Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Aspen Custom Modeler

Caricato da

Dr-Taha MahdiDescrizione originale:

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Aspen Custom Modeler

Caricato da

Dr-Taha MahdiCopyright:

Formati disponibili

Aspen Custom Modeler

Aspen Custom Modeler enables users to quickly create custom models to incorporate their companies unique expertise and knowledge, enabling them to fully leverage the benefits of process simulation throughout their company.

The Challenge: High Total Cost of Custom Models

Aspen Technologys simulation tools, such as Aspen Plus, HYSYS, and Aspen Dynamics, include comprehensive unit operation model libraries that have been used to successfully simulate thousands of processes. While these models provide significant value, they cannot always capture proprietary company knowledge or the latest published innovations. Custom models have traditionally been developed using standard programming languages, such as Microsoft Visual Basic, C++ or FORTRAN. Not only can this be very time consuming, but it also carries a high risk of failure, due to the expertise required in programming, numerical methods and process modeling. The outcome is a high cost for development and maintenance, with companies being reluctant to develop new models. Given increasing global competition and the increasing rate of innovation, how can engineers quickly and easily capture, create and test new process models to fully leverage company knowledge and expertise without generating difficult-to-maintain programs?

The Opportunity: Fully Leveraging Company Knowledge and Expertise

A key source of sustainable competitive advantage comes from rapidly using company knowledge and expertise, as well as external innovations. To do this, companies must have a common and consistent framework for creating, sharing and re-using custom models. A common modeling tool that promotes cooperation and the easy evaluation of new ideas can help shorten the innovation cycle, and enables users to fully leverage the benefits of process simulation throughout their company. Further, this helps to ensure consistency of custom model development and deployment provides users with faster access to the latest innovations and reduces total cost of ownership for custom models. Other business benefits of using a common modeling tool to capture the latest innovations include reduced time to market and lower capital costs, improved safety and environmental compliance and higher profitability from more optimal operation.

Aspen Custom Modeler provides an easy-to-use environment for both capturing and validating our process knowledge. As a standard modeling tool it also gives us a common language for sharing and exporting this knowledge across our enterprise. Recai Artan Process Engineer DSM Srevices/Engineering Stamicarbon

The Solution: Aspen Custom Modeler

Aspen Custom Modeler is designed to enable the quick and easy development and deployment of custom process models. Aspen Custom Modeler models can be used within AspenTech's other simulation tools, such as Aspen Plus, HYSYS and Aspen Dynamics, making innovation fully available and part of standard process design and operability studies. This enables users to fully leverage their existing models and helps to ensure consistency of simulation results.

Benefits Offered by Aspen Custom Modeler

Aspen Custom Modeler improves productivity and profitability by enabling innovative ideas and models to be quickly and easily shared enterprise-wide as part of standard process design and operability studies. It enables engineers to extract the most value and performance from the plant and equipment with improved designs, optimized production and enhanced decision-making. Some of the key business benefits offered by Aspen Custom Modeler are listed below:

Quickly and easily develop custom unit operation models including your specific expertise or proprietary knowledge Build these models into complete simulation flowsheets Run both steady-state and dynamic simulations for these flowsheets Package and deploy completed simulations for use across your enterprise Using models isnt just for the experts any more. At the end of each of my studies, I can deliver the simulation to my internal customer, knowing that he can derive additional value from it with a minimum of help from me. David Drew DuPont Engineering Technology

Aspen Custom Modeler Applications

Aspen Custom Modeler has provided users with significant benefits, including hundreds of man-hours and millions of dollars. Below are a few examples of Aspen Custom Modeler applications:

Optimizing grade transitions for a polymer reactor Estimation of kinetic parameters for a biochemical reaction Simulation of a divided-wall distillation column Design of control for a rotary kiln Design of a power plant Prediction of reaction runway in a batch reactor Optimizing operation of a batch reactor Optimizing operation of a batch distillation column Design of an automotive catalytic converter Inferential measurement in a steel furnace Minimizing energy consumption in a sugar refinery Simulation of a spray drier Design of a trickle-bed reactor

