Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Viscoelastic Evaluation of Topical Creams Containing Micro Crystalline Cellulose+Sodium Car Boxy Methyl Cellulose As Stabilizer

Caricato da

arevicDescrizione originale:

Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Viscoelastic Evaluation of Topical Creams Containing Micro Crystalline Cellulose+Sodium Car Boxy Methyl Cellulose As Stabilizer

Caricato da

arevicCopyright:

Formati disponibili

AAPS PharmSciTech 2002; 3 (2) article 8 (http://www.aapspharmscitech.

org)

Viscoelastic Evaluation of Topical Creams Containing Microcrystalline Cellulose/Sodium Carboxymethyl Cellulose as Stabilizer

Submitted: November 14, 2001; Accepted: December 7, 2001; Published: May 30, 2002.

Moji Christianah Adeyeye1, Ashwinkumar C. Jain1, Mohamed K.M. Ghorab1, and William J. Reilly, Jr2

1 2

Graduate School of Pharmaceutical Sciences, Duquesne University, Pittsburgh, PA 15282 Independent Pharmaceutical Formulation Consultant, New Hope, PA 18938 containing Avicel CL-611, the G' was above G'' with a good distance between them. The gel strength and the predominance of G' can be ranked 6% > 4% > 2%. The strain profiles for the 1% and 2% formulations were similar to those of the commercial formulation. The values for the 1% and 2% formulations were similar, and the formulations containing 4% Avicel CL-611 had lower values, indicating greater elasticity. Drug release from the commercial preparation was fastest compared to the formulations prepared using Avicel CL-611, a correlation with the viscoelastic properties. It was found that viscoelastic data, especially the strain sweep profiles of products containing Avicel CL-611 1% and 2%, correlated with the commercial formulation. Rheological tests that measure the viscosity, yield stress, thixotropic behavior, other oscillatory parameters such as G' and G'' are necessary tools in predicting performance of semisolids. Key Words: Viscoelastic, Microstructure, Cream, Avicel CL-611, Hydrocortisone acetate, Storage modulus, Loss modulus, Thixotropic, Bridging flocculation

ABSTRACT The purpose of this study was to

examine the viscoelastic properties of topical creams containing various concentrations of microcrystalline cellulose and sodium carboxymethyl cellulose (Avicel CL-611) as a stabilizer. Avicel CL-611 was used at 4 different levels (1%, 2%, 4%, and 6% dispersion) to prepare topical creams, and hydrocortisone acetate was used as a model drug. The viscoelastic properties such as loss modulus (G''), storage modulus (G'), and loss tangent (tan ) of these creams were measured using a TA Instruments AR 1000 Rheometer and compared to a commercially available formulation. Continuous flow test to determine the yield stress and thixotropic behavior, and dynamic mechanical tests for determining the linear viscosity time sweep data, were performed. Drug release from the various formulations was studied using an Enhancer TM Cell assembly. Formulations containing 1% and 2% Avicel CL-611 had relative viscosity, yield stress, and thixotropic values that were similar to those of the commercial formulation. The elastic modulus (G') of the 1% and 2% formulation was relatively high and did not cross the loss modulus (G''), indicating that the gels were strong. In the commercial formulation, G' increased after preshearing and broke down after 600 seconds. The strain sweep tests showed that for all formulations

INTRODUCTION

Products such as topical creams are designed for protracted residence on the skin and undergo a wide variety of stresses during removal from the container and application to the affected area. Therefore, it is important to consider the effects of such stress on the microstructure of products.

1

*Corresponding Author: Moji Christianah Adeyeye,

Graduate School of Pharmaceutical Sciences, Duquesne University, Pittsburgh, PA 15282. Telephone: (412) 396-5133; Email: adeyeyechri@duq.edu

AAPS PharmSciTech 2002; 3 (2) article 8 (http://www.aapspharmscitech.org)

Microstructural characteristics (e.g, lamellar gel phase, interfacial layer or membrane of the dispersed phase, micellar formation and physical stability, flocculation, ratio of free and bound water to surfactants) of topical creams-pharmaceutical, cosmetic, or food-have been evaluated using several analytical methods. These methods include viscoelastic measurements [1-4], low- and highangle X-ray diffractometry [2], confocal laser scanning microscopy [5], thermogravimetry [6], low-temperature scanning electron microscopy [1,7,8], differential scanning calorimetry [9], and 17 O nuclear magnetic relaxation [10]. More microstructure investigations have focused on foods than on pharmaceuticals. Therefore, microstructural characterization of topical pharmaceutical creams using methods such as rheology is necessary. Rheological or viscoelastic measurements are generally done to quantify the effects of aging, temperature, ingredients, and processing parameters on formulations. Additionally, they are performed to describe quantitatively the flow of a material for the purpose of quality control (e.g., pumping through pipes or tubes during processing; ease of dispensing of product from tubes, bottles, or jars; and spreadability on the skin surface) [11]. Additionally, textural analysis can be used for selection of candidate formulations for clinical applications [12,13]. Viscoelastic properties are derived from testing of materials without destroying the structure (i.e., the structure is flexed and material is measured in its "ground state"). The measurements are done through rheological flow and dynamic mechanical tests. The former investigates the flow viscosity, whereas the latter evaluates small periodic deformations that determine breakdown or rearrangement of structure or hysteresis. The dynamic mechanical "strain sweep" test examines the microstructural properties of the material under increased strain. It measures the storage modulus, G', which is an indicator of elastic behavior and reveals the ability of the polymer system to store elastic energy associated with recoverable elastic deformation. The loss modulus, G'', is a measure of the dynamic viscous behavior

