Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Fewa Earthing System

Caricato da

Paul HastieDescrizione originale:

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Fewa Earthing System

Caricato da

Paul HastieCopyright:

Formati disponibili

FEWA-PL-SS-E-0066 REV.

TECHNICAL SPECIFICATION EARTHING SYSTEM

13 - FEWA-PL-SS-E-0066 REV.0, EARTHING SYSTEM

TABLE OF CONTENTS

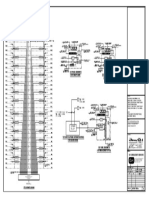

Page 1. 2. 3. 4. 5. 5.1. 5.2. 5.3. 5.4. 5.5. 6. 7. 8. INTENT OF SPECIFICATION AND SCOPE OF SUPPLY GAS INSULATED SWITCHGEAR CONNECTIONS TO ELECTRICAL EQUIPMENT CONNECTIONS TO STRUCTURAL ELECTRICAL EQUIPMENT MATERIALS AND INSTALLATION Conductors Earth Rods Fittings Joints Measurement of Earth Resistance DRAWING/DOCUMENTS REQUIRED EARTH RISERS LIST OF STANDARDS METALWORK AND NON4 4 4 4 5 5 6 6 6 7 3 3 3

VOL IV

EARTHING SYSTEM

Page 2 of 7

13 - FEWA-PL-SS-E-0066 REV.0, EARTHING SYSTEM

EARTHING SYSTEM

1. INTENT OF SPECIFICATION AND SCOPE OF SUPPLY

The intend of this specification is to cover the complete design, supply, installation and testing of grounding system including all necessary supervision, labour, tools, miscellaneous materials, accessories etc. required for new substations and extended part of existing substations. The earthing system for any new extension shall be suitably connected to the existing system. All the materials used for earthing shall be as per relevant IEC/BS/ISO standard and from countries in Western Europe, Japan or USA only. However earthing risers/cables from reputed manufacturer from GCC Countries is also acceptable. All civil works associated with this section of works shall be deemed to be included in the scope of work. No additional payment will be made for such works. The design and installation of below ground main earth mat, Auxiliary earth mat in switchgear and transformer rooms are excluded from the Scope of erection contract. However, all equipment earthing connections to main earth mat/auxiliary earth mat etc are included in the scope of work of substation erection contractor. The erection contractor shall co-ordinate with the OHL/cable contractor and substation civil contractor for earthing of cables and other accessories. 2. GAS INSULATED SWITCHGEAR

The earthing of gas insulated switchgear (GIS) installations shall be subject to special considerations regarding step and touch potentials in accordance with the manufacturers recommendations. However, the earthing conductor to auxiliary earth mat in the basement shall be yellow-green coloured PVC insulated stranded copper conductor with minimum conductor size 2 runs of 150 sq.mm. The connection shall be at multiple points for each bay. The erection contractor shall design the method of earthing the gas insulated switchgear in co-ordination with the GIS manufacturer. 3. CONNECTIONS TO ELECTRICAL EQUIPMENT

Connections between HV electrical equipment and the main earth bar and between LV electrical equipment comprising substantial multi-cubicle switchboards and the main earth bar shall be duplicated. The minimum conductor size shall be 300 sq.mm and shall be yellow- green coloured PVC insulated stranded copper conductor. For other auxiliary items the single conductor shall be rated to withstand the fault rating of the equipment. The conductor size shall not be less than 185sq.mm and shall be yellowgreen coloured PVC insulated stranded copper conductor. The auxiliary mat shall be directly bonded to the cubicle and the conductors forming the mat and the bonding connection shall have a copper cross-section area of 185 sq.mm or equivalent.

VOL IV EARTHING SYSTEM Page 3 of 7

13 - FEWA-PL-SS-E-0066 REV.0, EARTHING SYSTEM All the connection between equipments and auxiliary earth mat (above ground) shall be carried out by erection contractor. 4. CONNECTIONS TO STRUCTURAL METALWORK AND NON-ELECTRICAL EQUIPMENT

All metal work within the project area which does not form part of the electrical equipment shall be bonded to the main earth bar except where otherwise specified. The bonding conductor size shall be not less than 185 sq.mm yellow/green PVC insulated. Individual components of metallic structures of plant shall be bonded to adjacent components to form an electrically continuous metallic path to the bonding conductor. Small electrically isolated metallic components mounted on non-conducting building fabric need not be bonded to the main earth bar. 5. 5.1. MATERIALS AND INSTALLATION Conductors