Aspen Custom Modeler Custom Modeling Made Easy

Aspen Custom Modeler Features

Creating Custom Models

At the heart of Aspen Custom Modeler is a powerful, high-level process modeling language. Engineers can use this language to list the equations that describe a unit operation or equipment item, like those found in any chemical engineering textbook or literature. There is no need to create or incorporate solution methods as this is automatically handled by Aspen Custom Modeler. The result is compact, self-contained models that are easy to understand and easy to maintain. Aspen Custom Modeler uses advanced equation-based solution techniques and state-of-the-art numerical methods to ensure fast and reliable solution. Furthermore, it is also integrated with Polymers Plus for modeling of polymer processes. Aspen Custom Modeler also includes a limited-use license for Aspen Properties, AspenTech's industry-leading physical properties package. This enables Aspen Custom Modeler to access the comprehensive property models and data available within Aspen Properties. If required, custom physical properties may also be incorporated.

Aspen Custom Modeler also provides the following features:

The ability to interface to C++, C or FORTRAN legacy models The ability to create pre-configured tables and custom forms for entering input data, or reviewing results. Custom forms can also be created using Microsoft Visual Basic The ability to create libraries of custom models Language for direct entry of time differential equations for use in dynamic models and partial differential equations for modeling distributed systems The ability to create time-series or profile plots for viewing model results, such as example product flow rate over time or pressure drop through a pipe Integration with Polymer Plus for modeling of polymer processes Adding Custom Models to Flowsheets

Flowsheets can be built within Aspen Custom Modeler using the graphical flowsheet editor. Simply drag and drop models onto the flowsheet to create blocks. Connect these blocks with streams and use the tables and custom forms to enter required data for the models and streams. Aspen Custom Modeler models can also be exported and used seamlessly within Aspen Plus, HYSYS or Aspen Dynamics flowsheets.

Running Simulations Using Custom Models

Once a custom model is added to a flowsheet in Aspen Custom Modeler, it can be used for a variety of simulations, including:

Steady-state simulation to perform design or rating calculations Dynamic simulation to understand the dynamic behavior of your process Steady-state or dynamic estimation to fit model parameters to experimental or plant data Steady-state or dynamic optimization to optimize the design and operation of continuous or batch processes

To view simulation results, users can use the plots, tables and custom forms that are built into the custom models. New plots and tables can also be added quickly and easily as needed. For dynamic simulations, users can create tasks to define changes that are time or event driven. For example, to ramp an inlet flow rate at a certain time or turn off a feed when a vessel is full. Tasks can be used to define complex operating procedures, such as how to run a batch cycle for a batch reactor. Users can also take a snapshot of the simulation at any time, which can be rewound to replay a particular scenario or to initialize a new simulation.

Deploying Simulations

In addition to distribution of custom models within a simulation, models developed using Aspen Custom Modeler can be deployed enterprise-wide for use by personnel with little or no knowledge of process simulation (such as for planning or operations personnel). This enables non-experts to access the power of the custom model without being exposed to its complexity. Aspen Custom Modeler provides the following features to enable this:

Extensive support for Windows automation. This can be used to interface with Windows applications such as Microsoft Excel, or to construct a customized user interface using Microsoft Visual Basic

Linking Data to Excel

Built-in Microsoft Visual Basic scripting for automating common tasks The ability to create pre-defined screen layouts An OLE for Process Control (OPC) interface to enable easy exchange of data with process control and information management systems for applications such as training or inferential measurement

The Goal: Reduced Costs and Improved Profitability

Aspen Custom Modeler delivers an unrivalled combination of modeling power and ease of use. It can be used to develop models for use and re-use in a wide range of applications including steady-state simulation, dynamic simulation and optimization enabling companies to design and operate more efficient, safer and more profitable process plants.

