Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

2 CB50 D 01

Caricato da

Pichai ChaibamrungDescrizione originale:

Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

2 CB50 D 01

Caricato da

Pichai ChaibamrungCopyright:

Formati disponibili

Energy 28 (2003) 575589 www.elsevier.

com/locate/energy

Evaluation of the 200 MWe Tonghae CFB boiler performance with cyclone modication

Jong-Min Lee , Jae-Sung Kim, Jong-Jin Kim

Advanced Power Generation & Combustion Group, Power Generation Laboratory, Korea Electric Power Research Institute, Korea Electric Power Corporation, 103-16 Munji-dong, Yusung-gu, TaeJon 305-380, South Korea Received 21 February 2001

Abstract The performance of the Tonghae CFB boiler with modication of the cyclone has been evaluated using the IEA-CFBC model. The effect of the cyclone efciency on solid hold-up and pressure and temperature proles in the combustor has been determined. From the calculated results, solid hold up in the lean phase of the combustor and pressure in the combustor increase, whereas solid hold-up in the dense phase and temperature in the combustor decrease as the cyclone efciency increases. After modication of the cyclone through extension of the vortex nder and reduction of the width of the cyclone inlet duct, Pupper part and Plower part in the combustor increase from 1328 to 1942 Pa and from 4402 to 4950 Pa, respectively. The temperature and the emission of SO2 of the combustor decrease after modication of the cyclone. Therefore, modication of the cyclone to improve its efciency can allow operation and control of the Tonghae CFB boiler to be stable. The simulation results by the IEA-CFBC model can also explain well the improved performance of the CFB boiler. 2003 Elsevier Science Ltd. All rights reserved.

1. Introduction The design engineering and construction project of the Tonghae thermal power plant CFB boiler (2 units), located in Tonghae, Korea, was begun by the Korea Electric Power Corporation (KEPCO) in early 1993. Combustion Engineering Inc. (ABB-CE) has designed a 200 MWe CFB, ring Korean anthracite fuel [1]. In this project, KOPEC (Korea Power Engineering Company) served as the project architectural engineering rm and is responsible for various other plant

Corresponding author. Tel.: +82-42-865-5362; fax: +82-42-865-5374. E-mail address: jmlee@kepri.re.kr (J.M. Lee).

0360-5442/03/$ - see front matter 2003 Elsevier Science Ltd. All rights reserved. doi:10.1016/S0360-5442(02)00155-X

576

J.-M. Lee et al. / Energy 28 (2003) 575589

system designs and equipment procurement. Additionally, HANJUNG, which is one of the heavy industry companies in Korea, is responsible for the boiler equipment fabrication and procurement. The Tonghae thermal power plant, ring domestic anthracite, is different from recent Korean power plants. It was selected over the conventional pulverized coal boiler because of its improved efciency of burning low-quality fuels and its improved emissions capability. The two 200 MWe units of the Tonghae thermal power plant had been designed in such a manner that they could operate more efciently and meet the Korean environmental standards without external environmental control systems. Also, they would not need to re supplemental fuel oil during normal operation, though all pulverized coal boilers in Korea should use fuel oil to burn Korean anthracite. The CFB unit 1 and unit 2 have been operated commercially since October 1998 and October 1999, respectively. The initial operation period of unit 1, in 1998, clearly demonstrated that full load operation was successful [2]. However, there was apparently some room for optimization, particularly regarding the temperatures of the furnace and cyclones/sealpots and the emission of SOx that were somewhat higher than expected. It was difcult to maintain stable operation due to the formation of clinker for high temperatures in the cyclones/sealpots. Therefore, modication of the cyclone to improve its efciency was accomplished through extension of the vortex nder and reduction of the width of the cyclone inlet duct. This modication improved the performance by lowering the temperature and SOx emissions through an increase in the solid circulation rate. This paper gives a description of the status of the Tonghae CFB boiler after cyclone modication with the simulation results by the IEA-CFBC model in which the effect of cyclone efciency on the performance of the CFB has been determined.