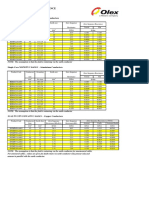

Conductors shall be of high conductivity copper in the form of circular conductors stranded to IEC 228 (BS 6360). Conductor sheaths shall be of yellow-green coloured PVC to meet the requirements of BS 6746 grade TM1 or IEC 502 Grade ST1 with a minimum thickness of 1.5 mm. Earth risers which are not part of the earth electrode mesh system shall be PVC sheathed yellow/green circular stranded cable. Bare conductors only shall be used for earth electrodes meshes buried below the ground. Conductors buried in the ground shall normally be laid at a depth of 1m below the ground in an excavated trench. The backfill in the vicinity of the conductor shall be free of stones and the whole backfill shall be well consolidated. Conductors not forming part of a voltage control mesh shall be laid at the depth required by the approved design and, in the case of a yellow-green coloured PVC sheathed conductor, at the same depth as any auxiliary power or control cables following the same route. All conductors not buried in the ground shall be straightened immediately prior to installation and supported clearly of the adjacent surface. 5.2. Earth Rods

The earth rods shall be of hard-drawn high conductivity copper with a diameter of not less than 19mm with hardened steel driving caps and tips. The rods shall be as long as possible but couplings may be used to obtain the overall depth of driving required by the design. The rods shall be installed by driving into the ground with a power hammer of suitable design to ensure the minimum of distortion to the rod. Where it is not possible to drive rods to the full depth required due to the presence of strata of rock, then holes shall be drilled or blasted in the rock. The holes shall be filled with bentonite or other approved material prior to inserting the rod. If difficult driving conditions arising from hard or rocky ground are encountered or are anticipated or there is a need for deep rods, then high tensile steel rods shall be used. High tensile steel rods shall have a molecularly bonded high conductivity copper coating with a

VOL IV EARTHING SYSTEM Page 4 of 7

13 - FEWA-PL-SS-E-0066 REV.0, EARTHING SYSTEM minimum radial thickness of not less than 0.25 mm. The overall diameter shall be not less than 19 mm. Rolled external screw threads shall be used on the rods for coupling and after rolling the thickness of the copper coating on the threaded portion shall be not less than 0.05 mm. Rods, and driving caps and tips shall treat at couplings to ensure that the couplings and screw threads are not subject to driving forces. All screw threads shall be fully shrouded at the couplings. Alternatively, conical couplings may be used to the approval of FEWA. High conductivity copper for earth rods shall have a minimum copper content (including silver) of 99.90%. The steel for copper-clad steel rods shall be low carbon steel with a tensile strength of not less than 570 N/sq.mm. Couplings for copper rods shall be 5% phosphor bronze (copper-tin-phosphorous) and for copper bonded steel rods of 3% silicon or 7% aluminium bronze. 5.3. Fittings

Clips for supporting strip conductors not buried in the ground shall be of the direct contact type and clips for circular conductors shall be of the cable saddle type. The clips shall support the conductors clear of the structure. Conductors shall be connected to earth rods by a bolted clamp to facilitate removal of the conductor for testing the rod. The number and location of links shall be agreed during design. Disconnecting links shall comprise a high conductivity copper link supported on two insulators mounted on a galvanized steel base for bolting to the supporting structure. The two conductors shall be in direct contact with the link and shall not be disturbed by the removal of the link. Links for mounting at ground level shall be mounted on bolts embedded in a concrete base. Disconnecting links mounted at ground level and the connections at the earth rods shall be enclosed in concrete inspection pits, with concrete lids, installed flush with the ground level. All conductor fittings shall be manufactured from high strength copper alloys with phosphor bronze nuts, bolts, washers and screws. Binary brass copper alloys will not be acceptable. All fittings shall be designed for the specific application and shall not be permanently deformed when correctly installed. Fittings not in direct contact with bare or sheathed conductors may be of hot dipped galvanized steel. Bi-metallic connectors shall be used between conductors of dissimilar materials and insulating material shall be interposed between metallic fittings and structures of dissimilar materials to prevent corrosion. 5.4. Joints

Permanent joints shall be made by brazing, exothermic welding or by crimping. Joints for conductors forming part of mesh system shall be exothermic welding by suitable moulds.