A Simple Visual Basic Front End

Aspen Custom Modeler is more than an isolated point solution. It is an integrated part of the Aspen Engineering Suite (AES), a suite of products designed to work together to optimize the engineering and innovation workflow processes. Aspen Custom Modeler is the model development environment for AES. Its technology is used to develop other AspenTech simulation products, including Aspen Dynamics, Aspen Adsim, Aspen Chromatography and Aspen Water, as well as rigorous polymer process models for Polymers Plus.

AspenTech: A Tradition of Innovation

Aspen Technology Inc.'s proven, integrated software and rapid implementation services enhance the efficiency and profitability of process companies. AspenTech's engineering software optimizes process designs to maximize lifecycle returns. Our manufacturing/supply chain software harmonizes production, inventory, demand, and delivery to improve operating margins. Together, these offerings create an integrated solution enterprise operations management (EOM) that transforms enterprise-wide operating performance.

[world wide web] www.aspentech.com

worldwide headquarters

Aspen Technology, Inc. Ten Canal Park Cambridge, MA 02141-2201 USA

houston office

[phone] +1 617 949 1000 +1 617 949 1030 [fax] [e-mail] info@aspentech.com

Aspen Technology, Inc. 1293 Eldridge Parkway Houston, TX 77077 USA

europe/middle east/africa headquarters

[phone] [fax] [e-mail]

+1 281 584 1000 +1 281 584 4329 info@aspentech.com

AspenTech Europe SA/NV Avenue Reine Astrid 92 1310 La Hulpe BELGIUM

asia headquarters

[phone] [fax] [e-mail]

+32 2 701 94 50 +32 2 701 95 00 ATE_info@aspentech.com

AspenTech, Inc. 371 Beach Road #23-00 KeyPoint Singapore 199597

japan headquarters

[phone] [fax] [e-mail]

+65 395 3900 +65 395 3950 info@aspentech.com

Copyright 2004. AspenTech, Aspen Custom Modeler, Aspen Plus, HYSYS, Aspen Dynamics, Aspen Properties, Process Control, Aspen Engineering Suite (AES), Aspen Adsim, Aspen Chromatography, Aspen Water, and the Aspen leaf logo are trademarks or registered trademarks of Aspen Technology, Inc., Cambridge, Massachusetts USA. All rights reserved. All other brand and product names are trademarks or registered trademarks of their respective companies. PB 177 03/16/04

AspenTech Japan Co., Ltd. Kojimachi Crystal City 10F 4-8 Kojimachi, Chiyoda-ku Tokyo 102-0083 JAPAN

[phone] +81 (0) 3 3262 1710 +81 (0) 3 3262 1765 [fax] [e-mail] info@aspentech.co.jp

Potrebbero piacerti anche

- Chemical Reactor Design, Optimization, and ScaleupDa EverandChemical Reactor Design, Optimization, and ScaleupNessuna valutazione finora

- Aspen Custom ModelerDocumento4 pagineAspen Custom ModelerJemar LimNessuna valutazione finora

- Seperation Model EquationDocumento130 pagineSeperation Model EquationHans WurstNessuna valutazione finora

- Aspen Polymers Ds D PDFDocumento2 pagineAspen Polymers Ds D PDFMasagus Sapta RyandaNessuna valutazione finora

- Aspen Custom Modeller Overview PDFDocumento29 pagineAspen Custom Modeller Overview PDFAbel EkwonyeasoNessuna valutazione finora

- ACM Modeling Language ReferenceDocumento193 pagineACM Modeling Language ReferenceSurya Budi Widagdo100% (1)

- ACM 111 SPEEDUP® 5 Source ConverterDocumento100 pagineACM 111 SPEEDUP® 5 Source Convertermehranlnjd100% (1)

- AspenPlus Solids JumpStartGuide ParticleScientist 120812 - DownLoadLy - Ir PDFDocumento22 pagineAspenPlus Solids JumpStartGuide ParticleScientist 120812 - DownLoadLy - Ir PDFMarcoiNessuna valutazione finora

