is considered the 100% machinable base reference.

Other Information

Welding: CK75 steel is weldable by all of the welding methods. However with its higher carbon content it is important to use both pre-heat at 150 to 260?C and post-heat at 590 to 650?C practice per an approved welding procedure. Cold working: Cold working of CK75 is difficult even in the annealed condition. However it may be done by conventional methods but requires more force than for the low carbon steels. Forms manufactured: Please see the Dimensional Sales Program.

http://www.metalravne.com/selector/steels/ck75.html

12/8/2009

Steel CK75 (Mat.No. 1.1248, DIN Ck75, AISI 1075)

Page 2 of 2

Disclaimer The information and data presented herein are typical or average values and are not a guarantee of maximum or minimum values. Applications specifically suggested for material described herein are made solely for the purpose of illustration to enable the reader to make his own evaluation and are not intended as warranties, either express or implied, of fitness for these or other puposes. There is no representation that the recipient of this literature will receive updated editions as the become available. Unless otherwise specified, registered trademarks are property of Metal Ravne company. Copyright 2005 by Metal Ravne. All rights reserved. Contact our Sales Office or one of our International Sales Offices for more information. Edition Date: 11/04/2005

http://www.metalravne.com/selector/steels/ck75.html

12/8/2009

Potrebbero piacerti anche

- Weldability of Alloy 718, 625 and VariantsDocumento12 pagineWeldability of Alloy 718, 625 and VariantsAlberto ChazarretaNessuna valutazione finora

- Duplex Stainless Steel 2507-Spec-SheetDocumento2 pagineDuplex Stainless Steel 2507-Spec-SheetAnoob NarayananNessuna valutazione finora

- Mat - No. 1.1181, DIN Ck35, AISI 1035: Designation by StandardsDocumento2 pagineMat - No. 1.1181, DIN Ck35, AISI 1035: Designation by StandardsBill MurrayNessuna valutazione finora

- Duplex Stainless Steel - Welding-TwiDocumento4 pagineDuplex Stainless Steel - Welding-TwiNatrajj SivakumarNessuna valutazione finora

- S 275Documento3 pagineS 275tnchsgNessuna valutazione finora

- SCV GBDocumento2 pagineSCV GBGyanendraNessuna valutazione finora

- Alloy 625 Weld Overlays For Offshore and Onshore ProjectsDocumento15 pagineAlloy 625 Weld Overlays For Offshore and Onshore ProjectsMarco MilaniNessuna valutazione finora

- EldaDocumento28 pagineEldaEldayadi Nefty Rizky ArismawanNessuna valutazione finora

- AL-6XN SourcebookDocumento59 pagineAL-6XN SourcebooklkrzyzanNessuna valutazione finora

- Material Recommendations For Production of Wellhead and Christmas Tree ComponentsDocumento6 pagineMaterial Recommendations For Production of Wellhead and Christmas Tree ComponentsJAVID TAJHIZ MAHANNessuna valutazione finora

- OCR12VMDocumento4 pagineOCR12VMcvgfgNessuna valutazione finora

- Alloy 625 Spec SheetDocumento3 pagineAlloy 625 Spec SheetLinnie McleodNessuna valutazione finora

- Steels For Cryogenic and Low-Temperature Service - KEY To METALS ArticleDocumento3 pagineSteels For Cryogenic and Low-Temperature Service - KEY To METALS Articlekumarpankaj030Nessuna valutazione finora

- En 10025Documento16 pagineEn 10025Sorin Radu100% (1)

- 15-5 PHDocumento2 pagine15-5 PHfedaquiNessuna valutazione finora

- Low Alloy Steels For Cryogenic ApplicationsDocumento0 pagineLow Alloy Steels For Cryogenic ApplicationsidienNessuna valutazione finora

- Stainless Steel Grade 904LDocumento5 pagineStainless Steel Grade 904LMadan YadavNessuna valutazione finora

- ST523Documento1 paginaST523سعد شحودNessuna valutazione finora

- Steel Cleanliness ReportDocumento8 pagineSteel Cleanliness ReportSiva SubramaniNessuna valutazione finora