2. IEA-CFBC model Many models of the CFBC have been developed since the early 1990s, based on the comprehensive bubbling uidized bed combustion model. In the CFBC modeling approaches, there are different types of model, which can be distinguished as the global model, the one-dimensional model (only gradients in vertical direction were considered), the 1.5-dimensional model (a lateral distinction between core and annulus was considered) and the multi-dimensional model (computational uid dynamics). The multi-dimensional model, which is in progress, is still far from mature because access to sufcient computational power, adequate for solution of the model, is limiting the use of CFD codes [3,4]. However, much work has been done, and some results have been applied to industrial CFB plants by modeling the CFBC with the one- and 1.5-dimensional models [5,6]. Of these models, the IEA-CFBC model, developed by the mathematical modeling group in the IEA (International Energy Agency), offers a good approach for comprehensive and suitable modeling. Also, it has been applied to several industrial CFB plants and has shown good accuracy for prediction of the performance of CFB plants [7,8]. The IEA-CFBC model consists of several elds of mechanical, chemical and thermal processes, which are dependent on each other during the CFBC processes. The overview of the processes of this model was well presented in previous studies [7,9].

J.-M. Lee et al. / Energy 28 (2003) 575589

577

3. Tonghae CFB boiler features 3.1. CFB boiler features The Tonghae CFB combustor is shown in Fig. 1(a). It consists of parts of feeding coal and limestone, primary air (PA), secondary air (SA) and uidizing air (FA) suppliers, the main combustion part (furnace, cyclones, sealpots), a FBHE (external Fluidized Bed Heat Exchanger), a FBAC (Fluidized Bed Ash Cooler) and backpass. The combustor (19 m (W)7 m (L)32 m (H)) has a rectangular footprint and is signicantly wider than it is deep, incorporating an aspect ratio of more than 2:1. The lower section (to about 7 m from the distributor) of the combustor is tapered and is covered with an erosion resistant plastic refractory material. As all the fuel feed points are along the combustor front wall, the rectangular geometry was chosen to allow for good fuel mixing. Fuel is introduced into the combustor at six locations along the front wall. Limestone is injected with the fuel in two injection ports along the rear wall. PA is introduced to the combustor via the uidizing air grate. The grate is comprised of T-style uidizing nozzles patented by ABB-CE. The T-style uidizing nozzles include relatively large openings to reduce the potential of plugging associated with many nozzle designs while maintaining a pressure drop to preclude backsifting. The T-style uidizing nozzles are employed in the uid bed heat exchangers as well as in the sealpots. SA is introduced at the lower combustor along the front and rear walls and into the four start-up burners. Bottom ash is removed from the bottom of the combustor via two ash control valves (ACV) and is introduced into a FBAC, which contains an economizer and cooling water heat transfer surface. Heated uidizing air is returned from the FBAC vents into the combustor at four locations along the front wall. Three refractory lined steel plate cyclones are tted to receive the ue gas and solids mixture from the combustor. The cyclone dimensions before and after modication are shown in Fig. 1(b). The sealpots serve to create a pressure seal from the positive pressure in the combustor to the negative pressure in the cyclone. This pressure seal prevents the ow of material back up the cyclone from the bottom of the combustor. The sealpot is a compact, low-velocity multi-chamber uidization grate. In the Tonghae CFB unit, the boiler turndown requirement, coupled with the difcult to burn anthracite fuel, resulted in FBHEs. At each of the three sealpots, a stream of the solid materials is diverted and introduced into a FBHE. The FBHEs are bubbling beds, containing natural circulation evaporative, superheat and reheat heat transfer surfaces. As the solids from the sealpots ow over and through the FBHE heat transfer surfaces, the ash is cooled and then returned to the combustor. 3.2. Properties of coal and limestone Korean anthracite contains 39% ash, 4% VM (volatile matter), 53.7% FC (xed carbon) and 3.3% moisture. The coal contains low S (0.6%) and N (0.2%) and has a relatively low heating value (4600 kcal/kg). The fraction of coal in the size range of 0.16 mm is over 95% on the design basis. Limestone contains 90% CaCO3 and 4.2% MgCO3, and all particles are smaller than 1.0 mm ( 0.7 mm95%, 0.5 mm90%). The proximate and ultimate analyses and the particle size distribution of the coal and the limestone are shown in Tables 1 and 2, respectively.

578

J.-M. Lee et al. / Energy 28 (2003) 575589

Fig. 1. (a) Schematic of the Tonghae CFB boiler and (b) dimensions of the cyclone.