- Manual Aspen Analyzer Version 7Documento520 pagineManual Aspen Analyzer Version 7David Sanchez0% (1)

- Aspen Plus, Reaction Engineering and DesignDocumento45 pagineAspen Plus, Reaction Engineering and Designnikhilgoyal4100% (1)

- Jump Start To Crushing and Milling in AspenPlus v8 - DownLoadLy - IrDocumento14 pagineJump Start To Crushing and Milling in AspenPlus v8 - DownLoadLy - IrMarcoiNessuna valutazione finora

- Aspen Custom Modeler Equations of The Flash Model PDFDocumento5 pagineAspen Custom Modeler Equations of The Flash Model PDFkiny81Nessuna valutazione finora

- Aspen DynamicsDocumento311 pagineAspen DynamicsHoang-Vu BuiNessuna valutazione finora

- At-04304-Aspen ELearning Catalog 0918Documento57 pagineAt-04304-Aspen ELearning Catalog 0918jimmNessuna valutazione finora

- How To Write You Own User Kinetics Fortran Routine 06 UserKineticsDocumento16 pagineHow To Write You Own User Kinetics Fortran Routine 06 UserKineticsEden HuangNessuna valutazione finora

- Modeling and Simulation of A Distillation Column Using ASPEN PLUS Libre PDFDocumento9 pagineModeling and Simulation of A Distillation Column Using ASPEN PLUS Libre PDFmehul10941Nessuna valutazione finora

- Lec SimulationDocumento80 pagineLec SimulationDr Tajammal MunirNessuna valutazione finora

- EHY2511 Flare Network Design and RatingDocumento2 pagineEHY2511 Flare Network Design and RatingEdi SaputraNessuna valutazione finora

- HYSYS2016Documento254 pagineHYSYS2016Lizet Daniela Chambi100% (1)

- EE105 Matlab TutorialDocumento3 pagineEE105 Matlab TutorialEdison ZhaoNessuna valutazione finora

- Aspen Plus ReformerDocumento134 pagineAspen Plus ReformerIbrahim RagabNessuna valutazione finora

- Module 2: Polymer Reactions Segment-Based Power-Law KineticsDocumento15 pagineModule 2: Polymer Reactions Segment-Based Power-Law KineticsYu An Shih100% (1)

- Fortran User ModelDocumento20 pagineFortran User ModelkingboboNessuna valutazione finora

- AspenEngineeringSuiteV7 1 IssuesDocumento100 pagineAspenEngineeringSuiteV7 1 IssuesSJSZCGRDHSNessuna valutazione finora

- ACM MembraneDocumento69 pagineACM Membraneingbarragan87Nessuna valutazione finora

- Aspen ConvergenceDocumento40 pagineAspen ConvergenceKaushal SampatNessuna valutazione finora

- Getting Started With Relative Economics in Aspen PlusDocumento20 pagineGetting Started With Relative Economics in Aspen PlusAndrés Esteban Granada ZapataNessuna valutazione finora

- Modeling of CO2 Capture Via Chemical Absorption Processes An ExtensiveliteraturereviewDocumento21 pagineModeling of CO2 Capture Via Chemical Absorption Processes An ExtensiveliteraturereviewRene QuisNessuna valutazione finora

- HYSYS Simulation BasisDocumento527 pagineHYSYS Simulation BasisAbdallah FEKKAINessuna valutazione finora

- Benefits of The NIST Thermo Data Engine in AspenONE EngineeringDocumento12 pagineBenefits of The NIST Thermo Data Engine in AspenONE EngineeringMohammed MorsyNessuna valutazione finora

- Solids Process Modeling in Aspen PlusDocumento26 pagineSolids Process Modeling in Aspen Plusmontoyazumaeta50% (2)

- AD ExamplesDocumento49 pagineAD Exampleszubair1950Nessuna valutazione finora

- AspenPlus Learning PathDocumento1 paginaAspenPlus Learning PathKhaledAhmedNessuna valutazione finora

