Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Quality Manager or Compliance Manager or Facilitator

Caricato da

api-121425613Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Quality Manager or Compliance Manager or Facilitator

Caricato da

api-121425613Copyright:

Formati disponibili

John R JOHN R. MEAGHER 83 Parma Center Road Hilton, New York 14468 1 (585) 729-3816 jm1327626@westpost.

net _OBJECTIVE: _ _UNITED STATES NAVY VETERAN WILL USE THE PROVEN TOOLS OF LEADERSHIP, LEAN AND SIX SIGMA TO ADD VALUE TO ANY TEAM, PROCESS OR ORGANIZATION BY ELIMINATION OF WASTE, IMPROVING THE EFFICIENCY AND SHARING THE TOOLS AND METHODS TO GROW THE ORGANIZATION AS WELL AS ITS EMPLOYEES. _ _BUSINESS EFFICIENCY CONSULTING, HILTON, NY (2007 - PRESENT)_ _PRIMARY CONSULTANT _ * Founded Business Efficiency Consulting, LLC - primary focus is on problem solving, adherence to regulations and improved business processes with proven results in increased performance and high levels of customer satisfaction. Built the capabilities of employees within their industry resulting in their ability to successfully comply with requirements and become industry leaders using lean and six sigma methodologies. * Lead activities in Documenting Investigations, Corrective and Preventive Actions (CAPA), Flowcharting/Process Mapping to manufacturers worldwide. Clients included; Boston Scientific, Varian Medical Systems (SAFC/Sigma Aldrich, Angiotech, Depuy and Cummins Diesel * Coached and certified in-house trainers on PathWise(R) training materials. * Provided Quality Management Support and mentored to clientas compliance on their problems and documentation in the areas of distribution, labeling, design verification through the manufacturing process. Provided remediation and coached on how to meet all a21 CFR part 280a requirements * Conducted internal audits of the processes and documentation as well as reconciled gaps at Boston Scientificsa manufacturing and distribution centers (US and Europe) resulting in a azero findinga FDA audit * Developed the work process and led a team of subject matter experts

to clearly write Standard Operating Procedures, roles/responsibilities and documentation for Cummins Diesel which resulted in reduced labor, duplication, errors, increased customer satisfaction and 50 trained and certified ateam leadersa * Defined IT strategy and a path forward for Excellus Blue Cross Blue Shield, Rochester, NY. _EASTMAN KODAK COMPANY, ROCHESTER, NY (1978 - 2007)_ SENIOR LEAN/ 6 SIGMA SPECIALIST a" CORPORATE FINANCE Divisional Newsletter graphic designer and publisher. * Major contributor and driving force for the successful Lean Education Series launched in 2006. Taught aLeading Changea (Change Management modules) as well as basic and intermediate quality tools * Lead 45 problem solving Kaizens and managed them through effectiveness checking and future problem prevention, as well as the completion of action items and documentation. PROJECT MANAGER / QUALITY MANAGER a" BUSINESS PROCESS EXCELLENCE a" EASTMAN KODAK CO. * Served as a process expert and consultant for business problems escalated to the Chief Quality Officer. Helped business leaders solve problems utilizing teamwork, Six Sigma and Lean Methodologies. * Used Root Cause Analysis on the Digital and Chemical style radiography equipment to solve their manufacturing problems, * Used Design of Experiments to determine the correct parameters for their manufacturing process and worked with the design teams to design products with quality and efficiency in mind. * Analyzed the Consumer Imaging customer satisfaction survey and developed plans for improvements * Consolidated and Simplified ISO certifications for Kodak Worldwide, (e.g. 9001, 14001, 13485) reduced duplication and costs associated with management of these certifications by 45% * Evaluated and improved the Supplier Quality process adopted worldwide resulting in inventory reductions, and improved quality of products received by partnering when solving problems. WORLD WIDE MANAGER AND INSTRUCTOR FOR SIX SIGMA UNIVERSITY GREEN BELT PROGRAM a" EASTMAN KODAK CO.

* Managed and taught three week curriculum. Conducted training in Canada, Japan, China, England, Italy, and US * Six Sigma University programs certification projects totaled $663M (2003) since Oct. 1997. * Personally conducted and coached 31 cycles of Six Sigma training. * Coached and mentored students through project barriers to successful completion * Was instrumental in the re-design of the Six Sigma programs * Facilitated PathWise(R) Innovation Thinking, Root Causes Analysis workshops. QUALITY IMPROVEMENT FACILITATOR a" EASTMAN KODAK CO. * Coached and mentored 17 Process Improvement Teams. Managed divisional reports and communicated results to Corporate Management. * Implemented and Lead efforts for a Work System Redesign within Utilities Organization, building capabilities and skills of the workforce and empowering teams and individuals to develop a multi-tasked empowered workforce. STEAM AND ELECTRIC DIVISION a"OPERATIONS MANAGER/OPERATING ENGINEER a" EASTMAN KODAK CO. * Responsible for managing operations for the power plant as the Chief Engineer. 48 direct reports * Managed the Health, Safety, and Environmental compliance issues, personnel development and environmental issues. * Obtained corporate certification for instructing Kodakas Quality Improvement Facilitator program. * Managed $197M annual budget, 24/7 operation with 48 operators and five support business teams, within two years, reduced budget to $122M by removing non value added work and making processes more efficient. *

