Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

TTTech Automotive Inverter Safety Unit Flyer 01

Caricato da

davidgaouwDescrizione originale:

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

TTTech Automotive Inverter Safety Unit Flyer 01

Caricato da

davidgaouwCopyright:

Formati disponibili

Inverter Safety Unit

Monitoring unit for safety-related electric drive systems

With the increasing electrification of the drive train, new components are playing a more and more important role in system safety. Supervising the torque generated by the electric motor is crucial. Even in case of a failure the torque must remain under control since most systems do not have a clutch or any other mechanism that could mechanically disconnect the electric motor from the wheels. With the Inverter Safety Unit (ISU), TTTech Automotive has developed a modular monitoring unit for inverters which continuously monitors the torque generated by the connected electric motor by evaluating the electrical signals. In case of failure, the ISU brings the system to the safe state via internal and external shut-down paths. Specialized Variation of TTC 90 Hardware The ISU is a hardware variation of TTC 90 that is specialized according to ISO/DIS 26262 ASIL C, and which has an XC2287M and HC908 CPU core. The safety control unit uses a special sensor system and innovative algorithms to calculate the actual moment and independently detect errors that could cause safety goals to be breached.

KEY FEATURES/BENEFITS 80 MHz CPU for continuous torque monitoring and shut-down decision Comprehensive self-diagnostics Permanent mutual monitoring of main CPU and watchdog CPU ISO 26262, ASIL C certifiable Complements existing drive train components (developed according to QM) Customer-specific integration possible

Self-Contained Monitoring Unit If the deviation between the target and the actual moment is too great, the safe state of the electric power train is entered through internal and external shut-off paths. The ISU can be integrated into the power train as a self-contained monitoring unit, or be integrated into the inverter itself.

Features 80 MHz CPU for torque monitoring and shut-down decision 4 current sensors (hall effect) 6 configurable outputs (for shut-down paths) 2 CAN-interfaces 1 FlexRay-channel (optional) Inputs 3 x voltage measurement of motor phases (up to 288 Vp) 3 x current measurement of motor phases (up to 700 Ap) 1 x current measurement of DC current (up to 700 A) 2 digital inputs (optional for quadrature signal) 2 analog inputs (optional) Functional Safety System consisting of inverter und Inverter Safety Unit: ISO 26262 ASIL C

Bus Interfaces 2 x CAN, up to 1 Mbit/s optional: 1 x FlexRay 10 Mbit/s System CPU Infineon 16/32-bit XC2287M main CPU with Memory Protection Unit, 80 MHz, 832 kB int. Flash, 58 kB int. RAM 8 kB EEPROM Freescale HC908 watchdog CPU Outputs 3 digital outputs up to 1 A, high-side switches for external shut-down paths 2 of them configurable as inputs (optional) ON/OFF or PWM capability 3 digital outputs for internal shut-down paths to inverter

TTTech Automotive contact information Headquarter Europe, Austria Tel.: +43 1 585 65 38-5000 E-Mail: products@tttech-automotive.com Germany Tel.: +49 8458 39 7603-0 E-Mail: products@tttech-automotive.com

www.tttech-automotive.com

Asien, Japan Tel.: +81 45 470 1867 E-Mail: products@tttech-automotive.com

Copyright TTTech Automotive GmbH. All rights reserved. All trademarks are the property of their respective holders. To the extent possible under applicable law, TTTech Automotive GmbH hereby disclaims any and all liability for the content and use of this flyer.

Potrebbero piacerti anche

- ABB Unitrol 6800 Brochure PDFDocumento12 pagineABB Unitrol 6800 Brochure PDFhvhung165Nessuna valutazione finora

- ABB Unitrol 6080 Excitation SystemDocumento12 pagineABB Unitrol 6080 Excitation SystemRajeev Thakur100% (3)

- 3bhs343110 E01 A oDocumento12 pagine3bhs343110 E01 A obacuoc.nguyen356Nessuna valutazione finora

- I-Monitor Flyer - 01-14-10Documento2 pagineI-Monitor Flyer - 01-14-10Novan WPNessuna valutazione finora