- Aspen Process Ecoinomic Analyzer QueriesDocumento4 pagineAspen Process Ecoinomic Analyzer QueriesHaseeb AhmadNessuna valutazione finora

- Aspentech Course Catalog Fy18Documento27 pagineAspentech Course Catalog Fy18LION_FIRENessuna valutazione finora

- Aspen Plus Workshop For Reaction EngineeringDocumento44 pagineAspen Plus Workshop For Reaction EngineeringkotiNessuna valutazione finora

- Use of Dynamic Simulation To ConvergeDocumento8 pagineUse of Dynamic Simulation To ConvergeneftNessuna valutazione finora

- Aspen 2013 InputLanguageGuideDocumento893 pagineAspen 2013 InputLanguageGuidemf1506100% (1)

- AspenPolymersUnitOpsV8 - 4-Usr PDFDocumento841 pagineAspenPolymersUnitOpsV8 - 4-Usr PDFValeria MolinaNessuna valutazione finora

- Aspen ExamplesDocumento100 pagineAspen ExamplesEngr Mohammad Farhan100% (1)

- Aspen Plus CourseDocumento4 pagineAspen Plus CourseVigneshwaran Santharam100% (1)

- APLUS 111 Getting Started EO ModelingDocumento100 pagineAPLUS 111 Getting Started EO ModelingIvo Matheus SkiavineNessuna valutazione finora

- Aspenhysysoliif2006 RefDocumento232 pagineAspenhysysoliif2006 RefKrishanu SahaNessuna valutazione finora

- UniSim Thermo Reference GuideDocumento332 pagineUniSim Thermo Reference Guideapi-3750488100% (2)

- D. Reactions in HYSYS - NewDocumento12 pagineD. Reactions in HYSYS - NewRafael FaioliNessuna valutazione finora

- Aspen Plus GuideDocumento745 pagineAspen Plus GuideReza Anggara0% (1)

- Renewable Energy Resources: Introduction & Economic Analysis of A Gasification PlantDocumento36 pagineRenewable Energy Resources: Introduction & Economic Analysis of A Gasification PlantfaizanNessuna valutazione finora

- AspenProcessEconAnalyzerV9 0 UsrDocumento506 pagineAspenProcessEconAnalyzerV9 0 UsrivanNessuna valutazione finora

- CH 07Documento189 pagineCH 07Kate MontaluisaNessuna valutazione finora

- Column For New OnesDocumento8 pagineColumn For New OnesSpicyNessuna valutazione finora

- Aspen HYSYS BrochureDocumento4 pagineAspen HYSYS BrochureNabeel TahirNessuna valutazione finora

- Aspen HYSYS BrochureDocumento4 pagineAspen HYSYS BrochureLuiz OviedoNessuna valutazione finora

- Aspen Plus Dynamics DatasheetDocumento2 pagineAspen Plus Dynamics Datasheetatsomech132206Nessuna valutazione finora

- 1270 Aspen HYSYS Product Brochure FINALDocumento4 pagine1270 Aspen HYSYS Product Brochure FINALTaniadi SuriaNessuna valutazione finora

- Software ArenaDocumento3 pagineSoftware ArenaAlex -Nessuna valutazione finora

- Introduction To Chemical Process SimulatorsDocumento12 pagineIntroduction To Chemical Process Simulatorsanand upadhyayNessuna valutazione finora

- M.Anas Assigment #2 SimulationDocumento10 pagineM.Anas Assigment #2 SimulationMubasher RajputNessuna valutazione finora

- Hanif Assigment #2 SimulationDocumento10 pagineHanif Assigment #2 SimulationMubasher RajputNessuna valutazione finora

- Aspen PIMS BrochureDocumento4 pagineAspen PIMS BrochureckwabiNessuna valutazione finora

- Plant Simulation: Simulation and Optimization of Production Systems and ProcessesDocumento2 paginePlant Simulation: Simulation and Optimization of Production Systems and ProcessesMateo QuispeNessuna valutazione finora

