Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Pyinkado

Caricato da

Nay Win SheinDescrizione originale:

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Pyinkado

Caricato da

Nay Win SheinCopyright:

Formati disponibili

Scientific Name Xylia xylocarpa Trade Name Pyinkado Family Name Leguminosae Synonyms Xylia dolabriformis

Common Names Boja, Bojeh, Cam xe, Eruvalu, Irul, Irummala, Jamba, Jambe, Jambu, Kada, Kadamaram, Konda tangedu, Kongora, Mai-sa-lan, Mai-sak, Orjori, Panga, Pangali, Pegu ironwood, Pinkado, Pkhay, Praing, Pran, Pyin, Pyinkado, Shilve, Sokram, Suaba, Suria, Tangani, Tangedi, Tangudu, The ironwood of Burma, Tiriwa, Trul, Trumalla, Yerul Regions of Distribution Oceania and S.E. Asia Countries of Distribution [VIEW MAP] Burma, Cambodia, China, India, Laos, Myanmar, Philippines, Thailand, Vietnam Common Uses Agricultural implements, Barge fenders, Boat building (general), Boat building, Bridge beams, Bridge construction, Bridge joists, Building construction, Building materials, Cabin construction, Canoes, Chemical derivatives, Construction, Crossties, Decks, Docks, Dockwork, Factory construction, Flooring, Flooring: commercial heavy traffic, Flooring: industrial heavy traffic, Golf club heads, Handles: general, Harbor work, Heavy construction, Ladders, Lifeboats, Light construction, Marine construction, Mine timbers, Naval architecture, Piling, Poles, Posts, Raft floats, Rafts, Railroad ties, Shipbuilding, Structural work, Textile equipment, Tool handles, Utility poles, Vehicle parts, Wharf construction Environmental Profile The future survival of this species is at risk Some long-term concern for the species Generally secure within its natural habitat Data source is World Conservation Monitoring Center

Distribution Overview Xylia is a small genus of trees distributed in tropical Asia and Africa. X. xylocarpa is common in the forest of the Western Ghats in southern Maharashtra, Mysore, and Kerala in India. Its range is also reported to extend in a scattered manner from Madhya Pradesh eastward to the Esatern Ghats in Orissa and Andra Pradesh, and is locally common in Ganjam. also introduced into West Bengal. Heartwood Color Brown Yellow Orange Red

Reddish brown Golden brown with a reddish cast Darkens significantly upon exposure Dark gum streaks Dark brown

Sapwood Color Yellow White

White to yellow Pale pink Well defined

Grain Interlocked Wavy Straight Figure Growth rings (figure) Closed Even Distinct (figure) Interlocked Wavy Straight Clear growth rings (figure) May be wavy or curly Distinct figure

Texture Fine Coarse

Fine to medium Medium Medium to coarse Fine Hard Luster High

Dull

Natural Durability Very durable Durable

Very durable Resistant to attack from termites (Isoptera) Resistant to attack from marine borers Susceptible to attack from powder post (Lyctid & Bostrychid) beetles Very high natural resistance

Moderately resistant to termite (Isoptera) attack Resistance to termite attack Odor No specific smell or taste

Light-Induced Color Change Darker

Toxicity Respiratory effects

Kiln Schedules Dry at a slow speed Dry at a slow speed UK=C US=T3C2/T3C1 Fr=3 UK=C US=T3C2/T3C1 Fr=3 T3 - C2 (4/4); T3 - C1 (8/4) US Schedule C (4/4) United Kingdom/T3 - C2 (4/4); T3 - C1 (8/4) US Schedule C (4/4) United Kingdom

Drying Defects Distortion

Moderate end spitting Slight twist/warp Slight surface checking Moderate surface checking Warping can be expected Slight end splitting Severe twisting/warping Moderate twist/warp Expect splits Checking

