Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

RSE013104

Caricato da

benlamfaceDescrizione originale:

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

RSE013104

Caricato da

benlamfaceCopyright:

Formati disponibili

Effect of wind speed and load power factor variation on optimal sizing of the machine and converters for

double output induction generator based stand-alone wind energy conversion systems

T. K. Saha, D. P. Bagarty, and D. Kastha Citation: J. Renewable Sustainable Energy 1, 013104 (2009); doi: 10.1063/1.3076056 View online: http://dx.doi.org/10.1063/1.3076056 View Table of Contents: http://jrse.aip.org/resource/1/JRSEBH/v1/i1 Published by the American Institute of Physics.

Additional information on J. Renewable Sustainable Energy

Journal Homepage: http://jrse.aip.org/ Journal Information: http://jrse.aip.org/about/about_the_journal Top downloads: http://jrse.aip.org/features/most_downloaded Information for Authors: http://jrse.aip.org/authors

Downloaded 31 Oct 2011 to 41.201.58.37. Redistribution subject to AIP license or copyright; see http://jrse.aip.org/about/rights_and_permissions

JOURNAL OF RENEWABLE AND SUSTAINABLE ENERGY 1, 013104 2009

Effect of wind speed and load power factor variation on optimal sizing of the machine and converters for double output induction generator based stand-alone wind energy conversion systems

T. K. Saha,1,a D. P. Bagarty,2,b and D. Kastha3,c

1

Department of Electrical Engineering, National Institute of Tech., Durgapur, W. B., 713209 India 2 Department of Electrical Engineering, College of Engg. & Tech., Bhubaneswar Orissa 751010, India 3 Department of Electrical Engineering, Indian Institute of Tech., Kharagpur, 721302 India Received 12 August 2008; accepted 7 January 2009; published online 10 February 2009

In this paper, an algorithm for nding out the optimal ratings of the machine and power electronic converters of a wind turbine driven stand-alone double output induction generator based variable speed constant frequency generation system is reported, which seeks to minimize the cost of energy generation. The nonlinear constrained optimization technique employed includes, among others, the reactive power balance constraints, which are not often considered for stand-alone systems. For this purpose, the load power factor is modeled as a random variable with known probability density function. The total energy captured is calculated for a given wind velocity density function and load power factor density function. The proposed method nally nds the optimum combination of machine and converter ratings, which results in minimum cost of energy. The effects of changes in load power factor and wind velocity distribution are also discussed in detail. 2009 American Institute of Physics. DOI: 10.1063/1.3076056

I. LIST OF SYMBOLS AND ACRONYMS

DOIG SQIM WECS DSP PWM IGBT SPWM PDF VSCF v vf Rt

t

Cp Cp

opt

t max

Double output induction generator Squirrel cage induction machine Wind energy conversion systems Digital signal processor Pulse width modulated Insulated gate bipolar transistor Sinusoidal PWM Probability density function Variable speed constant frequency Wind velocity Furling wind velocity Radius of turbine Tip speed ratio of turbine TSR Power coefcient of the turbine Maximum value of C p Tip speed ratio at which C p = 0

a b c

Electronic address: tapassaharec@yahoo.com Electronic address: dpbagarty03@yahoo.co.in Electronic address: kastha@ee.iitkgp.ernet.in 1, 013104-1 2009 American Institute of Physics

1941-7012/2009/1 1 /013104/17/$25.00

Downloaded 31 Oct 2011 to 41.201.58.37. Redistribution subject to AIP license or copyright; see http://jrse.aip.org/about/rights_and_permissions

013104-2

Saha, Bagarty, and Kastha

J. Renewable Sustainable Energy 1, 013104 2009

t max tf

n, g Pt max H

s / Rs , Rr Rms , Rmsq Rmr Rconv Xs , Xr Xm Note: / Ir , Is Ii Ias, Ibs, Ics Iar, Ibr, Icr / / Iqr , Idr Iqs , Ids Iqi , Idi Irms Vbase Ibase Vcond Vqs , Vds / / Vqr , Vdr e r sl m base

Csw on Csw off Pl max

Turbine speed at v f and t max Upper limiting value of TSR corresponding to turbine speed limit Gear ratio and gear efciency, respectively Maximum turbine output power at the furling wind velocity No. of hours in a year Stator ux linkage Power factor angle of the load Per phase stator and rotor resistance of the DOIG Per phase DOIG and SQIM stator core loss equivalent resistances at rated frequency Per phase DOIG rotor core loss equivalent resistance at rated frequency Equivalent resistance between the collector and the emitter of a conducting IGBT Per phase stator and rotor reactance at rated stator frequency Magnetizing reactance at rated stator frequency R The normalized value of any quantity like Rs is expressed as s, and it is also expressed as s, when expressed in machine base. r Rotor current and stator current respectively Stator side converter current for DOIG and front end converter current for SQIM Stator side machine currents Rotor side machine currents q and d axis components of rotor current q and d axis component of stator current q and d axis components of stator side converter current for DOIG RMS value of current Base voltage, taken as the peak value of the line voltage of the generator Base current computed with maximum turbine power as power base Constant part of the collector to emitter voltage drop of a conducting IGBT q and d axis components of stator voltage q and d axis components of rotor voltage Frequency of the stator in rad/s Electrical speed of the rotor in rad/s Slip frequency Angular speed of rotor in mech. rad/s Rated stator frequency in rad/sec Turn-on loss constant of IGBT Turn-off loss constant of IGBT Maximum output power of the system for any given wind velocity and load power factor

