Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Executive Summary Hex-Pak Process Equipment Dwight Kinzer 22jan2012

Caricato da

dwight_KDescrizione originale:

Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Executive Summary Hex-Pak Process Equipment Dwight Kinzer 22jan2012

Caricato da

dwight_KCopyright:

Formati disponibili

Executive Summary

The Hex-Pak

Economical Segregated Bulk Storage

Process Equipment & Design LLC

413 29

th

Ave N, Fargo, ND 58102-1508

dwight.kinzer@gmail.com - 701.388.3645

This business plan is intended solely for informational purposes to assist you with a due-diligence investigation of this project. The

information contained herein is believed to be reliable, but the management team makes no representations or warranties with resp

ect to this information. The financial projections that are part of this plan represent estimates based on extensive research and on a

ssumptions considered reasonable, but they are of course not guaranteed. The contents of this plan are confidential and are not to

be reproduced without express written consent.

Page 2 of 4 The Hex-Pak 1/22/2012

Executive Summary

Business Concept Summary

The tremendous value proposition of this business venture is a considerable cost-effective solution to

what may be the greatest impediment of modern agriculture and biotechnology, which is the

extraordinarily high turnkey cost of segregated bulk storage systems for trace-ability, identity preserved

commodities, specialty crops, organic crops, grades, classifications, and holding bins for trait testing.

The Hex-Pak business venture is for developing economical segregated bulk storage that will be sold to

commercial grain warehouses, seed companies, animal feed manufacturers, nut processors, as well for

chemical and mineral storage. The Hex-Pak concept, which has been granted five US and numerous

international patents, reduces turnkey costs by up to 70%. See Appendix A for a summary fact sheet of

the Company.

Concept Description

The Hex-Pak is a revolutionary new patented design (5 USA, 1 Chinese, & 1 EPO) of economical

segregated bulk storage that solves not only a major impediment to crop improvement faced by modern

biotechnology but also the need for trace-ability that is desperately needed by post-harvest (grain, nut,

seed) handling facilities, large farming operations, flour millers, agricultural processors, seed companies,

animal feed manufacturing, and nut handling facilities. The Hex-Pak significantly reduces the turnkey

cost of multiple bulk storage bins for commodities that are currently constrained by their increasing

variance of characteristics and resulting need for identity preservation. In addition to the Hex-Pak, a

novel method of conveyance has also been designed.

Opportunity

A major roadblock to the progress of biotechnology in agriculture is the current grain handling and

storage infrastructure, which is comprised of large storage bins that do not provide for economical

segregation of grains based upon grower, variety, genetically modified organism (GMO) status, protein,

and moisture levels. Current material handling systems also have inherent flaws that commingle the

grains. Traditional building technology can only provide a high purity level of segregation at low storage

volumes and handling capacities similar to seed production facilities, which are very expensive to build

and make all but the most lucrative identity preserved opportunities unfeasible. The combined

advantages of the Hex-Pak and the novel method of conveyance that reduce turnkey costs by up to 70%,

a cost reduction that provides a cost-effective solution for segregating bulk commodities while eliminating

commingling issues.

Innovative Solution

The Modular Load-Bearing Structural Column, a primary component of the Hex-Pak, provides several

unique features that when combined with the novel conveyance method compound the turnkey cost

savings of the hexagon-shaped bins with hopper-bottoms. Features of the Hex-Paks structural column

include:

Fabrication of parts from coil steel using high-speed roll forming equipment can cost 40% to 70%

less than conventional fabrication techniques.

A plurality of hexagons has up to 40% less sq ft of sidewall than shared wall square bins

A plurality of hexagons has up to 39% less sq ft of sidewall than a plurality of round bins

Jack construction is up to 70% less costly than crane construction,

Jacks allow the structure to be built at grade, which is safer, and

Jacks can be used to build a complicated facility in remote locations without a crane.

Page 3 of 4 The Hex-Pak 1/22/2012

Executive Summary, continued

The track-and-trolley conveyor guidance system dramatically reduces the capital cost of conveyance,

energy, maintenance, and commingling of grains compared to conventional systems. Features of this

novel conveyance system include the following:

Up to 94% less linear-feet of distribution conveyance

Up to 85% less linear-feet of reclaim conveyance

All intermediate discharge gates (sources of cross-contamination) are eliminated

Significant reduction in energy and maintenance

Lends itself to computer automation for trace-ability documentation

Provides a conveying system in which product quality is preserved

The Hex-Pak reduces turnkey costs from $12 to $22 per bushel for conventional systems down to $6 to

$10 per bushel, which industry can afford.