2

that relates to the dissipation of energy associated with unrecoverable viscous loss. The loss tangent (tan ) is defined as the ratio of the loss modulus to the storage modulus and is dimensionless. It is a measure of the ratio of energy lost to energy stored in a cycle of deformation and provides a comparative parameter that combines both the elastic and the viscous contribution to the system [11,14]. The relationship between G', G'', and tan is shown in equations 1 and 2:

tan =

G' ' G'

(1)

G* = G' + iG''

(2)

G* is the complex modulus, a measure of the materials overall resistance to deformation, and i is the imaginary number, i = 1 [12]. Tan values were found to be of great interest in modeling viscoelastic behavior and were successfully used by Gasperlin et al [15] to study lipophilic semisolid systems. The dynamic viscosity ' is a function of the complex viscosity '' and is related to the steady shear viscosity. It measures the rate of energy dissipation in a viscoelastic material. The relationship between ' and loss modulus (G'') is given in equation 3:

' =

G' '

(3)

Various cellulose derivatives such as hydroxypropyl methylcellulose, hydroxyethyl cellulose, and sodium carboxymethylcellulose (NaCMC) have been used in the development of topical pharmaceutical cream emulsions. However, newer excipients such as Avicel CL-611 have not been well characterized as a dispersion stabilizer in topical preparations. Avicel CL-611 is microcrystalline cellulose coprocessed with a portion of NaCMC (11.3%-18.8%) that provides thixotropic behavior to the corresponding semisolid structural network formed [16,17]. The

AAPS PharmSciTech 2002; 3 (2) article 8 (http://www.aapspharmscitech.org)

hydrocolloids, the group to which colloidal Avicel CL-611 belongs, generally favor oil/water emulsions. They form very good hydrophilic barriers via adsorption on drug particles to form a 3dimensional network structure within the system, thus sterically stabilizing the system. The consequence is increased viscosity (due to particleparticle interaction) or stabilization of the system without a corresponding increase in the oil phase of emulsions. The aim of the present work was to investigate the rheological properties of creams (oil/water emulsions) prepared using various levels of Avicel CL-611 as the phase stabilizer and to study the drug release of the various formulations in comparison to a marketed formulation.

ingredients are listed in Table 1. The oil phase was then added to the aqueous phase and mixed with a Lightnin mixer (Aldrich Chemical Co., Milwaukee, WI) at 500 rpm for 2 minutes followed by increasing the speed to 1000 rpm for 10 minutes. The hot creams were poured into ointment tubes and allowed to cool for solidification. Different levels of Avicel CL-611 (1%, 2%, 4%, and 6% w/w) were used to develop oil/water creams. Based on a preliminary study, 4 replicate batches of creams containing 1% and 2% Avicel CL-611 only were made. Each formulation contained 1% hydrocortisone acetate as model drug.

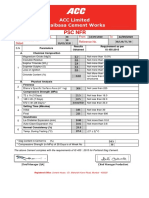

Table 1. Cream Formulation

MATERIALS AND METHODS

Materials

Avicel CL-611 was supplied by FMC Corporation, Princeton, NJ. Hydrocortisone acetate was purchased from Sigma Chemical Co., St. Louis, MI. Propylene glycol, methylparaben, propylparaben, cetyl alcohol, and glyceryl monostearate were all purchased from Spectrum Quality Products, New Brunswick, NJ. All solvents used in High Pressure Liquid Chromatography [HPLC]. Analysis were HPLC grade unless otherwise noted and were used as received. The commercial (oil/water) cream used in this study was Lanocort 10 containing 1% hydrocortisone acetate. Other ingredients in the formulation included aloe, ceteareth-20, cetearyl alcohol, cetyl alcohol, methylparaben, propylparaben, sorbitol, water, and zinc pyrithione.

Aqueous phase Avicel CL-611 dispersion Methylparaben Hydrocortisone acetate Propylene glycol Polysorbate 80 Oil phase Cetyl alcohol Propylparaben Glyceryl monostearate

Percentage To 100.0% w/w 0.25 1.0 10.0 5.0

2.50 0.15 15.0

Rheological studies

Rheological testing of the various cream formulations was performed at ambient temperature using a control-stress rheometer (TA Instrument AR 1000N). The general conditions for all tests included the use of a 4-cm acrylic plate with solvent trap and 1600- gap.

Steady shear

Methods

Preparation of creams

The oil phase ingredients and the aqueous phase ingredients (containing the Avicel CL-611 dispersion) were mixed separately and heated to 70C. The aqueous phase and the oil phase

3

A flow test was used to determine the relative viscosity of all formulations with the following parameters: For the upcurve, a continuous ramp with shear rate as controlled variable (0-100 1/sec), log mode, 2 minutes ramp duration at 25C was applied. The same procedure was used for the

AAPS PharmSciTech 2002; 3 (2) article 8 (http://www.aapspharmscitech.org)

downcurve with reversed shear rate (100-0 1/sec) to measure thixotropy and yield stress.

Dynamic Mechanical Testing

Strain sweep

phase consisted of methanol:water:acetonitrile (3:6:2.5) with a flow rate of 1 mL/min (Shimadzu Liquid Chromatography LC 10AS, Columbia, MD). The eluent was monitored with an UV detector at 242 nm (Shimadzu UV-VIS Detector SPD-10A), and chromatograms were analyzed using EZChrome software (Shimadzu Scientific Instruments, Columbia, MD).

All test samples were subjected to constant frequency (10 rad/sec) using an amplitude ramp with 0.2%-100% strain at 25C. The aim was to investigate the structural properties of the creams under increased strain.