II. INTRODUCTION

A double output induction generator DOIG based wind energy conversion system comprises of a wound rotor induction machine and two pulse width modulated PWM voltage source converters, which are to be sized properly, so as to produce energy at minimum cost. In this paper, a detailed optimization technique is described to nd the ratings of these components. The modeling aspect of a DOIG based variable speed constant frequency VSCF system is addressed in Refs. 1 and 2. For stand-alone operation, the employed scheme controls the generator troque via one auxiliary load. Only resistive load has been considered in this paper. Another DOIG based VSCF system, analyzed in Ref. 8, considers both resistive and inductive loads. The paper describes a control algorithm for the complete system including voltage build-up phase. These models were used in Ref. 9 to calculate the maximum power extractable from wind under certain constraints. The paper nally presents a control algorithm to minimize electrical lossees in the generator. Net cost of energy in a wind energy generation system depends on the rating of the compo-

Downloaded 31 Oct 2011 to 41.201.58.37. Redistribution subject to AIP license or copyright; see http://jrse.aip.org/about/rights_and_permissions

013104-3

Effect of sizing of components

J. Renewable Sustainable Energy 1, 013104 2009

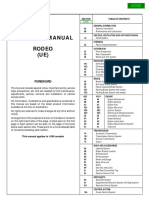

FIG. 1. Schematic block diagram of a DOIG based VSCF system.

nents that satisfy all technical constraints. Reference 10 outlines a methodology for sizing wind and pumped-hydro turbine ratings and reservoir capacities with a view toward optimizing the cost of electricity, using the software HOMER. Though the software studies the cost aspect in detail, it does not consider all technical constraints such as variation of output due to change in reactive demand, the current limit of back to back converters for stand-alone operation. Reference 3 describes a methodology to nd the size of battery storage based on the excess wind enegry available during opeartion. However, it does not consider the power electronic converters for the generators. Reference 4 describes different limitations of wind energy penetration in an autonomous system. The method described in this reference to nd the annualized cost of wind energy conversion systems has been used in this paper. Interestingly none of the studies except Ref. 7 presented a method to nd the actual size of the generators and converters required to extract power at minimum cost, from a given wind turbine, working in the stand-alone mode. Their work deals with a wind driven DOIG based stand-alone system, optimally operated under nonlinear equality and inequality constraints. But the effect of variation of load power factor distribution was not addressed there. Therefore, the objective in this paper is to nd the combination of machine and power converter ratings to produce electrical energy at minimum cost for given wind speed and load power factor probability density function. The steady state power ow equations involving a DOIG, a squirrel cage induction machine SQIM , and a known turbine are modeled. A control system to arrive at the steady state has been analyzed in detail in Ref. 8. A few representative results from an experimental prototype are included in this paper. The annual energy captured and unit energy cost from a DOIG and a SQIM based system are computed for a particular site data and are compared. Finally, the optimum combinations of machines and converters for a DOIG based system are determined for different load power factor proles and wind velocity proles.

III. DOIG BASED SYSTEM DESCRIPTION

Figure 1 shows the schematic block diagram of the DOIG based system under consideration. The load is connected at the stator side of the DOIG. Power generation is maintained from well below the synchronous speed up to double the synchronous speed when power output is almost double the stator rated power.

Downloaded 31 Oct 2011 to 41.201.58.37. Redistribution subject to AIP license or copyright; see http://jrse.aip.org/about/rights_and_permissions

013104-4

Saha, Bagarty, and Kastha

J. Renewable Sustainable Energy 1, 013104 2009

IV. THE OPTIMIZATION PROBLEM A. Problem statement

For a given: Turbine size and characteristics, the scale and shape parameters of the Weibull probability density function, used to model the wind speed data, the mean and variance of the Normal probability density function, used to model the load power factor variation, nd the optimum current rating of the machine, the stator side converter, and the rotor side converter so as to minimize the cost of energy generation.

B. Mathematical formulation

The following assumptions are made to solve the problem: The wind turbine is assumed to operate at steady state speed corresponding to the prevailing wind velocity. All the power generated by the system is consumed by the load. Under these assumptions, the power output from the DOIG system, which equals the load power, is given by PL = Xm / K sIqr Xs + Csw on + Csw on V2 V2 3 2 /2 Is Rs + Ir Rr base base 2 2Rms 2Rmr F.F. F.F. + Csw off + Csw off

/ VbaseIr sl base

Vcond Vcond

/ Ir /2 + RconvIr F.F.

/ VbaseIr

2KI 2KI

2KI 2KI

F.F. F.F.

