Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

1hz Generator

Caricato da

marco.dado2700Descrizione originale:

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

1hz Generator

Caricato da

marco.dado2700Copyright:

Formati disponibili

My Nixie Clock Project

http://www.mcamaa.de/nixie/ncp_en/ncp.htm

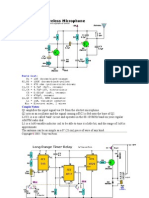

Getting started with it: the proper timing Heart of any clock is a source for a timing signal. Cheap AC-powered alarm clocks use the 50 or 60 Hz AC line to generate a more or less accurate clock-signal from it. Usually that would do given that the accuracy over the whole year on the AC-line is within a 1 % range. Nontheless I'd decided not to use that. First reason was to be independent from the AC frequency. Secondly a crystal oscillator offers even better accuracy than line-AC and third I had a circuit at hand anyway I used for a couple of applications in the past. Main advantage: it operates with a generic 32.768 KHz mini crystal widely available - and comes out with a 1 Hz timing pulse. The schematic below shows the circuit.

There are two resistors: R1 acting as current-limiting resistor and R2 bias resistor. This latter one is a) dependent to the circuit voltage applied to the 4060 divider chip and b) dependent to the current ow through the crystal and its capacity. I made good results with either omitting this one or using a 10 Mega-Ohms to start with. Your individual mileage may vary. The crystal I used is a miniature clock crystal X1 in a round case with 19 pF internal capacity. The "tie-up" capacitor C1 is a low-loss ceramic type, the trimmer capacitor C2 is a standard plastic type. With a frequency counter connected to the 4060's pin 9 you can measure the buffered crystal frequency and adjust it to read exactly 32.768 Hz. The 4013 RS Flipop is used to divide the 2 Hz from the 4060 down to the 1 Hz base clock. The second half of the 4013 might be used to divide the 8 Hz signal at pin 1 down to 4 Hz for a "fast forward" set mode - not shown here however. If you are not using the second half of the 4013: tie the pins 8, 10 and 11 to GND and connect 9 and 12. Pin 13 stays open. If you decide to use the 4013 pin 11 is your input, 13 the output. It is highly recommended to keep the wires of the components (caps and resistors) short trimmed and the leads between the components as short as possible. If the oscillator fails to start up or dies after several seconds: make the bias resistor larger. It may go up to 10 MOhm with these miniature crystals - or even left away. The bigger HC-style crystals with higher internal capacity may require 100 KOhm - 1 MOhm bias resistors. If you don't want a trimmer capacitor you may use a ceramic capacitor of the same value as C1 as well. Doesn't hurt the overall accuracy that much. In the meantime - after I edited this page for the last time - I had built numerous oscillators with the 4060 and got a lot responses from other folks. Alternative concepts for the trimmer position, values of R1 and R2 and the C1 and C2 have been discussed. Usually you have a datasheet for the mini xtal X1 to start with. This datasheet shows the internal capacity - which *use to be* about 16 - 19pF.

1 di 2

04/11/11 16.19

My Nixie Clock Project

http://www.mcamaa.de/nixie/ncp_en/ncp.htm

capacity - which *use to be* about 16 - 19pF. The value for the tie-up cap C1 should be 2x the xtal capacity. 39pF ts quite nicely here. The value for C1 should be [xtal capacity < C2 < 3x xtal capacity], where 5 - 50pF covers the entire range. Determining the values for R1 and R2 is more tricky. While R2 could be ommitted in the best case for very dense packing of components R1 is essential for the clean function here. If it is too high the xtal fails to start - if it is too low the xtal enters "overtone mode" and the oscillator output frequency is either totally erratic or way higher than supposed. For R1 220KOhm has prooved to be a good value, R2 should be 10M. If you have xtals larger than these micro-types your R1 needs to be reduced - down to 2K2 for a HC32 xtal and R2 might be reduced to 4M7 for stable operation. The 4060 allowes to run at up to 4MHz @ 15V supply. If you have too much room and wouldn't care about two more 4017 dividers: pick a 3.2768 MHz xtal, leave R1 away or reduce it to 2K2, R2 to 10M, C1 to 22pF and install a 2 - 22pF trimmer. You get 200Hz at the Q13 - divided by 2 in the 4013 for 100Hz. Add two more 4017s and you are again at 1Hz with -probably- higher stability due to the higher reference frequency. However: you should not test the 4060 frequency at pin 9. The probe capacity will alter the result. You should test at O4 (pin 7) and your counter should read 204.800 Hz. The trimmer allows a change of about +/- 25 Hz. If you don't have one adjust C2 to the center, where about the half of the static "leafes" are visible. That will do to for most cases.