3.3. Operating conditions and modeling of the CFB boiler The operation conditions with the variations of load are shown in Table 3. The ratio of primary air to secondary air supplied to the CFB combustor is from 0.62 to 0.73. Coal ow rate changes

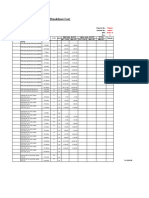

J.-M. Lee et al. / Energy 28 (2003) 575589 Table 1 Analyses of coal used in the Tonghae CFB boiler Proximate analysis wt.% Ultimate analysis C H O N S Ash wt% (dry basis) 54.7 0.3 3.8 0.2 0.6 40.4

579

Moisture Volatile matters Fixed carbon Ash Heating value (dry basis)

3.3 4.0 53.7 39.0 4600 (kcal/kg)

Table 2 Particle size distribution of the coal and the limestone Range (mm) 5.6 4.755.6 2.84.75 22.8 1.02.0 0.61.0 0.250.6 0.10.25 0.0750.1 0.075 Coal (wt%) 0 1.0 2.0 16.0 31.0 16.0 17.0 10.0 2.0 5.0 Limestone (wt%) 0 0 0 0 1 16 41 17 15 10

Table 3 Operation conditions with different load #a Combustor height (m) Additional air ow rate (m3/s) 100% load 1 2 3 4 5 6 7 8 9

a

75% load 76.3 4.4 0.93 9.14 14.54 9.9 0 20.7 0.63

50% load 65.58 4.4 0.93 9.14 14.54 9.9 0 14.5 0.44

30% load 68.34 4.4 0.93 7.34 14.54 9.9 0 7.9 0.38

0.0 0.43 1.37 1.70 2.44 4.48 28.53 (32.9) Coal (kg/s) Lime (kg/s)

87.22 10.26 0.93 9.14 18.94 23.09 0 27.3 0.83

Air inlet position: 1, PA; 2, SA (four-injector); 3, feeder (coal and limestone) transport air; 4, sealpot+FBHE return air; 5, SA(three-injector); 6, SA (nine-injector); 7, exit (top of combustor); 8, 9, coal and limestone feed rate.

580

J.-M. Lee et al. / Energy 28 (2003) 575589

from 7.9 to 27.3 kg/s and the ratio of limestone to coal ow rate is from 0.03 to 0.046 with the variations of load. To compare the calculation data with the measured data for the CFB boiler, temperature and pressure proles, particle size distribution, ue gases concentration and the amount of y and bottom ash were measured during the operation of the CFB boiler. Pressure along the combustor was measured at 0.9, 5.2 and 28.5 m above the distributor. Total pressure, including pressure drop of the distributor, was also measured by a pressure transmitter installed at the windbox. Temperature measuring points along the combustor were selected at 0.75 and 5.65 m from the distributor and at the three cyclone inlet ducts. In each point in the combustor, six different horizontal temperatures were measured. Measurement of particle size distribution was achieved by sampling from the backpass and electric precipitator (lter ash), FBHE (recirculating particles) and FBAC (overow particles). However, since the Tonghae CFB boiler is a commercial one for the generation of electricity, the measurements were restricted to its operation point. In order to measure the reliable data from the CFB boiler, all measurements were taken for 6 months and the average data values were used in this study. The sequence of calculation in the model study is as follows [7,9,10]: 1. After initialization of the riser geometry, the gas and solid properties and the uid dynamic fundamentals are calculated. The input values are based on Tables 13. Other important values used in this model are shown in Table 4. 2. A preliminary balance of fuel and air is performed. 3. After initial pre-balancing of an average size distribution function for estimation of the circulation rate, cyclone load and dense bed height, the real particle size distribution is balanced for each material such as coal, char and limestone. 4. Reactions such as dry, devolatilization, combustion and sulphur capture are linked to the particle phase and catalytic particle surfaces, where oxygen consumption and release of combustion products are also calculated and further reactions of the gas products are calculated in the gas phase. 5. The balances of solid and gas species concentration are solved independently, and both mass balances are adjusted in an iteration loop. 6. The energy released by the reactions with the heat ow and the heat transfer is balanced to

Table 4 Input data for the Tonghae CFB boiler modeled Parameters Density (kg/m3) Sphericity [12] Heat capacity (J/kg K) Attrition constant [13] (1/m) Fragmentation constant [14] Pre-exponential factor [15] (kg/m2 s Pa) Activation energy, E/R [15] (K) Sulphation constant [16] (m/s) Decay constant [17], au (1/s) Coal 2200 0.71 840 1.010 1.0 5.5 Char 1710 0.71 600 2.810 1.0 0.79 19,000 5.5 Limestone 2600 0.71 840 1.010 1.0 0.15 5.5