3 ,

Ii + RconvI2 i F.F. 1

VbaseIi

VbaseIi

where PL = Mechanical power converted to electrical form in the generator Rotor and Stator copper loss Rotor and Stator core loss Converter conduction and switching loss , F . F . = Form factor of full wave rectied sine wave= 1.11, KI = Maximum voltage gain of PWM VSI = 0.612, Csw-on = Energy loss/ turn on * Switching frequency / voltage rating of the device * current rating of the device . Similarly Csw-off is also found for turn off. It is assumed that the energy loss data are obtained from the manufacturers data sheet for the rated voltage and current operation of the device. Normalizing the load power with respect to the maximum turbine output power Pt max, = PL , PL Pt max 1 3 A C popt vF . 2 2

where Pt max =

The inequality constraints are as follows: i Peak rotor current Rotor converter current limit. ii Peak stator side converter current Stator side converter current limit. iii Tip speed ratio should be such that at any wind speed the turbine speed lies within its optimum value and turbine speed limit. The normalized forms of these constraints are given by

Downloaded 31 Oct 2011 to 41.201.58.37. Redistribution subject to AIP license or copyright; see http://jrse.aip.org/about/rights_and_permissions

013104-5

Effect of sizing of components

J. Renewable Sustainable Energy 1, 013104 2009

/2 + /2 Idr Iqr 2 + 2 Idi Iqi topt

1/2

/ Ir max , Ii max , tf ,

1/2

5 6

where all currents are normalized with respect to Ibase. t is normalized with respect to t max. Equality constraints: i Power output from the turbine gMechanical losses in the generator= Mechanical power converted to electrical form in the generator. Power output from the turbine is given by the well known equation Pt = 1 AC pv3 . 2 7

C p as function of t is obtained from Ref. 5. The mechanical losses in the generator were found by experiment to follow the following equation: Mechanical losses = 0.0119 The normalized form of this equality constraint is v 0.000 28 2n t Iqr p

2 m 2

+ 1.7198

+ 0.000 13

v 2n t p

v C p 2 , t n

where p = no. of poles= 8 for the chosen machine. Cp , Cp = C p opt t =

t t max

,

opt

= v

v , vf

= n

n , no

no =

2 P

base t max

t max =

t maxv f

Rt

tf = min 1,

10

ii Active power balance: The net active power owing out of the dc link capacitor including inverter losses is zero so as to maintain dc link voltage constant. The normalized form of this constraint is s I r Lm I L s base didr + qiqr + qi = r base dr + qr mqr 1 t . Idi I I I2 I2 r I I I r I nv s Ls Ls Ir max Ir max x 11

Here all the impedances are normalized in machine base. iii Reactive power balance: The net reactive power demand by the load+ the reactive power demand by the generator = reactive power supplied by the converters. The normalized form of this constraint is + Iqi IdiIqr IqiIdr xm = Idr s r Ir max Ibase Ir max Ibase 1 s m rx Ls Lm

2

Idi s r

Ir max Ibase

L,

Ir max Ibase

+ L tan P

12

where L is found from Eq. 2 . P

Downloaded 31 Oct 2011 to 41.201.58.37. Redistribution subject to AIP license or copyright; see http://jrse.aip.org/about/rights_and_permissions

013104-6

Saha, Bagarty, and Kastha

J. Renewable Sustainable Energy 1, 013104 2009

TABLE I. Machine and converter parameters.

Name of parameter Value considered p.u. value in machine base p.u. values in system base

Rs 0.872 0.1511

Rr 0.8635 0.1497

Xs

Xr

Xm 11.294 1.9574

Rms 1452 251.64

Rmr 2420 419.41

Rms-sq 1814 314.4

Rconv 0.0428

Vcond 1V

Csw-on

Csw-off

12.414 12.414 2.1515 2.1515

1.3333 0.8333 103 103

0.0398

3.21

103

The objective function L was maximized subjected to the equality constraints 9 , 11 , and P 12 and inequality constraints 4 6 in ve variables, qi, di, qr, dr, and t, using Lagrangian I I II II technique. This procedure requires that an initial Guess Vector be supplied to the algorithm, which must satisfy all equality and inequality constraints.

C. Guess value selection

To get a global optimum solution, the whole feasible guess-vector space is divided in ve parts. Two sets of initial guess-vectors are chosen randomly from the boundary of each part and approximately the center set is also chosen as initial vector. This is to ensure that the optimization procedure involves several starting points to arrive at the globally optimized result. The optimized power is used to obtain total energy captured by the system.

D. Energy calculation

For every site the probability density function of the wind velocity is modeled by the two parameter Weibull function. The Weibull function is K v C C

K1

f v =

exp

v C

13

where K is the shape parameter and C is the scale parameter. They are variable from site to site. The load power factor probability density function is represented by the Normal function.

TABLE II. Range of component rating and costs per kW, KVA . For DOIG Rotor side conv rating 8.1 KVA

Turbine rating Initial power rating In p.u. Range of variation Cost 45 Kw at the furling wind speed a 1 Fixed 1 pu/ Kw

Generator rating 8.1 KVA

For DOIG Stator side conv rating 8.1 KVA

0.18 0.1 to 0.8 P.U. 0.075 pu/KVA

0.18 0.1 to 0.8 P.U. 0.1538 pu/KVA

0.18 0.8 to 1.4 times of rotor side Conv 0.1538 pu/ KVA

Turbine power rating= 15 Kw at 2/3rd of furling wind speed, which is considered as the rated wind speed of the turbine.

