Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Jla 22 Pressure Hydrotest

Caricato da

Haziq BahruddinDescrizione originale:

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Jla 22 Pressure Hydrotest

Caricato da

Haziq BahruddinCopyright:

Formati disponibili

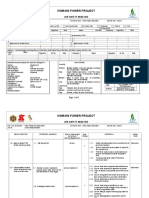

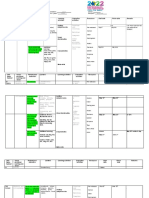

CERICORN (M) SDN.

BHD JOB LOSS ANALYSIS (JLA)

GENERAL INFORMATION PROJECT TITLE TYPE OF WORKS RISK RATING FACILITY : TANK CLEANING, REPAIR AND ANCILLARY WORKS : HYDROSTATIC TEST (HYDROTEST) : MEDIUM : CHEVRON PASIR GUDANG JV TERMINAL DATE:

JLA 22

WORK PERMIT:

LOCATION OF WORK : TANK 6 (INTERNAL TANK)

REQUIRED PERSONAL PROTECTIVE EQUIPMENT (tick X which is required) Safety Helmet Safety Shoes / Boots Safety Glasses Face / Welding Shield Cotton Gloves Rubber/Nitrile Gloves Leather Gloves Goggles Work Vest/ Full Suit of Blasting Uniform Reflective Vest Full Body Harness Face Mask DEVELOPMENT TEAM NO. 1 2 3 4 NAME AFFANDI MOHD SALLEH LAU CHI MIN HAZIQ BAHRUDDIN NGIAN CHIN BOON POSITION QC/QA BLASTING PAINTING SUPERVISOR HSE OFFICER PROJECT SUPERINTENDANT Ear Protection Leather Apron

OTHER SAFETY EQUIPMENT / REQUIREMENTS Fire Extinguisher Gas Detector Safety Signs Barricades Lifeline Tag Out / Lock Out Work Permit Competency Certificate Respirator (Organic Vapor Cartridge) First aid equipment

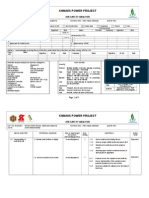

CERICORN (M) SDN. BHD

JLA 22

JOB DESCRIPTION 1.0 Conduct briefing

POTENTIAL HAZARD 1.0 Accident, injury and damage occur due to inadequate info or wrong step of job.

CONSEQUENCES INDICES SAFETY

RECOVERY MEASURES 1.1.1 Briefing of procedure to be carried out before start work. 1.1.2 Ensure all workers are wearing correct PPE 1.1.3 Ensure general work permit obtain at site. 1.1.4 Cordon work area and put signage.

ACTION PARTY CERICORN CHEVRON

2.0 Prepare testing equipment

1.0 Tripping 2.0 Body Injury 3.0 Finger pinched

SAFETY

2.1.1 Ensure area is clear of any tripping hazards. 2.2.1 Ensure weight of any equipment that will be lifted manually does not exceed individuals ability. 2.2.2 Position correctly when lifting. 2.3.1 Ensure First Aid Box, Barricade and Safety Sign.

CERICORN

3.0 System/Test Limit/Line Check

1.0 Tripping 2.0 Body injury

SAFETY

3.1.1 Ensure to arrange the line properly before install spade and blind. 3.2.1 Clear out all hydrotest procedure.

CERICORN

4.0 Install Test Blinds/Spade & Hook-up Test

1.0 Finger pinched 2.0 Ergonomic

SAFETY

4.1.1 Ensure access is clear. Be aware of the surroundings. 4.2.1 Be in the position when tightening stud bolts.

CERICORN

3.0 Equipment Damaged 4.3.1 Ensure that equipment or instruments nearby are not disturbed during tightening of stud bolts. 5.0 Fill-up with test medium and start pressurization 1.0 Body injury to testing crew and to other personnel SAFETY 5.1.1 Ensure test equipment and accessories are in good condition 5.1.2 Barricade the area and hang no entry signboards for unauthorized personnel while line is pressurized. 6.0 Hold Pressure per Requirements/Check for 1.0 Tripping SAFETY 6.1.1 Keep area clear of any obstruction. CERICORN CERICORN