2 di 2

04/11/11 16.19

Potrebbero piacerti anche

- Newnes Electronics Circuits Pocket Book (Linear IC): Newnes Electronics Circuits Pocket Book, Volume 1Da EverandNewnes Electronics Circuits Pocket Book (Linear IC): Newnes Electronics Circuits Pocket Book, Volume 1Valutazione: 4.5 su 5 stelle4.5/5 (3)

- Infrared Emitter From CMOS 555 Robot RoomDocumento6 pagineInfrared Emitter From CMOS 555 Robot RoomnkimlevnNessuna valutazione finora

- Free Forming The 44-Pin PLCC SocketDocumento4 pagineFree Forming The 44-Pin PLCC SocketvishalbauNessuna valutazione finora

- After Making A Couple of Waveform Generators Based On Direct Digital SynthesizerDocumento5 pagineAfter Making A Couple of Waveform Generators Based On Direct Digital Synthesizerluis cortelezziNessuna valutazione finora

- CBC Expander-160 UserDocumento11 pagineCBC Expander-160 UserGerardo HernándezNessuna valutazione finora

- HV Resonance CollectionDocumento4 pagineHV Resonance CollectionfreiwildNessuna valutazione finora

- AM ReceiverDocumento7 pagineAM ReceiverNguyen Manh TuanNessuna valutazione finora

- Basic Pic16/17 Oscillator Design: By: Dan MatthewsDocumento4 pagineBasic Pic16/17 Oscillator Design: By: Dan Matthewsandi2k9Nessuna valutazione finora

- XR2206 DIY Kit ManualDocumento13 pagineXR2206 DIY Kit ManualCol Sanjay BajpaiNessuna valutazione finora

- 2 Guide SSHV2Documento3 pagine2 Guide SSHV2Calsonic CMGNessuna valutazione finora

- XR-2206 Function GeneratorDocumento15 pagineXR-2206 Function GeneratorWagner MirandaNessuna valutazione finora

- AM Receiver: Home Analysis Help Media Links PracticalDocumento10 pagineAM Receiver: Home Analysis Help Media Links PracticalĐinh Văn HiếuNessuna valutazione finora

- Devantech Srf04 TechDocumento5 pagineDevantech Srf04 TechEikNessuna valutazione finora

- Ultrasonic SRF-04 PDFDocumento6 pagineUltrasonic SRF-04 PDFdwiaguspurwantoNessuna valutazione finora

- Rangkaian RangkaianDocumento30 pagineRangkaian RangkaianAhmad JuheriNessuna valutazione finora

- RF VM 2017Documento3 pagineRF VM 2017DayaSubramani100% (1)

- La 4108Documento12 pagineLa 4108andrzej_w_k100% (3)

- AC Current Monitor by LM358Documento14 pagineAC Current Monitor by LM358wlen2012Nessuna valutazione finora

- 6111 Kit Manual - PagesDocumento6 pagine6111 Kit Manual - PagesPeterNessuna valutazione finora

- Detector de MetaleDocumento7 pagineDetector de Metalefanei100% (1)

- 6n6p Kit ManualDocumento17 pagine6n6p Kit Manualaleksa64Nessuna valutazione finora

- This Project in PDF: Construction-1 Construction-2 Construction-3 CalibrationDocumento15 pagineThis Project in PDF: Construction-1 Construction-2 Construction-3 CalibrationPravin MevadaNessuna valutazione finora