- InteliCompact NT Datasheet 2011-11 CPLEICNTDocumento6 pagineInteliCompact NT Datasheet 2011-11 CPLEICNTThao Nguyen XuanNessuna valutazione finora

- CY310 Product InfoDocumento2 pagineCY310 Product InfoAnonymous xTGQYFrNessuna valutazione finora

- tps653853 q1Documento13 paginetps653853 q1123Nessuna valutazione finora

- Freescale Kinetis M Customer 2014-03Documento17 pagineFreescale Kinetis M Customer 2014-03Andres Baena ZuluagaNessuna valutazione finora

- ST Digital Motion Engine DriversDocumento75 pagineST Digital Motion Engine DriversminitecoNessuna valutazione finora

- Tms 320 F 2803525Documento167 pagineTms 320 F 2803525jainil shahNessuna valutazione finora

- Panel 4008Documento8 paginePanel 4008westupinan7380Nessuna valutazione finora

- Chapter 6 - PLC Selection and MaintenanceDocumento50 pagineChapter 6 - PLC Selection and MaintenanceNurul Azimah Ahmad Arzaai100% (3)

- MDAHitachi VCS6000 Brochure1Documento8 pagineMDAHitachi VCS6000 Brochure1rhoney012Nessuna valutazione finora

- Vickers Electrics Db3 ManualDocumento138 pagineVickers Electrics Db3 ManualRana M. ZubairNessuna valutazione finora

- I815 - BrochureDocumento46 pagineI815 - Brochurecarruba14Nessuna valutazione finora

- Relay NM 10Documento8 pagineRelay NM 10Ayahnya Rizla Atha RayyanNessuna valutazione finora

- 3bht490300 E01 B oDocumento8 pagine3bht490300 E01 B oadinamartinsNessuna valutazione finora

- AzLM Axle COunters ReportDocumento44 pagineAzLM Axle COunters Reportcdevikar50% (2)

- Tyco Eclipse Traffic ControllerDocumento4 pagineTyco Eclipse Traffic Controlleradeewijaya32Nessuna valutazione finora

- Ai 708P PDFDocumento29 pagineAi 708P PDFAnthony CasasNessuna valutazione finora

- Ai Series Artificial Intelligence Industrial ControllerDocumento30 pagineAi Series Artificial Intelligence Industrial ControllerMatt WrightNessuna valutazione finora

- I/A Series Hardware: ® Product SpecificationsDocumento20 pagineI/A Series Hardware: ® Product Specificationsrasim_m1146Nessuna valutazione finora

- The Drive Design of The STM32-based Brushless DC Motor: Song Wang, Wang Guo, Wenqiang DunDocumento9 pagineThe Drive Design of The STM32-based Brushless DC Motor: Song Wang, Wang Guo, Wenqiang DunMarco LisiNessuna valutazione finora

- Remote Speed Control by Thyristor Trigger Angle Change With Display of Delayed Firing AngleDocumento18 pagineRemote Speed Control by Thyristor Trigger Angle Change With Display of Delayed Firing Anglemahasweta banerjeeNessuna valutazione finora

- Falcon - Alarm System That Will Fit Any Type of Vehicle.Documento2 pagineFalcon - Alarm System That Will Fit Any Type of Vehicle.Israel ExporterNessuna valutazione finora

- Digital Relay HardDocumento10 pagineDigital Relay HardSharmaine MeranoNessuna valutazione finora

- NM20 Flyer 08 2012 PDFDocumento12 pagineNM20 Flyer 08 2012 PDFandy175Nessuna valutazione finora

- Control: Monitoring With IntelligenceDocumento4 pagineControl: Monitoring With IntelligenceyoeckoeNessuna valutazione finora

- DKG207 PDFDocumento2 pagineDKG207 PDFRoberto MerizaldeNessuna valutazione finora

- ATMEL High Temp H BridgeDocumento13 pagineATMEL High Temp H BridgeGoran ŠtetinNessuna valutazione finora

- Automation Component AK 1703 ACP: Answers For EnergyDocumento6 pagineAutomation Component AK 1703 ACP: Answers For EnergybepperigaNessuna valutazione finora