J.-M. Lee et al. / Energy 28 (2003) 575589

581

yield the temperature prole in the riser. The feedback of the temperature to the reaction rate is considered in an iteration loop. 7. Pollutants are calculated in a post process, to avoid solution of all kinetic equations inside the iteration loops. 4. Results and discussion 4.1. Variation of the CFB performance with cyclone modication The effects of the cyclone efciency and cyclone modication on the performance of the Tonghae CFB were determined by using the IEA-CFBC model. The overall separation efciency of the cyclone is dened as the summation of the entrance efciency and single particle efciency [7]. The saturation carrying capacity, which is related to the entrance efciency, can be adjusted by changing the cyclone entrance efciency coefcient and acceleration coefcient in the model. The predicted results of the axial solid hold up and the pressure prole in the combustor with variation of the cyclone efciency are shown in Fig. 2(a) and (b), respectively. The solid hold up in the dense phase gradually decreased (0.1870.059) with increasing cyclone efciency, whereas it increased (0.0050.014) in the lean phase. The dense bed height also increased. This is because the fraction of ne particles, which can be captured by the cyclone and circulated, increases in the total bed material. As depicted in Fig. 2(b), this solid hold up variation affected the pressure prole. The differential pressure, as well as temperature, in the CFB combustor, which can be obtained as practical operation data, is important to analyze and control the operating condition. During the operation of the CFB combustor, Pupper part ( Pupper part P2 P1) regarded as the basis of completion of solid circulation, was 1328 Pa (standard deviation, SD 156.5, standard error, SE 24.4) and Plower part ( Plower part P3 P1) was 4402 Pa (SD 326.5, SE 50.9) at 100% load before modication. So, the cyclone efciency can be considered as about 98.7% from these data, which could also be determined from the data of temperature proles, y/bottom ash ratios and particle size distributions. The differential pressures in the dense phase and lean phase showed the same tendency of solid hold up variation. The calculated temperature in the dense phase, as shown in Fig. 3, was almost the same variation with cyclone efciency, whereas the temperature decreased gradually in the lean phase. The temperature of the annular wall layer was lower than that of the core region and also decreased with increasing cyclone efciency because the particles were in contact with the membrane walls and ow down into the dense phase. The cyclone inlet temperature (symbol) was measured somewhat higher because of the low solid circulation rate and low combustion reactivity of the Korean anthracite. From this, an improvement of cyclone efciency is expected to allow the temperature, especially in the cyclone and sealpots, to be lower. The calculated particle size distribution in the overow, bed content, recirculation and bag lter appeared to include more ne particles with increasing cyclone efciency. The calculated results appeared to be tted well by the samples taken from the boiler. The cyclone efciency, which did not show a signicant difference at 98.7%, could also be estimated by comparing the calculated and sampled data. The calculated discharge rate of bottom ash increased, whereas that of y ash from the bag lter (backpass and electric precipitator) decreased with increasing cyclone

582

J.-M. Lee et al. / Energy 28 (2003) 575589

Fig. 2.

Axial solid hold up (a) and pressure (b) proles with variation of cyclone efciency.

efciency. The calculated ratio of bottom to y ash was about 4:6 at 98.7% cyclone efciency, and this value showed reasonable agreement with the measured values, which are about 410 tonbottom ash/day and 630 ton-y ash/day, from the boiler before cyclone modication. As the cyclone efciency increased, the model calculations predicted higher emissions of CO,

J.-M. Lee et al. / Energy 28 (2003) 575589

583

Fig. 3. Axial temperature prole with cyclone efciency in the combustor (line: calculated value, symbol: measured value).

O2 and NOx and lower emissions of CO2 and SO2. The higher emission of CO may be caused by the increase in the circulated ne particles, including unburned carbon, as reported previously [10]. The lower SO2 emission was because of the increase in circulated limestone particles and the decrease in the freeboard temperature with increasing cyclone efciency. In addition, the calculated SO2 emission with increasing Ca/S mole ratio (1.53.0) changed from 300 to 150 ppm at a cyclone efciency of 98.7%. These values corresponded to the measured SO2 emissions. In the model calculation, the increase in Ca/S mole ratio appeared to be limited in reducing the SO2 emission, so it was necessary to improve the cyclone efciency to enhance the SO2 capture efciency. The effects of modication of the cyclone on the performance of the CFB boiler are shown in Fig. 4(a) and (b). With increasing the length of the vortex nder, the cyclone separation diameter and the discharge rate of the y ash decreased, and the solid circulation rate increased, as shown in Fig. 4(a). The predicted results showed a performance improvement of about 1020% as the length of the vortex nder was increased by 1 m. With reducing the cyclone inlet duct through decreasing its width, the model results had the same tendency, but the improvement in performance was not appreciable, as shown in Fig. 4(b). Therefore, modication of the cyclone through extension of the vortex nder was more effective. The model calculation for modication of the cyclone also predicted lower temperature and lower SO2 emissions in the combustor and showed signicant effects. Consequently, the variation of cyclone efciency had a great inuence on the performance of the CFB boiler. To achieve stable operation and control of the CFB, it was necessary to modify the cyclone geometry as well as optimize the units.

