Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Mahari - 1 Drilling Program

Caricato da

Peter AliDescrizione originale:

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Mahari - 1 Drilling Program

Caricato da

Peter AliCopyright:

Formati disponibili

Maharvi 1 Drilling Program

S ECTION

P S

LAN

UMMARY

Maharvi 1 Drilling Program

1) Executive Summary

MAHARVI 1 is an exploratory well in the Maharvi Concession. The objective of this well is to test the SaltRange Formation / Khewra Sandstone with the well to be drilled to a Target Depth of 7,300ft-RT or 200 ft inside Basement (whichever is shallower) Spudded with the 12 bit, the well will be drilled to 1917ft-RT in the first hole section. This section will be cased with 9 casing and cemented to the surface. After the casing/cementing job, 11 x 9 5K SOW wellhead will be installed. The final phase will be drilled with 8 hole to the T.D at 7,300ft-RT. This section will be drilled to test the potential of Salt Range Formation / Khewra Sandstone and will be logged as per the logging program. Decision to run 7 casing will be based on the E-log results, open hole testing and hydrocarbon shows. 8 hole will be cased with 7 casing followed by cementation job to the surface. After cementing 7 casing hanger will be landed inside 9 Casing Head Housing & 11 5K x 11 5K Tubing spool will be installed. After running 7 casing, completion will be run, X-mass tree installed and pressure tested. The well will then be perforated and tested as per program. In the event well has to be abandoned, appropriate abandonment procedure will be set in place as per the guidelines in the Plug and Abandonment section of this Program. The well will be drilled and completed so that oil & gas production may commence as soon as possible.

Maharvi 1 Drilling Program

S ECTION

W S

ELL

YNOPSIS

Maharvi 1 Drilling Program

2) WELL SYNOPSIS

WELL CLASSIFICATION LOCATION CO-ORDINATES ELEVATION EASTING NORTHING CONCESSION AREA PROSPECT TYPE REFERENCE SYSTEM PROGNOSED T.D OBJECTIVE AREAL CLOSURE VERTICAL CLOSURE RIG OUTFIT TO BE DEPLOYED COMPLETION OF DRILLING RESPONSIBILITY OF EXECUTION MAHARVI 1 Exploratory Line 2007 - MRV - 07, SP 1574 Latitude 29 51' 32.9817" N Longitude 72 55' 55.7589" E RT 506 ft. (AMSL) GL 476 ft. (AMSL) 3219437.00 E 632898.90 N Maharvi E.L. Tilted Fault block Everest 1830 (Pakistan) Ellipsoid. Lambert Projection India Zone I 7300 ft RT (6794 ft SS) or 200 ft inside Basement (whichever is shallower) SaltRange Formation / Khewra Sandstone. 4895 Acres 18317Acres 100 ft Global Drilling GD-1. 20 Days after spud in (excluding 7 Casing & Cmt) OPII Drilling Department

Maharvi 1 Drilling Program

S ECTION

GEOLOGY

Maharvi 1 Drilling Program

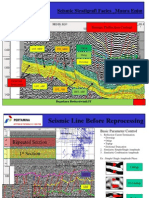

3.1) PROGNOSED SECTION

MAHARVI - 1

WIRELINE LOGGING CASING

MAHARVI BLOCK

PROGNOSED SECTION

FORMATION

LITHOLOGY

LAT : 29 51' 32.9817" N LONG :72 55' 55.7589" E

RT: 506 FT GL: 476 FT

DEPTH IN FEET (RT)

MUD WEIGHT (PPG)

AGE

REMARKS

SIWALIKS

NEOGENE

9-5/8" CASING @ 1917 FT RT

(+1887')

BHC-GR

1000

DOMINANTLY SANDSTONE WITH INTERCALATION OF CLAYSTONE.

EOCENE

E- JURASSIC

NAMMAL (167')

SAKESAR +

DATTA(128')

2000 2084'

2212'

1917' S

9 - 10

DOMINANTLY LIMESTONE WITH THIN BEDS OF CLAYSTONE. DOMINANTLY SANDSTONE WITH CLAYSTONE CLAYSTONE WITH INTERCLATION OF SANDSTONE

PERMIAN

SARDHAI

(449')

2661'

OPTIONAL 7" CASING TO BE RUN IF REQUIRED

WARCHHA

(493')

3000

8-1/2" HOLE TO BE DRILLED TO TD 3154' 3380' 3426' S 3688'

DOMINANTLY SANDSTONE WITH INTERCALATION OF CLAYSTONE.

DOMINANTLY SANDSTONE WITH CLAYSTONE

DLL-MSFL-BHC-GR-SP LDL-CNL-NGS, SHDT-GR

DANDOT

(226')

TOBRA (46')

JUTANA

(262')

SANDSTONE WITH THIN BEDS OF CLAYSTONE.

CAMBRIAN

PREDOMINANTLY DOLOMITE

4000

KUSSAK + KHEWRA

(1149')

9 - 10

SANDSTONE WITH INTERCALATION OF LIMESTONE, THIN BEDS OF SILTSTONE AND DOLOMITE.

4837'

SALT RANGE (2165')

5000

vv vv vv vv vv vv vv vv vv P v vv v vv v vv v vv v vv v vv v vv v vv v vv SALT SATURATED MUD TO BE USED

INFRA CAMBRIAN

6000

DOMINANTLY EVAPORITES (DOLOMITE,ANHYDRITE AND SALT) WITH THIN BEDS OF CLAY AND SANDSTONE.

vv

vv

vv

vv vv

vv vv v v

vv v

v v

PRECAMBRIAN

BASEMENT (298'+)

TD. 7,300 FT RT (6794 FT SS ) NOTE : TD WILL BE 7300 FT RT OR 200 FT INSIDE BASEMENT ( WHICHEVER IS SHALLOWER )

LEGEND

SHALE VV VV VV VV ANHYDRITE SILTSTONE LIMESTONE SANDSTONE DOLOMITE CLAYSTONE SALT

X X X X X X X X X X X X

X X X X X

X X X X X

X X X X X

X X X X X

X X X X X

X X X X X

X X X X X

X X X X X

X X X X X

X X X X X

7000 7002'

vv P

IGNEOUS BASEMENT.

IGNEOUS PRIMARY OBJECTIVE

SECONDARY OBJECTIVE

Maharvi 1 Drilling Program

3.2) PROGNOSIS SUMMARY

RT: GL: 506 ft (AMSL) 476 ft (AMSL) Age NEOGENE EOCENE E.JURASSIC Formation SIWALIKS SAKESAR + NAMMAL DATTA SARDHAI WARCHHA PERMIAN DANDOT TOBRA JUTANA CAMBRIAN INFRA CAMBRIAN PRE CAMBRIAN KUSSAK + KHEWRA SALT RANGE BASEMENT TD

NOTE: T.D. will be 7300 ft RT or 200 ft inside Basement (whichever is shallower).

Top - RT (Ft) Surface 1917 2084 2212 2661 3154 3380 3426 3688 4837 7002 7300

Top - SS (Ft) +476 1411 1578 1706 2155 2648 2874 2920 3182 4331 6496 6794

Thickness (Ft) +1887 167 128 449 493 226 46 262 1149 2165 298+

Maharvi 1 Drilling Program

3.3) FORMATION CHARACTERISTICS

3.3.1) RECENT SIWALIKS : ( Surface 1917 ft RT )

Recent: ( Surface 830 ft )

The Lithology consists dominantly of loose Sand with Clay.

Rawalpindi Group: ( 830 1917 ft RT )

Lithology

The Lithology typically consists of red Claystone with Sandstone. At the base which is overlain by thick Sandstone and Claystone with minor Limestone. Rawalpindi group is anticipated at 830 ft. The thickness of the Limestone encountered at the Top of this group is 50 m at Marot # 1 and 20 m at Bahawalpur East # 1.

Sandstone:

Light brown, clear, white, pale yellow, fine to medium grained, i/p coarse grained, angular to subangular, unconsolidated to consolidated, i/p sorted, calcareous cement, micaceous.

Claystone:

Medium to light brown, grey, soft, swell, calcareous..

Siltstone:

Reddish brown, buff, greenish grey, calcareous cement.

Limestone:

Off white, light grey, moderately hard, microcrystalline.

SAKESAR AND NAMMAL FORMATION : ( 1917 2084 ft RT )

3.3.2) SAKESAR FORMATION:

Lithology

Maharvi 1 Drilling Program

At type locality the formation consists dominantly of Limestone with subordinate Marl. The Limestone is cream coloured to light grey, nodular, usually massive with considerable development of Chert in the upper part. The Marl is cream coloured to light grey. At Bahawalpur East #1 and Marot #1 the lithology encountered is as follows:

Limestone:

White, off white, yellowish brown, occasionally brown, microcrystalline, argillaceous, moderately hard to hard, traces fossils, Packstone. chalky,

Clay stone:

Light brown, green, buff, bluish grey, i/p grey, sticky, firm, amorphous, blocky, silty, calcareous..