Ease of Drying Rapidly Reconditioning Treatement

Dries well under good controlled conditions Dries slowly Difficult Felling should be done during or just after the rainy season and logs should be converted green or stored under water until ready to convert. Sawn material should be stored under cover and protected against rapid drying Tree Identification Bole/stem form is straight Bole/stem form is cylindrical Bole/stem form is fluted

Tree Size Tree height is 30-40 m Tree height is 20-30 m Tree height is 0-10 m Tree height is 40-50 m

Tree height is 50-60 m Trunk diameter is 100-150 cm Trunk diameter is 200-250 cm Trunk diameter is 250-300 cm

Product Sources The bark and oil from the seeds of Irul are used for medicinal purposes. Comments Deposits - Wood vessels may contain whitish deposits. General finishing qualities are rated as good General finishing qualities are rated as good The woods of Irul (X. xylocarpa ) and Pyinkado (X. dolabriformis ) are very similar in structural and other properties, and are very difficult to distinguish. Wood vessels may contain white deposits. Blunting Effect Moderate

Blunting effect on machining is severe High effect Blunting effect on sawing dry wood is severe

Boring Fair to good results Fairly easy to very easy

Carving Fair to Good Results Fairly Easy to Very Easy

Cutting Resistance Easy to saw

Cutting Resistance with dry wood is difficult Difficult to saw Cutting Resistance with green wood is difficult

Gluing Fair to Good Results Fairly Easy to Very Easy

Fairly difficult to glue Difficult to glue

Mortising Fair to Good Results Fairly Easy to Very Easy

Moulding Fair to Good Results

Fairly Easy to Very Easy

Movement in Service Fair to Good Stability - Medium Movement

Medium Moderate dimensional stability after seasoning

Nailing Fair to Good Results Fairly Easy to Very Easy

Difficult to nail Poor resistance to decay Holds nails well

Planing Fair to Good Results Fairly Easy to Very Easy

Requires sharp cutting edges Difficult to plane Wavy and interlocked grain, as well as varying amounts of resin, are reported to influence the machining characteristics of the timber. A cutting angle of 20 degrees is recommended in planing to prevent torn grain Resistance to Impregnation Resistant sapwood Resistant heartwood

Heartwood is highly resistant Sapwood is moderately resistant

Response to Hand Tools Responds Readily Easy to Work

Difficult to machine

Routing & Recessing Fair to Good Results Fairly Easy to Very Easy

Sanding Fair to Good Results Fairly Easy to Very Easy

Fairly good sanding characteristics

Screwing Very Good to Excellent Results Fair to Good Results

Screwing yields good results

Turning Fair to Good Results Fairly Easy to Very Easy

Veneering Qualities Veneers easily Veneers moderately easy Difficult to veneer Suitable for peeling

Steam Bending Fair to Good Results

Polishing Very Good to Excellent Results Fairly Easy to Very Easy

Satisfactory results Good results Excellent results Good results except when very high resin context Staining Rated as excellent Finish is generally satisfactory

Strength Properties Density (dry weight) = 61-67 lbs/cu.ft Density (dry weight) = 53-60 lbs/cu. ft Max. crushing strength = high Modulus of Elasticity (stiffness) = medium