584

J.-M. Lee et al. / Energy 28 (2003) 575589

Fig. 4. Effects of the modication of the cyclone on the performance of the CFB boiler (a) with modication of the vortex nder and (b) with modication of the inlet duct.

4.2. Improved CFB performance after cyclone modication After modication of the cyclone, which was made through increasing the length of the vortex nder about 0.9 m and reducing the width of the cyclone inlet duct about 0.2 m, the differential pressure of the upper part, Pupper part, in the combustor was about 1942 Pa (SD 143.4, SE 22.4). It was higher than the unmodied case (1328 Pa). The differential pressure of the lower part also increased from 4402 to 4950 Pa (SD 313.9, SE 49.0). These were the results from the changes of the solid hold up in the combustor due to the increase in cyclone efciency. The calculated results of the axial solid hold up and the pressure proles before and after modication of the cyclones are shown in Fig. 5(a) and (b), respectively. The solid hold up in the dense phase decreased, whereas it increased in the lean phase after modication. These effects are because the fraction of ne particles, which can be captured by the cyclone and circulated, increased in the total bed material. The increases of solid circulation rate and solid hold up in the lean phase can be estimated from the increase in the differential pressure. In the model calcu-

J.-M. Lee et al. / Energy 28 (2003) 575589

585

Fig. 5. Axial solid hold up (a) and pressure proles (b) in the Tonghae CFB combustor before and after modication of the cyclone.

lation for the solid hold up and the pressure proles in the combustor, the predicted results for before and after cyclone modication had good ts. The temperature proles before and after modication are shown in Fig. 6 with the predicted results. The temperature in the combustor, after modication of the cyclone, became lower (866 C with SD 15.2 and SE 1.9) than that before modication (896 C with SD 21.7 and SE 1.4). The cyclone inlet temperature (924 C with SD 12.0 and SE 1.1), as well as the sealpots temperature (943 C with SD 15.6 and SE 1.5), also became lower than before due to the increase in solid circulation rate. Stable operation could be achieved successfully, and the calculations showed good agreement with the operation results. The calculated cumulative size fractions of discharged bottom ash, recycle ash and lter ash (backpass and electric precipitator) and samples (symbols) from the eld after modication are depicted in Fig. 7. The calculated results predicted that more smaller particles (100300 m) were circulated, and the particles in all parts appeared to be smaller after modication of the cyclone. The predicted results also tted relatively well with the samples from the eld. The predicted gas concentrations in the combustor are shown in Fig. 8(a)(c) with operation results (symbols) measured from the stack of the CFB. In the calculated results, the concentration of CO2 increased along the combustor height and increased drastically in the dense region, whereas the O2 concentration showed the reverse tendency as shown in Fig. 8(a). The CO concentration increased rapidly in the lower dense region and then drastically decreased with combustor

586

J.-M. Lee et al. / Energy 28 (2003) 575589

Fig. 6. Comparison of temperature proles before and after modication of the cyclone (line: calculated value, symbol: measured value).

height as shown in Fig. 8(b). From these facts, the combustion reaction was found to be mainly occurring in the dense region and to be kept somewhat in the freeboard region. Also, the calculated concentrations of CO2 and CO at the combustor exit showed increases of 0.9% and 150 ppm, respectively, after cyclone modication, due to the augmentation of ne coal particles in the bed [11]. However, the measured values of these gaseous concentrations at the stack of the CFB boiler did not change appreciably. To reduce SO2 emission, it was found necessary to increase the circulating particles of limestone in the bed material because SO2 was mainly produced in the dense region and was gradually taken up by the entrained limestone particles in the freeboard region as shown in Fig. 8(c). The calculated and measured SO2 emission after modication became lower and the sulfur capture efciency was higher. The reduction in slope of SO2 in the freeboard region also increased due to increasing the circulating particles of limestone. The emission of NOx was very low and did not change appreciably before and after modication of the cyclone because of the relatively low operating temperature in the combustor. Therefore, the modication of the cyclone to improve separation efciency allowed the temperatures of the furnace and cyclones/sealpots and the emissions of SO2 to be lower and gave more stable operation.

J.-M. Lee et al. / Energy 28 (2003) 575589

587

Fig. 7. Comparison of particle size distribution before and after modication of the cyclone (line: calculated value, symbol: measured value).