Time sweep

RESULTS AND DISCUSSION

Rheological Evaluation

Steady shear

Each sample was subjected to preshearing (1 minute applied value of 20 1/sec shear rate at 25C). The aim was to examine the structure recovery after the structure was broken down. The samples were subjected to a frequency of 10 rad/sec, with a 1.0% strain (this value was part of the established procedure in the laboratory used) as controlled variable for 30 minutes at 25C.

Drug Release Study

The drug release from various formulations was evaluated using United States Pharmacopoeial [USP] Type II apparatus and an Enhancer Cell assembly [18]. The release medium consisted of 200 mL of 60% vol/vol ethanol. A polyethylene membrane (CoTran, 3M Pharmaceuticals, St. Paul, MN) was used as the permeating membrane. A 1mL sample was withdrawn at 1, 2, 3, 4, 6, and 8 hours. The analysis sample (50 L) was directly injected into the HPLC for analysis. Drug release from a commercial formulation was compared to that of the creams prepared in the laboratory.

Based on a preliminary screening, we found that formulations containing 1% and 2% Avicel CL-611 had viscosity and yield stress similar to those of the commercial formulation (Table 2). Hence, replicate batches were made only for creams containing 1% and 2% Avicel CL-611. The thixotropic values for 1% or 2% Avicel CL-611 creams were lower than those of the commercial formulation,indicating that these formulations had better structure recovery properties. However, creams containing 4% and 6% Avicel CL-611 had much higher thixotropic values, implying that these formulations took longer to rebuild viscosity at rest after being sheared, which is potentially an undesirable property. A typical flow curve (shear rate vs shear stress) of the cream containing 1% Avicel CL-611 is shown in Figure 1. The yield stress values for the various formulations are reported in Table 2. The magnitude of yield stress relates to the strength of interparticle interaction in the three-dimensional network microstructure of the creams. Both 4% and 6% creams had higher yield stress values compared to the other three formulations, indicating more contact surfaces, stronger packing between particles, lower packing fraction (m), and less tendency for bridging flocculation. This is to be expected, since greater concentration of hydrocolloid will cause better interpenetration of the polymer coils. In contrast, the yield stress of the

4

HPLC Assay

The concentration of hydrocortisone acetate released was quantified by a reverse-phase HPLC method. A C18 column (4.6 x 100 mm, 5 m) (Phenomenex, Torrance, CA) was used. The mobile

AAPS PharmSciTech 2002; 3 (2) article 8 (http://www.aapspharmscitech.org) Table 2. Relative Viscosity/Yield Stress/Thixotropy of Various Formulations and Commercial Cream Levels of Avicel CL-611 Relative Viscosity (Pa.s) 6 sec-1 1% 2% 4% 6% Commercial 22.7 (5.4) 28.3 (1.5) 58.4 89.5 13.5 12 sec-1 11.9 (2.9) 15.3 (1.3) 22.5 36.9 11.2 100 sec-1 1.58 (0.29) 1.9 (0.1) 2.1 3.04 2.4 101.1 (22.1) 121.8 (9.1) 235.1 355.3 121.1 1818 (262.9) 2257 (154.9) 9578 14,710 5020 Yield Stress, Apparent (Pa) Thixotropy (Pa/s)

*Values in parentheses are standard deviations (n = 3). At selected points (6 sec-1, 12 sec-1, 100 sec-1). Bingham statistical model ( = y + K y, where = shear stress, y = yield stress, K = Bingham viscosity, =shear rate).

1% Avicel CL-611 was the lowest, suggesting that a small stress is needed to initiate flow, which may be better in terms of applicability of the formulation to the skin. Although the stress values were the same for the cream containing 2% Avicel and the commercial formulation, the commercial cream took more time to rebuild its structure at rest after shear, as shown by the greater thixotropic value of the commercial cream.

Henderson et al [19] determined that creams generally encountered a shear rate of 120 sec-1 during topical application. Viscosity at this shear range could determine the ease of rubbing a cream or emulsion and hence influence the end-use performance of the product. Table 2 shows the viscosity of the various formulations used in this study at selected shear rates. The viscosities of the 1% and 2% formulations at shear rate of 100 sec-1 (1.58 and 1.9 Pa.s) were lower compared to the viscosity of commercial cream (2.4 Pa.s), indicating better spreadability upon topical application of the formulations.

Dynamic Mechanical Tests

Strain sweep

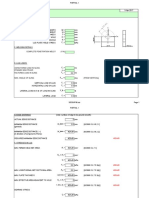

Figure 1. Typical flow curve (shear rate vs shear stress of a batch) of cream containing 1% w/w Avicel CL-611 [Top of the rheogram is the upcurve and the lower is the down curve].

Creams prepared using 1% or 2% Avicel CL-611 had similar strain profiles (Figure 2A). The phase angle , which is a good indicator of the overall viscoelastic nature of the sample, was found to be 62 and 61 for the 1% and 2% Avicel, respectively, and 67 for the commercial cream (Figure 2D). These values range between 0 (ideal elastic solid) and 90 (completely viscous flow liquid), indicating that the creams are viscous enough to allow for