- Pixman 2Documento8 paginePixman 2MR XNessuna valutazione finora

- Ve Diy StrobeDocumento5 pagineVe Diy Strobeasa2034Nessuna valutazione finora

- Constant Current SourceDocumento5 pagineConstant Current SourceAnonymous TPVfFif6TONessuna valutazione finora

- A Simple Regen Radio For BeginnersDocumento4 pagineA Simple Regen Radio For BeginnersEsequiel YakueczikNessuna valutazione finora

- SRF04 Technical DocumentationDocumento4 pagineSRF04 Technical Documentationt8823pc100% (1)

- CCCCCCCCCCCCCCCCCCCCCCCC C CCCCCCCCCCCCCCCCCCCCCCCCCCCCCDocumento10 pagineCCCCCCCCCCCCCCCCCCCCCCCC C CCCCCCCCCCCCCCCCCCCCCCCCCCCCCgopaldxtNessuna valutazione finora

- High Frequency Function Generator With The Maxim MAX038Documento11 pagineHigh Frequency Function Generator With The Maxim MAX038JCNessuna valutazione finora

- Designing Loop AntennasDocumento18 pagineDesigning Loop AntennasCesar AvilaNessuna valutazione finora

- RF Transmitter and Antenna Design HintsDocumento8 pagineRF Transmitter and Antenna Design HintsDaniel Roberto KrammerNessuna valutazione finora

- Ic Crystal Oscillator CircuitsDocumento4 pagineIc Crystal Oscillator Circuitsipa76100% (2)

- Antenna Analyzer vk5jst Version 1 Instructions PDFDocumento10 pagineAntenna Analyzer vk5jst Version 1 Instructions PDFPisu Miau Pisu MiauNessuna valutazione finora

- Laser Snooper: Projeto de Escuta A Distância Com LaserDocumento4 pagineLaser Snooper: Projeto de Escuta A Distância Com LaserJulio Ribeiro Del CistiaNessuna valutazione finora

- AM Radio Modulator / Short Range Transmitter V2: InstructablesDocumento12 pagineAM Radio Modulator / Short Range Transmitter V2: InstructablesSACFANessuna valutazione finora

- A Simple Regen Radio For Beginner NotesDocumento3 pagineA Simple Regen Radio For Beginner NotesMR X100% (1)

- FT 102 ModDocumento13 pagineFT 102 ModMihai BerarNessuna valutazione finora

- SSgenUseful Free EnergyDocumento15 pagineSSgenUseful Free EnergyWe RigdonNessuna valutazione finora

- Coil Measuring-, and Q-MetersDocumento10 pagineCoil Measuring-, and Q-MetersNiket Sali SureshNessuna valutazione finora

- 93004diDocumento8 pagine93004dirogererfredererNessuna valutazione finora

- Kit 32. Two Stage FM Transmitter About Range of 1killo-MeterDocumento4 pagineKit 32. Two Stage FM Transmitter About Range of 1killo-Metermi1350Nessuna valutazione finora

- ART Tube MP ModificationDocumento14 pagineART Tube MP Modificationtitov33Nessuna valutazione finora

- Low Voltage - Two Tube Regen ReceiverDocumento8 pagineLow Voltage - Two Tube Regen Receiverest_nuNessuna valutazione finora

- Pixie2 v6Documento4 paginePixie2 v6TabletaUnica100% (1)

- Guide SSHV2Documento4 pagineGuide SSHV2vinhson65-1Nessuna valutazione finora

- Arduino Based Lightning Detector ProjectDocumento6 pagineArduino Based Lightning Detector ProjectBenjamin DoverNessuna valutazione finora

- CloudDocumento4 pagineCloudapi-3731916Nessuna valutazione finora

- Auto-Fan, For Automatic Temperature ControlDocumento3 pagineAuto-Fan, For Automatic Temperature Controlrik206Nessuna valutazione finora

- 2-Channel AF Power Amplifier For Radio, Tape Recorder Use: Package Dimensions FeaturesDocumento11 pagine2-Channel AF Power Amplifier For Radio, Tape Recorder Use: Package Dimensions FeaturesMiloud ChouguiNessuna valutazione finora