Marl:

Light grey, moderately hard..

3.3.3) NAMMAL FORMATION:

Lithology

At type locality the formation consists alternation of Shale, Marl and Limestone. The Shale is grey to olive green, while the Limestone and Marl are light grey to bluish grey. The Limestone is argillaceous in places. The Lower part of the formation is composed of bluish grey Marl with subordinate interbedded calcareous Shale and minor Limestone. The upper part consists of bluish grey to dark grey Limestone with intercalation of Marl and Shale. At Bahawalpur East # 1 and Marot #1 the lithology encountered is as follows :

Claystone:

Dark grey, green, light grey, olive green, soft, traces pyrite, calcareous, non swell..

Marl:

Off white, brown, soft, sticky.

Siltstone:

Grey, off white, moderately hard, calcareous, argillaceous, mic..

Contact

The Upper contact with Sakessar Limestone is transitional..

Maharvi 1 Drilling Program

EARLY JURASSIC 3.3.4) DATTA FORMATION: (2084 2212 ft RT )

Lithology

At type locality the formation is mainly of continental origin and consist of varigated (red, maroon, grey, green and white) Sandstone, Shale, Siltstone and Mudstone with irregularly distributed calcareous, dolomitic, carbonaceous, ferruginous glass Sand and fireclay horizons. Fireclay is normally present in the Lower part while the upper part includes a thick bed of maroon Shale. At Bahawalpur East # 1 and Marot #1 the lithology encountered is as follows :

Limestone:

Grey, off white, clear, fine to medium grained, angular to subangular, i/p subrounded, sorted, lig streaks, calcareous cement. Claystone / Shale: Reddish brown, dark grey, chocolate brown, soft to hard, calcareous, silty, sticky, i/p amorphous, (org).

Siltstone:

Grey, moderately hard, calcareous, micaceous..

PERMIAN 3.3.5) SARDHAI FORMATION: (2212 2661 ft RT )

Lithology

At type locality the formation is composed of bluish and greenish grey Clay, with some minor Sand and Siltstone beds. It also contains some carbonaceous Shale. The Clay predominantly displays Lavender colour. Minor chert and gypsum are found dissiminated in the formation with occasional calcareous beds in the upper part of it. 10

Maharvi 1 Drilling Program

At Bahawalpur East #1 Sardhai Formation predominantly composed of Sandstone..

Sandstone:

Grey, dark grey, green, occasionally yellow, clear, fine to medium grained, i/p coarse grained, angular to subangular, quartz, calcareous cement, glauconitic, sorted.

Claystone:

Olive green, grey, firm, calcareous, non swell..

3.3.6) WARCHHA SANDSTONE: (2661 3154 ft RT )

Lithology

The formation consists of medium grained Sandstone, conglomeratic in places and has interbeds of Shale / Claystone.

Sandstone:

Clear, translucent, light brown, fine to medium grained, angular to sub rounded, moderately sorted, calcareous cement. At type locality it is red, purple or shows lighter shades of pink, arkosic, the pebble of the unit are mostly of pink colour and of quartzite..

Claystone:

Dark brown, dark grey, green, reddish brown, moderately hard to firm, calcareous, nonswell, (pyr), silty..

Contact

The Warchha Sandstone conformably overlies the Dandot Formation.

3.3.7) DANDOT FORMATION: (3154 3380 ft RT )

Lithology

The formation consists of light to dark grey, olive green, yellowish Sandstone with occasional thin pebbly beds and subordinate dark grey and greenish splintery Shales.

Sandstone:

11

Maharvi 1 Drilling Program

Dark grey, fine grained, angular to subangular, sorted, argillaceous.Boulder Bed: dark grey, Clayey matrix, firm, non calcareous, Sandy..

Claystone / Shale:

Dark grey, green, i/p brown, i/p silty, i/p calcareous.The formation has a gradational contact with the underlying Tobra Formation and is terminated in sharp but conformable contact with the overlying Warchha Sandstone.

3.3.8) TOBRA FORMATION: (3380 3426 ft RT )

Lithology

The formation consists of marine Sandstone, alternating facies of Siltstone and Shale.At Bahawalpur East # 1 and Marot #1 the formation dominantly consists of Sandstone.

Sandstone:

Dark grey, fine grained, angular to subangular, sorted, argillaceous.Boulder Bed: dark grey, Clayey matrix, firm, non calcareous, Sandy.

CAMBRIAN 3.3.9) JUTANA FORMATION: (3426 3688 ft RT )

Lithology

The Lower part of the formation consists of light green, hard, massive, partly Sandy Dolomite and the upper part is composed of light green to dirty white massive Dolomite.

Dolomite:

Light brown, grey, hard, cryptocrystalline, Sandy.The formation is conformably underlain by the Kussak Formation.

KUSSAK AND KHEWRA FORMATION: (3688 4837 ft RT ) 3.3.10) KUSSAK FORMATION:

Lithology

The formation is composed of Sandstone and Siltstone, with minor light grey Dolomite, pink Gypsum lenses may be present near the Top.

Sandstone:

12

Maharvi 1 Drilling Program

Brown, greenish grey, yellow, clear, i/p light brown, i/p translucent, fine grained, angular to subangular, i/p dol, moderately sorted to sorted, i/p glauconitic, i/p micaceous, i/p argillaceous.

Siltstone:

Brown, greenish grey, dolomitic, pyrite.parts, slightly to non calcareous, silty in parts, occasionally grades to siltstone, traces of pyrite.

3.3.11) KHEWRA SANDSTONE:

Lithology

The formation consists predominantly of purple to brown, yellowish brown, fine grained Sandstone and Siltstone. The Lower most part of the formation is red, flaggy shale with minor Siltstone.

Sandstone:

Purple to brown, yellowish brown, fine grained.

Shale / Claystone:

Reddish brown, non calcareous, non-swell, silty..

Siltstone:

Reddish brown, off white, firm to hard, i/p dolomitic.

INFRA CAMBRIAN 3.3.11) SALT RANGE FORMATION: (4837 7002 ft RT )

Lithology

The Lower part of SaltRange Formation is mainly composed of Marl with Salt, Sandstone and Claystone while the beds of Dolomite, Anhydrite, Limestone, Siltstone and Shale are the constituents of the Upper part.

Dolomite:

White, creamy, grey, off white, i/p green, i/p light grey, i/p light brown, massive, hard, i/p moderately hard to hard, blocky, microcrystalline, argillaceous, chalky, dense, i/p suc,i/p calc cmt, loc vuggy. 13

Maharvi 1 Drilling Program

Limestone:

Light brown to brown, off white, grey, i/p light grey, firm to moderately hard, argillaceous, microcrystalline, stromatolitic filaments, dolomitic, Mudstone.

Claystone:

Off white, grey, reddish brown, bluish grey, i/p light grey, i/p green, i/p dark brown, mic, soft to moderately hard, i/p sticky, non-swell, silty, calcareous.

Sandstone:

Brown, green, reddish brown, dark brown, i/p white to off white, fine to coarse grained, angular to subrounded, micaceous, sorted, calcareous to non calcareous cement, silty, brecciated, with dolomitic streaks, ferru, lam.

Siltstone:

White, off white, dark brown to red, dark grey, friable to moderately hard, ferru, crm, i/p oolitic, moderately calcareous to calcareous cement.

Marl:

Grey, green, i/p red, dolomitic

Anhydrite:

White, off white, green, soft to firm, i/p moderately hard, i/p amorphous, chalky, occasionally Siltstone with few Anhydrite, Dolomite beds (Breccia ), i/p lam.

Salt:

Clear, occasionally translucent, i/p pink, hard to moderately hard.

Shale:

Dark grey, black, firm, crm, non calcareous, lam, (org).

PRE CAMBRIAN 3.3.12) BASEMENT: (7002 7300+ ft RT )

Lithology

These oldest rocks are composed of sedimentary, metasedimentary, metamorphic and igneous complexes. The lithology is composed of dark coloured and hard but more importantly fractured rock. 14

Maharvi 1 Drilling Program

At Bahawalpur East #1 and Marot # 1 the characteristics of the formation are as follows:

Basement:

Black, dark green, hard, fractured, calc veins, chlorite, pyrite, metamorphosed basic Igneous rock, Dolerite.

