Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Shift Register

Caricato da

madhurithkDescrizione originale:

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Shift Register

Caricato da

madhurithkCopyright:

Formati disponibili

PL S Controls Div.

Technical Information

Using Electro Cam Corp. PLS Controller in Conjunction with External Shift Register

Electro Cam Corp. PLS Programmable Limit Switches (PLS) have the ability to turn on outputs based on a product present input signal, such as a photo eye or proximity switch. When the input is received, the corresponding output is enabled to turn ON within the same revolution or product cycle. If the output is not required until several cycles after the input, an external shift register can be used in conjunction with the Electro Cam Corp. PLS to accomplish the task. The product present detect signal can often be too fast for a PLC input to register. The high speed scan time of the Electro Cam Corp. PLS gives you the capability to read the input and provide the PLC input with a longer duration pulse that it can read. This gives you the high-speed capabilities of the PLS controller along with the shift functions that a PLC can provide. Shift Registers Defined A shift register is a logic process that allows the controller to keep track of what happens at one point, and remember it until another specified point occurs. An example would be a machine that has several pockets or stations, and every one of the pockets or stations has its own product cycle. The shift register takes a data bit (ON or OFF condition) from one station to another. This information is used in the logic process at that predetermined station to decide if it does something based on what happened at the first station. Most shift register logic is performed in a process that is commonly referred to as FIFO (First In, First Out). This means that the register has a specific number of positions. At the first position the data bit for that position is either turned ON, if the proper conditions are met, or is left OFF if the proper conditions are not met. The controller receives a signal that tells it to move the information (ON or OFF state) of the bit, one position down the register. When that particular data bit gets to the last position in the register, the controller looks to see if it is ON or OFF, then the controller knows whether to do something because of the condition of the bit. After the next shift of the register bits, the last bit is dropped and the bit before it now takes its place. This is a continual process in that as bit information is put into the first position, the bit information in the last position is removed. Now lets use the example of a label application process for a bottle filler. At the first position there is no bottle, so the shift register has an OFF data bit for that nest. As that nest moves through the filling process, the data bit (OFF switch) moves as each new bottle enters the filler. When the nest that doesnt have a bottle gets to certain stations, the controller looks at the data bit to determine whether it should do something (if the bottle is there, it does something, if there is no bottle, it does nothing). When the nest gets to the label applicator the data bit is OFF, so the label applicator doesnt try to apply a label to a bottle that is not present! Setting Up Electro Cam Corp. PLS with an External Shift Register The diagrams below all refer to the Electro Cam Corp. controllers inputs and outputs, and how they interface with the external shift register. The PLS will need to be set up into 3 groups as follows: Group 1: The first group is set to mode 4 and receives the product present input. (Note: Modes are explained in detail in the controller Programming & Installation manual.) If the input falls within the product present window, the groups output is enabled to turn ON at its programmed ON/OFF setpoints. The resulting PLS output is fed into the shift register, and sets the shift register bit. Mode 4 Product window (PLS group channel window) Product present eye to PLS input PLS output to shift register

Continued on page 2...

260 01/00

13647 Metric Rd Roscoe, IL 61073 USA 815-389-2620 FAX 815-389-3304 800-228-5487 (USA & Canada) Web Site: www.electrocam.com email: ecam@electrocam.com

Group 2: This group is set to mode 0. The output will turn ON every cycle, and will serve as the shift pulse input for the shift register. Mode 0 Shift pulse from PLS output Group 3: This group is set to mode 4 and receives its input from the shift register output. When the shift register gives an output within the PLS group window, the controllers real world output is enabled to turn ON and perform the desired operation on the product. A typical example would be a reject operation on a defective product that was detected in an earlier cycle. Mode 4 Window (PLS group channel window) Input to PLS from shift register output Final PLS real world Output

Copyright 2000 All Rights Reserved Neither this document nor any part may be reproduced or transmitted in any form or by any means without permission in writing from the publisher. , PLS, SLIMLINE, and PLSNET are all registered trademarks of