Downloaded 31 Oct 2011 to 41.201.58.37. Redistribution subject to AIP license or copyright; see http://jrse.aip.org/about/rights_and_permissions

013104-7

Effect of sizing of components

J. Renewable Sustainable Energy 1, 013104 2009

FIG. 2. Schematic diagram of the experimental setup.

FIG. 3. Voltage and current waveforms during load transient. a Load line voltage and phase current, and b machine stator and rotor line currents

Downloaded 31 Oct 2011 to 41.201.58.37. Redistribution subject to AIP license or copyright; see http://jrse.aip.org/about/rights_and_permissions

013104-8

Saha, Bagarty, and Kastha

J. Renewable Sustainable Energy 1, 013104 2009

FIG. 4. System variables during load transient. a dc link voltage and machine speed, b transformed machine currents, and c stator ux linkage.

f cos

1 2

exp

cos 2

14

where is the standard deviation and is the mean. cos and v are independent random variables, and multiplication of their individual probability density functions will produce their joint probability density functions. The joint probability gives the idea about the time of occurrence of a combination of a particular wind velocity with a particular load power factor. This can be multiplied by the optimized power to produce the energy captured by the system at that wind velocity and load power factor. Total yearwise schedule can thus be prepared by taking the whole range of both of the variables, i.e.,

FIG. 5. Maximum power with variable stator and rotor side converter rating.

Downloaded 31 Oct 2011 to 41.201.58.37. Redistribution subject to AIP license or copyright; see http://jrse.aip.org/about/rights_and_permissions

013104-9

Effect of sizing of components

J. Renewable Sustainable Energy 1, 013104 2009

FIG. 6. Schematic block diagram of a SQIM based VSCF system.

vf

+3

E Ii,Ir =

0 3

H . PL max v,cos

f cos

f v d cos

dv .

15

Using this equation, the net energy is calculated for each combination of machine and converters. is obtained from the optimization procedure described in Sec. IV B. PL max v , cos

E. Cost calculation

Total installation cost, U = ut + Ptr + umSm + uc Ssc + Src , 16

where ut is turbine cost/kW, um is machine cost/KVA, uc is converter cost/KVA, Ptr is turbine power rating, kW, Sm is machine rating, KVA, and Ssc and Src are stator side and rotor side converter ratings, KVA. The installation cost of the system can be annualized by multiplying the total installation cost U with the following annualization factor used in Ref. 4:

FIG. 7. Maximum power from SQIM with variable front end converter and stator side converter current rating.

Downloaded 31 Oct 2011 to 41.201.58.37. Redistribution subject to AIP license or copyright; see http://jrse.aip.org/about/rights_and_permissions

013104-10

Saha, Bagarty, and Kastha

J. Renewable Sustainable Energy 1, 013104 2009

FIG. 8. Energy captured by different machine and converters at a site with C = 11, K = 2.5,

= 0.9 lagging , and

= 0.1.

a=

r 1 1+r

TE

and r =

1+i 1, 1+u

where TE is the expected wind generator service time, i is the market interest rate, u is the ination rate, and r is the real interest rate. The total annual expenditure of the system is obtained by adding the operation and maintenance cost O&M cost with the annualized installation cost, i.e., Ua = aU + UomU, where Oom is the yearly O&M cost expressed as a percentage of the total installation cost.

F. Cost and size optimization

17

In order to nd the optimum size in the sense of minimum energy cost of each component, the total yearly energy generated for a given site with xed wind velocity and load power factor PDF is computed using Eq. 15 for a large number of combinations of machine and converter ratings within a certain range. The annualized installation cost is also found for each combination following the procedure described in Sec. IV E. For each combination, the unit cost of energy is obtained dividing the annual expenditure Ua of Eq. 17 by the total yearly energy generated of Eq. 15 . For a given site, the combination of machine and converter combination that achieves minimum unit energy cost is designated as the optimum combination. This optimum combination is then determined for a number of sites with varying wind speed and load power factor density functions.

Downloaded 31 Oct 2011 to 41.201.58.37. Redistribution subject to AIP license or copyright; see http://jrse.aip.org/about/rights_and_permissions

013104-11

Effect of sizing of components

J. Renewable Sustainable Energy 1, 013104 2009

FIG. 9. The cost of energy obtained by different machine and converters at a site with C = 11, K = 2.5, = 0.1.

= 0.9 lagging , and

V. CASE STUDY

The systems base values are taken as follows: Vbase = 220 2 V, Pbase = 45 kW, Ibase = 167.08 Amp, f base = 50 Hz, and vbase = vF = 25 m/s.

TABLE III. Optimum energy cost and converter ratings for the DOIG based system for different wind velocity PDF = 0.9, = 0.1 . K 1.5

l Ir

2

l Ir

2.5

l Ir

3

l Ir

3.5

C 4 5 6 7 8 9 10 11 12 13

l Ii Rate Ii Rate Ii Rate Ii Rate Ir Ii Rate US$/kWh p.u. p.u. US$/kWh p.u. p.u. US$/kWh p.u. p.u. US$/kWh p.u. p.u. US$/kWh p.u. p.u.