15

Maharvi 1 Drilling Program

4 DRILLING & CASING

S ECTION

16

Maharvi 1 Drilling Program

4.1) Planned Well Schematic

9 Top of cement

16 Line Pipe Conductor @ 60 - 80 ft

12 Hole 1,917 ft

9 Casing 47 PPF, L-80, BTC, Shoe @ 1,917 ft Top of 7 Liner @ 7,300 ft, 300 ft Liner Lap

Hole 9,709 ft

7 29 ppf TPCQ pin X Box casing Shoe @ 7,300 ft, 8 Hole 7,300 ft

17

Maharvi 1 Drilling Program

4.2) Drilling Montage

18

RT : 506' (AMSL) GL : 476' (AMSL)

DEPTH (FT- RT)

AGE FORMATION

MAHARVI X-1

PROGNOSED

DRILLING MONTAGE

SCALE: 1: 6000

LOGGING

PROGNOSED ACTUAL

MAHARVI X-1

T I M E DEPTH

30

Maharvi 1 Drilling Program

KARAMPUR - 1 (WELL SUMMARY)

FORMATION

50 CASING LINER SHOE DEPTH

LITHOLOGY PROG. ACTUAL

TOPS

SAMPLE (FT - RT) ACTUAL (FT - RT)

TOP (FT- RT)

CASING / LINER SHOE DEPTH

PROGNOSED

DRILLING

0 10 20

CURVE

40

LITH. COLUMN

ACTUAL

NUMBER OF

DAYS

MUD WEIGHT

(PPG)

BIT DATA

26'' OSQ-2 (1 BIT USED) FT - DRILLED (212') 2.75 HR 77.1 FT/HR

AGE

FM-1 FM-2 S I W A L I K S (+1481')

(FT - KB)

SPUD DATE:

NEOGENE-QUATERNARY

SIWALIKS

NEOGENE

9-5/8" CASING @ 1917 FT RT

(+1887')

SIWALIKS

1000

12-1/4" HOLE

PROGNOSED

13-3/8" CASING @ 1983.1 FT

BHC-GR

17-1/2'' OSC-3 (1 BIT USED) FT - DRILLED (1774') 37.75 HR 47 FT/HR

1499'

M U R R E E (1270')

2769'

2000

EOCENE

E- JURASSI C

NAMMAL (167')

SAKESAR +

1917' 2084' 2212' S

WIRELINE LOGGING+ 9-5/8" CASING JOB + WORK ON WELL HEAD.

DATTA (128')

SARDHAI

(449')

PERMIAN

2661' WARCHHA

(493')

3000

(482')

RAWALPINDI

DANDOT

(226')

TOBRA (46')

3154' 3380' 3426' S 3688'

EOCENE

MES.JUR?

3251'

CENTRAL INDUS BASIN

9.4

(348')

JUTANA

(262')

3599'

ZALUCH / NILAWAHAN (1571)

MAHARVI BLOCK

12-1/2'' OSC-3J (4 BITS USED) FT - DRILLED (3143') 82.25 HR 38.2 FT/HR

CAMBRIAN

KUSSAK + KHEWRA

(1149')

DLL-MSFL-BHC-GR-SP LDL-CNL-NGS, SHDT-GR

PERMIAN

4000

MIDDLE PRODUCT BEDS

MAHARVI - 1

DRILLING MONTAGE

9-5/8" CASING @ 6000.7 FT

8-1/2" HOLE

4837' vv vv vv vv

5000 SALT RANGE (2165') INFRA CAMBRIAN

5170'

SALT PSEUDO MORPHS (?)

BAGHAN WALA (473)

JUTANA

P vv v vv v vv v vv v

RT = 506 (AMSL) GL = 476 (AMSL)

12-1/2'' OSC-J (2 BITS USED) FT - DRILLED (518') 32.50 HR 15.9 FT/HR 12-1/2'' OSQ-2J (1 BIT USED) FT - DRILLED (304') 15.50 HR 19.6 FT/HR 8-1/2" OSC-3J (2 BITS USED) FT - DRILLED (558') 18.75 HR 29.8 FT/HR

CAMBRIAN

5643' MAGNASIAN S.ST

KUSSAK

6000

J H E L U M (1257)

7" CASING @ 7205.6 FT

PURPLE S.ST

vv vv vv vv

KHEWRA

PUNJAB SALINE SERIES (2900')

TD. 7,300 FT RT ( 6794 FT SS )

10

20

30

PRE-CAMBRIAN

40

50

SALT RANGE

8000

TD WILL BE 7300 FT RT OR 200 FT INSIDE BASEMENT ( WHICHEVER IS SHALLOWER )

LEGEND

SHALE VV VV VV VV ANHYDRITE SILTSTONE LIMESTONE SANDSTONE DOLOMITE CLAYSTONE SALT

X X X X X X X X X X X X

IGNEOUS PRIMARY OBJECTIVE

SECONDARY OBJECTIVE

9800'

BASEMENT (161' +)

BASEMENT

TD. 9,961' KB

19

V V V V V V V V

PRECAMBRIAN

BASEMENT (298'+)

WIRELINE LOGGING + 7" LINER / CASING ( OPTIONAL ) + COMPLETION & TESTING TD. 7,300 FT RT ( 6794 FT SS )

V V V V V V V V V V V V V V V V V V V V V V V V V V V V V V V V

X X X X X

X X X X X

X X X X X

X X X X X

X X X X X

7000

v v v v

7002'

6900'

8-1/2" OSC-J (3 BITS USED) FT - DRILLED (544') 40 HR 13.6 FT/HR 8-1/2" OSQ-2J (1 BIT USED) FT - DRILLED (42') 8.25 HR 5.1 FT/HR 8-1/2" OWS-J (7 BITS USED) FT - DRILLED (272') 69.25 HR 3.9 FT/HR

10 9.43

8-1/2" OWV-J (6 BITS USED) FT - DRILLED (402') 71 HR 5.7 FT/HR

8-1/2" OWC-J (8 BITS USED) FT - DRILLED (860') 98.25 HR 8.6 FT/HR

10.8

8-1/2" W7R (28 BITS USED) FT - DRILLED (1190') 288.75 HR 4.2 FT/HR

8-1/2" R1 (1 BIT USED) FT - DRILLED (7') 4.5 HR 1.6 FT/HR

FM - 1 (FROM COMPOSITE LOG ) FM - 2 (FROM SUMMARY CHART )

Maharvi 1 Drilling Program

4.3) GENERAL DRILLING INSTRUCTIONS

Hold pre-spud meeting Prior to spud in, ensure that the conductor is correctly aligned & centered below the rig rotary table to prevent offset casing wear. Maintain at least 500 bbls of 12 ppg (appropriate kill mud) in reserve at all times commencing from spud. Maintain hole verticality as straight as possible. If necessary ream hole section repeatedly to reduce angle. Survey frequency should be increased if hole deviation becomes a problem. Time spent on drilling with low weights and reaming to reduce angle would prevent problems with casing wear in later stages. All casing strings must be hung in tension to reduce the effect of helical buckling on the casing. The slips should be set with 70% of casing hanging weight in mud. Maximum internal test pressure to be applied to any casing string must not exceed 65% of the casing burst rating taking into consideration the fluids inside and outside the casing string. Maximum external test pressure to be applied to any casing string must not exceed 75% of the rated collapse pressure. These ratings can only be increased after specific instructions received from head office. Drill pipe-casing protector must be used during drilling 8 hole section. At no time should drill pipe fitted with protector be allowed to enter into open hole. Extreme care should be taken at all times while tripping. Swab/surge pressures can cause serious problems, especially when a delicate balance between losses and inflows exist. Consequently during critical conditions, swab/surge pressure, pulling/running speeds must be determined and used as a guide in these situations. Regular well control drills should be carried out from below the 9 casing shoe. These drills should be noted in the IADC drilling reports & proper record maintained at the rigsite. During all long string cement jobs, every precaution must be taken to prevent cement from hardening in the wellhead sections. Immediately after displacing cement, the wellhead sections must be thoroughly flushed out to remove any excess cement displaced or channeled to the surface. SCR should be recorded as per directions in section 7.1. Work instructions should be issued in written form to drilling contractor and other service personnel. A proper record to be maintained at the rig site of such documents. It would be appreciated if good drilling practices are followed with special emphasis on safety measures.

20

Maharvi 1 Drilling Program

4.4) 12 HOLE (SURFACE TO 1,917 ft)

4.4.1) SECTION OBJECTIVE

The main objective of the 12 section is to set a competent casing string to provide well control for the continuation of the drilling to the next casing seat. The other objective is to isolate surface aquifers and seal off the loose / top sediments of Siwaliks.