- Duplex Stainless Steel Part 1Documento2 pagineDuplex Stainless Steel Part 1aviant_gardNessuna valutazione finora

- Rolling Technology Training Programme - AnnealingDocumento52 pagineRolling Technology Training Programme - Annealingrabikm100% (1)

- Alloy 625 Spec SheetDocumento3 pagineAlloy 625 Spec SheetJSH100Nessuna valutazione finora

- Welding of HSLA Steels: Weldability and Joining of MaterialsDocumento2 pagineWelding of HSLA Steels: Weldability and Joining of MaterialsMehmet SoysalNessuna valutazione finora

- Alloy Steels 8620: Chemistry DataDocumento6 pagineAlloy Steels 8620: Chemistry DataVijay PalNessuna valutazione finora

- Inconel 625Documento3 pagineInconel 625alokbdasNessuna valutazione finora

- Use of Alloy 718 and 725 in Oil and Gas IndustryDocumento9 pagineUse of Alloy 718 and 725 in Oil and Gas IndustryEddyWangNessuna valutazione finora

- Cladding & Overlay - Ni InstituteDocumento24 pagineCladding & Overlay - Ni Institutesajid aslamNessuna valutazione finora

- Effects of HT On Continuous Cast Direct Rrolling 6065, Cold Rolling Char, Tensile Fracture PropertiesDocumento13 pagineEffects of HT On Continuous Cast Direct Rrolling 6065, Cold Rolling Char, Tensile Fracture PropertiestarunNessuna valutazione finora

- Arcelormittal Pressure VesselDocumento10 pagineArcelormittal Pressure VesselkokopirokoNessuna valutazione finora

- China Steel Nippon CRC PDFDocumento30 pagineChina Steel Nippon CRC PDFsuksesNessuna valutazione finora

- Superalloys 1997 447 458Documento12 pagineSuperalloys 1997 447 458Jacky ChinNessuna valutazione finora

- Welding of HSLA Steels - Job Knowledge 98Documento2 pagineWelding of HSLA Steels - Job Knowledge 98tuanNessuna valutazione finora

- AISI 1020 Low Carbon/Low Tensile Steel: Element ContentDocumento4 pagineAISI 1020 Low Carbon/Low Tensile Steel: Element ContentRatno WijayaNessuna valutazione finora

- Inconel 625 Significance in The Industrial ApplicationsDocumento7 pagineInconel 625 Significance in The Industrial Applicationsheanjiametals100% (1)

- Material Properties Required For Design: Strength Toughness Ductility Weldability DurabilityDocumento3 pagineMaterial Properties Required For Design: Strength Toughness Ductility Weldability DurabilityCvaShangkaranNessuna valutazione finora

- Niobium Microalloyed Cold Heading Steel Wire Rods Without Heat Treatment For Fastener ApplicationsDocumento7 pagineNiobium Microalloyed Cold Heading Steel Wire Rods Without Heat Treatment For Fastener Applicationsnvc_vishwanathanNessuna valutazione finora

- 1.2436 (62-63HRc)Documento3 pagine1.2436 (62-63HRc)Michel PortalNessuna valutazione finora

- Astm A 143M-03Documento3 pagineAstm A 143M-03MritunjayNessuna valutazione finora

- Cu Ni FabricationDocumento28 pagineCu Ni FabricationAli Varmazyar100% (1)

- Annealing FundamentalsDocumento41 pagineAnnealing FundamentalsSuvro ChakrabortyNessuna valutazione finora

- S7 Tool Steel: What Is ?Documento3 pagineS7 Tool Steel: What Is ?Sama UmateNessuna valutazione finora

- Job Knowledge 100Documento3 pagineJob Knowledge 100Mehmet SoysalNessuna valutazione finora

- 9 Information Series Casting of Stainless SteelDocumento6 pagine9 Information Series Casting of Stainless SteelDgk RajuNessuna valutazione finora