1.4747 0.6622 0.3658 0.2297 0.1624 0.1244 0.1023 0.08849 0.0795 0.0736

0.1 0.2 0.2 0.3 0.4 0.4 0.4 0.5 0.5 0.5

0.09 0.2 0.24 0.33 0.4 0.44 0.44 0.45 0.45 0.5

2.7982 1.1050 0.5772 0.3326 0.2126 0.1495 0.1114 0.0879 0.0734 0.0640

0.1 0.1 0.2 0.2 0.3 0.3 0.4 0.4 0.4 0.5

0.08 0.08 0.16 0.18 0.24 0.3 0.36 0.4 0.44 0.45

4.4479 1.4830 0.7202 0.4192 0.2597 0.1769 0.1258 0.0947 0.0743 0.0614

0.1 0.1 0.1 0.2 0.2 0.2 0.3 0.3 0.4 0.4

0.08 0.08 0.08 0.16 0.16 0.2 0.27 0.33 0.36 0.44

6.4411 1.8048 0.8225 0.4679 0.2914 0.1936 0.1379 0.1011 0.0777 0.0616

0.1 0.1 0.1 0.1 0.2 0.2 0.3 0.3 0.4 0.4

0.08 0.08 0.08 0.08 0.16 0.16 0.24 0.24 0.32 0.36

8 2.0715 0.8940 0.4968 0.3129 0.2049 0.1445 0.1060 0.0805 0.06303

0.1 0.1 0.1 0.1 0.2 0.2 0.2 0.3 0.3 0.4

0.08 0.08 0.08 0.08 0.16 0.16 0.24 0.24 0.32 0.36

Downloaded 31 Oct 2011 to 41.201.58.37. Redistribution subject to AIP license or copyright; see http://jrse.aip.org/about/rights_and_permissions

013104-12

Saha, Bagarty, and Kastha

J. Renewable Sustainable Energy 1, 013104 2009

FIG. 10. Cost of energy, by optimum combination of machines and by one xed combination of machines, for sites with different power factor prole.

The machine and converter parameters considered for the calculations are given at Table I. The constants used are also included in it. The cost of machine and converters are considered to be following recent trends.3,4 The range of component sizes and their cost per Kw or KVA considered are described in Table II. The parameters considered for annualizing the cost, are TE = 20 years, i = 13%, u = 6.6%, Cost: 1 p.u.= 1202.5 $. The operation and maintenance cost O&M can be assumed as 1% of total installation cost.4

TABLE IV. Optimum energy cost and converter ratings for the DOIG based system for different load power factor PDF C = 11, K = 2.5 .

0.025 Rate US$/kWh 1 0.95 0.9 0.85 0.8 0.75 0.7 0.08661 0.0879 0.0890 0.0899 0.0909 0.0920 0.0931

l Ir

0.05 Ii p.u. 0.27 0.3 0.33 0.36 0.39 0.44 0.48 Rate US$/kWh 0.0868 0.0879 0.0889 0.0899 0.0910 0.0920 0.932

l Ir

0.075 Ii p.u. 0.27 0.3 0.33 0.36 0.4 0.44 0.48 Rate US$/kWh 0.0870 0.0880 0.0890 0.0900 0.0911 0.0921 0.0934

l Ir

0.1 Ii p.u. 0.27 0.3 0.33 0.36 0.4 0.44 0.48 Rate US$/kWh 0.0873 0.0881 0.0891 0.0901 0.0912 0.0923 0.0936

l Ir p.u.

p.u. 0.3 0.3 0.3 0.3 0.3 0.4 0.4

p.u. 0.3 0.3 0.3 0.3 0.4 0.4 0.4

p.u. 0.3 0.3 0.3 0.3 0.4 0.4 0.4

Ii p.u. 0.27 0.3 0.33 0.36 0.4 0.44 0.48

0.3 0.3 0.3 0.4 0.4 0.4 0.4

Downloaded 31 Oct 2011 to 41.201.58.37. Redistribution subject to AIP license or copyright; see http://jrse.aip.org/about/rights_and_permissions

013104-13

Effect of sizing of components

J. Renewable Sustainable Energy 1, 013104 2009

FIG. 11. The cost of energy by optimum combinations of machines and by one xed combination of machines for different scale parameters.

FIG. 12. Optimum rating of rotor converter current for a different scale parameter.

Downloaded 31 Oct 2011 to 41.201.58.37. Redistribution subject to AIP license or copyright; see http://jrse.aip.org/about/rights_and_permissions

013104-14

Saha, Bagarty, and Kastha

J. Renewable Sustainable Energy 1, 013104 2009

FIG. 13. Optimum rating of rotor converter current for different shape parameters. Cost of energy generation from a DOIG based wind energy generation system, satisfying all operational constraints.

The power factor probability density function PDF for all the sites has been considered to follow Normal distribution. The mean of the distribution is varied from 0.7 lagging to unity power factor. The variance, , is varied from 0.025 to 0.1. A total of 28 different distributions are considered. The wind velocity PDF is considered to be following the Weibull distribution. The scale parameter C and shape parameter K are different for sites. After consulting several sources in the literature, the practical values of the C and K, in India, are found to be varying between 4 and 13 and 1.5 and 3.5, respectively.6 For the present analysis, 50 combinations of C and K are chosen.