- Scada Compone NTS: Prepared By:-Animesh Ghosh Roll No - 4 M.Tech (EE)Documento28 pagineScada Compone NTS: Prepared By:-Animesh Ghosh Roll No - 4 M.Tech (EE)Animesh GhoshNessuna valutazione finora

- 509 ITM Back Deck March 2011 PDFDocumento68 pagine509 ITM Back Deck March 2011 PDFmartin zunigaNessuna valutazione finora

- Integrator Series AC DrivesDocumento9 pagineIntegrator Series AC Drivesjohxav10Nessuna valutazione finora

- Railway Accident Monitoring System: A Project Report ONDocumento13 pagineRailway Accident Monitoring System: A Project Report ONPrateek SrivastavNessuna valutazione finora

- Td02600004e Emr-4000Documento20 pagineTd02600004e Emr-4000CristhJuliang100% (1)

- 1 OverviewDocumento6 pagine1 Overviewupper paunglaungNessuna valutazione finora

- Doc9166s PDFDocumento109 pagineDoc9166s PDFWaseem WisalNessuna valutazione finora

- Allen Bradley MCC ArchitectureDocumento2 pagineAllen Bradley MCC Architecturewvwinters100% (2)

- Exfire360 Fire&Gas Control PanelDocumento6 pagineExfire360 Fire&Gas Control PanelKorichiKarimNessuna valutazione finora

- CDA3000Documento2 pagineCDA3000Edilson AmilNessuna valutazione finora

- EPC 15 and 30 Data SheetDocumento2 pagineEPC 15 and 30 Data SheetNordson Adhesive Dispensing SystemsNessuna valutazione finora

- At91sam7s64 DsDocumento491 pagineAt91sam7s64 DsLord_JoelNessuna valutazione finora

- Atxmega16 128a4uDocumento121 pagineAtxmega16 128a4udiegoquindioNessuna valutazione finora

- First Revzcn, Zxiew Project ReportDocumento11 pagineFirst Revzcn, Zxiew Project ReportamkrishnakumarNessuna valutazione finora

- 327 DatatakomDocumento2 pagine327 DatatakomNorman RuizNessuna valutazione finora

- HariffDocumento20 pagineHariffMuflich PuteraNessuna valutazione finora

- Wolftrack: Installation ManualDocumento19 pagineWolftrack: Installation ManualchauduonguyenNessuna valutazione finora

- Sitop Psu8600 enDocumento8 pagineSitop Psu8600 endineshsoni29685Nessuna valutazione finora

- Hercules IntroductionDocumento29 pagineHercules IntroductionMañe CasillasNessuna valutazione finora

- PC1616 PC1832 PC1864 V4 2 Installation Manual enDocumento68 paginePC1616 PC1832 PC1864 V4 2 Installation Manual enScarlat MadalinNessuna valutazione finora

- 3.3V and 5.0V pASIC 2 Fpga Combining Speed, Density, Low Cost and FlexibilityDocumento10 pagine3.3V and 5.0V pASIC 2 Fpga Combining Speed, Density, Low Cost and FlexibilityCristian Camilo Lara MonteroNessuna valutazione finora

- Networked Control System: Fundamentals and ApplicationsDa EverandNetworked Control System: Fundamentals and ApplicationsNessuna valutazione finora

- Practical Data Acquisition for Instrumentation and Control SystemsDa EverandPractical Data Acquisition for Instrumentation and Control SystemsNessuna valutazione finora

- Preliminary Specifications: Programmed Data Processor Model Three (PDP-3) October, 1960Da EverandPreliminary Specifications: Programmed Data Processor Model Three (PDP-3) October, 1960Nessuna valutazione finora

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1Da EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1Valutazione: 2.5 su 5 stelle2.5/5 (3)

- EYE DiagramDocumento10 pagineEYE DiagramNuwan WeerasekaraNessuna valutazione finora

- 19b LCD Display 1602Documento4 pagine19b LCD Display 1602Nguyen Thai Bao (K15 HL)Nessuna valutazione finora

- Node-B Wcdma EricssonDocumento54 pagineNode-B Wcdma Ericssonfalberto08100% (3)

- X130 SVC Eng 091225Documento92 pagineX130 SVC Eng 091225oiramlopesNessuna valutazione finora