- NID DATPrelimsTestPaper2018 BDesDocumento24 pagineNID DATPrelimsTestPaper2018 BDesManaswini ReddyNessuna valutazione finora

- Company ProfileDocumento36 pagineCompany ProfileShahzad Nasir SayyedNessuna valutazione finora

- 1.toyotamarklogo Standard Jan 2021 eDocumento43 pagine1.toyotamarklogo Standard Jan 2021 eMercadeo TosakaNessuna valutazione finora

- Acc05 SCG116Documento42 pagineAcc05 SCG116Hilal HazaaNessuna valutazione finora

- Stahl - PUDSDocumento29 pagineStahl - PUDSsusanasusana_Nessuna valutazione finora

- Idlers: TRF Limited TRF LimitedDocumento10 pagineIdlers: TRF Limited TRF LimitedAjit SarukNessuna valutazione finora

- Emcoturn 365Documento362 pagineEmcoturn 365mikadoturkNessuna valutazione finora

- Anish Pandey ResumeDocumento4 pagineAnish Pandey ResumeAnubhav ChaturvediNessuna valutazione finora

- An Overview of The IEEE Color BooksDocumento6 pagineAn Overview of The IEEE Color BooksOhm666Nessuna valutazione finora

- Citadel of Kirkuk 1Documento17 pagineCitadel of Kirkuk 1ArézAzadNessuna valutazione finora

- The Use of Proton Pump Inhibitors in Treating and Preventing NSAID-induced Mucosal DamageDocumento6 pagineThe Use of Proton Pump Inhibitors in Treating and Preventing NSAID-induced Mucosal DamageFriska Rachmanita PrayogoNessuna valutazione finora

- Motion of A Simple Pendulum in A FluidDocumento16 pagineMotion of A Simple Pendulum in A FluidGokul JeevaNessuna valutazione finora

- Mits Chocolates: Let The Life Be More Sweet'Documento30 pagineMits Chocolates: Let The Life Be More Sweet'Azaz NathaniNessuna valutazione finora

- Balmatech Go Ep Tds 2022-03 GBDocumento2 pagineBalmatech Go Ep Tds 2022-03 GBAnalista De CalidadNessuna valutazione finora

- Anatomia Dezvoltarii PancreasuluiDocumento49 pagineAnatomia Dezvoltarii Pancreasuluitarra abuNessuna valutazione finora

- The Russian Review - 2020 - ROTH EY - Listening Out Listening For Listening in Cold War Radio Broadcasting and The LateDocumento22 pagineThe Russian Review - 2020 - ROTH EY - Listening Out Listening For Listening in Cold War Radio Broadcasting and The LateOkawa TakeshiNessuna valutazione finora

- Silo Dryers: Mepu - Farmer S First Choice Mepu To Suit Every UserDocumento2 pagineSilo Dryers: Mepu - Farmer S First Choice Mepu To Suit Every UserTahir Güçlü100% (1)

- 300 20Documento3 pagine300 20Christian JohnsonNessuna valutazione finora

- Yamaha rx-v395 v395rds htr-5130 5130rdsDocumento55 pagineYamaha rx-v395 v395rds htr-5130 5130rdsdomino632776Nessuna valutazione finora

- 06ESL37 Analog Electronics Lab MANUALDocumento70 pagine06ESL37 Analog Electronics Lab MANUALSan AngadiNessuna valutazione finora

- Project Report of Dhanashree Goat FarmDocumento56 pagineProject Report of Dhanashree Goat FarmNandan GowdaNessuna valutazione finora

- MIKE21BW Step by Step GuideDocumento124 pagineMIKE21BW Step by Step Guideflpbravo100% (2)

- 33 SriSriTadepalliShastryGaru 1Documento4 pagine33 SriSriTadepalliShastryGaru 1Kiran GopalanNessuna valutazione finora

- Lecture 9: Quarter-Wave-Transformer Matching.: R JZ L Z Z Z JR LDocumento13 pagineLecture 9: Quarter-Wave-Transformer Matching.: R JZ L Z Z Z JR LRuth EnormeNessuna valutazione finora