VOL IV

EARTHING SYSTEM

Page 5 of 7

13 - FEWA-PL-SS-E-0066 REV.0, EARTHING SYSTEM Detachable joints shall be bolted and stranded conductors at bolted joints shall be terminated in exothermically welded lugs or a crimped cable socket. The diameter of any holes drilled in strip conductors shall not be greater than half the width of the strip. Connections to electrical equipment shall be detachable and made at the earthing studs or bolts provided on the equipment by the manufacturer. When an earthing point is not provided the point and method of connection shall be agreed with FEWA. Connections to metallic structures for earthing conductors and bonding conductors between electrically separate parts of a structure shall be either by direct exothermic welding or by bolting using a stud welded to the structure. Drilling of a structural member for a directly bolted connection shall only be carried out to the approval of FEWA. Bolted joints in metallic structures including pipe work, which do not provide direct metallic contact shall be bridged by a bonding conductor or both sides of the joint shall be separately bonded to earth unless the joint is intended to be an insulated joint for cathodic protection or other purposes. When the reinforcing in concrete is used as a part of the earthing system the fittings used to provide a connection point at the surface of the concrete shall be exothermically welded to a reinforcing bar. This fitting shall be provided with a bolted connection for an earthing conductor. The main bars in the reinforcing shall be welded together at intervals to ensure electrical continuity through out the reinforcing. 5.5. Measurement of Earth Resistance

The resistance of the complete earth system shall be measured before installation of outgoing cables by the contractor and with OHL termination towers disconnected from the earth mat with an approved form of earth resistance tester. The measured value shall be submitted for approval and shall not exceed 1 ohm when measured between the earth system and the surrounding earth. On completion of the earth mat system, the step and touch potentials shall be measured in accordance with IEEE/BS/DIN/IEC etc. 6. 6.1 6.2 DRAWING/DOCUMENTS REQUIRED Equipment earthing connections details Catalogues for all Earthing materials, moulds, joints, conductors, earth rods, fittings and accessories etc. EARTH RISERS

7.

Earth risers shall be of high quality stranded copper conductor, yellow-green coloured PVC insulated. All earth risers for the entire substations including but not limited to the following earth risers shall be provided. S.No. 1. Description 132kV GIS Minimum size of riser fromequipment to Earth mat(Erection Contractor) 2 runs of 150 sq.mm stranded, PVC insulated Y/G copper conductor

VOL IV

EARTHING SYSTEM

Page 6 of 7

13 - FEWA-PL-SS-E-0066 REV.0, EARTHING SYSTEM 2. 3. 4. 5. 6. 7. 33kV Switchgear (GIS) 11kV switchgear Power transformer Auxiliary transformer NER/NES Equipments Other S/S equipments including control room, LVAC/DC equipments, AC & Ventilation roof equipments etc. 300 sq.mm stranded, PVC insulated Y/G copper conductor 300 sq.mm stranded, PVC insulated Y/G copper conductor 300 sq.mm stranded, PVC insulated Y/G copper conductor 300 sq.mm stranded, PVC insulated Y/G copper conductor 300 sq.mm stranded, PVC insulated Y/G copper conductor 185 sq.mm stranded, PVC insulated Y/G copper conductor

8.

All other equipments as per 185 sq.mm stranded, PVC insulated Y/G site layout copper conductor

In addition to the above, the following risers supplied by the civil contractor shall be connected to equipments by erection contractor. 1. 2. 3. Power transformer Auxiliary transformer 300 sq.mm stranded PVC insulated Y/G, Cu. Conductor for earthing neutral. 300 sq.mm stranded PVC insulated Y/G, copper conductor for earthing LV neutral.

Any other equipments as per 185 sq.mm stranded PVC insulated Y/G, site layout copper conductor.

The number of risers for each equipment shall be as per FEWAs standard practice and subjected to approval of FEWA. The earth mat copper strips/risers shall be clamped to wall by using saddle clips at spacing not more than 1.5 meter. 8. LIST OF STANDARDS IEEE - 80 ANSI/IEEE/std 81 IEEE Guide for safety in AC substation grounding. IEEE Guide for Measuring Earth Resistivity, Ground Impedance, and Earth Surface Potential of a Grounding System. Code of Practice for Earthing. Protection of Structures against Lightning.