- Felezjoo Pi - Part ListDocumento8 pagineFelezjoo Pi - Part ListRani SilvaNessuna valutazione finora

- Am CircuitsDocumento14 pagineAm CircuitsIngkz JeraeNessuna valutazione finora

- An-779 Low-Distortion 1.6 To 30 MHZ SSB Driver DesignsDocumento10 pagineAn-779 Low-Distortion 1.6 To 30 MHZ SSB Driver DesignsEdward YanezNessuna valutazione finora

- Examen en Electronica 3Documento7 pagineExamen en Electronica 3Erick MartinezNessuna valutazione finora

- Arduino Waveform Generator: Step 1: Technical ConsiderationsDocumento11 pagineArduino Waveform Generator: Step 1: Technical ConsiderationsdheenadayalanNessuna valutazione finora

- Getting The Right: FOR SDocumento12 pagineGetting The Right: FOR SferdinandNessuna valutazione finora

- Design Guidelines For Bipolar Transistor Audio Pre Amplifier CircuitsDocumento4 pagineDesign Guidelines For Bipolar Transistor Audio Pre Amplifier CircuitsUtpal100% (5)

- Audio IC Projects: A Collection of Useful Circuits Based on Readily Available ChipsDa EverandAudio IC Projects: A Collection of Useful Circuits Based on Readily Available ChipsNessuna valutazione finora

- Marlin Using Manual and Mesh Bed LevelingDocumento1 paginaMarlin Using Manual and Mesh Bed Levelingmarco.dado2700Nessuna valutazione finora

- Rocket Science - Hall Effect Sensor Placement For Permanent Magnet Brushless DC Motors PDFDocumento4 pagineRocket Science - Hall Effect Sensor Placement For Permanent Magnet Brushless DC Motors PDFmarco.dado2700Nessuna valutazione finora

- Using The Client PDFDocumento1 paginaUsing The Client PDFmarco.dado2700Nessuna valutazione finora

- Solidcam GpptoolDocumento288 pagineSolidcam Gpptoolyasim422100% (1)

- Hall Effect Sensor Placement For Permanent Magnet Brushless DC MotorsDocumento4 pagineHall Effect Sensor Placement For Permanent Magnet Brushless DC Motorsmarco.dado2700Nessuna valutazione finora

- Uniprocessor Scheduling PDFDocumento58 pagineUniprocessor Scheduling PDFmarco.dado2700Nessuna valutazione finora

- Venkatesh Venkataramanan 2015 ThesisDocumento88 pagineVenkatesh Venkataramanan 2015 Thesismarco.dado2700Nessuna valutazione finora

- More Precision.: Basics of Non Contact Temperature MeasurementDocumento20 pagineMore Precision.: Basics of Non Contact Temperature MeasurementAnonymous jmCvEw100% (1)

- Step by Step Manual-bluumax-CNC With EMC2Documento13 pagineStep by Step Manual-bluumax-CNC With EMC2udaya_k_6Nessuna valutazione finora

- ContentsDocumento10 pagineContentsmarco.dado2700Nessuna valutazione finora

- Amiga XP x86Documento5 pagineAmiga XP x86marco.dado2700Nessuna valutazione finora

- Amiga XP x86Documento5 pagineAmiga XP x86marco.dado2700Nessuna valutazione finora

- ELL-332 Electric Drives Lecture 3: Different Types of Load TorquesDocumento25 pagineELL-332 Electric Drives Lecture 3: Different Types of Load TorquesNikhil KumarNessuna valutazione finora

- Peugeot 306 Cabriolet Roof OperationDocumento3 paginePeugeot 306 Cabriolet Roof OperationKenneth NelsonNessuna valutazione finora

- Generator Relay Protection Setting Calculation REV 1.0Documento18 pagineGenerator Relay Protection Setting Calculation REV 1.0SreekanthMylavarapuNessuna valutazione finora

- Solar Manufacturers India 2010Documento30 pagineSolar Manufacturers India 2010redrag505100% (1)