- Ec210b Pub20021241-I PDFDocumento1.046 pagineEc210b Pub20021241-I PDFCholif 'oliph' Fadhilah100% (16)

- E11133 MB Pin Definition v2 Print Vendor Only PDFDocumento18 pagineE11133 MB Pin Definition v2 Print Vendor Only PDFLuciano MalancaNessuna valutazione finora

- Glamour Secrets Prices For Products and ServicesDocumento1 paginaGlamour Secrets Prices For Products and ServiceslocalintheknowNessuna valutazione finora

- ECE 374 - Part - 1c - S2017Documento37 pagineECE 374 - Part - 1c - S2017Zakaria ElwalilyNessuna valutazione finora

- NCP DehydrationDocumento4 pagineNCP DehydrationYnah Sayoc100% (2)

- Embedded Systems:: Hacking of Electronic EquipmentsDocumento76 pagineEmbedded Systems:: Hacking of Electronic EquipmentsKailashi Chandra SekharNessuna valutazione finora

- Ikigai: The Japanese Life Philosophy to Finding Happiness and PeacefulnessDa EverandIkigai: The Japanese Life Philosophy to Finding Happiness and PeacefulnessValutazione: 5 su 5 stelle5/5 (91)

- Twelve Caesars: Images of Power from the Ancient World to the ModernDa EverandTwelve Caesars: Images of Power from the Ancient World to the ModernValutazione: 3.5 su 5 stelle3.5/5 (9)

- $100M Leads: How to Get Strangers to Want to Buy Your StuffDa Everand$100M Leads: How to Get Strangers to Want to Buy Your StuffValutazione: 5 su 5 stelle5/5 (19)

- To Pixar and Beyond: My Unlikely Journey with Steve Jobs to Make Entertainment HistoryDa EverandTo Pixar and Beyond: My Unlikely Journey with Steve Jobs to Make Entertainment HistoryValutazione: 4 su 5 stelle4/5 (26)

- Bare Bones: I'm Not Lonely If You're Reading This BookDa EverandBare Bones: I'm Not Lonely If You're Reading This BookValutazione: 4 su 5 stelle4/5 (11)

- The Gardner Heist: The True Story of the World's Largest Unsolved Art TheftDa EverandThe Gardner Heist: The True Story of the World's Largest Unsolved Art TheftNessuna valutazione finora

- I Didn't Come Here to Make Friends: Confessions of a Reality Show VillainDa EverandI Didn't Come Here to Make Friends: Confessions of a Reality Show VillainValutazione: 3 su 5 stelle3/5 (47)

- Creative Abstract Watercolor: The beginner's guide to expressive and imaginative paintingDa EverandCreative Abstract Watercolor: The beginner's guide to expressive and imaginative paintingValutazione: 3 su 5 stelle3/5 (1)

- House Rules: How to Decorate for Every Home, Style, and BudgetDa EverandHouse Rules: How to Decorate for Every Home, Style, and BudgetNessuna valutazione finora

- The Black Star of Kingston: Tales of Old Natalia 1Da EverandThe Black Star of Kingston: Tales of Old Natalia 1Valutazione: 5 su 5 stelle5/5 (153)

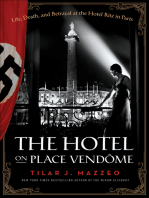

- The Hotel on Place Vendôme: Life, Death, and Betrayal at the Hotel Ritz in ParisDa EverandThe Hotel on Place Vendôme: Life, Death, and Betrayal at the Hotel Ritz in ParisValutazione: 3.5 su 5 stelle3.5/5 (49)

- Summary: The Creative Act: A Way of Being By Rick Rubin: Key Takeaways, Summary and AnalysisDa EverandSummary: The Creative Act: A Way of Being By Rick Rubin: Key Takeaways, Summary and AnalysisValutazione: 4.5 su 5 stelle4.5/5 (2)