5

AAPS PharmSciTech 2002; 3 (2) article 8 (http://www.aapspharmscitech.org)

spreading and rubbing on the skin. Looking at the values of tan for the commercial cream (2.36) compared to the 1% and 2% Avicel CL-611 formulations (1.80 and 1.88), commercial cream is more viscous. Tan greater than 3 indicates that particles are nonassociated; 1 < tan > 3 indicates that particles are weakly associated and tan < 1 signifies highly associated particles [20]. Therefore, it can be inferred that particles or the hydrocolloid polymer network within the laboratory-made cream products were more highly associated (more densely packed) or there was less bridging flocculation compared to the commercial cream [21]. The elastic modulus, G', for the 1% or 2% Avicel CL-611 and the commercial (Figures 2A and D) formulation was over G'' with a good distance between them, signifying strong thickening or solidifying behavior. However, at about 10% strain, the products started to break down, with G' and 'G'''' crossing each other. The lower strain is a desirable feature since it simulates the onset of spreading of cream on the skin, as discussed earlier under Steady shear. This would also allow better absorption from the skin, considering the fact that the cream has to spread well on the skin surface before absorption could take occur. In contrast, the 4% and 6% formulations did not show breakdown of elastic modulus (G') and crossing with the loss modulus (G'') until strain reached about 70% (Figures 2B and C). This demonstrates that greater strain is needed to cause effective spreading and rubbing, a correlation with the observed yield stress data discussed earlier under Steady shear above. The higher the percent strain, the stronger the cream structure. The greater strain is not desirable in a formulation, thus, 4% and 6% formulations were considered unsuitable. Therefore, knowledge of these viscoelastic indices could be used to predict the performance of topical delivery systems such as creams.

Time sweep

Creams prepared using 1% Avicel CL-611 had lower G', G'', and ' compared to creams prepared using 2% Avicel CL-611 and commercial formulation (Table 3, Figures 3A and C). Interestingly, in creams containing 1% or 2% Avicel CL-611, the structure recovered rapidly, G' (the solid-like component) never crossed G'' (the liquid-like component) during the test. This indicates a strong network of polymer entanglement and possibly better long-term stability compared to the commercial product. The commercial formulation had an increase in G' after preshearing that decreased substantially after approximately 600 seconds (Figure 3C, Table 3). However, the formulations containing 4% or 6% Avicel CL-611 (Figure 3B) had much stronger solid-like properties (G' was very predominant) compared to other formulations. This is in agreement with the high yield stress values needed to initiate flow and the longer time needed to rebuild structure at rest after shear, as reflected in the high thixotropic values in Table 2. The viscoelastic moduli, storage modulus (G'), and viscous modulus (G'') are direct measurements of particle-particle interaction (i.e., they measure structural characteristics of the cream formulations). The response is sensitive to the amplitude of applied deformation, that is, to strain or stress ( or ). Although the rheology is measured macroscopically, the measurement depends on microscopic considerations and it yields valuable information about the microstructure [22].

Drug release

The amount of the drug released (Q) was plotted against the square root of time (t), based on Ficks law of diffusion.

Q = AC O (t )1 / 2

(4)

In the above equation, A is the cross-sectional area of the Enhancer Cell and C0 is the initial concentration of the drug in the formulation.

6

AAPS PharmSciTech 2002; 3 (2) article 8 (http://www.aapspharmscitech.org)

Figure 2. Typical strain sweep profiles for formulations containing Avicel CL-611, A - 1% & 2%; B- 4%; C -

6% and for the commercial cream - D. The release of drug from the various creams fitted the square root of time relationship (Figure 4), indicating that the release was by diffusion. As expected, higher concentration of the Avicel CL611 resulted in a slower drug release as a result of less bridging flocculation. This correlates with the relative viscosity data in Table 2, indicating that formulations with higher viscosity had lower release compared to the commercial formulation. The drug release profiles for creams containing 1% or 2% Avicel CL-611 were similar, while the release from the commercial formulation was faster than that of

7

the other formulations. This could be due to the hydrophilic excipients such as ceteareth-20 (a surfactant) and sorbitol, a humectant that retards the recrystallization of dispersed solids, thus increasing the solubility of hydrocortisone acetate in the marketed product.

AAPS PharmSciTech 2002; 3 (2) article 8 (http://www.aapspharmscitech.org) Table 3. Viscoelastic Properties of Various Formulations Containing Different Levels of Avicel CL-611 and the Commercial Cream Levels of Avicel CL-611 Crossover Time (G'=G'' Crossover) (sec) NC NC NC NC Crossover Modulus G' = G'' ( at y-Axis) (Pa) NC NC NC NC Dynamic Viscosity at G' =G'' (' at y-Axis) (Pa.s) NC NC NC NC Elastic Modulus (G') 900 Sec (G' at y-Axis)(Pa)

1% 2% 4% 6%

739 (173) 1204 (252) 1484 1471 639

Commercial 556.4 963.5 93.89 *Values in parentheses are standard deviations of the elastic modulus (G') NC indicates no crossover of G' with G'', G'> G''

Figure 3. Typical time sweep profiles for formulations containing Avicel CL-611, A - 1% or 2%; B - 4% or 6%; and commercial cream - C. Closed circles - ', open circles - G' and open triangles - G''

AAPS PharmSciTech 2002; 3 (2) article 8 (http://www.aapspharmscitech.org)

his useful suggestions during the preparation of the manuscript.