260 01/00

Potrebbero piacerti anche

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (344)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (120)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (73)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- Basic Electronics Experiment of Thevenine - NortanDocumento4 pagineBasic Electronics Experiment of Thevenine - NortanmadhurithkNessuna valutazione finora

- List of Experiment SITDocumento1 paginaList of Experiment SITmadhurithkNessuna valutazione finora

- Integrator Differntial Op-Amp (An Experiment of Basic Electronics)Documento3 pagineIntegrator Differntial Op-Amp (An Experiment of Basic Electronics)madhurithkNessuna valutazione finora

- State Space AnalysisDocumento21 pagineState Space AnalysismadhurithkNessuna valutazione finora

- AVR Microcontroller Question BankDocumento2 pagineAVR Microcontroller Question BankmadhurithkNessuna valutazione finora

- Basic Electronics Lab Experiment - RLC Series ResonanceDocumento3 pagineBasic Electronics Lab Experiment - RLC Series ResonancemadhurithkNessuna valutazione finora

- Digital Logic Design AssignmentDocumento1 paginaDigital Logic Design AssignmentmadhurithkNessuna valutazione finora

- S&S QuestionsDocumento1 paginaS&S QuestionsmadhurithkNessuna valutazione finora

- AVR Microcontroller Question BankDocumento2 pagineAVR Microcontroller Question BankmadhurithkNessuna valutazione finora

- Digital Logic Design Solution of Any One K MapDocumento1 paginaDigital Logic Design Solution of Any One K MapmadhurithkNessuna valutazione finora

- Digital Logic Design Solution of Any One K MapDocumento1 paginaDigital Logic Design Solution of Any One K MapmadhurithkNessuna valutazione finora

- On BlurDocumento1 paginaOn BlurmadhurithkNessuna valutazione finora

- Introduction of Control SystemsDocumento1 paginaIntroduction of Control SystemsmadhurithkNessuna valutazione finora

- Eln & Ckts-Y.jayasimha NotesDocumento79 pagineEln & Ckts-Y.jayasimha NotesAsha NaiduNessuna valutazione finora

- On ClickDocumento1 paginaOn ClickmadhurithkNessuna valutazione finora

- 8051 Derivatives: LCALL or LJMP Instructions, 64 Bytes Internal, No External Data Memory)Documento1 pagina8051 Derivatives: LCALL or LJMP Instructions, 64 Bytes Internal, No External Data Memory)madhurithkNessuna valutazione finora

- 8051 Derivatives: LCALL or LJMP Instructions, 64 Bytes Internal, No External Data Memory)Documento1 pagina8051 Derivatives: LCALL or LJMP Instructions, 64 Bytes Internal, No External Data Memory)madhurithkNessuna valutazione finora

- Radiation PrincipleDocumento1 paginaRadiation PrinciplemadhurithkNessuna valutazione finora

- What Is DTH: Direct To Home Is A Term Used To Refer To Satellite TelevisionDocumento1 paginaWhat Is DTH: Direct To Home Is A Term Used To Refer To Satellite TelevisionmadhurithkNessuna valutazione finora

- On BlurDocumento1 paginaOn BlurmadhurithkNessuna valutazione finora

- Generic Linear CodeDocumento1 paginaGeneric Linear CodemadhurithkNessuna valutazione finora

- Questions HTML 2Documento1 paginaQuestions HTML 2madhurithkNessuna valutazione finora

- Research 9: Activity 4: Background of The StudyDocumento7 pagineResearch 9: Activity 4: Background of The StudyPhilip AmelingNessuna valutazione finora

- PienaDocumento1 paginaPienaMika Flores PedroNessuna valutazione finora

- Parkinson S Disease Detection Based On SDocumento5 pagineParkinson S Disease Detection Based On SdaytdeenNessuna valutazione finora

- Entropy Equation For A Control VolumeDocumento12 pagineEntropy Equation For A Control VolumenirattisaikulNessuna valutazione finora

- 141-203 Solar 660 60 - 40 - 30 - 225 Amp Fleet Battery ChargerDocumento10 pagine141-203 Solar 660 60 - 40 - 30 - 225 Amp Fleet Battery Chargerjose alberto alvarezNessuna valutazione finora