4.4.2) DRILLING 12 HOLE

Carry out full inspection of rig in accordance with the checklist available with the Company Man and rectify all shortfalls. Check that the conductor pipe is centralized. Prepare spud mud. Install cellar-jetting system. Before spud in of the well check entire mud hook up. Nipple up the bell nipple and flow line. Function test rig components & pressure test H.P lines at 3500 psi. M/u and rack back stands of DCs & 5 HWDPs required for the BHA, & around 75 stands of 5 DPs in derrick. Arrange pre-spud meeting to be chaired by Senior OPII representative. All the aspects of the well operations and materials to be thoroughly discussed and recorded. Spud in well, drill initial 100 ft with low rpm and flow rate. Drill 12 hole down to 1,917 (9 casing shoe depth). Drill hole with lightweight on bit to ensure vertical hole. Circulate out Hi-Vis pills to ensure hole cleaning as required. Take deviation survey after every 250 interval and on bit change depending upon hole condition. At the Section T.D. sweep hole with Hi-Vis pill and spot 20 bbls Hi-Vis pill at bottom. POOH for casing.

21

Maharvi 1 Drilling Program Rig up and run 9 casing. Carry out cement job as per program. Complete work on wellhead and pressure test all pressure control equipment.

4.4.3) INSTRUCTIONS WHILE DRILLING

12 HOLE

Keep the mud rheology and pumping rate to effectively lift the cuttings to surface. Continuously run solids removal equipment in order to effectively control mud rheology including mud weight in order to minimize loading of mud with solids and to minimize possibilities of losses, cavings & washouts.

4.4.4) RUNNING 9 CASING

R/UP to run casing and hold pre job safety meeting. Run 9 casing. Carry out cement job as per program. Cut conductor casing. If needed, carry out top cement job so that the wellhead area is properly anchored and sealed. Wait on cement 06 Hrs. If the cement does not appear on surface, conduct Top Cement Job. Cut 9 casing. Install & weld wellhead and pressure test weldment at 1000 psi. N/UP, function and pressure test 13 BOP stack. Install wear bushing.

4.4.5) INSTRUCTIONS FOR 9 CASING JOB

Prior running in casing, condition mud and circulate till shale shakers are free from cuttings. Prior running in casing drift and visually inspect each joint on rack for any damaged threads. Measure casing on rack, make up float shoe and install stop collars on the rack. Thread-lock shoe with first casing joint. 22

Maharvi 1 Drilling Program Fill up casing string with mud after every 2 to 3 joints. Monitor and record hook load before and after filling casing with mud. While running in casing avoid shock load to casing string and cautiously land the string in slips. Adjust casing tally prior to running in hole to avoid coupling at casing cutting point. Slack 2 5T weight on sting in adapter. Circulate through stinger to check any leakage from 9 x 5 annulus prior to start pumping cement slurry. Chain down casing and drill pipes to avoid floating action. Install centralizers as per casing program. Check wellhead and 7 casing hanger profile for any damage etc. prior to installation. After WOC cut and dress 9 casing joint. Weld and pressure test weldment of 9 x 5K casing head housing at 1000 psi. Complete work on wellhead, N/UP BOP and all pressure control equipment. Pressure test as per details mentioned in Section 8. Time spent on wellhead should be reduced by efficient planning and preparation. Install wear bushing prior to RIH with 8 bit.

23

Maharvi 1 Drilling Program

4.4.6) WH & BOP STACK AFTER PHASE 1

Flow Riser Annular BOP 5K

Upper Pipe Ram 10K

Blind Ram 10K

Lower Pipe Ram 10K

Mud Cross

13 10K Top x 13 10K Btm

Cross over Spool

13 10K Top x 11 5K Btm

Casing Head Assembly

11 5K Top x 9 SOW Btm

24

Maharvi 1 Drilling Program

4.5) 8 HOLE ( 1,976 ft TO 7,300 ft) 8

4.5.1) SECTION OBJECTIVE

The objective of this section is to case off the SaltRange Formation / Khewra Sandstone, which will enable to control the properties of mud system in the reservoir section. Well directionality is critical in this section and all surveys will be plotted and verified to ensure the well bore positional uncertainty places it in the target area.

4.5.2) DRILLING 8 HOLE

RIH with 8 PDC bit with stabilized BHA to top of 9 casing shoe and test casing at 1500 Psi (SAP). Drill out cement/shoe and cement in rat hole.

Pump 20 bbls of water ahead and displace spud mud with KCl PHPA polymer mud. Drill out new formation to 1,986 ft. Pull back to shoe, rig up cementing unit for formation integrity test (FIT). Make sure that mud is properly homogenized before conducting FIT. Conduct FIT at 12ppg EMW. Apply lower drilling parameters while stabilizers are inside the casing.

Pump Hi-Vis pills to ensure hole cleaning after drilling every 2-3 stands or as required. Conduct deviation survey after every 250 / 500 ft and on bit change depending upon hole condition. At section T.D. 7,300 ft sweep hole with a Hi-Vis pill. Conditioning trip to be done with same BHA used in drilling. Spot 30 bbls Hi-Vis pill at bottom prior to POOH for logging. POOH. Conduct logs as per program. 25

Maharvi 1 Drilling Program Retrieve wear bushing & change one set of D.P. ram with 7 casing ram. R / u to run 7 casing.

26

Maharvi 1 Drilling Program

4.5.3) INSTRUCTIONS FOR DRILLING 8 HOLE

Keep the mud rheology and pumping rate to effectively lift the cuttings to surface. Prior using PDC Bit ensure the hole is clean from any steel junk/debris etc.

Due to high rate of penetration while drilling with PDC Bit, hole cleaning is of prime importance. Therefore, observe and ream hole on connections and sweep hole with Hi-Vis after drilling every 2 to 3 stands. Continuously run solids control equipment in order to effectively control mud rheology. Monitor and record upward and downward over pull / drags while drilling this hole section.

4.5.4) RUNNING 7 CASING

Retrieve wear bushing from 9 casing head housing. Run casing to section T.D. and circulate. Casing not to be rotated. Perform cement job as per cementing program. Flush BOPs, wellhead with water by opening side outlet valve on CHH. N / d bell nipple and lift BOP stack. Set slip and seal assembly as per instructions of wellhead engineer. Cut and dress 7 casing. Use cold cutter if available. Install and test tubing spool as per wellhead manufacturers specifications.

N / u BOP stack, change casing rams to DP rams and test. (Test pressure rating attached) . N / u bell nipple and the flow line. Install wear bushing in 11 tubing spool bowl.

27

Maharvi 1 Drilling Program

4.5.5) INSTRUCTIONS FOR 7 CASING JOB

Prior to running in, drift casing and visually inspect each joint on rack for any damaged threads. Measure casing on rack, make up Float Shoe, Float collar and stop collars on the rack. Thread lock shoe, float collar and bottom three joints. Fill up the casing with mud after every 4 to 5 joints. Monitor and record hook load before and after filling casing with mud. Calculate volumetric efficiency of mud pumps to be used for displacement.

While running in casing avoid shock load to casing string and cautiously land the string in slips. Minimize rat hole to avoid down hole problems. For this adjust casing tally prior to running in hole. Install centralizers as per casing program.

28

Maharvi 1 Drilling Program

4.5.6) WH & BOP STACK UP AFTER PHASE 2

29

Maharvi 1 Drilling Program

Flow Riser

Annular BOP 5K

Upper Pipe Ram 10K

Blind Ram 10K

Lower Pipe Ram 10K

Mud Cross

13 10K Top x 13 10K Btm

DSA

11 5K x 13 10K

Tubing Spool

11 5K Top x 11 5K Btm W/- NX Btm. Prep for 7 csg.

Casing Head Assembly

11 5K Top x 9 SOW Btm 9 Casing 7 Casing

30

Maharvi 1 Drilling Program

4.7) BIT PROGRAMME

DESCRIPTION OF QTY. BITS

Mill tooth IADC 117 & 217 2

BIT SIZE

DEPTH INTERVAL

NOZZLE

1 x 14/32 + 3 x 18/32 6 x 12/32 5 x 12/32

12

Surf. to 1,917 ft

PDC: 7 Bladed

1,917 ft to 7,300 ft

PDC: 6 Bladed TCI: IADC: 517 Milled Tooth IADC: 517/537 IADC: 117/127

3 x 14/32

For clean out & Drilling Optional.

3 x 14/32 & Open

31

Maharvi 1 Drilling Program

4.8) DRILLING PARAMETERS

Hole size

12 (TCI) 8 (PDC) 8 (TCI)

WOB

15 5 10 5 10

RPM

60-90 70-100 70-100

Flow rate (GPM)

200-400 400 500 450 550

SPP (PSI)

100 1400 1500 2500 1500 2500

32

Maharvi 1 Drilling Program

33

Maharvi 1 Drilling Program

4.9) DRILL PIPES

34

Maharvi 1 Drilling Program

OD

ID

Capac i Wt./ft. t ( y l b ( s GRAD b . E b / l f / t f . t ) . )

Metallic Disp lace men t (bbl /ft.)