CERICORN (M) SDN. BHD

Leaks 7.0 Depressurize/Re-instate to normal specs 2.0 Falling from height 1.0 Tripping 2.0 Body injury 3.0 Equipment Damaged 8.0 Secure work area before shifts ends and or after work completion 1.0 Tripping 2.0 Falling from height, 3.0 Finger pinched 8.2.1 Use manila rope in lowering down hoisting equipment and other heavy tools. 8.3.1 Remove any signboards and other temporary aids 9.0 Housekeeping 1.0 Tripping SAFETY HEALTH 9.1.2 Ensure closing of work permit are logged PREPARED BY: Contractors Representative: REVIEW BY: Clients Representative: 9.1.1 Ensure surroundings and walkways are clear of any obstruction. SAFETY 7.2.1 Keep area clear of other personnel until depressurization is completed. 8.1.1 Ensure all redundant materials are secured at the right place. SAFETY 6.2.1 Use proper access (i.e. scaffolding or ladder) when trying to access test point at height. 7.1.1 Ensure area is clear during and after re-instatement to normal requirements.

JLA 22

CERICORN

CERICORN

CERICORN

. NAME : DESIGNATION: CERICORN - HSE OFFICER

... NAME : DESIGNATION :

Potrebbero piacerti anche

- Horned Hunter - Shaman, Ancestor, and Deity PDFDocumento22 pagineHorned Hunter - Shaman, Ancestor, and Deity PDFAranykoremberNessuna valutazione finora

- To Kill A MockingbirdDocumento147 pagineTo Kill A MockingbirdIvan Sokolov100% (1)

- Air Compressor Air Compressor: (Small) (Small)Documento1 paginaAir Compressor Air Compressor: (Small) (Small)alcrosalitaNessuna valutazione finora

- Hydro Testing Handbook: Principles, Practices, Applications, Formulas, and Common Q&ADa EverandHydro Testing Handbook: Principles, Practices, Applications, Formulas, and Common Q&ANessuna valutazione finora

- Brick StitchDocumento15 pagineBrick StitchMojisola Famuyide100% (3)

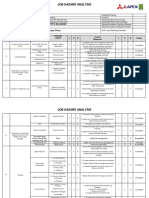

- Kimanis Power Project: Job Safety AnalysisDocumento6 pagineKimanis Power Project: Job Safety AnalysisLuqman OsmanNessuna valutazione finora

- Installation of Cabinetry - JoineryDocumento4 pagineInstallation of Cabinetry - JoineryJonas100% (2)

- JHA Manual Excavation For Cable TrenchDocumento5 pagineJHA Manual Excavation For Cable TrenchNasrullah Jan100% (4)

- Tom Sellers Immediate Magic PDFDocumento24 pagineTom Sellers Immediate Magic PDFbecker3918275% (8)

- IBEJIDocumento1 paginaIBEJIodditrupo100% (1)

- Safety Training Hydrojetting of Exchangers GeneralDocumento15 pagineSafety Training Hydrojetting of Exchangers GeneralandinumailNessuna valutazione finora

- Facility/Plant Location: Description of Work: Contractor:: PCD Project: Water Treatment Facilities - 3Documento8 pagineFacility/Plant Location: Description of Work: Contractor:: PCD Project: Water Treatment Facilities - 3AldrinNessuna valutazione finora

- JSA For KAHSDocumento6 pagineJSA For KAHSFrancis Enriquez TanNessuna valutazione finora

- Method Statement and Risk Assessment For Electrical Cable Trench ExcavationDocumento8 pagineMethod Statement and Risk Assessment For Electrical Cable Trench Excavationfehmi-fjr469650% (2)