- Compressor-Less: Historical ApplicationsDocumento70 pagineCompressor-Less: Historical Applicationssuryakantshrotriya100% (1)

- An Introduction To EFTDocumento24 pagineAn Introduction To EFTkunjammuNessuna valutazione finora

- Budget of Work Inquiries Investigations and Immersion 19 20Documento1 paginaBudget of Work Inquiries Investigations and Immersion 19 20alma florNessuna valutazione finora

- CHAPTER 2 - ALGEBRA (Latest)Documento41 pagineCHAPTER 2 - ALGEBRA (Latest)FirdausNessuna valutazione finora

- Evolis User ManualDocumento28 pagineEvolis User ManualIonmadalin1000Nessuna valutazione finora

- Lithospheric Evolution of The Pre-And Early Andean Convergent Margin, ChileDocumento29 pagineLithospheric Evolution of The Pre-And Early Andean Convergent Margin, ChileAbdiel MuñozNessuna valutazione finora

- Differential Settlement at Bridge ApproaDocumento5 pagineDifferential Settlement at Bridge ApproaVictor De los ReyesNessuna valutazione finora

- Travel Advertisement RubricDocumento2 pagineTravel Advertisement Rubricapi-316353024Nessuna valutazione finora

- One Wavelength To Loop SkywireDocumento2 pagineOne Wavelength To Loop SkywireRobert TurnerNessuna valutazione finora

- 12 ĀnurũpyenaDocumento7 pagine12 ĀnurũpyenashuklahouseNessuna valutazione finora

- Chapter 1 MPLS OAM Configuration Commands ...................................................................... 1-1Documento27 pagineChapter 1 MPLS OAM Configuration Commands ...................................................................... 1-1Randy DookheranNessuna valutazione finora

- 2021 3 AbstractsDocumento168 pagine2021 3 AbstractsLong An ĐỗNessuna valutazione finora

- VSR Trans. PPT3Documento16 pagineVSR Trans. PPT3VSR TRANSNessuna valutazione finora

- Entrepreneurship: Presented By: Marlon N. Tabanao JR., LPTDocumento14 pagineEntrepreneurship: Presented By: Marlon N. Tabanao JR., LPTRoj LaguinanNessuna valutazione finora

- MLAB 3 - BoilerDocumento3 pagineMLAB 3 - BoilerReden LopezNessuna valutazione finora

- The Extension Delivery SystemDocumento10 pagineThe Extension Delivery SystemApril Jay Abacial IINessuna valutazione finora

- Analytical Chemistry (CHM111) Laboratory ManualDocumento73 pagineAnalytical Chemistry (CHM111) Laboratory ManualKatrina BucudNessuna valutazione finora

- Rule Based ClassificationsDocumento14 pagineRule Based ClassificationsAmrusha NaallaNessuna valutazione finora

- Sheet Metal Cutting Using Geneva MechanismDocumento27 pagineSheet Metal Cutting Using Geneva MechanismsingamNessuna valutazione finora

- 93c3 Document 3Documento14 pagine93c3 Document 3NONON NICOLASNessuna valutazione finora

- Chess AI: Competing Paradigms For Machine Intelligence: Shiva Maharaj Nick Polson Alex TurkDocumento15 pagineChess AI: Competing Paradigms For Machine Intelligence: Shiva Maharaj Nick Polson Alex TurkDomingo IslasNessuna valutazione finora

- Palmiye Leaflet 2015 enDocumento4 paginePalmiye Leaflet 2015 ensaraju_felixNessuna valutazione finora

- Hemo TecaDocumento17 pagineHemo TecaMafer PilcoNessuna valutazione finora

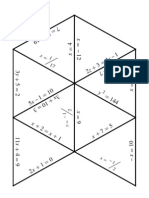

- Algebra1 Review PuzzleDocumento3 pagineAlgebra1 Review PuzzleNicholas Yates100% (1)

- Addressing Diversity Through The Years Special and Inclusive EducationDocumento6 pagineAddressing Diversity Through The Years Special and Inclusive EducationJiezel SurinNessuna valutazione finora