BS 7430 BS 6651

VOL IV

EARTHING SYSTEM

Page 7 of 7

Potrebbero piacerti anche

- Building services engineering Standard RequirementsDa EverandBuilding services engineering Standard RequirementsNessuna valutazione finora

- FEWA LV Cable SpecsDocumento46 pagineFEWA LV Cable Specsjtwani100% (2)

- Access Control System A Complete Guide - 2020 EditionDa EverandAccess Control System A Complete Guide - 2020 EditionNessuna valutazione finora

- Fewa ReqDocumento12 pagineFewa ReqMoin AhmedNessuna valutazione finora

- ADDC - Elctricity Wiring RulesDocumento224 pagineADDC - Elctricity Wiring RulesT.i GroonNessuna valutazione finora

- Mew R6 2016Documento31 pagineMew R6 2016Zaid Zi0% (1)

- Fewa Regulation 2013Documento219 pagineFewa Regulation 2013Anonymous GdZqtY88ZR92% (25)

- Cable Size Fewa ChartDocumento1 paginaCable Size Fewa Chart2003vinayNessuna valutazione finora

- S Aa Cab Inst LV (Rev.0 2010)Documento20 pagineS Aa Cab Inst LV (Rev.0 2010)Wael AlmassriNessuna valutazione finora

- ADM Lighting Specification IRI Roads Rev01 1nov2011Documento35 pagineADM Lighting Specification IRI Roads Rev01 1nov2011hintesarNessuna valutazione finora

- Pervez Ahmad Khan: Job Objective Areas of ExpertiseDocumento6 paginePervez Ahmad Khan: Job Objective Areas of ExpertisePERVEZ AHMAD KHANNessuna valutazione finora

- EP-DP-C1 Electricity Planning Regulations For Supply-FinalDocumento27 pagineEP-DP-C1 Electricity Planning Regulations For Supply-FinalVladimir Simeunovic100% (2)

- Guide Lines For The Distribution Substation Equipment Layout and LocationDocumento3 pagineGuide Lines For The Distribution Substation Equipment Layout and LocationAnirban Chakraborty50% (2)

- Dewa TablesDocumento13 pagineDewa TablesKrishna KumarNessuna valutazione finora

- ADDC RegulationDocumento18 pagineADDC RegulationLester Bencito75% (4)

- Requirements For Electrical Installations Iet Wiring Regulations 17th Edition PDFDocumento7 pagineRequirements For Electrical Installations Iet Wiring Regulations 17th Edition PDFSyed Sufyian AliNessuna valutazione finora

- Addc Sector Measuring Point (Ip54) : Uncontrolled If PrintedDocumento1 paginaAddc Sector Measuring Point (Ip54) : Uncontrolled If PrintedWael Almassri100% (1)

- 3 Transformer RoomDocumento30 pagine3 Transformer Roomcherif yahyaouiNessuna valutazione finora

- ADDC ProcessDocumento19 pagineADDC ProcessfaizalpsNessuna valutazione finora

- Amtech ProDesign Product GuideDocumento3 pagineAmtech ProDesign Product GuideShanti Naidu0% (1)

- Warehouse Electrical DrawingDocumento1 paginaWarehouse Electrical Drawinghastmish100% (1)

- SEWA Regulations For Electrical ConnectionDocumento2 pagineSEWA Regulations For Electrical ConnectionVineesh Vinu100% (1)

- DEWA Distribution Substation Guidelines Mar 2007Documento36 pagineDEWA Distribution Substation Guidelines Mar 2007majortay100% (2)

- Central Battery System DesignDocumento11 pagineCentral Battery System Designssatgr100% (1)

- Elv Panel Schematic (For Tenant'S Unit) Elv Panel Schematic (For Gym Room)Documento1 paginaElv Panel Schematic (For Tenant'S Unit) Elv Panel Schematic (For Gym Room)sana ullah100% (1)

- Fewa SpecificationsDocumento28 pagineFewa SpecificationsAnonymous GdZqtY88ZRNessuna valutazione finora

- Sharjah RegulationsDocumento129 pagineSharjah RegulationsAbdallah Omar Al Ayoubi86% (121)

- LDN Consultants v0.6Documento29 pagineLDN Consultants v0.6Wael AlmassriNessuna valutazione finora

- Design of Electrical InfrastructureDocumento54 pagineDesign of Electrical InfrastructureCharles Benwari100% (1)