- Betp Exporting Clientele Directory 2012Documento187 pagineBetp Exporting Clientele Directory 2012Mbamali Chukwunenye100% (4)

- Hot Works Safety TrainingDocumento80 pagineHot Works Safety TrainingJohn Paul Bañaria50% (2)

- Risk Assessment For Sand Blasting PDFDocumento8 pagineRisk Assessment For Sand Blasting PDFOvais FarooqNessuna valutazione finora

- JSA Cable Pulling and Laying Works AutosavedDocumento6 pagineJSA Cable Pulling and Laying Works AutosavedWisnu Wijaya100% (1)

- Horizon Forbidden West Aloy Nora Huntress Cosplay GuideDocumento18 pagineHorizon Forbidden West Aloy Nora Huntress Cosplay GuideJoan Jesus Jaramillo Abad100% (1)

- Safe Work Method Statement Template SampleDocumento5 pagineSafe Work Method Statement Template SampleHaneefa ChNessuna valutazione finora

- Sabic ExamDocumento9 pagineSabic ExamSyed Ahmed manzoor100% (3)

- Job Safety Analysis: Pipe Cutting Cleaning and Flushing GeneralDocumento2 pagineJob Safety Analysis: Pipe Cutting Cleaning and Flushing GeneralNico Raharjo60% (5)

- Saw Cutting Concrete (Wet Method)Documento1 paginaSaw Cutting Concrete (Wet Method)Junard M. Lu HapNessuna valutazione finora

- JSA Erection of Steel StructureDocumento9 pagineJSA Erection of Steel StructureLuqman Osman77% (13)

- How Chin Engineering: Job Safety AnalysisDocumento6 pagineHow Chin Engineering: Job Safety AnalysisHow Chin Engineering Sdn BhdNessuna valutazione finora

- Pha ExcavationDocumento13 paginePha ExcavationirshadNessuna valutazione finora

- Jsa Copper Grounding at Fire PumpDocumento5 pagineJsa Copper Grounding at Fire PumpHow Chin Engineering Sdn BhdNessuna valutazione finora

- Safety Interview QuestionDocumento8 pagineSafety Interview QuestionMaaloul FakherNessuna valutazione finora

- JSA FormDocumento6 pagineJSA FormAjeesh CochinNessuna valutazione finora

- 2011 Mazda 2 30231 PDFDocumento340 pagine2011 Mazda 2 30231 PDFArchip GabrielNessuna valutazione finora

- Safe Work Method Statement Template SampleDocumento5 pagineSafe Work Method Statement Template SampleTAHER AMMARNessuna valutazione finora

- JHA Valve Leak Test and RepairDocumento16 pagineJHA Valve Leak Test and Repairrosevelvet100% (1)

- Jsa Installation of HV ApparatusDocumento6 pagineJsa Installation of HV ApparatusLuqman OsmanNessuna valutazione finora

- JSA NO 3-Pile CapDocumento8 pagineJSA NO 3-Pile Capknabpsho50% (2)

- Job Safety Analysis Work Sheet: Arabian Pipeline & Services Company WR # K002849Documento20 pagineJob Safety Analysis Work Sheet: Arabian Pipeline & Services Company WR # K002849Barkat Ullah50% (2)

- Steel Structure WorkDocumento9 pagineSteel Structure Workmohd firdaus100% (1)

- APV Paraflow Plate HX ManualDocumento31 pagineAPV Paraflow Plate HX ManualAnonymous gwldee5100% (2)

- Jha Lin FillingDocumento6 pagineJha Lin FillingLuqman OsmanNessuna valutazione finora

- Jsa General HousekeepingDocumento2 pagineJsa General HousekeepingHow Chin Engineering Sdn Bhd44% (9)

- Kevlar Cut Protection TestingDocumento6 pagineKevlar Cut Protection Testingalvares90Nessuna valutazione finora