VI. RESULTS

Figure 2 shows the schematic diagram of the prototype experimental DOIG based VSCF generator. The machine and the converters used in this setup have parameter values and ratings as given in Tables I and II initial power rating , respectively. The control algorithm as given in Ref. 8 has been implemented in the digital signal processor DSP based controller DS1104. Figures 3 and 4 show a few representative experimental results obtained from this setup. To obtain these results, the generator was operated at 1000 rpm at no load. At 15.6 s, 1.8 kW load at 0.86 pf lagging was switched on. Figure 3 a shows the load line voltage Vba and phase current Ib as captured in a digital storage oscilloscope. Figure 3 b shows the corresponding machine currents captured by the DSP. After the application of load, the load voltage reduces due to a drop in the machine stator resistance and lter inductance 5 mH per phase while all the currents increase. However, none of these waveforms show any undesirable oscillation, which demonstrates the effectiveness of the stator ux oriented control algorithm. Figure 4 a shows that both dc link voltage and machine speed start dropping on application of load. However, the dc link voltage settles back shortly to its reference value 400 V due to

Downloaded 31 Oct 2011 to 41.201.58.37. Redistribution subject to AIP license or copyright; see http://jrse.aip.org/about/rights_and_permissions

013104-15

Effect of sizing of components

J. Renewable Sustainable Energy 1, 013104 2009

FIG. 14. Optimum rating of stator converter current for a different scale parameter.

closed loop control action. It is evident from Figs. 4 b and 4 c that the load transient affects only the torque producing component Iqr of the machine current but not the ux producing components Idr and Ids or the ux itself. This is as per expectation from a eld oriented controller. Next the optimization problem of Sec. IV B was solved using the machine and converter combinations, given in Table II. Figure 5 shows extracted maximum power variation with respect to wind speed and power factor angle for different stator and rotor converter current ratings. For each current rating, initially load power increases rapidly with wind speed reaching machine torque limit rst, thereafter increased load power is supplied by increasing the rotor speed up to the rotor speed limit xed at twice the synchronous speed . When both current and speed limits of the induction generator are reached, extra power is shed by resorting to pitch control mode for the turbine. Although the rotor converter current rating r and stator converter current I/ I/ rating i are shown to be the same here, it is not essential. In this study, r is varied from I 0.1 to 0.8 p.u., while Fig. 5 shows the output up to r =i = 0.6 p.u. only, so as to provide a better I/ I / understanding of the power variation with r. I A similar optimization problem Sec. IV A was solved for the SQIM based system shown in Fig. 6. Here Fig. 7 shows the same plots as Fig. 5 for a SQIM based system having parameters as in Table I and operated under identical conditions. The nature of verication of captured energy, as computed from Eq. 15 , with varying converter ratings for one site 6 with C = 11, K = 2.5, = 0.9 lagging , = 0.1 is shown in Fig. 8. It is observed that once the DOIG machine and converter rating exceeds a critical value around 0.25 p.u. in this case , it always captures more energy than the SQIM based system irrespective of the rating of the latter. As seen from Fig. 7, the rating of the SQIM based system that can capture power comparable to the DOIG based system at higher wind velocity is signicantly larger. However, a larger rated SQIM based system actually captures less power at lower wind velocities compared to a lower rated system due to higher losses. It is also observed from Fig. 8 that the captured energy almost saturates beyond a converter rating of 0.6 p.u. for the SQIM based system.

Downloaded 31 Oct 2011 to 41.201.58.37. Redistribution subject to AIP license or copyright; see http://jrse.aip.org/about/rights_and_permissions