Bending strength (MOR) = medium Bending strength (MOR) = high Shrinkage, Volumetric = moderate Hardness (side grain) = hard Shrinkage, Tangential = moderate Modulus of Elasticity (stiffness) = high Max. crushing strength = very high Shrinkage, Tangential = very small Shrinkage, Radial = very small Shrinkage, Radial = moderate Max. crushing strength = medium Density (dry weight) = 67-75 lbs/cu. ft Density (dry weight) = 46-52 lbs/cu. ft. Bending strength (MOR) = low Shrinkage, Tangential = small Shrinkage, Radial = small Modulus of Elasticity (stiffness) = very low Modulus of Elasticity (stiffness) = low High in density Heavy Hardness (side grain) = very hard Compression strength (parallel to grain) = high Bending strength (MOR) = very high Numerical Data Item Bending Strength Density Hardness Impact Strength Maximum Crushing Strength Shearing Strength Stiffness Specific Gravity Weight Radial Shrinkage Tangential Shrinkage Volumetric Shrinkage Item Bending Strength Density Hardness Impact Strength Maximum Crushing Strength Shearing Strength Stiffness Specific Gravity Weight Radial Shrinkage Tangential Shrinkage 130 0.69 961 3 6 73 506 1853 0.69 60 3 6 11 Green 867 29 7201 Green 12336 Dry English 18006 psi 55 lbs/ft3 2369 lbs 29 inches 10756 psi 2205 psi 2134 1000 psi 0.76 54 lbs/ft3 % % % Dry Metric 1265 kg/cm2 881 kg/m3 1074 kg 73 cm 756 kg/cm2 155 kg/cm2 150 1000 kg/cm2 0.76 865 kg/m3 % %

Potrebbero piacerti anche

- Woodworker's Pocket Reference: Everything a Woodworker Needs to Know at a GlanceDa EverandWoodworker's Pocket Reference: Everything a Woodworker Needs to Know at a GlanceValutazione: 4 su 5 stelle4/5 (4)

- Carpentry ManualDocumento22 pagineCarpentry ManualMaison KidsNessuna valutazione finora

- Wood ConservationDocumento67 pagineWood ConservationKrishna KumarNessuna valutazione finora

- Timber Lesson 1 PDFDocumento59 pagineTimber Lesson 1 PDFdummya790Nessuna valutazione finora

- 200 Questions and Answers On Practical Civil Engineering Works 2008Documento84 pagine200 Questions and Answers On Practical Civil Engineering Works 2008ramdj100% (4)

- Woodworker's Handbook: The Beginner's Reference to Tools, Materials, and Skills, Plus Essential Projects to MakeDa EverandWoodworker's Handbook: The Beginner's Reference to Tools, Materials, and Skills, Plus Essential Projects to MakeNessuna valutazione finora

- Quality Control - Works Inspection: Base Coat For WallDocumento1 paginaQuality Control - Works Inspection: Base Coat For WallParasNessuna valutazione finora

- TimberDocumento55 pagineTimberAra Abdullah100% (1)

- Timber: Building Constrction and MaterailsDocumento70 pagineTimber: Building Constrction and MaterailsWilliam Arpit SinghNessuna valutazione finora

- Fundamentals of Wood Anatomy and DryingDocumento51 pagineFundamentals of Wood Anatomy and DryingnamkvalNessuna valutazione finora

- TimberDocumento127 pagineTimberptgopoNessuna valutazione finora

- Moisture Susceptibility of Hot Mix Asphalt Mixes: Identification of Problem and Recommended SolutionsDocumento39 pagineMoisture Susceptibility of Hot Mix Asphalt Mixes: Identification of Problem and Recommended SolutionsProf. Prithvi Singh Kandhal100% (3)

- Practical Woodwork for Laboratory Technicians: Pergamon Series of Monographs in Laboratory TechniquesDa EverandPractical Woodwork for Laboratory Technicians: Pergamon Series of Monographs in Laboratory TechniquesNessuna valutazione finora

- sp001 5thedition ChecklistsDocumento14 paginesp001 5thedition ChecklistsJavier Mauricio Higuera MoraNessuna valutazione finora

- Test For BentoniteDocumento3 pagineTest For BentoniteNay Win SheinNessuna valutazione finora

- Project On Stones & TilesDocumento41 pagineProject On Stones & TilesMegha GolaNessuna valutazione finora

- ECM 206 CHAPTER 4 TimberDocumento8 pagineECM 206 CHAPTER 4 TimberAZUAN BIN AHMAD FAUZI100% (1)

- CMT - WoodsDocumento22 pagineCMT - WoodsPrecious Anne PalmaNessuna valutazione finora