- JSA Concereting and PaintingDocumento4 pagineJSA Concereting and PaintingHow Chin Engineering Sdn BhdNessuna valutazione finora

- JRA Exxon Format - Insulation Removal and ReinstatementDocumento3 pagineJRA Exxon Format - Insulation Removal and ReinstatementJayesh J PillaiNessuna valutazione finora

- Difference Between Fashion and StyleDocumento2 pagineDifference Between Fashion and Stylewikki86Nessuna valutazione finora

- JSA NO 3-Pile CapDocumento8 pagineJSA NO 3-Pile CapknabpshoNessuna valutazione finora

- Split Unit Installation MethodDocumento2 pagineSplit Unit Installation MethodLimsreang Eang77% (26)

- Split Unit Installation Method PDFDocumento2 pagineSplit Unit Installation Method PDFMohamad Hafiz50% (2)

- Weaving, Knitting, Poy, CP, TexturisingDocumento17 pagineWeaving, Knitting, Poy, CP, TexturisingGanga DharanNessuna valutazione finora

- Christian Dress and Adornment by Samuele BacchiocchiDocumento13 pagineChristian Dress and Adornment by Samuele Bacchiocchimauricejunior100% (3)

- United Mining Industries "Health Safety and Environment General Rules"Documento139 pagineUnited Mining Industries "Health Safety and Environment General Rules"Jakaria Al-MahmudNessuna valutazione finora

- Personnel Protection and Safety Equipment for the Oil and Gas IndustriesDa EverandPersonnel Protection and Safety Equipment for the Oil and Gas IndustriesValutazione: 5 su 5 stelle5/5 (3)

- English Project On The Rat TrapDocumento17 pagineEnglish Project On The Rat Trapsakshamamitagarwal80% (5)

- Manual Book Mesin HDPE SHD 315 PDFDocumento22 pagineManual Book Mesin HDPE SHD 315 PDFYuwantoniAl100% (1)

- Jsa Welding Diesel PipelineDocumento3 pagineJsa Welding Diesel PipelineHow Chin Engineering Sdn BhdNessuna valutazione finora

- SOP-15-Installation and Disassembly of BOP Hydraulic Control LineDocumento6 pagineSOP-15-Installation and Disassembly of BOP Hydraulic Control LineDQE040 HSSENessuna valutazione finora

- BRIEFING ON HSE DM Water TankDocumento7 pagineBRIEFING ON HSE DM Water Tankssb goddaNessuna valutazione finora

- Basic Health, Safety, AND Environmental Work Requirements FOR Contractors AT AIR Liquide SitesDocumento12 pagineBasic Health, Safety, AND Environmental Work Requirements FOR Contractors AT AIR Liquide Sitesferry ferdiansyah pradanaNessuna valutazione finora

- Job Safety Analysis: Client: ContractorDocumento7 pagineJob Safety Analysis: Client: Contractorloveson709Nessuna valutazione finora

- Conference Centre CWDocumento18 pagineConference Centre CWAsas ArifNessuna valutazione finora

- Water Injection AreaDocumento5 pagineWater Injection Areasudeesh kumarNessuna valutazione finora

- Sop LadderDocumento8 pagineSop LadderMohamad AfifNessuna valutazione finora

- Answer Construction Equipment Can Be Categorized Into 4 Main Sections Based On Purpose and UseDocumento19 pagineAnswer Construction Equipment Can Be Categorized Into 4 Main Sections Based On Purpose and UseSuraj SivaNessuna valutazione finora

- Sop WahDocumento7 pagineSop WahMohamad AfifNessuna valutazione finora

- AIIL KAWAI CONFINED SPACE FormDocumento3 pagineAIIL KAWAI CONFINED SPACE FormLijo JohnNessuna valutazione finora

- Entry and Work in Confined SpacesDocumento51 pagineEntry and Work in Confined Spacesyadhu100% (1)