Value Proposition

There is a tremendous need for economical segregated storage facilities without inherent cross

contamination issues. The Hex-Pak will have an important, enviable, and profitable role to play in

domestic and international agriculture from seed genetics, to animal feed manufacturing, to farm and

commercial storage facilities for the foreseeable future as it demonstrates and applies its unique design

features that radically reduce turnkey costs while eliminating typical points of cross-contamination. No

other technology will likely affect as wide a spectrum of applications around the globe as one that results

in a substantial cost reduction in post-harvest identity preserved segregated storage structures.

Competitive Advantage

Six US patents along with numerous international granted patents (Australia, Canada, Chinese, European,

and India) and pending in Brazil. This intellectual property provides monopolistic protection for the key

components of the Hex-Pak that insures a 40% to 70% cost reduction advantage compared to

conventional designs. The Track-And-Trolley Conveyor Guidance System does not require traditional

intermediate discharge gates required for multiple silos, thus eliminating a source of cross contamination.

An 80% to 94% reduction of linear-feet of conveyance significantly reduces energy usage and

maintenance requirements. See Appendix B for a competitive matrix comparing the Hex-Pak with

conventional round and square bin systems.

Entrepreneurial Team

The inventor and company founder Dwight Kinzer has twenty-eight years of experience with designing

and project managing the construction of commercial grain handling, seed conditioning, and feed

manufacturing facilities, domestica and international, for private and leading agricultural processing

corporations. Dwight will conduct or manage several roles such as design, sales, and company

management. Consulting engineers specializing in bin failure analysis will conduct the initial investigation

using proprietary calculations that will be peer reviewed during Round A. During Round B a civil engineer

with a background of structural engineering will be added to the staff as well as a manufacturing

engineer. Each of these two engineering managers will need one or two design technicians/engineers.

International marketing personnel will also be added during Round B.

Recognition

The Hex-Pak was honored to be vetted and selected by The Worlds Best Technology showcase (WBT) as

one of the top 100 emerging technologies in the world for 2010.

Page 4 of 4 The Hex-Pak 1/22/2012

Executive Summary, continued

Financial Highlights and/or Offering

It is estimated that the Hex-Pak can generate $20 million to $50 million of revenue per year, per

continent, which translates to $100 million to $300 million in annual global sales in 7 to 10 years.

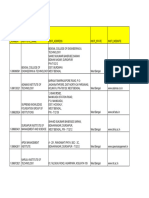

Estimated sales for the first six years are as follows:

Round A: No sales during engineering, opportunity analysis, and focused marketing

Round B:

Year 1: $900,000 2 small Hex-Pak sales at a reduced margin

Year 2: $4,000,000 6 Hex-Paks (12 bin) or 2 Hex-Paks (36 bin)

Year 3: $6,721,862 12 Hex-Paks (12 bin) or 4 Hex-Paks (36 bin)

Year 4: $13,847,037 24 Hex-Paks (12 bin) or 8 Hex-Paks (36 bin)

Year 5: $24,959,283 42 Hex-Paks (12 bin) or 14 Hex-Paks (36 bin)

NPV cash flow valuation of the Hex-Pak is between $2.7 million and $3.7 million.

Round A - $750,000 of investment in exchange for 35% equity.

Round B - $2,500,00 investment in exchange for approximately 35% equity based upon re-valuation at

end of Round A.

A Pro Forma balance sheet and cash flow valuation are available in Appendix K, L, and M.