REFERENCES

1. Smith AK, Goff HD, Kakuda Y. Microstructure and rheological properties of whipped cream as affected by heat treatment and addition of stabilizer. Int Dairy J. 2000;10(4): 295-301. 2. Eccleston GM, Behan-Martin MK, Jones GR, TownsAndrew E. Synchrotron X-ray investigations into lamellar gel phase formed in pharmaceutical creams prepared with cetrimide and fatty alcohols. Int J Pharm. 2000;203(1-2):127-139. 3. Dickinson E, Golding M. Influence of calcium ions on creaming and theology of emulsions containing sodium caseinate. Colloids Surf. A 1998;144: (1-3): 167-177. 4. Dickinson E, Golding M. Rheology of sodium caseinate stabilized oil-in-water emulsions. J Colloid Interface Sci. 1997;19(1):166-176. 5. Teo YH, Goddard P, Barrett DA, Melia CD. The microstructure of creams revealed by confocal laser scanning microscopy. J Pharm Pharmacol. 1998; 50(suppl):132. 6. Regola A, Carnesi M, Dolfini A, Gazzaniga A. Use of thermogravimetry in the physicochemical characterization of hydrophilic creams. Boll Chim Farm. 1996; 135(2):67-71. 7. Caldwell KB, Goff HD, Stanley D. A low-temperature scanning electron microscopy study of ice cream: II. Influence of selected ingredients and processes. Food Struct. 1992;11(1):11-23. 8. Holland SJ, Warrack JK. Low-temperature scanning electron microscopy of the phase inversion process in a cream formulation. Int J Pharm. 1990;65(3):225-234. 9. Niemi L, Laine E. Effect of water content on the microstructure of an o/w cream. Int J Pharm. 1991;68(13):205-214. 10. Tiemessen HLGM, Van der Maarel JRC, Bodde HE, Jousma H, Jinginger HE. Probing the microstructure of liquid crystalline surfactant systems: a physicochemical study using the rheometry, DTA and oxygen-17 NMR. Neth J Controlled Release. 1990;13(1):73-81. 11. Radebaugh, GW. Rheological and mechanical properties of dispersed Ssystems. In: Liberman HA,Rieger MM, and Banker GS, eds. Pharmaceutical Dosage Forms: Disperse Systems. 2nd ed. New York, NY: Marcel Dekker; 1996: 153-209.

Figure 4. Drug release profiles of various cream formulations containing different levels fo Avicel CL-611 and commercial cream.

CONCLUSIONS

Microstructure characterization of the Avicel CL611 creams was investigated using rheological, dynamic mechanical viscoelastic measurements and drug release rate, and it revealed a dependence on the excipient level. Measurement of various rheological properties can serve as a good preformulation tool in predicting the performance of semisolids during processing, packaging, storage stability, spreadability during use, and subsequent absorption of the hydrocortisone. Such tests could also be considered for future regulatory guidance deliberations or USP specifications in addition to the current test for drug release.

ACKNOWLEDGMENTS

We are grateful to John Colliopoulos and Dr. Bill Bubnis (formerly with FMC Corporation) for their technical assistance and suggestions. The project was supported financially through a grant awarded to M. C. A. by FMC Corporation, Princeton, NJ. We would like to thank Dr. Peter Whittingstall for

9

AAPS PharmSciTech 2002; 3 (2) article 8 (http://www.aapspharmscitech.org)

12. Jones DS, Woolfson AD, Brown AF. Viscoelastic properties of bioadhesive, chlorhexidine-containing semisolids for topical application to the oropharynx. Pharm Res. 1998;15:1131-1136. 13. Tamburic S, Craig DQ, Vuleta G, Milic J. An investigation into the use of thermorheology and texture analysis in the evaluation of w/o creams stabilized with a silicone emulsifier. Pharm Dev Technol. 1996; 1: 299306. 14. Yu DM, Amidon GL, Weiner ND, Goldberg AH. Viscoelastic properties of Poly(ethylene oxide) solution. J Pharm Sci. 1994; 83: 1443-1449. 15. Gasperlin M, Tusar L, Tusar M, Kristl J, SmidKorbar J. Lipophilic semisolid emulsion systems: viscoelastic behavior and prediction of physical stability by neural network. Int J Pharm. 1998; 168: 243-254. 16. Dolz M, Roldan C. The influence of heating time on the rheological behavior of a microcrystalline cellulose hydrogel. Pharmazie. 1992; 47: 134-136. 17. Avicel RC/CL Microcrystalline Cellulose and Carboxymethylcellulose Sodium, NF. Bulletin RC-16, FMC Corporation. 1988: 3. 18. Villivalam VD, Rege PR, Collins CC. Development in release testing of topical dosage forms: use of the Enhancer CellTM with automated sampling. J Pharm Biomed Anal. 1998; 17: 1225-1233. 19. Henderson NL, Meer PM, Kostenbauder HB. Approximate rates of shear encountered in some pharmaceutical processes. J Pharm Sci. 1961; 50: 788791. 20. Rohn CL. The rheology of coatings and dispersions. J. Water-borne Coatings. 1987:10(3): 9, 12-17. 21. Lippacher A, Muller RH, Mader K. Investigation on the viscoelastic properties of lipid -based colloidal drug carriers. Int J Pharm. 2000; 196: 227-230. 22. Ulbrich R. Rheology of liquids and viscoelastic characterization of semisolids, TA Instruments. Paper presented at: Duquesne University Pharmaceutical Seminar Series: Pharmaceutical Unit Processes and Liquid Dosage Form Development: Industry and Regulatory Perspectives: May 22-25, 2000; Pittsburgh, PA.