- REF54 Tob 750443 ENhDocumento158 pagineREF54 Tob 750443 ENhUday PowarNessuna valutazione finora

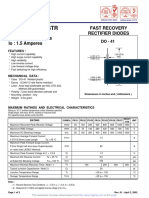

- FR151 - FR157-STR: Fast Recovery Rectifier Diodes PRV: 50 - 1000 Volts Io: 1.5 AmperesDocumento2 pagineFR151 - FR157-STR: Fast Recovery Rectifier Diodes PRV: 50 - 1000 Volts Io: 1.5 AmperesJOHN BRICCO A. MATACSILNessuna valutazione finora

- Digital TV Fundamentals Lectures For StudentsDocumento17 pagineDigital TV Fundamentals Lectures For StudentsVince MurilloNessuna valutazione finora

- LM 2936Documento17 pagineLM 2936a durgadeviNessuna valutazione finora

- General Specifications: Model ALP121 PROFIBUS-DP Communication Module (For N-IO/FIO)Documento7 pagineGeneral Specifications: Model ALP121 PROFIBUS-DP Communication Module (For N-IO/FIO)timsar1357Nessuna valutazione finora

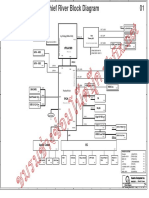

- Toshiba c840 m840 Daby3cmb8e0 SchematicDocumento49 pagineToshiba c840 m840 Daby3cmb8e0 SchematicDouble HelixNessuna valutazione finora

- 2SC3133Documento464 pagine2SC3133Pravin Mevada0% (1)

- Practical Clamping CircuitDocumento11 paginePractical Clamping Circuitarjuna4306Nessuna valutazione finora

- Tutorial Sheet Analog ElectronicsDocumento7 pagineTutorial Sheet Analog ElectronicsPraney KalraNessuna valutazione finora

- Design and Architecture of Intel's Core I7 ProcessorDocumento6 pagineDesign and Architecture of Intel's Core I7 Processorpratik mahajanNessuna valutazione finora

- Presentation 05272011Documento55 paginePresentation 05272011gkreuginerajNessuna valutazione finora

- B.E E&C Seventh Semester Syllabus Microwaves and AntennasDocumento15 pagineB.E E&C Seventh Semester Syllabus Microwaves and AntennasKausthubha BkNessuna valutazione finora

- Module 4 ACA NotesDocumento53 pagineModule 4 ACA NotesShylajaNessuna valutazione finora

- ECE745 Lec1 Course OverviewDocumento31 pagineECE745 Lec1 Course OverviewtreewindNessuna valutazione finora

- Ece2201 SJB Lab7x Audio Inv PDFDocumento7 pagineEce2201 SJB Lab7x Audio Inv PDFxiditoNessuna valutazione finora

- Evolis Zenius Troubleshooting GuideDocumento2 pagineEvolis Zenius Troubleshooting GuideAdorjan Sandor Zoltan100% (1)

- DSP Laboratory Activity 2 NewDocumento16 pagineDSP Laboratory Activity 2 NewBradLyBerroyaNessuna valutazione finora

- Yuan 2016Documento11 pagineYuan 2016Ahmed ShafeekNessuna valutazione finora

- Pocketpico Manual PDFDocumento17 paginePocketpico Manual PDFRichard BedellNessuna valutazione finora

- Habot Ollege: 4A-Cable Testing LabDocumento3 pagineHabot Ollege: 4A-Cable Testing LabArifAzizNessuna valutazione finora

- Tech. Specifications On Power TransformerDocumento2 pagineTech. Specifications On Power Transformershine1975Nessuna valutazione finora

- LDR Project RepoertDocumento35 pagineLDR Project Repoertsatvik100% (1)

- TV080WXM NL0 LenovoDocumento41 pagineTV080WXM NL0 Lenovozaur.bNessuna valutazione finora

- Physical Design GuidelinesDocumento4 paginePhysical Design Guidelinesjeevan_rao0% (1)

- Cad 1133 Powersupply FinalreportDocumento47 pagineCad 1133 Powersupply Finalreportapi-300000636Nessuna valutazione finora

- Turntable ManualDocumento2 pagineTurntable Manualreneleones0% (1)