- Job Safety Analysis: Job Title: Installing Pneumatic Rubber FenderDocumento3 pagineJob Safety Analysis: Job Title: Installing Pneumatic Rubber FenderIhwan AsrulNessuna valutazione finora

- SMP For Pullcord and BeltswayDocumento2 pagineSMP For Pullcord and BeltswayROHIT SINGHNessuna valutazione finora

- Requirement To Use Welding Safety Equipment During Welding ActivityDocumento7 pagineRequirement To Use Welding Safety Equipment During Welding ActivitysyooloveNessuna valutazione finora

- Sop Drills Screwdrivers CordlessDocumento1 paginaSop Drills Screwdrivers CordlessSravan CholeteNessuna valutazione finora

- Construction Method of Statement: Submitted By: Mega Air EnterprisesDocumento12 pagineConstruction Method of Statement: Submitted By: Mega Air Enterprisesallen bernabeNessuna valutazione finora

- Hot Works Safety TrainingDocumento77 pagineHot Works Safety TrainingWathiq Ghareeb SalmanNessuna valutazione finora

- DIAL WORK PERMIT NewDocumento5 pagineDIAL WORK PERMIT NewAkshay PotekarNessuna valutazione finora

- Knitting CourseDocumento5 pagineKnitting CourseRadha Krishnan K K VNessuna valutazione finora

- 2021-2022 Interior Design Scenario and Resources 1Documento6 pagine2021-2022 Interior Design Scenario and Resources 1api-601042997Nessuna valutazione finora

- How To Start A Clothing Brand - SBH E-BookDocumento32 pagineHow To Start A Clothing Brand - SBH E-Bookzrd4rpt9hfNessuna valutazione finora

- About Echo SourcingDocumento35 pagineAbout Echo Sourcingmafiullah100% (1)

- Tyfo SCH 41 PDFDocumento2 pagineTyfo SCH 41 PDFJorge HerreraNessuna valutazione finora

- 1-Acción Didáctica 1er Grado Primaria Regular - Mayo, Junio y Julio 2022Documento4 pagine1-Acción Didáctica 1er Grado Primaria Regular - Mayo, Junio y Julio 2022William JimenezNessuna valutazione finora

- Onde MandeDocumento5 pagineOnde MandeIqbal AhmadNessuna valutazione finora

- Execises 1st Year Bachillerato (3rd Term)Documento11 pagineExecises 1st Year Bachillerato (3rd Term)centralvarNessuna valutazione finora

- Ambitious Vocabulary: So First Next Lonely Afraid Because Interesting ExcitingDocumento4 pagineAmbitious Vocabulary: So First Next Lonely Afraid Because Interesting ExcitingBilbo BagginsNessuna valutazione finora

- All American Driving School Self Study Drivers Education ManualDocumento290 pagineAll American Driving School Self Study Drivers Education ManualCaitlin ThomsonNessuna valutazione finora

- Gta Cheat CodesDocumento6 pagineGta Cheat CodesSuresh MuraliNessuna valutazione finora

- Quotation Tabung Haji Perak 20230920Documento1 paginaQuotation Tabung Haji Perak 20230920su.surauarraudhaheristanaNessuna valutazione finora

- Wal Mart Bangladesh Factory List PDFDocumento6 pagineWal Mart Bangladesh Factory List PDFVishalNessuna valutazione finora

- Boomerang Interior SPECIALDocumento694 pagineBoomerang Interior SPECIALTemba MagorimboNessuna valutazione finora

- Merchant Marine Academy 2nd Semester - P. Papaleonidas - 2011-89-99Documento11 pagineMerchant Marine Academy 2nd Semester - P. Papaleonidas - 2011-89-99Наталья ЛандикNessuna valutazione finora

- Work 2Documento726 pagineWork 2mohsinNessuna valutazione finora

- SCM310 Sec1 Group Project HMDocumento27 pagineSCM310 Sec1 Group Project HMShrinidhi Priyankaa 1912985630Nessuna valutazione finora