5. Conclusion During the initial operation period, the Tonghae CFB boiler was demonstrated successfully in spite of some problems, such as a higher temperature prole and higher SO2 emissions than desired. After modication of the cyclone, based on the simulation results, through extension of the vortex nder and reduction of the width of the cyclone inlet duct, Pupper part and Plower part in the combustor increase from 1328 to 1942 Pa and from 4402 to 4950 Pa, respectively. Consequently, the temperature and the emission of SO2 of the combustor decrease after modication of the cyclone, and then stable and improved operation of the Tonghae CFB boiler was achieved. The simulation results by the IEA-CFBC model explain well the performance of the Tonghae CFB combustor with cyclone modication.

588

J.-M. Lee et al. / Energy 28 (2003) 575589

Fig. 8. Gas concentration proles in the CFB combustor before and after modication of the cyclone. (a) CO2, O2 and H2O concentrations, (b) CO concentration and (c) SO2 concentration cyclone (line: calculated value, symbol: measured value).

References

[1] Maitland J, Schaker Y. Design of the 200MWe Tonghae thermal power plant circulating uidized bed steam generator. In: Preto FDS, editor. Proceedings of the 14th International Conference on Fluidized Bed Combustion; Vancouver, Canada. ASME; 1997. p. 1916. [2] Kim JS, Lee JM. Status of the 200MWe Tonghae thermal power plant circulating uidized bed boiler using Korean anthracite coal. In: Proceedings of the 2nd Korea-China Joint Workshop; Taejon, Korea. KIER; 1998. p. 44554. [3] Pritchett JW, Blake TR, Garg SK. A numerical model of gas uidized beds. AIChE Symp. Ser. 1978;74:13448. [4] Boemer A, Qi H, Renz U. Modeling of N2O from four different large scale circulating uidized bed combustors. In: Proceedings of the 29th IEA-FBC meeting; Paris, France. IEA-FBC; 1994. [5] Mori S, Narukawa K, Yamada I, Takebayashi T, Tanii H, Tomoyasu Y, Mii T. Dynamic model of a circulating uidized bed coal red boiler. In: Anthony EJ, editor. Proceedings of the 11th International Conference on Fluidized Bed Combustion; Montreal, Canada. ASME; 1991. p. 12615. [6] Zhang L, Li TD, Zhen QY, Lu CD. A general dynamic model for circulating uidized bed combustion systems with wide particle size distributions. In: Anthony EJ, editor. Proceedings of the 11th International Conference on Fluidized Bed Combustion; Montreal, Canada. ASME; 1991. p. 128994.

J.-M. Lee et al. / Energy 28 (2003) 575589

589

[7] Hannes JP. Mathematical modeling of circulating uidized bed combustion. PhD thesis, Delft University of Technology, The Netherlands; 1996. [8] Lee JM, Kim JS. Simulation of the 200MWe Tonghae thermal power plant circulating uidized bed combustor by using IEA-CFBC model. Korean J. Chem. Eng. 1999;16(5):6405. [9] Hannes JP, Bleek CM, Renz U. The IEA model for circulating uidized bed combustion. In: Heinschel KJ, editor. Proceedings of the 13th International Conference on Fluidized Bed Combustion; Orlando, FL. ASME; 1995. p. 28796. [10] Rhee KS, Lee JM, Kim JS, Kim JJ. Mathematical modeling of Tonghae circulating uidized bed combustor (200MWe). In: Gelling DW, editor. Proceedings of the 16th International Conference on Fluidized Bed Combustor; Reno, NV. ASME; 2001. p. 10515. [11] Cheliand PK. Combustion of fuel with high nes in Ahlstrom Pyroow CFB boiler. Gamble R. In: Heinschel KJ, editor. Proceedings of the 13th International Conference on Fluidized Bed Combustion; Orlando FL. ASME; 1995. p. 53550. [12] Ergun S. Fluid ow through packed beds. Chem. Eng. Prog. 1952;48:8994. [13] Merrick D, Highley J. Particle size reduction and elutriation in a uidized bed process. AIChe Symp. Ser. 1974;70(137):36678. [14] Bellgardt D, Hembach F, Schoessler M, Werther J. Modeling of large scale atmospheric uidized bed combustors. In: Mustoned JP, editor. Proceedings of the 9th International Conference on Fluidized Bed Combustion; Boston, MA. ASME; 1987. p. 71322. [15] Smith IW. The intrinsic reactivity of carbons to oxygen. Fuel 1978;57:40914. [16] Wolff EHP. Regenerative sulfur capture in uidized bed combustion of coal. PhD thesis, Delft University of Technology, The Netherlands; 1991. [17] Kunii D, Levenspiel O. Fluidization engineering, 2nd ed. MA: Butterworth-Heinemann, 1991.