10

Potrebbero piacerti anche

- Emulsion-based Systems for Delivery of Food Active Compounds: Formation, Application, Health and SafetyDa EverandEmulsion-based Systems for Delivery of Food Active Compounds: Formation, Application, Health and SafetyShahin RoohinejadNessuna valutazione finora

- Advances in Physicochemical Properties of Biopolymers: Part 2Da EverandAdvances in Physicochemical Properties of Biopolymers: Part 2Nessuna valutazione finora

- Car BomerDocumento8 pagineCar BomerEr RicitosNessuna valutazione finora

- Controlling The Emulsion Stability of Cosmetics Through Shear Mixing ProcessDocumento7 pagineControlling The Emulsion Stability of Cosmetics Through Shear Mixing ProcessPark JiminNessuna valutazione finora

- Stability Testing of Beclomethasone Dipropionate NanoemulsionDocumento7 pagineStability Testing of Beclomethasone Dipropionate NanoemulsionEdgar Pardo SotoNessuna valutazione finora

- Jurnal Mikroemulsi PDFDocumento8 pagineJurnal Mikroemulsi PDFRiee Naxx RekaccNessuna valutazione finora

- Dissolution Testing of Bilayer TabletsDocumento10 pagineDissolution Testing of Bilayer TabletsAmjad KhanNessuna valutazione finora

- In Uence of Disperse Phase Characteristics On Stability, Physical and Antimicrobial Properties of Emulsions Containing CinnamaldehydeDocumento10 pagineIn Uence of Disperse Phase Characteristics On Stability, Physical and Antimicrobial Properties of Emulsions Containing CinnamaldehydeJONATHAN ALEJANDRO CORTES BALLENNessuna valutazione finora

- Djordjevic 2004Documento9 pagineDjordjevic 2004Rizza AmbarNessuna valutazione finora

- Development and Evaluation of Nanoemulsion of RepaglinideDocumento8 pagineDevelopment and Evaluation of Nanoemulsion of Repaglinidevikrantkadam12Nessuna valutazione finora

- JBiomaterAppl 2016 Hu 1080 91Documento12 pagineJBiomaterAppl 2016 Hu 1080 91Mheliendha Cyank Z'muanyaNessuna valutazione finora

- Venlafaxine-Loaded Sustained-Release Poly (Hydroxyethyl Methacrylate-Co-Itaconic Acid) Hydrogel Composites: Their Synthesis and in Vitro/in Vivo AttributesDocumento8 pagineVenlafaxine-Loaded Sustained-Release Poly (Hydroxyethyl Methacrylate-Co-Itaconic Acid) Hydrogel Composites: Their Synthesis and in Vitro/in Vivo AttributesshamsNessuna valutazione finora

- GlibenclamideDocumento13 pagineGlibenclamiderotuaserevinaNessuna valutazione finora

- Evaluation For Collagen Products For Cosmetic ApplicationDocumento15 pagineEvaluation For Collagen Products For Cosmetic ApplicationDumy DumiterrNessuna valutazione finora

- Formulation and Evaluation of Multiple Emulation of Diclofenac SodiumDocumento7 pagineFormulation and Evaluation of Multiple Emulation of Diclofenac SodiumIJRASETPublicationsNessuna valutazione finora

- Research Articel (ESC)Documento8 pagineResearch Articel (ESC)artaNessuna valutazione finora

- Materials Science and Engineering CDocumento6 pagineMaterials Science and Engineering CAndreea TudorascuNessuna valutazione finora

- A Validated Stability Indicating Method For The Estimation of Diclofenac Acid in Bulk and Dosage Forms Using Lc-PdaDocumento14 pagineA Validated Stability Indicating Method For The Estimation of Diclofenac Acid in Bulk and Dosage Forms Using Lc-PdaSaravanan RamNessuna valutazione finora

- 581-Article Text-1044-1-10-20190102Documento6 pagine581-Article Text-1044-1-10-20190102John BansahNessuna valutazione finora

- Co Che Phan Ung Ester Hoa DmapDocumento16 pagineCo Che Phan Ung Ester Hoa DmapLinh TrươngNessuna valutazione finora

- Intralesional MicroemulsionDocumento24 pagineIntralesional MicroemulsionanilNessuna valutazione finora

- Ketoconazole LiposomesDocumento8 pagineKetoconazole LiposomesRohit SharmaNessuna valutazione finora

- Stability Evaluation of Celecoxib Nanoemulsion Containing Tween 80Documento6 pagineStability Evaluation of Celecoxib Nanoemulsion Containing Tween 80fikriNessuna valutazione finora

- Rheology Filler JurnalDocumento6 pagineRheology Filler JurnalRobertoNessuna valutazione finora

- 1 s2.0 0168365995001034 MainDocumento9 pagine1 s2.0 0168365995001034 MainfauziaNessuna valutazione finora

- Jurnal Jelly EngDocumento10 pagineJurnal Jelly EngSabilatun NajahNessuna valutazione finora

- Gao 1996Documento9 pagineGao 1996Chương PhanNessuna valutazione finora

- Spray Dryer-EncapsulationDocumento6 pagineSpray Dryer-EncapsulationhhkkllNessuna valutazione finora

- Development of Sucrose Stearate-Based Nanoemulsions and Optimisation ThroughDocumento10 pagineDevelopment of Sucrose Stearate-Based Nanoemulsions and Optimisation ThroughVenu Gopal NNessuna valutazione finora

- The Rheology of Pharmaceutical and Cosmetic SemisolidsDocumento3 pagineThe Rheology of Pharmaceutical and Cosmetic SemisolidsOzana VladNessuna valutazione finora

- Visco Did AdDocumento10 pagineVisco Did AdDiego Andres ChavarroNessuna valutazione finora

- Development of Curcumin Based Ophthalmic FormulationDocumento9 pagineDevelopment of Curcumin Based Ophthalmic FormulationBagus Prasetya WirawanNessuna valutazione finora

- Research Article: Received: 23 July 2016, Revised and Accepted: 30 September 2016Documento7 pagineResearch Article: Received: 23 July 2016, Revised and Accepted: 30 September 2016AndreyNessuna valutazione finora