Torsio n Torsio Tensil a Tensil n e l e a Y l B i Y C u e i o r l e ll s d l a t d p S s P t S e r r t P e e r r s n e e s g n s u t g s r h t u e h r ( e ( f ( ( P t l P s . b s i l s i . b ) . ) s ) )

35

Maharvi 1 Drilling Program

4.276

E-75 X-95 G-105 S-135

19.5

0.01776

0.0071

41, 167 52, 144 57, 633 74, 100

395, 595 501, 087 553, 833 712, 070

9, 962 12, 026 12, 999 15, 672

9, 503 12, 037 13, 304 17, 105

2.764

E- 75 X- 95 G- 105 S- 135

13.30

0.0074

0.0048

18, 551 23, 498 25, 972 33, 392

271, 569 343, 988 380, 197 488, 825

14, 113 17, 877 19, 758 25, 404

13, 800 17, 480 19, 320 24, 840

36

Maharvi 1 Drilling Program

4.10) BOTTOM HOLE ASSEMBLY

Bit sub (with recess)/ NB stab

Bit

Drill Collar

String Stab

Drill collar

String Stab

Drill Collar

Cros s over

Drill Coll ar

Jar

Drill Colla r

Cros s over

HWD P

12

1/1

8 x 2 6 NMDC x 1

8 x 5 6 DC x 2

6 x 10

8 x 2 6 x 3

5 x 12

8 x 1

8 x 1

8 x 1

5 x 12

37

Maharvi 1 Drilling Program

4.11) MUD PARAMETERS

Hol e size Densi ty (ppg.) Gel 10 Cak sec/ e 10m in

-

Mud Type

VIS

W/L

PV

YP

PH

%S

% Oil

Benton 12 ite Spud mud 5% KCL Polyme r Non damagi ng

8.6 - 9.2

60-70

8.5+

9.0 10.0

50-55

4-5/1215

Less than 5cc

18 - 20

20 25

8.5-9.5

Min

Note: KCL Polymer PHPA will be used to drill shale section upto +/4500 ft Mud system will be replaced with salt saturated mud while drilling in the salt range. while drilling in the salt range

38

Maharvi 1 Drilling Program

4.12) HAZARDS SUMMARY

Hole Size

Interval

Hazards

Loss circulation High ROP hole pack off

Mitigation

LCM material Mud rheology ROP high pump rates

12

Surface -

1,976 Pipe 7,300

control

Reactive shales Well Bore Stability Stuck Drill High ROP hole pack off Missing geological target Hydrocarbon kick/swab kick

1,976 -

Inhibitive mud system (PHPA) polymer Salt range will be drilled with slat saturated mud Mud Type, Weight, Selection and Maintenance Mud rheology, flow rates and controlled ROP Surveying/ correction run

39

Maharvi 1 Drilling Program

4.13) CASING PROGRAMME

Hole size Casin Specificati g OD on Cased Interval Pressu re Test Shoe Track Centralizers

Float Equipment

Float shoe 1 conventional Float collar- 1 conventional Plugs Top and Bottom 1 each Float shoe 1 conventional Float collar- 1 conventional Plugs Top and Bottom 1 each

12

47 PPF, L80, BTC

1 SB in 16 cond.

1,976 to surface 1500 Psi 2 jts 1 SB x 5 jts 1 SB on shoe jt

3 Rigid inside 9

29 PPF, L-80 TPCQ

7,300 to surface

3000 Psi

2 jts

csg. 1 SB x 5 jts over coupling 1 SB x coupling in shoe track 1 SB on shoe jt

Note: Final Centralization program will be conveyed by the Head Office at the time of casing

40

Maharvi 1 Drilling Program

4.14) CASING SPECIFICATIONS

COLLAPSE RESISTANC E Psi.

CASING OD

BODY INTERNAL YIELD YIELD SPECIFICATION STRENGTH PRESSURE (1000lbs) Psi.

47 lbs/ft L-80 BTC

1086

6870

4760

29 lbs/ft L-80 TPCQ

676

8160

7020

41

Maharvi 1 Drilling Program

5 GDO

S ECTION

42

Maharvi 1 Drilling Program

PUBJAB PLAT FORM

MAHARVI - 1

CONCESSION AREA: TYPE OF WELL: CO - ORDINATES : MAHARVI E.L. EXPLORATORY 29 51' 32.9817" N 72 55' 55.7589" E LOCATION: PROGNOSED TD. ELEVATION: LINE 2007 - MRV - 7, SP 1574 7300' RT (6794' SS) RT: 506 FT (AMSL) GL: 476 FT (AMSL) DISTRICT: PROVINCE: DRILLING RIG : SPUDED ON: DRILLING PARAMETERS

BIT SIZE & TYPE

GEOLOGICAL DRILLING ORDER

MAHARVI BLOCK (LOCATION MAP)

S ARA SID I HU-01

NA N D P UR

CHA K12 -01

O DL GC

NA NDP UR-01 ALI SH AIB - 1

MAHARVI - 1

P U N JA B

N A TIV S

PIRANWA L-01

S H A K A R G ANJ W E S T

TOLA-01

NA TI VU S

3073 - 3 2 50 5 .18 Z ONE - II N A TIV S

BAHAWALNAGAR PUNJAB GLOBAL DRILLING

MU LTA N

B A GH S OUTH

Z ON E - I I

3 0 72 - 4 2 5 35 .4 1 S Q . KM S ZO NE - II

KA RAMP UR-01

O DC G L

M UL TA N S O UTH

N OOR

M L GC

LIJ SUT

ER RIV

C HIS HTIA N M A ND I

MA HAR V I

29 72 - 3 1 8 38 .6 0 S Q. K MS Z ON E - I I

OP I I

SUTLEJ

JUGU WA LA OIL S EEP AGE

P A IG E

C H O LIS TA N

AN ST PA KI

MA ROT-01

297 2 - 4 19 2 7 . 94 S Q. K MS Z O NE - II

( 2 9 7 1 -5)

2 9 S Km 4 5 q. s ZO E =II N

B AHAWALP E A UR ST-01

(SCALE: = 1 : 6,000)

WELL CONSTRUCTION

PPL

GEOLOGICAL

DATA

MUD PARAMETERS

PV / YP (CPS / LBS / 100 FT ) 2 PH OIL (%) SOLIDS (%) CAKE (M. M) WATER LOSS (C.C. / 30 MINS) GEL, 10 SEC. 10 MIN. (LBS/100FT.)

F. VISCOSITY (SECOND / QRT.) WEIGHT (PPG) TYPE OF MUD FOR DRILLING FOR OPENING HOLE WEIGHT ON BIT(Klbs) ROTARY (RPM) DRILLING PIPES DRILL STRING DRILLING COLLARS COMPOSITION

MUD HYDRAULICS

ANNULAR VELOCITY AROUND D/ PIPES (FT / MIN.) STAND PIPE PRESSURE (PSI)

STRUCTURAL CONDITIONS

FORMATION PRESSURE IN TERMS OF MUD WEIGHT

BOTTOM HOLE ASSEMBLY

CASING SETTING DEPTHS AND CEMENT POSITION

OBJECTIVES + EXPECTED OIL & GAS SHOWS

LINER SIZES (INCHES) STROKES / MINUTE JET SIZE (INCHES) JET NOZZLE VEL (FT/SEC.)

PROBABLE / POSSIBLE COMPLICATION DURING DRILLING

EXPECTED FORMATION PRESSURES

LOGGING PROGRAMME

10

11

12

13

14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29

30

31

32

33 34 35 36

37

38

39

PUMP OUT (GPM)

DEPTH IN FEET

LITHOLOGY (DESCRIPTION)

FORMATION LITHOLOGY

NO & TYPE OF PUMPS

HOLE SIZE & VOLUME

REMARKS/ PRODUCTION TESTING / WRITE UP

NO. OF LINES

CORES

40

12-1/4" BIT + NB STAB + 2 x 8" DC + S.STAB + 5 x 8" DC 8" JAR + 2 x 8" DC + XO + 12 x 5" HWDP

NORMAL HYDROSTATIC PRESSURE

2 x Triplex HHF - 1600 HP

BENTONITE SPUD MUD

18/32, 18/32,18/32, 14/32

100 - 1400 PSI

SIWALIKS (+1887')

BHC - GR

12-1/4"

1000

DOMINANTLY SANDSTONE WITH INTERCALATION OF CLAYSTONE.

1917' 2000 2084'

9-5/8'' CASING @ 1917' RT

SAKESAR +

NAMMAL (167')

DOMINANTLY LIMESTONE WITH THIN BEDS OF CLAYSTONE. DOMINANTLY SANDSTONE WITH CLAYSTONE

DATTA(128')

WARCHHA SARDHAI

2212'

2661'

(493')

(449')

CLAYSTONE WITH INTERCALATION OF SANDSTONE

DOMINANTLY SANDSTONE WITH INTERCALATION OF CLAYSTONE

3000 3154'

DANDOT (226')

3380' 3426'

TOBRA (46')

DOMINANTLY SANDSTONE WITH CLAYSTONE

JUTANA

(262')

3688'

SANDSTONE WITH THIN BEDS OF CLAYSTONE.