013104-16

Saha, Bagarty, and Kastha

J. Renewable Sustainable Energy 1, 013104 2009

Even for the DOIG based system, the rate of increase in the captured energy is very small beyond this point. The cost plot in Fig. 9 shows that for similar ratings, the energy cost from the DOIG based system is always lower than the SQIM based system. The optimum energy cost from the former is about 25% lower than the optimum energy cost from the latter. Therefore, in the subsequent discussion only the DOIG based system is analyzed. A representative scenario for the DOIG based systems is presented in Tables III and IV. The cost of energy varied widely with wind velocity prole and varied in small range with power factor prole. With xed load power factor = 0.9 lagging and = 0.1 and variable wind velocity PDF, the cost varied from PDF 6.14 cents/ kWh to 8 US $/kWh at different sites as shown in Table III. A windy site C = 11, K = 2.5 gives almost constant cost of energy for wide change in reactive power prole Table IV . From these data, it can be concluded that the DOIG based systems offer a competitive price of energy, for sites with moderately good wind potential. The rate does not get signicantly affected with a change in load power factor prole. The cost of energy is found to be varying widely from a poor choice of machine-converter combination to an optimum choice as shown in Fig. 10. On the other hand, once an optimum combination of machine and converters is chosen for a particular site, the cost of energy is found to be varying in a small range for different reactive power loading. The nature is shown in Fig. 10. In this gure, for sites with xed wind velocity prole C = 11, K = 2.5 , the mean of load power / factor prole is varied. The cost of energy, for a combination with Ir = 0.4 p.u. and Ii = 0.44 p.u., which is one-time optimum for a load with = 0.8, is plotted in Fig. 10. Costs with the optimum combination of machine and converters at those loads are also plotted. It is clear that the difference in cost is 0.1 cents, at most, for different loads. According to the gure, another nonoptimum / combination with Ir = 0.7 p.u. and Ii = 0.56 p.u. is giving a wide deviation from the optimum situation. The change in cost of energy becomes considerably more with the change in the sites wind velocity prole, particularly with the sites scale parameter. For a site with xed load power factor prole = 0.9 lagging and = 0.1 and xed shape parameter K = 2.5, the cost varied with scale parameters as shown in Fig. 11. This wide variation is expected since the wind velocity variable has a much more dominant effect on energy production than the power factor variable. The difference of cost of energies between a one-time optimum combination of machine and converters and the optimum combination are found to be more at less windy sites. However, at reasonably windy sites this difference is negligible. The optimum ratings of both the converters are observed to be varying with the scale and the shape parameters of the wind velocity PDF. The nature of this variation is captured following the procedure described in Sec. IV F and presented in Figs. 1214. The optimum current rating of the rotor side converter, which is the same as the generator current rating, is varying from 0.1 to 0.5 p.u. for different scale parameters as shown in Fig. 12. This signies the importance of the proper choice of machine and converter ratings for the system. Similar variation in rating is also observed with shape parameters. The nature of variation is presented in Fig. 13. From Figs. 12 and 13 it is observed that the rotor side converter rating increases with the scale parameter, but decreases with the shape parameters. A higher value of the scale parameter implies higher wind energy potential of the site, which justies larger investment in a larger size converter. However, for a given scale parameter, increasing the shape parameter reduces the duration of higher wind velocities. Hence larger size converters are not justied from the cost point of view. The optimum stator converter current rating is found to be varying from 0.08 to 0.45 p.u., depending upon the site. The nature of variation is presented in Fig. 14.

VII. CONCLUSION

The optimization program developed evaluates the effects of variable wind speed and load power factor prole on the cost of energy generation from a DOIG based wind energy generation system, satisfying all operational constraints. It is found that the energy cost is highly sensitive to the wind speed prole, whereas the rate does not get signicantly affected with change in the load power factor prole. The energy captured by higher rated machines does not have a linear relationship with rating. The increased energy captured gets almost saturated, as shown in Fig. 8 after

Downloaded 31 Oct 2011 to 41.201.58.37. Redistribution subject to AIP license or copyright; see http://jrse.aip.org/about/rights_and_permissions

013104-17

Effect of sizing of components

J. Renewable Sustainable Energy 1, 013104 2009

0.6 p.u. converter ratings for the chosen site . Hence for any site it is not advisable to increase machine and converter ratings beyond their saturation points. Minimum cost of energy may occur at even lower rating. The cost of energy decreases signicantly with increasing value of the scale parameter of the wind velocity PDF of the site. The cost comes down to as low as 6.1 cents/ kWh, for good sites. The sites with C less than 8 are not suitable for wind energy conversion system installation. The optimization algorithm developed in this work assumes that the generation system works in steady state, which is ensured by a proper control system. An experimental prototype of a DOIG based generator has been fabricated in the laboratory and extensively tested. A few representative results obtained from this setup are also presented in this paper to demonstrate the efcacy of the control algorithm employed against load disturbance.

R. Pena, J. C. Clare, and G. M. Asher, IEE Proc.: Electr. Power Appl. 143, 380 1996 . R. Pena, J. C. Clare, and G. M. Asher, IEE Proc.: Electr. Power Appl. 143, 231 1996 . S. H. Karaki and R. B. Chedid, IEEE Trans. Energy Convers. 15, 284 2000 . 4 P. S. Dokopoulos, A. C. Saramourtsis, and A. G. Bakirtzis, IEEE Trans. Energy Convers. 11, 385 1996 . 5 G. S. Stavrakakis and G. N. Kariniotakis, IEEE Trans. Energy Convers. 10, 584 1995 . 6 S. H. Jangamsetti and V. G. Rau, IEEE Trans. Energy Convers. 16, 8 2001 . 7 T. K. Saha and D. Kastha, Performance analysis of optimally operated DOIG based stand-alone wind power generation system at different sites, in Proceedings of the 2006 IEEE International Conference on Industrial Technology IEEE, Piscataway, NJ, 2006 , pp. 18851889. 8 D. Kastha and T. B. Isha, Analysis and simulation of a novel stand-alone variable speed constant frequency generation system, in Proceedings of the 2000 IEEE International Conference on Industrial Technology IEEE, Piscataway, NJ, 2000 , pp. 554561. 9 D. P. Bagarty and D. Kastha, Analysis and simulation of an optimally operated DOIG based stand-alone VSCF system under converter current and machine speed constraints, in Proceedings of the 2005 IEEE International Conference on Industrial Technology IEEE, Piscataway, NJ, 2005 , pp. 203208. 10 S. Bose, Y. Liu, S. Talya, P. Vyas, S. Videhult, M. Bjerke, and B. Boerresen, A methodology for sizing and cost optimization of wind power with pumped-hydro storage, in Proceedings of the 2004 International Conference on RES and RUE for Islands Larnaka-Cyprus IEEE, Piscataway, NJ, 2004 .