- FEWADocumento33 pagineFEWArasheed313Nessuna valutazione finora

- Kahramaa RegulationsDocumento27 pagineKahramaa Regulations360sameh50% (2)

- Section 3.3.15 Building Services r3Documento21 pagineSection 3.3.15 Building Services r3sahmeduNessuna valutazione finora

- Guidelines For Utility Impact Assessment For Local Roads in Developed Areas MME 2012 Cross-SectionDocumento81 pagineGuidelines For Utility Impact Assessment For Local Roads in Developed Areas MME 2012 Cross-Sectionirfan mohammedNessuna valutazione finora

- Addc Guidlines For LV Services Cable Selection and Fuse RatingDocumento10 pagineAddc Guidlines For LV Services Cable Selection and Fuse RatingJon Smith50% (4)

- Distribution Substation Guideline - of 11-22 KV Substation-26 01 2009Documento54 pagineDistribution Substation Guideline - of 11-22 KV Substation-26 01 2009Khaled Faceb79% (19)

- DEWA Regulations 2017Documento123 pagineDEWA Regulations 2017siva_nagesh_280% (5)

- Dewa Installation - Regulstions1997Documento62 pagineDewa Installation - Regulstions1997Imran Mughle AzamNessuna valutazione finora

- Specification of Lightning Protection Based On BSEN 62305Documento8 pagineSpecification of Lightning Protection Based On BSEN 62305Ayman SaberNessuna valutazione finora

- Busbar SizeDocumento1 paginaBusbar SizealageshvijayNessuna valutazione finora

- Feeder Pillar BoxDocumento7 pagineFeeder Pillar BoxshanthikumaravelNessuna valutazione finora

- Lighting ControlDocumento87 pagineLighting Controlbuco2312100% (3)

- Design of Electrical Services For Buildings 4th Edition 1Documento329 pagineDesign of Electrical Services For Buildings 4th Edition 1Ar Vishul Saxena100% (1)

- Guideline of 11-22 KV Substation-26.01.2009.Docx 2013Documento49 pagineGuideline of 11-22 KV Substation-26.01.2009.Docx 2013Arun UdayabhanuNessuna valutazione finora

- S-AA-MVLV - LVND - LV Network Design Guideline (ADDC) Rev 0 2019Documento16 pagineS-AA-MVLV - LVND - LV Network Design Guideline (ADDC) Rev 0 2019Wael Almassri100% (1)

- MEP CoordinationDocumento15 pagineMEP CoordinationJahferOlambilNessuna valutazione finora

- 11 KV RMU-Tech. Spec PDFDocumento23 pagine11 KV RMU-Tech. Spec PDFMohsin ElgondiNessuna valutazione finora

- Electrical Scope Part 7Documento4 pagineElectrical Scope Part 7shameemNessuna valutazione finora

- Earthing InstallationDocumento24 pagineEarthing InstallationTuhin SheikhNessuna valutazione finora

- Earthing SystemDocumento6 pagineEarthing SystemsallammohamedNessuna valutazione finora

- Specifications of Typical Substation Earthing SystemDocumento5 pagineSpecifications of Typical Substation Earthing SystemYahya Faiez WaqqadNessuna valutazione finora

- SECTION 16450 Grounding Part 1 - GeneralDocumento5 pagineSECTION 16450 Grounding Part 1 - GeneraljosemartinpenatorresNessuna valutazione finora

- Cable LayingDocumento6 pagineCable LayingPramod B.WankhadeNessuna valutazione finora

- Bonding and Grounding CodeDocumento8 pagineBonding and Grounding CodeKenon FlemingsNessuna valutazione finora

- Electrical ConditionDocumento7 pagineElectrical ConditionmaheshnavamiNessuna valutazione finora

- Gi Conduit LayingDocumento5 pagineGi Conduit LayingPrasad PanchatsaramNessuna valutazione finora

- Sec-09 Electrical Works and InstallationDocumento6 pagineSec-09 Electrical Works and InstallationOmer HayatNessuna valutazione finora

- Facility ManagementDocumento7 pagineFacility ManagementTajudeen IbrahimNessuna valutazione finora

- DG260543Documento7 pagineDG260543Ahmed OsamaNessuna valutazione finora

- Lightning and Earthing Protection SystemDocumento3 pagineLightning and Earthing Protection SystemFarah Wahidah MazlanNessuna valutazione finora