- Timber Classification, Properties, Types and Uses in ConstructionDocumento57 pagineTimber Classification, Properties, Types and Uses in ConstructionSufian Pian100% (1)

- Aircraft Wood InformationDocumento52 pagineAircraft Wood Informationjmercano100% (1)

- Singapore National Annexure To Eurocode 8 PDFDocumento21 pagineSingapore National Annexure To Eurocode 8 PDFPankaj MunjalNessuna valutazione finora

- BS en 10130 2006Documento16 pagineBS en 10130 2006Phong TongNessuna valutazione finora

- Commercial Hardwood in MyanmarDocumento108 pagineCommercial Hardwood in Myanmarpanamiko100% (3)

- Meranti PropertiesDocumento4 pagineMeranti PropertiesChung Yiung YungNessuna valutazione finora

- Ke RuingDocumento3 pagineKe RuingAjay KumarNessuna valutazione finora

- Compression of Wood (E45)Documento31 pagineCompression of Wood (E45)Fernando LopezNessuna valutazione finora

- Table of Wood DensityDocumento9 pagineTable of Wood DensityAri WahyuNessuna valutazione finora

- Douglas-Fir: Pseudotsuga Menziesii (Mirb.) FrancoDocumento4 pagineDouglas-Fir: Pseudotsuga Menziesii (Mirb.) FrancoRobert AmorusoNessuna valutazione finora

- Manufacturing Processes: Drnksingh Associate Professor (Workshop) Department of Mech Engg I S M DhanbadDocumento78 pagineManufacturing Processes: Drnksingh Associate Professor (Workshop) Department of Mech Engg I S M DhanbadAbhinavGuptaNessuna valutazione finora

- Technical Information - KeruingDocumento3 pagineTechnical Information - KeruingMuhammad MustahsinNessuna valutazione finora

- Timber Properties and Conversion TechniquesDocumento24 pagineTimber Properties and Conversion TechniquesTerkuma IorpendaNessuna valutazione finora

- Stone Inlaid Woodturning ~ Minerals for InlayDocumento6 pagineStone Inlaid Woodturning ~ Minerals for InlayEdwin HarrisNessuna valutazione finora

- 03 Timber PDFDocumento49 pagine03 Timber PDFGautam Lele100% (1)

- Timber Wood Suppliers FRM MalaysiaDocumento41 pagineTimber Wood Suppliers FRM MalaysiaomarfarookkhanNessuna valutazione finora

- Dark Red Meranti PropertiesDocumento4 pagineDark Red Meranti PropertiesChung Yiung YungNessuna valutazione finora

- Palestine University: Building MaterialDocumento35 paginePalestine University: Building MaterialMuhammad Irfan KhanNessuna valutazione finora

- BluegumDocumento2 pagineBluegumsmyliedaleNessuna valutazione finora

- Caracteristics of LarchDocumento1 paginaCaracteristics of LarchValeriu CernalevschiNessuna valutazione finora

- Basic Construction SkillsDocumento3 pagineBasic Construction SkillsZee ZeeNessuna valutazione finora

- Gmelina Tree PropertiesDocumento3 pagineGmelina Tree PropertiesajaytrixNessuna valutazione finora

- TimberDocumento3 pagineTimberAllan SsemujjuNessuna valutazione finora

- Presentation WoodDocumento18 paginePresentation Woodapi-265125200Nessuna valutazione finora

- TimberDocumento33 pagineTimberDr Omega YTNessuna valutazione finora

- Carpentry ShopDocumento26 pagineCarpentry ShoplogwolvyNessuna valutazione finora

- Chapter 5 TimberDocumento44 pagineChapter 5 TimbertrfuawlachewNessuna valutazione finora

- Balau WoodDocumento6 pagineBalau WoodAri WahyuNessuna valutazione finora

- Wood and Its DerivativesDocumento35 pagineWood and Its DerivativesA 04 Ankit SharmaNessuna valutazione finora