Licensed First Class Stationary Engineer - Certified of power, electric, compressed air and water generation, reaching lead operator status across multiple plants. * Maintained State and other Government records, and managed personnel, as well as training others. * Liaison between Eastman Kodak , Combustion Engineering and General Electric for 2 year Boiler and Turbine installation Project. Instructed 40 employees on the new systems and equipment operation. _LICENSES / CERTIFICATIONS / ACCREDITATION / EDUCATION_ * Lean Manufacturing a" Strategic direction and implementation a" Kodak/Shigeo Shinjitsu group partnership * Certified Six Sigma Green Belt and Black Belt, as well as Instructor for Kodakas Lean/Six Sigma Programs * Awarded five United States Navy Accommodations for Personal Performance, and received an Honorable Discharge. * United States Navy - Propulsion Engineering School, Great Lakes, Illinois * State University of New York at Morrisville - Mechanical Technology A.A.S. * First Class Stationary Engineers License, Rochester, NY Meagher

Potrebbero piacerti anche

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (400)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (74)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (345)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (121)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- CoSiO2 For Fischer-Tropsch Synthesis Comparison...Documento5 pagineCoSiO2 For Fischer-Tropsch Synthesis Comparison...Genesis CalderónNessuna valutazione finora

- Mule 4 Error Handling DemystifiedDocumento8 pagineMule 4 Error Handling DemystifiedNicolas boulangerNessuna valutazione finora

- Ch06 Allocating Resources To The ProjectDocumento55 pagineCh06 Allocating Resources To The ProjectJosh ChamaNessuna valutazione finora

- MV Lec PDFDocumento102 pagineMV Lec PDFJonas Datu100% (1)

- Business CombinationsDocumento18 pagineBusiness Combinationszubair afzalNessuna valutazione finora

- List of Phrasal Verbs 1 ColumnDocumento12 pagineList of Phrasal Verbs 1 ColumnmoiibdNessuna valutazione finora

- Docsity Detailed Lesson Plan 5Documento4 pagineDocsity Detailed Lesson Plan 5Sydie MoredoNessuna valutazione finora

- Karthik ResumeDocumento2 pagineKarthik ResumeArun Raj ANessuna valutazione finora

- Information Technology Project Management: by Jack T. MarchewkaDocumento44 pagineInformation Technology Project Management: by Jack T. Marchewkadeeps0705Nessuna valutazione finora

- Discovery and Integration Content Guide - General ReferenceDocumento37 pagineDiscovery and Integration Content Guide - General ReferencerhocuttNessuna valutazione finora

- Innovativ and Liabl :: Professional Electronic Control Unit Diagnosis From BoschDocumento28 pagineInnovativ and Liabl :: Professional Electronic Control Unit Diagnosis From BoschacairalexNessuna valutazione finora

- The International Poker RulesDocumento2 pagineThe International Poker RulesOutontheBubbleNessuna valutazione finora

- Power Control 3G CDMADocumento18 paginePower Control 3G CDMAmanproxNessuna valutazione finora

- IPM GuidelinesDocumento6 pagineIPM GuidelinesHittesh SolankiNessuna valutazione finora

- N2 V Operare ManualDocumento370 pagineN2 V Operare Manualramiro0001Nessuna valutazione finora

- Japanese GardensDocumento22 pagineJapanese GardensAnmol ChughNessuna valutazione finora

- Redirection & PipingDocumento16 pagineRedirection & PipingPraveen PatelNessuna valutazione finora

- Addition Color by Code: Yellow 1, 2, Blue 3, 4, Pink 5, 6 Peach 7, 8 Light Green 9, 10, Black 11Documento1 paginaAddition Color by Code: Yellow 1, 2, Blue 3, 4, Pink 5, 6 Peach 7, 8 Light Green 9, 10, Black 11Noor NadhirahNessuna valutazione finora

- Automated Dish Washer v1.1Documento21 pagineAutomated Dish Washer v1.1Anonymous XXCCYAEY6M67% (3)

- UnixDocumento251 pagineUnixAnkush AgarwalNessuna valutazione finora

- Holiday AssignmentDocumento18 pagineHoliday AssignmentAadhitya PranavNessuna valutazione finora

- FAO-Assessment of Freshwater Fish Seed Resources For Sistainable AquacultureDocumento669 pagineFAO-Assessment of Freshwater Fish Seed Resources For Sistainable AquacultureCIO-CIO100% (2)

- Rubric For Aet570 BenchmarkDocumento4 pagineRubric For Aet570 Benchmarkapi-255765082Nessuna valutazione finora

- Centrifuge ThickeningDocumento8 pagineCentrifuge ThickeningenviroashNessuna valutazione finora

- Ubi Caritas Guitar Solo Arrangement by Patrick Glenn BalanzaDocumento8 pagineUbi Caritas Guitar Solo Arrangement by Patrick Glenn BalanzaPatrick Glenn BalanzaNessuna valutazione finora

- Building For The Environment 1Documento3 pagineBuilding For The Environment 1api-133774200Nessuna valutazione finora

- Accounting Worksheet Problem 4Documento19 pagineAccounting Worksheet Problem 4RELLON, James, M.100% (1)

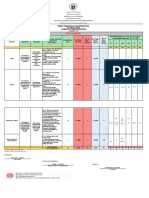

- Revised Final Quarter 1 Tos-Rbt-Sy-2022-2023 Tle-Cookery 10Documento6 pagineRevised Final Quarter 1 Tos-Rbt-Sy-2022-2023 Tle-Cookery 10May Ann GuintoNessuna valutazione finora

- Assignment Csi104Documento11 pagineAssignment Csi104Minh Lê KhảiNessuna valutazione finora

- Clash of Clans Hack Activation CodeDocumento2 pagineClash of Clans Hack Activation Codegrumpysadness7626Nessuna valutazione finora