- Dynamic Engineering Consultant Mina Al Arab Precinct - 5 MEP SpecificationDocumento8 pagineDynamic Engineering Consultant Mina Al Arab Precinct - 5 MEP SpecificationBala Krishna GallaNessuna valutazione finora

- CIN 2103: Networking Fundamentals: CLO1 - Protocols and ModelsDocumento36 pagineCIN 2103: Networking Fundamentals: CLO1 - Protocols and ModelsAisha Alkhateri ZeeDimensionNessuna valutazione finora

- Habilis Ee Training Center, Inc. 61st Isabel Ramiro Road, Purok 6A, Tambo-Hinaplanon, Iligan City, 9200 Tel No. (063) 2250809Documento8 pagineHabilis Ee Training Center, Inc. 61st Isabel Ramiro Road, Purok 6A, Tambo-Hinaplanon, Iligan City, 9200 Tel No. (063) 2250809Gino Anthony DayoNessuna valutazione finora

- Chimney - Electrical Works SpecDocumento54 pagineChimney - Electrical Works Specmyselfashinthedark100% (1)

- Price-List Polycab Industrial Flexible CablesDocumento4 paginePrice-List Polycab Industrial Flexible Cablesusama zedanNessuna valutazione finora

- ScheduleDocumento131 pagineScheduleAnonymous bqTQaq0gDNessuna valutazione finora

- 0.6/1 KV N2Xry - Cu/Xlpe/Pvc/Swa/Pvc: ConstructionDocumento2 pagine0.6/1 KV N2Xry - Cu/Xlpe/Pvc/Swa/Pvc: ConstructionIvan Nur BhaktiNessuna valutazione finora

- 1tlivo: War Department Field ManualDocumento204 pagine1tlivo: War Department Field ManualdarkNessuna valutazione finora

- 127/230 (245) KV With Copper Wire ShieldDocumento1 pagina127/230 (245) KV With Copper Wire ShieldErick EspirituNessuna valutazione finora

- 33& 11kv Terminations. KitsDocumento9 pagine33& 11kv Terminations. Kitsnvinodn06Nessuna valutazione finora

- Project Report On Sudhir Generator SetDocumento89 pagineProject Report On Sudhir Generator SetYadwinder Singh67% (3)

- LS Copper Wire Rod: Leading SolutionDocumento12 pagineLS Copper Wire Rod: Leading SolutionhuynhvanquynhNessuna valutazione finora

- Conductors Used For Transmitting Electric PowerDocumento52 pagineConductors Used For Transmitting Electric PowerNaresh GollapalliNessuna valutazione finora

- (No. 90) - 11 - SDMS-04 - R0 - FinalDocumento20 pagine(No. 90) - 11 - SDMS-04 - R0 - Finalpmurali_10490025467% (3)

- STD SPN For Material & Works Vol II (Electrical) With Rev 2 DTD 17.01.2017 PDFDocumento429 pagineSTD SPN For Material & Works Vol II (Electrical) With Rev 2 DTD 17.01.2017 PDFSudhir Pandey100% (1)

- Pre Commission Check List For 2DP1S-Ver1 PDFDocumento21 paginePre Commission Check List For 2DP1S-Ver1 PDFecarvind100% (1)

- BS 07870-3.12-2011 (2012)Documento22 pagineBS 07870-3.12-2011 (2012)Fernando Sánchez RomeroNessuna valutazione finora

- Iec60502 PVC Lead SHTMLDocumento3 pagineIec60502 PVC Lead SHTMLAliNessuna valutazione finora

- Zero Sequence1 - SummaryDocumento4 pagineZero Sequence1 - SummaryTosikur Rahman100% (1)

- RFP - 2023 02 16 17 14 06Documento53 pagineRFP - 2023 02 16 17 14 06Barun kumar paridaNessuna valutazione finora

- Determine Best Fit Information SheetDocumento101 pagineDetermine Best Fit Information Sheetmuluken100% (2)

- AutoDocumento18 pagineAutoManimaran DevaNessuna valutazione finora

- Current Rating - Electrical Notes & ArticlesDocumento6 pagineCurrent Rating - Electrical Notes & Articlesans_pup09Nessuna valutazione finora

- Spec - Ohe - Cat (Cu MG) 0120 (11 - 12Documento21 pagineSpec - Ohe - Cat (Cu MG) 0120 (11 - 12hardeep08Nessuna valutazione finora