- Civil Wood Shopassignment Group ADocumento7 pagineCivil Wood Shopassignment Group AFaith Gwamure JafariNessuna valutazione finora

- Common Timber DefectsDocumento4 pagineCommon Timber DefectsGabriel OnalekeNessuna valutazione finora

- Versatile Building Material TimberDocumento93 pagineVersatile Building Material TimberAbenet GetachewNessuna valutazione finora

- WS PresentationDocumento60 pagineWS PresentationtechnologicaluniversityyangonNessuna valutazione finora

- I2433e02 PDFDocumento48 pagineI2433e02 PDFanon_556243061Nessuna valutazione finora

- Properties of WOOD - Page 1 To 41Documento41 pagineProperties of WOOD - Page 1 To 41Jebone Stein Web JuarbalNessuna valutazione finora

- Types Od WoodDocumento4 pagineTypes Od Woodkath mirandaNessuna valutazione finora

- Artificial TimbersDocumento39 pagineArtificial TimbersDarshit ShahNessuna valutazione finora

- Wood Defects - Davids TimberDocumento1 paginaWood Defects - Davids Timberadrilot1812Nessuna valutazione finora

- Major Timber yielding plants of J&K state – Morphology, Botanical Name and FamilyDocumento19 pagineMajor Timber yielding plants of J&K state – Morphology, Botanical Name and FamilySarovshNessuna valutazione finora

- Meranti: Frequently Called Philippine Mahogany, This Wood Isn't Mahogany at AllDocumento4 pagineMeranti: Frequently Called Philippine Mahogany, This Wood Isn't Mahogany at AllPbts CorpNessuna valutazione finora

- CE 479: DESIGN OF BUILDING COMPONENTS AND SYSTEMS FALL 2012 – J. LIU Wood: Intro, Properties, GradesDocumento106 pagineCE 479: DESIGN OF BUILDING COMPONENTS AND SYSTEMS FALL 2012 – J. LIU Wood: Intro, Properties, GradesThulasi Raman KowsiganNessuna valutazione finora

- 2013 - Timber Notes PDFDocumento18 pagine2013 - Timber Notes PDFArifsalim0% (1)

- WOOD April 26 2015Documento59 pagineWOOD April 26 2015Miguel ApiladoNessuna valutazione finora

- Spotted Gum: Corymbia MaculataDocumento1 paginaSpotted Gum: Corymbia MaculataScooby DooNessuna valutazione finora

- Wood B. ConstDocumento60 pagineWood B. ConstPhilippe AntonioNessuna valutazione finora

- Boat Building Materials and Construction of Boat Wooden BoatDocumento32 pagineBoat Building Materials and Construction of Boat Wooden BoatAnthony HidalgoNessuna valutazione finora

- INTD402 Furniture, Fittings, Textile & AcessoriesDocumento38 pagineINTD402 Furniture, Fittings, Textile & AcessoriesAmr MohamedNessuna valutazione finora

- Timber: Name:-Yash.H.SutharDocumento35 pagineTimber: Name:-Yash.H.SutharYash SutharNessuna valutazione finora

- Front-Cover BT Group1Documento12 pagineFront-Cover BT Group1GUTIERREZ, VIANCA MARIE R.Nessuna valutazione finora

- Drawing ToiletDocumento1 paginaDrawing ToiletNay Win SheinNessuna valutazione finora

- Zaw & Hnin - Polypur TC 20Documento1 paginaZaw & Hnin - Polypur TC 20Nay Win SheinNessuna valutazione finora

- Zaw & Hnin - PolycapDocumento1 paginaZaw & Hnin - PolycapNay Win SheinNessuna valutazione finora

- Specimen Size and Shape EffectDocumento17 pagineSpecimen Size and Shape EffectpedrotacoNessuna valutazione finora

- AXIAL LOAD TEST PROCEDURESDocumento6 pagineAXIAL LOAD TEST PROCEDURESNay Win SheinNessuna valutazione finora