PREDOMINANTLY DOLOMITE

4000

KUSSAK + KHEWRA

(1149')

PDC ( 6 x 12 / 32", 5 x 12 / 32") ( 3 x 14/32") TCI

*

vv vv vv

8-1/2" BIT + N. B. STAB + 1 x 6-1/2" NMDC+ S. STAB + 2 x 6-1/2" DC + S.STAB + 10 x 6-1/2" DC + 6-1/2" JAR + 2 x 6-1/2" DC + XO + 12 x 5" HWDP

NO STRUCTURE COMPLICATIONS ARE EXPECTED

SANDSTONE WITH INTERCALATION OF LIMESTONE, THIN BEDS OF SILTSTONE AND DOLOMITE.

P R E S S U R E

TCI: (10 - 25 Klbs) / PDC: (10 - 25 Klbs)

TCI: (70 - 100) / PDC: (80 - 120)

LESS THAN 5 C.C.

4 - 5 / 12 -15

5% KCL POLYMER

4837' 5000 8-1/2"

H Y D R O S T A T I C

2 x Triplex HHF - 1600 HP

9.0 - 10.0 PPG

(WASHOUTS AGAINST SALT WITHIN SALT RANGE FORMATION)

160 - 180 mm

1500 - 2500

6 -1/2" x 15

MINIMUM

250 - 300

200 - 250

8.5 - 9.5

20 - 25

50 - 55

8-1/2"

120

10

5"

SALT RANGE (2165')

*

vvv vvv vvv

DOMINANTLY EVAPORITES (DOLOMITE,ANHYDRITE AND SALT) WITH THIN BEDS OF CLAY AND SANDSTONE

6,000

v v v

vv vv vv

TD. 7300' RT (6794' SS)

LEGEND

SHALE SILTSTONE SANDSTONE

VV VV

VV VV

ANHYDRITE

LIMESTONE

DOLOMITE

CLAYSTONE

43

X X X

X X X

X X X

X X X

X X X X X X X X X X X

X X X X X X X X X X X

X X X X X X X X X X X

7,000 7002'

P

IGNEOUS BASEMENT.

BASEMENT

(298'+)

NOTE : TD WILL BE 7300 FT RT OR 200 FT INSIDE BASEMENT (WHICHEVER IS SHALLOWER)

IGNEOUS SALT

P

N O R M A L

DLL - MSFL - BHC - GR - SP LDL - CNL - NGS, SHDT - GR

PRIMARY OBJECTIVE

(400 - 500 TCI)

(450 - 550 PDC)

200 - 400

(10 Klbs)

8.6 - 9.2

80 - 120

180 mm

12-1/4"

60 - 90

60 - 70

60 - 80

8" x 9

8.5 +

256

10

5"

SECONDARY OBJECTIVE

IND

IA

BA A AL R EA H W PU ST

Maharvi 1 Drilling Program

S ECTION

CEMENTING

44

Maharvi 1 Drilling Program

6.1) Specifications

9 Casing 1,976 ft 7 Casing 7,300 ft

Interval: Surf. 1,976 ft Open Hole Excess 150 % Cementing Method: Conventional Density 15.0 ppg

Lead Cmt: Surface 6,400 ft Tail Cmt: 6,400 ft 7,300 ft Open Hole Excess: 20% Cementing Method: Conventional Lead Slurry: 13.2 ppg. Tail Slurry: 15.8 ppg.

Note: Exact volume of cement slurry (tail and lead) and cement recipe will be advised by the Head Office at the time of job.

45

Maharvi 1 Drilling Program

6.2) ANNULAR VOLUME (bbls / ft)

46

Maharvi 1 Drilling Program

Inner Tubing

Size

Capac ity

Annulus Capacity

0.0252 0.0152 0.1215 0.0489 0.0459 0.0322 0.0291 0.0256 0.0226 0.0836 0.0558 -

OH 12 CSG 9 OH 8 CSG 7

0.1458 0.0732 0.0702 0.0371

S ECTION

47

Maharvi 1 Drilling Program

WELL CONTROL

48

Maharvi 1 Drilling Program

7.1) GENERAL INST INSTRUCTIONS

General Instructions to avoid / combat well control situations: Record mud weights every 15 / 30 mins as directed. Monitor well for signs of changing pressures Record SCR regularly in every shift and specially in the following situations: 1. 2. 3. 4. Significant change of mud properties Change of BHA Change of bit / bit nozzle configuration After changing mud pump liner piston sizes

5. Before entering into a potential pay zone and after entering into new formations Before entering a potential high-pressure zone, ensure that the MW is appropriate enough. Minimize contamination of mud with foreign elements like drill solids / cement / hydrocarbons. Ensure proper hole fill up during tripping through a properly calibrated trip tank.

Ensure integrity of low-pressure mud system to avoid intercommunication / intermittent dilution. Maintain reasonable stock of weighting agent (Barite / CaCO3) on location as advised by the Company Man. Conduct flow-check at following situations: 1. 2. 3. 4. 5. 6. During tripping When at bottom after running in After entering in cased hole from OH while tripping out. Before pulling out BHA. When at surface after pulling out Observing kick warning signs as mentioned above.

49

Maharvi 1 Drilling Program

7.2) WARNING SIGNS OF A KICK

Observe for following changes in well behavior so that a potential kick can be handled promptly and safely: Increase in Flow rate Increase in Pit Volume Well not static on flow check Reduced hole fill up volume during tripping out. Gas cuts Drilling break Erratic torque

7.3) SHUT IN PROCEDURES

7.3.1) WHILE DRILLING

If a kick is encountered while drilling, follow the procedure outlined below: 1. Stop drilling. 2. Stop rotation. 3. Raise the string so as to bring tool joint above the rotary table. 4. Stop the pump(s). Observe well & conduct flow check. 5. Close the annular preventer and open HCR valve to the hydraulic choke. Keep the choke lined up for hard shut-in (i-e closed position during normal drilling operations) 6. Inform Company Man, Tool pusher and other crew members. 7. Record the following: i. ii. iii. Shut-in casing pressure at the choke manifold (SICP) Shut-in Drill pipe pressure at the standpipe manifold (SIDPP) The pit gain Note: Sufficient time must be allowed for the readings to be stabilized before recording. (30 mins) 50

Maharvi 1 Drilling Program

7.3.2) WHILE TRIPPING

If a kick is encountered while tripping, following procedure must be followed: 1. Run down stand to bring tool joint at the rotary table and set slips under it. 2. Install a Fully Opened Safety Valve and close it. Ensure at hand availability of a fully opened safety valve on the rig floor during the entire time of tripping. 3. Close the annular preventer and open HCR to the hydraulic choke. 4. Inform Company Man, Tool pusher and other crew members. 5. Record the following: i. ii. iii. Shut-in casing pressure at the choke manifold (SICP) Shut-in Drill pipe pressure at the standpipe manifold (SIDPP) The pit gain

Note: Sufficient time must be allowed for the readings to be stabilized before recording. (30mins)

7.4) KILLING METHOD

The underlying principle is to: Keep the bottom hole pressure constant and just above formation pressure at all times. Minimize the pressure exerted on the open formations (1st priority), the casing shoe and the BOP

The DRILLERS METHOD will be employed to combat any kick situation. Following outline procedure shall be adopted: 1. 2. 3. Shut in the well Read & record SIDPP, SICP and pit gain. Brief the crew about the procedure

4. Open the choke and simultaneously start pumping mud (of current weight) at the SCR. 5. Whilst reaching and maintaining the SCR adjust the choke opening until the choke pressure equals the closed-in annulus pressure. Record and keep the choke pressure constant throughout the first circulation.

51

Maharvi 1 Drilling Program 6. Read standpipe pressure. It should equal the normal pre-kick pump test circulation pressure at the selected pump speed plus the closed-in drill pipe pressure. If the observed standpipe pressure does not agree with the calculated value, consider the observed pressure to be correct. 7. Maintain constant standpipe pressure and pump rate (SCR) whilst the influx is circulated out. 8. When all influx has been circulated out, stop the pump and close in the well to check the closed-in drill pipe and annulus pressures. At the end of the first circulation the closed-in pressures of the annulus and drill pipe should be the same and equal to the initial closed-in drill pipe pressure. The well is controlled but not killed. 9. Once the drilling fluid has been weighed up to the correct density the second circulation can begin. Prepare kill sheet & pumping schedule (Kill sheet format attached in Section 7.5) format and follow through out the second circulation. 10. Start the pump and circulate kill mud at the SCR. Hold casing pressure constant until the kill mud reaches the bit. At the same time monitor DP pressure against the pump schedule. 11. When the kill mud reaches the bit, hold drill pipe pressure constant at Final Circulating Pressure (FCP) until the weighted mud is surfaced. 12. When the kill mud is surfaced shut off the pump, close the well and check pressures. Both pressures should record zero. If so open the well and conduct a flow check. If it is not flowing, the well has been killed successfully. If it flows, follow the killing procedure again.