- SMK0765FJ: Switching Regulator ApplicationsDocumento8 pagineSMK0765FJ: Switching Regulator ApplicationsranaateeqNessuna valutazione finora

- Cross-Curricular Focus: Life Science: NameDocumento2 pagineCross-Curricular Focus: Life Science: NameAndreea Dragomir67% (3)

- Solar Panel Thesis PhilippinesDocumento6 pagineSolar Panel Thesis Philippinesmelanierussellvirginiabeach100% (2)

- Mic Electronics Research ReportDocumento17 pagineMic Electronics Research ReportSudipta BoseNessuna valutazione finora

- Investigation Into The Probable Cause of Failure of Economizer Tube of A Thermal Power PlantDocumento5 pagineInvestigation Into The Probable Cause of Failure of Economizer Tube of A Thermal Power PlantKR PANessuna valutazione finora

- 37, 41, 42MT SSL Solenoids PDFDocumento4 pagine37, 41, 42MT SSL Solenoids PDFjuanNessuna valutazione finora

- Space News - Sukhbir GDocumento6 pagineSpace News - Sukhbir Gapi-288584327Nessuna valutazione finora

- W22 Homework #8 AnwsersDocumento4 pagineW22 Homework #8 Anwsersiamayesha725Nessuna valutazione finora

- Part Cat-Soil Compactor BW 212Documento218 paginePart Cat-Soil Compactor BW 212Dhru Ti100% (7)

- Southwark Schools For The FutureDocumento59 pagineSouthwark Schools For The FuturewilliamsaminNessuna valutazione finora

- Subsea Pipeline Design Report.Documento26 pagineSubsea Pipeline Design Report.Luke6nNessuna valutazione finora

- 28 Psychrometric ProcessesDocumento19 pagine28 Psychrometric ProcessesPRASAD326100% (7)

- 8.5 Final Review Key PDFDocumento4 pagine8.5 Final Review Key PDFAlex VongNessuna valutazione finora

- Catalogo Das Bomba Danfoss s90 100.Documento240 pagineCatalogo Das Bomba Danfoss s90 100.Agrocampo PeçasNessuna valutazione finora

- Temperature Measurement Lab Report PDFDocumento13 pagineTemperature Measurement Lab Report PDFSyafiiqahNessuna valutazione finora

- STPxx-3SE-40-DS-en-11 Inversor SMADocumento4 pagineSTPxx-3SE-40-DS-en-11 Inversor SMAArnaldo Macchi MillanNessuna valutazione finora

- Surgical DiathermyDocumento27 pagineSurgical DiathermyNimi Batubo100% (1)

- Ch14HW AllDocumento9 pagineCh14HW Alldhiru12314Nessuna valutazione finora

- Mapúa University: Shop Practice No. 9Documento5 pagineMapúa University: Shop Practice No. 9marisonNessuna valutazione finora

- ConveyorDocumento20 pagineConveyormatealoredana8015Nessuna valutazione finora

- Soliton WavesDocumento42 pagineSoliton WavesAbdalmoedAlaiashyNessuna valutazione finora

- Semester Syllabus For M. Sc. in Chemistry: School of Chemistry (AutonomousDocumento22 pagineSemester Syllabus For M. Sc. in Chemistry: School of Chemistry (AutonomousDachou GeetuNessuna valutazione finora

- Slope Efficiency: Threshold Above Current Input in Increase Power Output Optical in IncreaseDocumento34 pagineSlope Efficiency: Threshold Above Current Input in Increase Power Output Optical in IncreaseRIzwanaNessuna valutazione finora

- SYLLABUS For CLASS-X (2018-19) English: 1.tenseDocumento12 pagineSYLLABUS For CLASS-X (2018-19) English: 1.tenseShadan NawazNessuna valutazione finora

- Nava Bharat Ventures Limited Power Plant (Orissa) : Unit ProfileDocumento8 pagineNava Bharat Ventures Limited Power Plant (Orissa) : Unit ProfileashifNessuna valutazione finora

- Viking RaidDocumento31 pagineViking RaidAnonymous 61kSe1MNessuna valutazione finora