- Formulation and Evaluation of Controlled Release Ocular Inserts of Betaxolol HydrochlorideDocumento5 pagineFormulation and Evaluation of Controlled Release Ocular Inserts of Betaxolol HydrochlorideIOSR Journal of PharmacyNessuna valutazione finora

- Spectrophotometric Method Development and ValidatiDocumento7 pagineSpectrophotometric Method Development and ValidatiEVELYN SOLANHS ACERO RODRIGUEZNessuna valutazione finora

- Development and Validation of An UHPLC Method For The DeterminationDocumento8 pagineDevelopment and Validation of An UHPLC Method For The Determinationferonica brillianNessuna valutazione finora

- Investigation of The Direct CompressionDocumento7 pagineInvestigation of The Direct CompressionCamila C.ANessuna valutazione finora

- Myristyl Nicotinate 2007 J.jpba.2006.09.007Documento7 pagineMyristyl Nicotinate 2007 J.jpba.2006.09.007Vita BūdvytėNessuna valutazione finora

- Component Screening of Miconazole Nitrate Nanoemulsion: Research ArticleDocumento8 pagineComponent Screening of Miconazole Nitrate Nanoemulsion: Research ArticleSiddhant YadavNessuna valutazione finora

- Preparation and Characterization of Melittin-Loaded Poly (Dl-Lactic Acid) or Poly (Dl-Lactic-Co-Glycolic Acid) Microspheres Made by The Double Emulsion MethodDocumento10 paginePreparation and Characterization of Melittin-Loaded Poly (Dl-Lactic Acid) or Poly (Dl-Lactic-Co-Glycolic Acid) Microspheres Made by The Double Emulsion MethoddetesNessuna valutazione finora

- Sari Et Al., 2024Documento14 pagineSari Et Al., 2024lucas.saldanha.da.rosaNessuna valutazione finora

- Formulation and Evaluation of Microemulsion Based Gel of KetoconazoleDocumento19 pagineFormulation and Evaluation of Microemulsion Based Gel of KetoconazoleAndre HopfnerNessuna valutazione finora

- Etoposide JurnalDocumento6 pagineEtoposide JurnalShalie VhiantyNessuna valutazione finora

- Nadifloxacin - HPTLC Stability Indicating PDFDocumento8 pagineNadifloxacin - HPTLC Stability Indicating PDFNájla KassabNessuna valutazione finora

- Pharmaceutics 10 00275Documento17 paginePharmaceutics 10 00275Thúy AnNessuna valutazione finora

- Development and Validation of Stability Indicating RPHPLC Method For The Determination of Axitinib in Bulk and Its PharmDocumento10 pagineDevelopment and Validation of Stability Indicating RPHPLC Method For The Determination of Axitinib in Bulk and Its PharmAllNessuna valutazione finora

- Acyclovir CreamDocumento6 pagineAcyclovir CreamMuqeet KazmiNessuna valutazione finora

- Preparation and Evaluation of Wound Healing Activity of Ursolic Acid Nanoemulgel Formulations in RatsDocumento11 paginePreparation and Evaluation of Wound Healing Activity of Ursolic Acid Nanoemulgel Formulations in RatsRAPPORTS DE PHARMACIENessuna valutazione finora

- The Application of The Accelerated Stability Assessment Program (ASAP)Documento6 pagineThe Application of The Accelerated Stability Assessment Program (ASAP)Martin CelestinoNessuna valutazione finora

- Double EmulsionDocumento11 pagineDouble EmulsionAashish GawriNessuna valutazione finora

- CosolvancyDocumento6 pagineCosolvancyyashpandya01Nessuna valutazione finora

- 5 Vol. 5 Issue 11 Nov 2018 IJP RA 430Documento9 pagine5 Vol. 5 Issue 11 Nov 2018 IJP RA 430Saba GheniNessuna valutazione finora

- Heidarifard 2021. Preparation of Nano Emulsion Based Hydrogels Conjugated Curcumin As ModelDocumento13 pagineHeidarifard 2021. Preparation of Nano Emulsion Based Hydrogels Conjugated Curcumin As ModelSantiago Rivera AlbaNessuna valutazione finora

- Microemulsion Binder 2 PDFDocumento320 pagineMicroemulsion Binder 2 PDFKhánh ToànNessuna valutazione finora

- 788 PDFDocumento5 pagine788 PDFSurendar KesavanNessuna valutazione finora

- Development and Validation of Stability Indicating Assay Method For Simultaneous Estimation of Amoxicillin Trihydrate and Cloxacillin Sodium in Pharmaceutical Dosage Form by Using RP-HPLCDocumento13 pagineDevelopment and Validation of Stability Indicating Assay Method For Simultaneous Estimation of Amoxicillin Trihydrate and Cloxacillin Sodium in Pharmaceutical Dosage Form by Using RP-HPLCJermy ErmiNessuna valutazione finora

- Franz Diffusion Cell Approach For Pre-Formulation Characterisation of Ketoprofen Semi-Solid Dosage FormsDocumento8 pagineFranz Diffusion Cell Approach For Pre-Formulation Characterisation of Ketoprofen Semi-Solid Dosage FormsHEMANessuna valutazione finora

- Black Soldier Fly Products: Generic Description and Analysis of the Production Process for Chitosan, Proteins and Lipid from Black Soldier Fly Larvae.Da EverandBlack Soldier Fly Products: Generic Description and Analysis of the Production Process for Chitosan, Proteins and Lipid from Black Soldier Fly Larvae.Valutazione: 4 su 5 stelle4/5 (1)

- Attrition in the Pharmaceutical Industry: Reasons, Implications, and Pathways ForwardDa EverandAttrition in the Pharmaceutical Industry: Reasons, Implications, and Pathways ForwardNessuna valutazione finora