- Onshore Cable SpecificationDocumento5 pagineOnshore Cable Specificationraghu_s27078Nessuna valutazione finora

- AOverhead Transmission LinesDocumento60 pagineAOverhead Transmission LinesjitendraNessuna valutazione finora

- M3382 Spec (Fusible Link)Documento4 pagineM3382 Spec (Fusible Link)DamonNessuna valutazione finora

- Superbar 2019 PDFDocumento32 pagineSuperbar 2019 PDFRamsey BoltonNessuna valutazione finora

- LDC LP No. 02 DTD 1st June 2023Documento12 pagineLDC LP No. 02 DTD 1st June 2023Hiral SolankiNessuna valutazione finora

- Polycab Cables PricelistDocumento4 paginePolycab Cables PricelistBu ManNessuna valutazione finora

- 3M Cold Shrink Cable Joints & Terminations, Scottish Power 11kV 33kVDocumento20 pagine3M Cold Shrink Cable Joints & Terminations, Scottish Power 11kV 33kVMarioNessuna valutazione finora

- The Things We Make: The Unknown History of Invention from Cathedrals to Soda CansDa EverandThe Things We Make: The Unknown History of Invention from Cathedrals to Soda CansValutazione: 4.5 su 5 stelle4.5/5 (21)

- To Engineer Is Human: The Role of Failure in Successful DesignDa EverandTo Engineer Is Human: The Role of Failure in Successful DesignValutazione: 4 su 5 stelle4/5 (138)

- Crossings: How Road Ecology Is Shaping the Future of Our PlanetDa EverandCrossings: How Road Ecology Is Shaping the Future of Our PlanetValutazione: 4.5 su 5 stelle4.5/5 (10)

- The Things We Make: The Unknown History of Invention from Cathedrals to Soda Cans (Father's Day Gift for Science and Engineering Curious Dads)Da EverandThe Things We Make: The Unknown History of Invention from Cathedrals to Soda Cans (Father's Day Gift for Science and Engineering Curious Dads)Nessuna valutazione finora

- The Great Bridge: The Epic Story of the Building of the Brooklyn BridgeDa EverandThe Great Bridge: The Epic Story of the Building of the Brooklyn BridgeValutazione: 4.5 su 5 stelle4.5/5 (59)

- Environmental Impact Assessment: Theory and PracticeDa EverandEnvironmental Impact Assessment: Theory and PracticeValutazione: 5 su 5 stelle5/5 (5)

- Bridge Engineering: Classifications, Design Loading, and Analysis MethodsDa EverandBridge Engineering: Classifications, Design Loading, and Analysis MethodsValutazione: 4 su 5 stelle4/5 (16)

- Rocks and Minerals of The World: Geology for Kids - Minerology and SedimentologyDa EverandRocks and Minerals of The World: Geology for Kids - Minerology and SedimentologyValutazione: 4.5 su 5 stelle4.5/5 (5)

- Principles of Forensic Engineering Applied to Industrial AccidentsDa EverandPrinciples of Forensic Engineering Applied to Industrial AccidentsNessuna valutazione finora

- Troubleshooting and Repair of Diesel EnginesDa EverandTroubleshooting and Repair of Diesel EnginesValutazione: 1.5 su 5 stelle1.5/5 (2)

- Skyway: The True Story of Tampa Bay's Signature Bridge and the Man Who Brought It DownDa EverandSkyway: The True Story of Tampa Bay's Signature Bridge and the Man Who Brought It DownNessuna valutazione finora

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- Composite Structures of Steel and Concrete: Beams, Slabs, Columns and Frames for BuildingsDa EverandComposite Structures of Steel and Concrete: Beams, Slabs, Columns and Frames for BuildingsNessuna valutazione finora

- The History of the Theory of Structures: From Arch Analysis to Computational MechanicsDa EverandThe History of the Theory of Structures: From Arch Analysis to Computational MechanicsNessuna valutazione finora

- Rock Fracture and Blasting: Theory and ApplicationsDa EverandRock Fracture and Blasting: Theory and ApplicationsValutazione: 5 su 5 stelle5/5 (2)

- Structural Cross Sections: Analysis and DesignDa EverandStructural Cross Sections: Analysis and DesignValutazione: 4.5 su 5 stelle4.5/5 (19)