Potrebbero piacerti anche

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (400)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (74)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (345)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (121)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- Toeic: Check Your English Vocabulary ForDocumento41 pagineToeic: Check Your English Vocabulary ForEva Ibáñez RamosNessuna valutazione finora

- CHAPTER 1 SBL NotesDocumento13 pagineCHAPTER 1 SBL NotesPrieiya WilliamNessuna valutazione finora

- Lamentation of The Old Pensioner FinalDocumento17 pagineLamentation of The Old Pensioner FinalRahulNessuna valutazione finora

- 15 Day Detox ChallengeDocumento84 pagine15 Day Detox ChallengeDanii Supergirl Bailey100% (4)

- Eggermont 2019 ABRDocumento15 pagineEggermont 2019 ABRSujeet PathakNessuna valutazione finora

- Government College of Nursing Jodhpur: Practice Teaching On-Probability Sampling TechniqueDocumento11 pagineGovernment College of Nursing Jodhpur: Practice Teaching On-Probability Sampling TechniquepriyankaNessuna valutazione finora

- Global Divides: The North and The South: National University Sports AcademyDocumento32 pagineGlobal Divides: The North and The South: National University Sports AcademyYassi CurtisNessuna valutazione finora

- PSA Poster Project WorkbookDocumento38 paginePSA Poster Project WorkbookwalliamaNessuna valutazione finora

- Interlocking Block TechnologyDocumento15 pagineInterlocking Block TechnologyChaula Trivedi100% (5)

- FuzzingBluetooth Paul ShenDocumento8 pagineFuzzingBluetooth Paul Shen许昆Nessuna valutazione finora

- NCP - Major Depressive DisorderDocumento7 pagineNCP - Major Depressive DisorderJaylord Verazon100% (1)

- 8051 NotesDocumento61 pagine8051 Notessubramanyam62Nessuna valutazione finora

- Modlist - Modlist 1.4Documento145 pagineModlist - Modlist 1.4Tattorin vemariaNessuna valutazione finora

- Cloud Comp PPT 1Documento12 pagineCloud Comp PPT 1Kanishk MehtaNessuna valutazione finora

- CL57T V4.0Documento14 pagineCL57T V4.0dimitriNessuna valutazione finora

- Physics Blue Print 1 Class XI Half Yearly 23Documento1 paginaPhysics Blue Print 1 Class XI Half Yearly 23Nilima Aparajita SahuNessuna valutazione finora

- Enochian Dragon Ritual PDFDocumento4 pagineEnochian Dragon Ritual PDFDenis NantelNessuna valutazione finora

- 50114a Isolemfi 50114a MonoDocumento2 pagine50114a Isolemfi 50114a MonoUsama AwadNessuna valutazione finora

- In Flight Fuel Management and Declaring MINIMUM MAYDAY FUEL-1.0Documento21 pagineIn Flight Fuel Management and Declaring MINIMUM MAYDAY FUEL-1.0dahiya1988Nessuna valutazione finora

- Comparison Between CompetitorsDocumento2 pagineComparison Between Competitorsritesh singhNessuna valutazione finora

- Lieh TzuDocumento203 pagineLieh TzuBrent Cullen100% (2)

- WBDocumento59 pagineWBsahil.singhNessuna valutazione finora

- Rana2 Compliment As Social StrategyDocumento12 pagineRana2 Compliment As Social StrategyRanaNessuna valutazione finora

- rp10 PDFDocumento77 paginerp10 PDFRobson DiasNessuna valutazione finora

- Promotion-Mix (: Tools For IMC)Documento11 paginePromotion-Mix (: Tools For IMC)Mehul RasadiyaNessuna valutazione finora

- Cisco UCS Adapter TroubleshootingDocumento90 pagineCisco UCS Adapter TroubleshootingShahulNessuna valutazione finora

- Bachelor of Arts in Theology: Christian Apologetics/ Seventh-Day Adventist Contemporary IssuesDocumento13 pagineBachelor of Arts in Theology: Christian Apologetics/ Seventh-Day Adventist Contemporary IssuesRamel LigueNessuna valutazione finora

- PDF Chapter 5 The Expenditure Cycle Part I Summary - CompressDocumento5 paginePDF Chapter 5 The Expenditure Cycle Part I Summary - CompressCassiopeia Cashmere GodheidNessuna valutazione finora

- Sociology As A Form of Consciousness - 20231206 - 013840 - 0000Documento4 pagineSociology As A Form of Consciousness - 20231206 - 013840 - 0000Gargi sharmaNessuna valutazione finora

- Thesis PaperDocumento53 pagineThesis PaperAnonymous AOOrehGZAS100% (1)