52

Maharvi 1 Drilling Program

7.5) KILL WORK SHEET

WELL CONTROL WORK SHEET

FORMATION STRENGTH DATA Well Name FIT EMW (A) ppg Current Drilling Mud Weight psi

DP

Date: __________________ CURRENT WELL DATA

Initial MAASP ((A) - Current MW) x Shoe TVD x 0.052 =

ppg

MUD PUMP DATA Pump Outout Pump 1 bbls / stk (PL) Dynamic Pressure Losses 30 SPM 45 SPM Pump 2 bbls / stk

Casing Shoe Data Size MD TVD OH Data Size MD TVD

" ft ft

SCR Pump No. 1 Pump No. 2

PRE-RECORDED VOL DATA LENGTH ft Drill Pipe HWDP Drill Collars Drill String Volume DC x OH DP x OH OH Volume DP x CSG. TOTAL ANNULUS VOL. TOT WELL SYS VOL. TOT ACTIVE SUR. VOL. TOT ACT. FLUID SYS x (F)+(G) = (H) (D)+(H) = (I) (J) (I)+(J) x x (F) (G) bbls bbls bbls bbls bbls bbls KICK DATA SIDPP psi SICP psi PIT GAIN bbls Strokes Strokes Strokes Strokes Strokes Strokes Mins Mins Mins x x x (D) bbls (E) Strokes Mins CAP bbls / ft VOLUME bbls PUMP STROKES Strokes VOLUME PUMP OUT PUT TIME Mins PUMP STROKES SCR

KILL MUD WEIGHT (KMW) Current MW + (SIDPP / TVD x 0.052 ) + ( / . x 0.052) = _________ INITIAL CIRCULATING PRESSURE (ICP) Dynamic Pressure Losses + SIDPP + = _________ FINAL CIRCULATING PRESSURE (FCP) KMW x Dynamic Losses / Current MW x / = _________ psi psi

PRESSURE DROP / 100 STKS (PSI PER 100 STKS) (K) = ICP - FCP - = ________ (K) x 100 / (E) x 100 / ... = _________

53

DC

60 SPM

" ft ft

Maharvi 1 Drilling Program

PUMP SCHEDULE

Pressure (psi)

Strokes

DP Pressure (psi)

Strokes

54

Maharvi 1 Drilling Program

55

Maharvi 1 Drilling Program

8 PRESSURE TEST

S ECTION

56

Maharvi 1 Drilling Program

8.1) PRESSURE TEST WELL CONTROL EQUIPMENTS

BOP SIZE

ANNULAR TYPE RATING

RAM TYPE RATING

PRESSURE TEST

ANNULAR

Low : 300 psi High : 2500 psi

RAM

Low : 300 psi High : 4500 psi

BLIND

Low : 300 psi High : 4500 psi

CHK / KILL LINE M / F

Low : 300 psi High : 4500 psi

13

5M

10 M

Low-pressure test for 10 min. High-pressure test for 15 min. Use test plug to test BOP stack and cup tester for newly installed casing spool, flanges & valves. Press test casing head housing (through weld test port. 75% of the casing collapse pressure or Well Head Housing rated press which ever is Lower).

57

Maharvi 1 Drilling Program

S ECTION

PLUG & ABANDONMENT

58

Maharvi 1 Drilling Program

9.1) OBJECTIVES

To place impermeable tested barriers between deep reservoirs and shallow aquifers / surface. Final P & A will be sent to the well site based on results, testing well bore conditions and formations.

9.2) SEQUENCE OF EVENTS

500' cement plug inside open / cased hole at the top of the sands. 500' plug around 9 (cement as per 9 tail slurry). 300' plug inside 9 casing from 100' to 400' Test (mechanically & hydraulically) all the cement plugs. N / d BOP stack and cut off wellhead.

Surface dry cement plug after having removed the wellhead (accelerated setting recipe).

59

Potrebbero piacerti anche

- Drilling Operation & Hazards Analysis PDFDocumento343 pagineDrilling Operation & Hazards Analysis PDF李建100% (5)

- Safe Work Procedure-Set Up RigsDocumento4 pagineSafe Work Procedure-Set Up RigsAsif KhanzadaNessuna valutazione finora

- Drilling Programme TemplateDocumento15 pagineDrilling Programme TemplateaMRHAGGAHNessuna valutazione finora

- 13A HPHT Procedure Presentation 20130420Documento21 pagine13A HPHT Procedure Presentation 20130420JohnSmith100% (2)

- Drilling Formulae - 9th Edition PDFDocumento87 pagineDrilling Formulae - 9th Edition PDFEng Mohamed SaberNessuna valutazione finora

- Fundamentals and Applications of Bionic Drilling FluidsDa EverandFundamentals and Applications of Bionic Drilling FluidsNessuna valutazione finora

- SWIM 001 R2 Complete FinalDocumento177 pagineSWIM 001 R2 Complete Finalmccallum1983100% (3)

- Mesin Bor XR220D Operating InstructionsDocumento237 pagineMesin Bor XR220D Operating Instructionsilonk antonieNessuna valutazione finora

- Rig IntroductionDocumento214 pagineRig IntroductionAnonymous 1pblc2Y100% (5)

- Rigs, Drilling A WellDocumento50 pagineRigs, Drilling A Wellfrganga100% (1)

- Datalog Wellsite Procedures Manual 1999Documento34 pagineDatalog Wellsite Procedures Manual 1999Muhammad HamdyNessuna valutazione finora

- Anti CollisionDocumento109 pagineAnti CollisionElmar Cahangirov100% (1)

- ALMagd C-86-C Drilling Program v1Documento46 pagineALMagd C-86-C Drilling Program v1Anonymous XbmoAFtI100% (2)

- EIA Drill WellDocumento129 pagineEIA Drill Wellavinash-mokashi100% (2)

- Drilling MatrixDocumento3 pagineDrilling Matrixjonny727100% (1)

- Group One Drilling Project 2018Documento150 pagineGroup One Drilling Project 2018Freda AmuahNessuna valutazione finora

- IntroductionDocumento18 pagineIntroductionEkkarat RattanaphraNessuna valutazione finora

- Well PlanningDocumento55 pagineWell Planningmts1234100% (1)

- End of Well ReportDocumento21 pagineEnd of Well ReportmkwendeNessuna valutazione finora

- Introduction To Drilling TechnologyDocumento68 pagineIntroduction To Drilling TechnologyKrupal Patel100% (1)

- HPHT Drill & Well ControlDocumento40 pagineHPHT Drill & Well ControlanilkumarNessuna valutazione finora

- Drilling Programme - Preparation and ContentDocumento2 pagineDrilling Programme - Preparation and ContentYougchu LuanNessuna valutazione finora

- Basic Course of Drilling ProcedureDocumento4 pagineBasic Course of Drilling ProcedureAli Samani100% (2)

- 3day Mud School Info6.24.07Documento4 pagine3day Mud School Info6.24.07محمد سعيدNessuna valutazione finora

- Chapter 10-FDocumento12 pagineChapter 10-FMahrouz MadoNessuna valutazione finora

- Drilling PlanningDocumento22 pagineDrilling PlanningSrikanth Bammhide0% (1)

- Offshore Drilling IntroductionDocumento56 pagineOffshore Drilling IntroductionnaefmubarakNessuna valutazione finora

- Drilling Health and Safety RequirementDocumento80 pagineDrilling Health and Safety RequirementSunday OluwanisolaNessuna valutazione finora

- Well Planning and DesignDocumento7 pagineWell Planning and DesignCyril PintoNessuna valutazione finora

- Analysis, Comparison and Application of CWD Against Conventional Drilling OperationsDocumento104 pagineAnalysis, Comparison and Application of CWD Against Conventional Drilling Operationsprakharmathur14100% (1)

- A Process Used in Evaluation of Managed-Pressure Drilling Candidates and Probabilistic Cost-Benefit AnalysisDocumento13 pagineA Process Used in Evaluation of Managed-Pressure Drilling Candidates and Probabilistic Cost-Benefit AnalysisMaulana Alan MuhammadNessuna valutazione finora

- Bench Marking Drilling OpsDocumento40 pagineBench Marking Drilling OpsSLACKENGINEERNessuna valutazione finora