- UntitledDocumento1 paginaUntitledarevicNessuna valutazione finora

- UntitledDocumento1 paginaUntitledarevicNessuna valutazione finora

- UntitledDocumento2 pagineUntitledarevicNessuna valutazione finora

- Althaea OfficinalisDocumento8 pagineAlthaea OfficinalisarevicNessuna valutazione finora

- 4/2 and 4/3 Directional Control Valve, Manually Operated: Size 04 (D 02) Q 30 L/min (8 GPM) P 320 Bar (4600 PSI)Documento2 pagine4/2 and 4/3 Directional Control Valve, Manually Operated: Size 04 (D 02) Q 30 L/min (8 GPM) P 320 Bar (4600 PSI)Vito LaudicinaNessuna valutazione finora

- Unit 3 Design of Keys Forces Acting On A Sunk KeyDocumento2 pagineUnit 3 Design of Keys Forces Acting On A Sunk KeyJayadev E100% (1)

- Project: 1x950 TDS/Day Soda Recovery Boiler Customer: ITC LTD., - PSPD Enmas Engenius Projects LimitedDocumento2 pagineProject: 1x950 TDS/Day Soda Recovery Boiler Customer: ITC LTD., - PSPD Enmas Engenius Projects LimitedV U P RaoNessuna valutazione finora

- Lysaght Trimdek-Optima 2021Documento12 pagineLysaght Trimdek-Optima 2021Fahmi YusoffNessuna valutazione finora

- Catalouge For Lenton CouplersDocumento18 pagineCatalouge For Lenton Couplerss.skumar1Nessuna valutazione finora

- Ce Great Minds PrebDocumento5 pagineCe Great Minds PrebSharaGailFuscabloNessuna valutazione finora

- Precedent Reliatel WiringDocumento64 paginePrecedent Reliatel WiringMihai IavorschiNessuna valutazione finora

- Technical Materials Ii. Metals: Ferrous Metals - Iron AlloysDocumento4 pagineTechnical Materials Ii. Metals: Ferrous Metals - Iron AlloysAlexis Vicente SandulacheNessuna valutazione finora

- 1c6g5spkr 259575Documento1 pagina1c6g5spkr 259575vladimirNessuna valutazione finora

- Interview Questions 1 TCSDocumento3 pagineInterview Questions 1 TCSSrinivas TumpalaNessuna valutazione finora

- Technical Data Sheet: Cable ConstructionDocumento1 paginaTechnical Data Sheet: Cable ConstructionYehude Guillen RomeroNessuna valutazione finora

- SUP032BR: Esp. E74104 Rev.01Documento5 pagineSUP032BR: Esp. E74104 Rev.01kimanski01Nessuna valutazione finora

- Cost Configuration: Total Haulage Cost/quantityDocumento11 pagineCost Configuration: Total Haulage Cost/quantityObinna ObiefuleNessuna valutazione finora

- Dear Ashok PathakDocumento60 pagineDear Ashok Pathakcpmishra2010Nessuna valutazione finora

- M Tech I Sem II Mid TDDocumento4 pagineM Tech I Sem II Mid TDMir Mustafa AliNessuna valutazione finora

- Asco - Jkh8551g401mmsDocumento4 pagineAsco - Jkh8551g401mmsBiến tần MICNONessuna valutazione finora

- F1 Flow Measurement in Closed ConduitDocumento5 pagineF1 Flow Measurement in Closed ConduitSzeQiLungNessuna valutazione finora

- What Is A Slab? 2. Two Types of SlabDocumento18 pagineWhat Is A Slab? 2. Two Types of SlabCian ChanNessuna valutazione finora

- BS 00437-2008Documento18 pagineBS 00437-2008Rachid TidjaniNessuna valutazione finora

- PL - 400-Hydrant LT Atap - Denah AtapDocumento2 paginePL - 400-Hydrant LT Atap - Denah AtapMuh SanadNessuna valutazione finora

- Roofing SafetyDocumento38 pagineRoofing SafetyDhârâñî KûmârNessuna valutazione finora

- Jet Pump Technical DataDocumento11 pagineJet Pump Technical DataIdelia Cutipa Yauri100% (1)

- Adani House, NR Mithakhali Circle, Navrangpura, Ahmedabad 380 009, Gujarat, IndiaDocumento34 pagineAdani House, NR Mithakhali Circle, Navrangpura, Ahmedabad 380 009, Gujarat, IndiaphanikrishnabNessuna valutazione finora

- ACS Heat - Loss - Calculator Dryer 3050D X 21000L Thermal Analysis ReportDocumento7 pagineACS Heat - Loss - Calculator Dryer 3050D X 21000L Thermal Analysis Reportdwi sutiknoNessuna valutazione finora

- Lifting Lug Design B 01Documento22 pagineLifting Lug Design B 01bakellyNessuna valutazione finora

- Sum FHT MD-SLDDocumento5 pagineSum FHT MD-SLDNebula RockbandNessuna valutazione finora

- ASTM C795 Insulation Material For Austenistic SteelDocumento3 pagineASTM C795 Insulation Material For Austenistic SteelAbass100% (1)

- Material Design of Aerated Concrete-An Optimum Performance DesignDocumento6 pagineMaterial Design of Aerated Concrete-An Optimum Performance DesignYuliusRiefAlkhalyNessuna valutazione finora

- Saes TABLEDocumento13 pagineSaes TABLERiyaz BasheerNessuna valutazione finora

- Acc PSC - NFR - 38 - 2020Documento1 paginaAcc PSC - NFR - 38 - 2020kartick adhikaryNessuna valutazione finora