2 3 1

Downloaded 31 Oct 2011 to 41.201.58.37. Redistribution subject to AIP license or copyright; see http://jrse.aip.org/about/rights_and_permissions

Potrebbero piacerti anche

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (121)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- 1999 Isuzu Rodeo UE US Version Service ManualDocumento2.613 pagine1999 Isuzu Rodeo UE US Version Service ManualRichard Tani100% (7)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (400)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (345)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (74)

- How To Adjust Rough Idle and Camshaft Timing On VW and Audi TDI Pumpe Duse EngineDocumento5 pagineHow To Adjust Rough Idle and Camshaft Timing On VW and Audi TDI Pumpe Duse EngineALP1981100% (2)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- 6.1 Mastering IELTS Writing Task 1 (PDFeBook) PDFDocumento228 pagine6.1 Mastering IELTS Writing Task 1 (PDFeBook) PDFHarsh Patel100% (6)

- Tesla CoilDocumento23 pagineTesla CoilredfordNessuna valutazione finora

- SteamTurbineGenerator Datasheet 500MWDocumento8 pagineSteamTurbineGenerator Datasheet 500MWParantap RahaNessuna valutazione finora

- Discussion & Conclusion Dry Fractionation MuzDocumento4 pagineDiscussion & Conclusion Dry Fractionation MuzAhmad MuzammilNessuna valutazione finora

- MCQ On Smart GridmisalpavDocumento4 pagineMCQ On Smart GridmisalpavSomnath Hadpe67% (3)

- 04 - Modul Simulasi Impetus Physics 2021Documento162 pagine04 - Modul Simulasi Impetus Physics 2021Doraemon Music100% (1)

- 2013 04Documento110 pagine2013 04Jose Emmanuel Martinez CordovaNessuna valutazione finora

- BNP C3015 PDFDocumento231 pagineBNP C3015 PDFAri Ercilio Farias FereirraNessuna valutazione finora

- Operations Manual 18WDocumento137 pagineOperations Manual 18Wto_john100% (1)

- Sales Training Slides - NetSure 501 AC0 (Actura Flex 48420)Documento63 pagineSales Training Slides - NetSure 501 AC0 (Actura Flex 48420)chkimkimNessuna valutazione finora

- Data Sheet 6ES7231-4HF32-0XB0: General InformationDocumento3 pagineData Sheet 6ES7231-4HF32-0XB0: General InformationRoberto cafeNessuna valutazione finora

- ME 503 DomDocumento9 pagineME 503 Domsuneel kumar rathoreNessuna valutazione finora

- A-Type Buyers Guide With Technology Comparison For Oxygen Plants 2021Documento19 pagineA-Type Buyers Guide With Technology Comparison For Oxygen Plants 2021Carlos Espinoza AzogueNessuna valutazione finora

- PHD Thesis On Thermal Power PlantDocumento6 paginePHD Thesis On Thermal Power Plantafkneafpz100% (1)

- Chp15notes Part 2Documento32 pagineChp15notes Part 2api-255402590Nessuna valutazione finora

- Greenhouse EffectDocumento15 pagineGreenhouse EffectNoor AdlinNessuna valutazione finora

- Cavigulation Water Treatment Technology 20 FT 2Documento3 pagineCavigulation Water Treatment Technology 20 FT 2firmansyachNessuna valutazione finora

- Industrial Waste Abatement SeafoodDocumento27 pagineIndustrial Waste Abatement SeafoodTuróczy EmőkeNessuna valutazione finora

- Lessons Learnt From HIAD 2.0-FinalDocumento38 pagineLessons Learnt From HIAD 2.0-FinalMathis ThollotNessuna valutazione finora

- Termotehnica Part2Documento95 pagineTermotehnica Part2Cirstea AlexandruNessuna valutazione finora

- Asic Lectrical Echnology: Parallel Magnetic CircuitsDocumento10 pagineAsic Lectrical Echnology: Parallel Magnetic CircuitsShivangNessuna valutazione finora

- ACTION TRACKERDocumento6 pagineACTION TRACKERShubham ChaudharyNessuna valutazione finora

- Design and Application of A Spreadsheet-Based ModelDocumento7 pagineDesign and Application of A Spreadsheet-Based ModelPassmore DubeNessuna valutazione finora

- RMG 4015 Crack Depth MeasurementDocumento4 pagineRMG 4015 Crack Depth MeasurementJozmel Blancas CamarenaNessuna valutazione finora

- C-00 & Er 91april - May-2012Documento39 pagineC-00 & Er 91april - May-2012John SandaNessuna valutazione finora

- Increasing Operational Stability in Low No GT Combustor by A Pilot FlameDocumento10 pagineIncreasing Operational Stability in Low No GT Combustor by A Pilot FlameGilles CabotNessuna valutazione finora

- Wave Energy Conversion#Documento3 pagineWave Energy Conversion#DimSolNessuna valutazione finora

- DS6527 Standard EU en BurkertDocumento4 pagineDS6527 Standard EU en BurkertDan PascaruNessuna valutazione finora