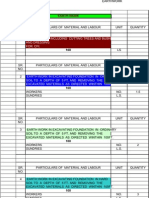

- EARTHWORK AND CONCRETE ESTIMATEDocumento248 pagineEARTHWORK AND CONCRETE ESTIMATENay Win SheinNessuna valutazione finora

- Strain Gauges: Mark ColtonDocumento15 pagineStrain Gauges: Mark ColtonGATE FACULTYNessuna valutazione finora

- Btech Acadcivil4Documento23 pagineBtech Acadcivil4Tvc TejaNessuna valutazione finora

- Table 5-4 Quantity of Lumber For Scaffolding and StagingDocumento1 paginaTable 5-4 Quantity of Lumber For Scaffolding and Stagingmark dominicNessuna valutazione finora

- Sports-Cote Pro PUDocumento2 pagineSports-Cote Pro PURahul KalathingalNessuna valutazione finora

- Seismic HotelDocumento6 pagineSeismic HotelThesis ConsultantNessuna valutazione finora

- Jobsheet MasonDocumento6 pagineJobsheet MasonLudivino Toto Ledesma CondalorNessuna valutazione finora

- TPI FacadeDocumento17 pagineTPI FacadeSohel DalalNessuna valutazione finora

- Bus Air Conditioner InstallationDocumento26 pagineBus Air Conditioner InstallationMaría AlvarezNessuna valutazione finora

- Acson Catalogue Air Handling Unit 1201 PDFDocumento12 pagineAcson Catalogue Air Handling Unit 1201 PDFfaiz budiNessuna valutazione finora

- Complete EDM Handbook - 14Documento12 pagineComplete EDM Handbook - 14soheil gazeranNessuna valutazione finora

- E21-G02 - 1 Identification of Circuit Conductor & Phase RelationDocumento6 pagineE21-G02 - 1 Identification of Circuit Conductor & Phase RelationMuhammad IrfanNessuna valutazione finora

- 3M - Switch - Electrical CompressedDocumento61 pagine3M - Switch - Electrical CompressedReymart ManablugNessuna valutazione finora

- ASME 2017 SA 312 Sublimentry RequirementsDocumento2 pagineASME 2017 SA 312 Sublimentry RequirementsKathir VelNessuna valutazione finora

- 250-122 (F) Equipment-Grounding Conductors For Parallel RunsDocumento3 pagine250-122 (F) Equipment-Grounding Conductors For Parallel RunsJOSE LUIS FALCON CHAVEZNessuna valutazione finora

- Fde 1Documento19 pagineFde 1Ivan MarijanovićNessuna valutazione finora

- Sans 10292Documento31 pagineSans 10292leandroNessuna valutazione finora

- Tutorial ProblemsDocumento3 pagineTutorial ProblemsJoel CurryNessuna valutazione finora

- C-31 - Defence Colony - Terrace Garden ProposalDocumento7 pagineC-31 - Defence Colony - Terrace Garden ProposalDevangie Shrivastava100% (1)

- 2000 IBC Handbook Seismic & WindDocumento11 pagine2000 IBC Handbook Seismic & WindcristinelbNessuna valutazione finora

- KK 225 PDFDocumento1 paginaKK 225 PDFVladimir Illich PinzonNessuna valutazione finora

- Technical Data Sheet: Hanson Construction AggregatesDocumento9 pagineTechnical Data Sheet: Hanson Construction AggregatesShaiful ZamriNessuna valutazione finora

- SP21Documento506 pagineSP21Venkata Raju Kalidindi100% (1)

- Active Infrared Thermography Technique F PDFDocumento14 pagineActive Infrared Thermography Technique F PDFsidNessuna valutazione finora

- Philips Lighting 1Documento45 paginePhilips Lighting 1Manisankar DhabalNessuna valutazione finora

- Aux Boiler Startup ChecklistDocumento4 pagineAux Boiler Startup ChecklistAmaresh NayakNessuna valutazione finora