- 2507 Spec SheetDocumento2 pagine2507 Spec SheetlazaroccsNessuna valutazione finora

- 17 4Documento2 pagine17 4fedaquiNessuna valutazione finora

- Histar ASTM A913 Seismic Ncee en PDFDocumento10 pagineHistar ASTM A913 Seismic Ncee en PDFGicuNessuna valutazione finora

- Plate A516 and A387 - Pressure Vessel SteelsDocumento16 paginePlate A516 and A387 - Pressure Vessel SteelsaladinsaneNessuna valutazione finora

- SIQUAL 5736 Steel: Designation by StandardsDocumento1 paginaSIQUAL 5736 Steel: Designation by Standardsarjun prajapatiNessuna valutazione finora

- Uns 925 Data SheetDocumento1 paginaUns 925 Data SheetsavanNessuna valutazione finora

- Wb8018-C1 M.M.A. Welding Electrode: Welding@wballoys - Co.ukDocumento1 paginaWb8018-C1 M.M.A. Welding Electrode: Welding@wballoys - Co.uksoroush1111Nessuna valutazione finora

- Oxy-Acetylene Welding and Cutting: Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonDa EverandOxy-Acetylene Welding and Cutting: Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonNessuna valutazione finora

- Advances in Solid Oxide Fuel Cells XDa EverandAdvances in Solid Oxide Fuel Cells XMihails KusnezoffNessuna valutazione finora

- Welding Craft Practice: Oxy-Acetylene Gas Welding and Related StudiesDa EverandWelding Craft Practice: Oxy-Acetylene Gas Welding and Related StudiesNessuna valutazione finora

- The Art of Welding: Practical Information and Useful Exercises for Oxyacetylene and Electric Arc WeldingDa EverandThe Art of Welding: Practical Information and Useful Exercises for Oxyacetylene and Electric Arc WeldingNessuna valutazione finora

- Handbook of Structural Welding: Processes, Materials and Methods Used in the Welding of Major Structures, Pipelines and Process PlantDa EverandHandbook of Structural Welding: Processes, Materials and Methods Used in the Welding of Major Structures, Pipelines and Process PlantValutazione: 3.5 su 5 stelle3.5/5 (3)

- Advanced and Refractory Ceramics for Energy Conservation and EfficiencyDa EverandAdvanced and Refractory Ceramics for Energy Conservation and EfficiencyHua-Tay LinNessuna valutazione finora

- Cathodic Corrosion Protection Systems: A Guide for Oil and Gas IndustriesDa EverandCathodic Corrosion Protection Systems: A Guide for Oil and Gas IndustriesValutazione: 4.5 su 5 stelle4.5/5 (5)

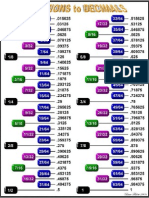

- Inch Fraction To Decimal ChartDocumento1 paginaInch Fraction To Decimal ChartvinibeNessuna valutazione finora

- Welding PositionDocumento6 pagineWelding Positionenels77Nessuna valutazione finora

- Or IngDocumento160 pagineOr IngvinibeNessuna valutazione finora

- Power Supply Voltage Around The WorldDocumento2 paginePower Supply Voltage Around The WorldvinibeNessuna valutazione finora

- Fundam Mech VibrationDocumento39 pagineFundam Mech VibrationRicardo ColosimoNessuna valutazione finora

- Fundam Mech VibrationDocumento39 pagineFundam Mech VibrationRicardo ColosimoNessuna valutazione finora

- Sanjay ProjectDocumento41 pagineSanjay ProjectPrynka RawatNessuna valutazione finora

- Oracle Partner Management-I PDFDocumento160 pagineOracle Partner Management-I PDFMukesh ManwaniNessuna valutazione finora

- Department of Education: Republic of The PhilippinesDocumento5 pagineDepartment of Education: Republic of The PhilippinesMirriam VillanuevaNessuna valutazione finora

- Chap002 - Competitivness, Strategy & ProductivityDocumento76 pagineChap002 - Competitivness, Strategy & ProductivityMohamed GalbatNessuna valutazione finora