Potrebbero piacerti anche

- Applsci 10 02975 v2Documento12 pagineApplsci 10 02975 v2Pichai ChaibamrungNessuna valutazione finora

- 31381.PDF Emmisions & SoundsDocumento4 pagine31381.PDF Emmisions & SoundsPichai ChaibamrungNessuna valutazione finora

- Acacia EIA - Final Construction EMPDocumento48 pagineAcacia EIA - Final Construction EMPPichai ChaibamrungNessuna valutazione finora

- Regulation of The Minister of Marine and Fisheries of The Republic of IndonesiaDocumento53 pagineRegulation of The Minister of Marine and Fisheries of The Republic of IndonesiaPichai ChaibamrungNessuna valutazione finora

- GE Digital Power Plant BrochureDocumento6 pagineGE Digital Power Plant BrochurePichai ChaibamrungNessuna valutazione finora

- 2014 Tentang Penyelenggaraan Sistem Drainase Perkotaan CompressDocumento18 pagine2014 Tentang Penyelenggaraan Sistem Drainase Perkotaan CompressPichai ChaibamrungNessuna valutazione finora

- Internoise-2015-437 - Paper - PDF Sound Standard Gas TurbineDocumento8 pagineInternoise-2015-437 - Paper - PDF Sound Standard Gas TurbinePichai ChaibamrungNessuna valutazione finora

- Leading Efficiency Lower Emissions Power & Heat in A Coal Rich WorldDocumento27 pagineLeading Efficiency Lower Emissions Power & Heat in A Coal Rich WorldPichai ChaibamrungNessuna valutazione finora

- Mini IR Thermometer: ExperienceDocumento1 paginaMini IR Thermometer: ExperiencePichai ChaibamrungNessuna valutazione finora

- CFB BoilerDocumento2 pagineCFB BoilerPichai ChaibamrungNessuna valutazione finora

- Testo 175 Compact Data Loggers For Temperature, Humidity, Voltage and CurrentDocumento6 pagineTesto 175 Compact Data Loggers For Temperature, Humidity, Voltage and CurrentPichai ChaibamrungNessuna valutazione finora

- Energies: Investigation of Heat Transfer in A Large-Scale External Heat Exchanger With Horizontal Smooth Tube BundleDocumento24 pagineEnergies: Investigation of Heat Transfer in A Large-Scale External Heat Exchanger With Horizontal Smooth Tube BundlePichai ChaibamrungNessuna valutazione finora

- Phase Control For P&IDDocumento1 paginaPhase Control For P&IDPichai ChaibamrungNessuna valutazione finora

- Temperature/humidity Measurement With The Testo 174H Mini Data LoggerDocumento1 paginaTemperature/humidity Measurement With The Testo 174H Mini Data LoggerPichai ChaibamrungNessuna valutazione finora

- OperationDocumento1 paginaOperationPichai ChaibamrungNessuna valutazione finora

- OperationDocumento1 paginaOperationPichai ChaibamrungNessuna valutazione finora

- OperationDocumento1 paginaOperationPichai ChaibamrungNessuna valutazione finora

- OperationDocumento1 paginaOperationPichai ChaibamrungNessuna valutazione finora

- OperationDocumento1 paginaOperationPichai ChaibamrungNessuna valutazione finora

- Investigation of Steam Turbine BladeDocumento25 pagineInvestigation of Steam Turbine BladePichai ChaibamrungNessuna valutazione finora

- Basic Biomass Power Plant EfficiencyDocumento12 pagineBasic Biomass Power Plant EfficiencyPichai ChaibamrungNessuna valutazione finora

- DSDDocumento1 paginaDSDPichai ChaibamrungNessuna valutazione finora

- ปริมาณท่อเหล็กDocumento1 paginaปริมาณท่อเหล็กPichai ChaibamrungNessuna valutazione finora

- Circulating Fluidized Bed Boiler (CFB Boiler) How Does It Work and Its PrincipleDocumento24 pagineCirculating Fluidized Bed Boiler (CFB Boiler) How Does It Work and Its PrinciplePichai Chaibamrung100% (2)

- Boiler Feed PumpDocumento69 pagineBoiler Feed PumpPichai Chaibamrung100% (1)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (400)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (73)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (344)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (121)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- Compressors and Silent Root Causes For FailureDocumento7 pagineCompressors and Silent Root Causes For Failurenaveenbaskaran1989Nessuna valutazione finora