- Serpent Da Drilling Programme Rev1Documento34 pagineSerpent Da Drilling Programme Rev1eng7mohamed7hashim100% (2)

- Iadc Drillersmethod Field 012214Documento3 pagineIadc Drillersmethod Field 012214E SchonNessuna valutazione finora

- PETE 411: Well DrillingDocumento41 paginePETE 411: Well Drillingshanecarl100% (1)

- Capella L17H Drilling ProgramDocumento57 pagineCapella L17H Drilling ProgramJorge Briñez100% (1)

- Well ControlDocumento10 pagineWell ControlSamad Ali SiddiquiNessuna valutazione finora

- AADE 2009NTCE-07-04 KPI BenchmarkingDocumento7 pagineAADE 2009NTCE-07-04 KPI Benchmarkingdrilling moneytreeNessuna valutazione finora

- Tally Well 6g-0203a R-OhgpDocumento15 pagineTally Well 6g-0203a R-OhgpLinheris Sitompul100% (1)

- Basic Drilling For WE ADP 2014Documento52 pagineBasic Drilling For WE ADP 2014Nabeel AmeerNessuna valutazione finora

- ANZ-37MH Final Drilling ProgramDocumento37 pagineANZ-37MH Final Drilling ProgramWilson OdiaNessuna valutazione finora

- Drilling and Well ConstructionDocumento36 pagineDrilling and Well ConstructionMarcio Nascimento BezerraNessuna valutazione finora

- Formulas and Calculations For Drilling Operations by Robello Samuel - Discount FlyerDocumento1 paginaFormulas and Calculations For Drilling Operations by Robello Samuel - Discount Flyerarzafar0% (1)

- Pick Up Drill PipeDocumento5 paginePick Up Drill PipeinfonexusNessuna valutazione finora

- 4 Casing DesignDocumento103 pagine4 Casing DesignZhong YingNessuna valutazione finora

- List of Components of Oil Drilling RigsDocumento4 pagineList of Components of Oil Drilling RigsIjlal AhmadNessuna valutazione finora

- Rig Safety PresentationDocumento20 pagineRig Safety PresentationMohamed MostafaNessuna valutazione finora

- BSD-GL-HAL-HMS-100 - (Terms & Definitions)Documento42 pagineBSD-GL-HAL-HMS-100 - (Terms & Definitions)Eduard GadzhievNessuna valutazione finora

- Overview of Drilling OperationDocumento106 pagineOverview of Drilling OperationTemitope Bello100% (1)

- 5M54C DC Duri0726120190423prf01Documento26 pagine5M54C DC Duri0726120190423prf01Ryan SinagaNessuna valutazione finora

- Drilling EngineeringDocumento167 pagineDrilling EngineeringLudovic NietzscheNessuna valutazione finora

- Drilling and Costs Chapter 6Documento51 pagineDrilling and Costs Chapter 6qatar4ever66Nessuna valutazione finora

- Extended Reach Drilling1 PDFDocumento18 pagineExtended Reach Drilling1 PDFMayra Betancourt Dominguez100% (1)

- Well Planing Hazard ChecklistDocumento7 pagineWell Planing Hazard Checklistmohammed mizbauddinNessuna valutazione finora

- Drilling and Well Operations - D-010r1Documento39 pagineDrilling and Well Operations - D-010r1jorge_h_riveroNessuna valutazione finora

- Formulas and Calculations for Drilling OperationsDa EverandFormulas and Calculations for Drilling OperationsNessuna valutazione finora

- Wave Propagation in Drilling, Well Logging and Reservoir ApplicationsDa EverandWave Propagation in Drilling, Well Logging and Reservoir ApplicationsNessuna valutazione finora

- Fundamentals of Drilling Engineering: MCQs and Workout Examples for Beginners and EngineersDa EverandFundamentals of Drilling Engineering: MCQs and Workout Examples for Beginners and EngineersNessuna valutazione finora

- Microbial Enhancement of Oil Recovery - Recent AdvancesDa EverandMicrobial Enhancement of Oil Recovery - Recent AdvancesNessuna valutazione finora

- Trenggalek - High Grade Copper & Gold ConfirmedDocumento15 pagineTrenggalek - High Grade Copper & Gold Confirmedakhmad ashariNessuna valutazione finora

- ST Dizier Tas Skarn (2018 - 05 - 12 04 - 38 - 28 UTC)Documento7 pagineST Dizier Tas Skarn (2018 - 05 - 12 04 - 38 - 28 UTC)dito suditoNessuna valutazione finora

- Seismic Stratigrafi Facies - Muara EnimDocumento40 pagineSeismic Stratigrafi Facies - Muara EnimBagaskara Rooshardwiadi100% (1)

- 200 Limestones of Jurong Formation Engineering ExperienceDocumento9 pagine200 Limestones of Jurong Formation Engineering ExperiencegahsoonNessuna valutazione finora

- 116.atlas Copco Roc d7 - HandbookDocumento8 pagine116.atlas Copco Roc d7 - Handbookadamajaks198575% (4)

- Boomer M2 C SP - 9851 2578 01aDocumento4 pagineBoomer M2 C SP - 9851 2578 01aPablo Luis Pérez PostigoNessuna valutazione finora

- Volume CalculationsDocumento30 pagineVolume CalculationsMohamad TayeaNessuna valutazione finora

- B.O FPI Operation Procedure 20131122Documento3 pagineB.O FPI Operation Procedure 20131122Feynce Jacob Morist KaseNessuna valutazione finora

- Sandvik DP1100i: Surface Top Hammer DrillsDocumento3 pagineSandvik DP1100i: Surface Top Hammer DrillsTuan Pham AnhNessuna valutazione finora

- Dp1500i t3 Specification Sheet EnglishDocumento3 pagineDp1500i t3 Specification Sheet EnglishSTANLEYNessuna valutazione finora

- SPE - 108075 - Horizontal Well Completion and Stimulation TechniquesDocumento15 pagineSPE - 108075 - Horizontal Well Completion and Stimulation Techniquesfendercolombo100% (1)

- Prepared By: Amrita Chatterjee Swarnendu Bhattacharjee: Adamas Institute of Technology, Civil Engineering, 3 YearDocumento79 paginePrepared By: Amrita Chatterjee Swarnendu Bhattacharjee: Adamas Institute of Technology, Civil Engineering, 3 YearMonjit RoyNessuna valutazione finora

- SOP Drilling - Geology PDFDocumento87 pagineSOP Drilling - Geology PDFAgustinus Kristanto100% (1)

- DX700 Product SpecDocumento4 pagineDX700 Product SpecshNessuna valutazione finora

- Resumo Alargado ImprimirDocumento10 pagineResumo Alargado Imprimirumesh deshmukhNessuna valutazione finora

- Summary Report PertaminaPBMSJ BTJ-206 HendrikSahertian 4August-13August2013Documento17 pagineSummary Report PertaminaPBMSJ BTJ-206 HendrikSahertian 4August-13August2013Menly TanNessuna valutazione finora

- KL 900 PDFDocumento4 pagineKL 900 PDFDamNessuna valutazione finora

- Code of Practice FINAL PDFDocumento36 pagineCode of Practice FINAL PDFhananhdNessuna valutazione finora

- SAES-Q-004 Installation Piles Offshore Structures 2004Documento22 pagineSAES-Q-004 Installation Piles Offshore Structures 2004ymaseda100% (2)

- Drilling Bits SPE Series-ADIDocumento62 pagineDrilling Bits SPE Series-ADIAlfredo TintayaNessuna valutazione finora

- Soil InvestigationsDocumento127 pagineSoil InvestigationsAntony GodwinNessuna valutazione finora

- DDR Abbreviation PDFDocumento41 pagineDDR Abbreviation PDFfdpNessuna valutazione finora

- DCM KellerDocumento8 pagineDCM KellerHumza MubarikNessuna valutazione finora

- QC 006 Rig Inspection WorkshopDocumento132 pagineQC 006 Rig Inspection WorkshopYacine Flyacinegazza100% (2)

- 550 HP Rig Pdsi PD 550 MDocumento1 pagina550 HP Rig Pdsi PD 550 MAnwarNessuna valutazione finora

- Subcontractor Safety (EDocFind - Com)Documento41 pagineSubcontractor Safety (EDocFind - Com)Satya NaiduNessuna valutazione finora

- Light EquipmentDocumento44 pagineLight EquipmentyoungonhuntNessuna valutazione finora

- Machine OptionsDocumento44 pagineMachine Optionsjose razoNessuna valutazione finora

- Brosur Sany SR155-C10-2020Documento2 pagineBrosur Sany SR155-C10-2020mbah petruk100% (1)

- Dc130ri Brochure EnglishDocumento2 pagineDc130ri Brochure Englishسالم دريديNessuna valutazione finora