- ERP (Enterprise Resource Planning)Documento7 pagineERP (Enterprise Resource Planning)NicoleNessuna valutazione finora

- Industrial House Keeping Through 5S Technique (HINDI)Documento79 pagineIndustrial House Keeping Through 5S Technique (HINDI)Aman Singh90% (69)

- Cost Chap 6 ContinuationDocumento7 pagineCost Chap 6 ContinuationPeter Paul DeiparineNessuna valutazione finora

- Wilson Tool X-Sharp CMGDocumento2 pagineWilson Tool X-Sharp CMGSM TECH SRLNessuna valutazione finora

- International Business Agreements: This Photo by Unknown Author Is Licensed Under CC BY-SADocumento21 pagineInternational Business Agreements: This Photo by Unknown Author Is Licensed Under CC BY-SAChinny PrenksamarNessuna valutazione finora

- Procure To Pay CircleDocumento2 pagineProcure To Pay CirclePuviNessuna valutazione finora

- Case Study About RolexDocumento6 pagineCase Study About Rolexrahmatullah KhairiNessuna valutazione finora

- Product Differentiation and ExamplesDocumento8 pagineProduct Differentiation and ExamplesApplopediaNessuna valutazione finora

- Competitor Inte-WPS OfficeDocumento3 pagineCompetitor Inte-WPS OfficeRabia khanNessuna valutazione finora

- Case Study1Documento17 pagineCase Study1Christine Alderama MurilloNessuna valutazione finora

- Toyota's Lean Lessons For WiproDocumento1 paginaToyota's Lean Lessons For WiproSam Chandran C100% (1)

- 200120-NSH AMC CONTRACT ConceptDocumento22 pagine200120-NSH AMC CONTRACT ConceptSaurabh YadavNessuna valutazione finora

- Almighty Containers Freight Stations Pvt. Ltd. (C.F.S: Ghavan Phata, Village Wahal Tal. Uran, Dist. Raigadh - Mumbai)Documento12 pagineAlmighty Containers Freight Stations Pvt. Ltd. (C.F.S: Ghavan Phata, Village Wahal Tal. Uran, Dist. Raigadh - Mumbai)Harsh AgrawalNessuna valutazione finora

- 2.SALES AND MARKE-WPS OfficeDocumento36 pagine2.SALES AND MARKE-WPS OfficeIts JohnNessuna valutazione finora

- Is There A Philippine Public Administrat PDFDocumento63 pagineIs There A Philippine Public Administrat PDFRona MayNessuna valutazione finora

- Quality Management System For Garment ManufacturingDocumento6 pagineQuality Management System For Garment ManufacturingAman Jain100% (3)

- Raj-Ratan: Welcomes YouDocumento23 pagineRaj-Ratan: Welcomes Youshantanu_adhicaryNessuna valutazione finora

- Management of Document ControlDocumento33 pagineManagement of Document Controlanon_627522566100% (1)

- The Innovation of Grocery StoresDocumento2 pagineThe Innovation of Grocery StoresLượng Vũ ĐứcNessuna valutazione finora

- AD - Delhi Meeting ListDocumento5 pagineAD - Delhi Meeting ListDevasyrucNessuna valutazione finora

- Deloitte Risk Management 2012Documento20 pagineDeloitte Risk Management 2012Julio RomoNessuna valutazione finora

- PVD and CVDDocumento13 paginePVD and CVDDishika PoddarNessuna valutazione finora

- Tareq CRMDocumento27 pagineTareq CRMtareq ranjbariNessuna valutazione finora

- Ch6 StudentsDocumento64 pagineCh6 StudentsSinethemba SibekoNessuna valutazione finora

- Group 4 Presentation - Pampers FinalDocumento17 pagineGroup 4 Presentation - Pampers Finalapi-581855371Nessuna valutazione finora

- Organization Change Management Plan TemplateDocumento4 pagineOrganization Change Management Plan Templateayansane635Nessuna valutazione finora