- MCQ 12345Documento77 pagineMCQ 12345Manish MahadevwalaNessuna valutazione finora

- Bucket Elevator Load CalculationsDocumento26 pagineBucket Elevator Load CalculationskingNessuna valutazione finora

- Unit Six (Lec-1)Documento39 pagineUnit Six (Lec-1)WALLELGNNessuna valutazione finora

- Effects of Helical Fins With Semi-Circular in Cross-Section On The Performance Characteristics of Novel Finned-Cyclone SeparatorsDocumento12 pagineEffects of Helical Fins With Semi-Circular in Cross-Section On The Performance Characteristics of Novel Finned-Cyclone SeparatorsMahesh DasarNessuna valutazione finora

- It Is The Maximum Height of Stacks For Warehouse Using Jute SacksDocumento134 pagineIt Is The Maximum Height of Stacks For Warehouse Using Jute SacksKristine JavierNessuna valutazione finora

- Training Doc Mercedes 900Documento195 pagineTraining Doc Mercedes 900mliugong98% (41)

- Hydrocyclones For Particle Size SeparationDocumento7 pagineHydrocyclones For Particle Size SeparationPukhraj DagaNessuna valutazione finora

- Ce 8005 - Air Pollution and Control Engineering: Unit IiiDocumento55 pagineCe 8005 - Air Pollution and Control Engineering: Unit IiiNAVEEN SNessuna valutazione finora

- Optimum Design of Cyclone Separator: SeparationsDocumento5 pagineOptimum Design of Cyclone Separator: SeparationsJeyakumar RajaNessuna valutazione finora

- Cyclone Separator ThesisDocumento4 pagineCyclone Separator ThesisWritingServicesForCollegePapersAlbuquerque100% (2)

- Lecture2 AirDocumento9 pagineLecture2 AirRaj BakhtaniNessuna valutazione finora

- Design Analysis of Dust Collections YstemDocumento31 pagineDesign Analysis of Dust Collections YstemsmendozaNessuna valutazione finora

- Scrubbing Line PaperDocumento8 pagineScrubbing Line PaperAndiNessuna valutazione finora

- Kelsey Centrifugal JigDocumento5 pagineKelsey Centrifugal JigYallarling NagureNessuna valutazione finora

- Ciclon PDFDocumento2 pagineCiclon PDFBarny GomesNessuna valutazione finora

- Zimbabwe School of Mines: Mineral Processing Eng. A. RunganiDocumento27 pagineZimbabwe School of Mines: Mineral Processing Eng. A. RunganiTatenda SibandaNessuna valutazione finora

- Dense Medium SeparationDocumento28 pagineDense Medium SeparationAdel Niño Liza Iligan100% (1)

- Water Pollution Control TechnologiesDocumento6 pagineWater Pollution Control Technologiesirfan aminNessuna valutazione finora

- Introducing The GEK Gasifier Systems - Rev3 PDFDocumento18 pagineIntroducing The GEK Gasifier Systems - Rev3 PDFpicotto100% (1)

- MO Syllabus PDFDocumento7 pagineMO Syllabus PDFBHAVINNessuna valutazione finora

- 74-88 Gravity SeparationDocumento15 pagine74-88 Gravity SeparationMohamed DraaNessuna valutazione finora

- Cyclone SeparatorsDocumento5 pagineCyclone SeparatorsRajagopalNessuna valutazione finora

- Pollution Control: Woods Practical Guide To Fan EngineeringDocumento13 paginePollution Control: Woods Practical Guide To Fan EngineeringprokjongNessuna valutazione finora

- Geothermal Steam-Water Separators: Design Overview: Geothermics January 2015Documento20 pagineGeothermal Steam-Water Separators: Design Overview: Geothermics January 2015Karla HerediaNessuna valutazione finora

- Analysis of The Performance of A Novel Dust Collector Combining Cyclone Separator and Cartridge FilterDocumento8 pagineAnalysis of The Performance of A Novel Dust Collector Combining Cyclone Separator and Cartridge FilterdadNessuna valutazione finora

- Kiln STEC and SEEC Reduction RB V2Documento13 pagineKiln STEC and SEEC Reduction RB V2Santanu PachhalNessuna valutazione finora

- Solid Proc RevisionDocumento51 pagineSolid Proc RevisionAli HussainNessuna valutazione finora

- Front End Engineering DesignDocumento35 pagineFront End Engineering DesignMehdi Nakouri80% (5)