Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Line-by-line conveyor code for material handling parameters and calculations

Caricato da

kmats2Descrizione originale:

Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Line-by-line conveyor code for material handling parameters and calculations

Caricato da

kmats2Copyright:

Formati disponibili

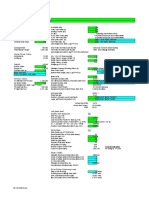

Line 0.0 1.0 1.1 1.2 1.3 1.4 1.5 2.0 2.1 2.2 2.3 2.4 2.5 2.

6 3.0 3.1 3.2 3.3 3.4 3.5 4.0 4.1 4.2 4.3 4.4 4.5 4.6 4.7 4.8 5.0 5.1 5.2 5.3 5.4 5.5 5.6 5.7 5.8 5.9 5.10 5.11 6.0 6.1 6.2 6.3 6.4 6.5 CONVEYOR CODE No MATERIAL PROPERTIES Material to be Handled Bulk Density Static Angle of Repose Dynamic Angle of Surcharge Lump Size TRANSFER PROPERTIES Conveying Distance Conveying Height Conveyor Length Gradient (rad) Gradient (degree) Gradient (%)

Variable

Symbol BC-00

Value

Units

Notes

Clincer of Cement 1.20 r s k 30 20 80-150 tn/m3 mm according to Table no 01 according to Table no 01 according to Table no 02

L H Lc gr a

150.00 15.00 150.75 0.10 5.71 10

m m m rad %

Datum no 01 Datum no 02 L c =(L 2 +H 2 ) 1/2 gr=arctan(H/L) =(360*gr)/(2* ) a=100*(H/L)

CROSS SECTION PROPERTIES Troughing Design Troughing Angle Belt Width Effective Belt Width Maximum Loaded Section Area CAPACITY Belt Speed Degree of Filling Degree of Uniformity Volume Rate Mass Rate Utilisation Daily Volume Rate Daily Mass Rate NUMBER OF IDLERS Transition Length Normal Troughing Set Pitch at the Upper Run Troughing Set Pitch at Loading Point Troughing Set Pitch at Lower Run Loading Length Number of TransitionTroughing Sets Number of Loading Troughing Sets Number of Normal Upper Run Troughing Sets Total Troughing Sets at the Upper Run Average Pitch at the Upper Run Troughing Sets at the Lower Run BELT PROPERTIES Type of Belt Belt Tensile Strength Thickness of Upper Layer Thickness of Lower Layer Belt Core Mass EP 315/2 (4+2) Ts Th u Th l m bc 315 4.0 2.0 3.00 N/mm mm mm Kg/m2 Datum no 07 acc to Table no 08 according to Belt Type according to Belt Type according to Belt Type according to Table no 08 L tr a nu a ld al L ld n tr n ld n nu nu au nl 2.70 1.20 0.60 3.00 1.20 2 3 123 128 1.18 51 m m m m m m according to Table no 06 according to Table no 07 a ld =a u /2 a l =2*a nu Datum no 07 n tr =INT(L tr /a nu ) n l =INT(L ld /a ld )+1 n nu =INT((L c -L tr -L ld )/a nu )+1 n u =n t +n l +n nu a u =L c /n u n l =INT(L c /a l )+1 v

1 2

3-part, Normal Trough 30 B b S 1000 850 0.1141 mm mm m2 b=0.9*B-50 according to Table no 03 Datum no 03

2.3 0.98 0.90 833 1000 12 9999

m/s

Datum no 04 acc to Table no 04 Datum no 05 acc to Table no 05 Datum no 06

Qv Qm t Q dv Q dm

m3/hr tn/hr hr/day m3/day

Q v =3600*S*v* Q m = *Q v Datum Q dv =t*Q v Q dm =t*Q m

1*

11999.06 tn/day

6.6 6.7 7.0 7.1 7.2 7.3 7.4 7.5 7.6 7.7 7.8 7.9 7.10 7.11 7.12 7.13 7.14 7.15 8.0 6.1 8.2 8.3 8.4 8.5 8.6 8.7 8.8 8.9 8.10 8.11 8.12 8.13 8.14 8.15 8.16 8.17 8.18 9.0

Belt External Layers Mass Belt Mass per Meter of Conveyor Length IDLER PROPERTIES Upper Idler Diameter Lower Idler Diameter Upper Idler Rotation Speed Lower Idler Rotation Speed Mass of Conveied Material per Meter of Conveyor Length Load on the Upper Idlers Load on the Lower Idlers Impact Factor Service Factor Enviromental Factor Speed Factor Participation Factor for the Upper Idlers Participation Factor for the Lower Idlers Design Load of the Upper Idlers (Minimum Required) Design Load of the Lower Idlers (Minimum Required) RESISTANCE FORCES Belt Mass per Meter of Conveyor Length Mass of Conveied Material per Meter of Conveyor Length Upper Idler Rotating Mass per Troughing Set Lower Idler Rotating Mass per Troughing Set Upper Idler Rotating Mass per Meter of Conveyor Length Lower Idler Rotating Mass per Meter of Conveyor Length Conveyor Length Coefficient of Internal Friction Coefficient of Fixed Resistance Coefficient of Passive Resistance Given By Temperature Relative Speed of the Material to Feed Resistance Forces Due to the Material Acceleration at the Feeding Point Height of Contactact Between Material and Chute Walls Resistance Forces Due to the Friction of the Material on the Chute Wall Resistance Forces Due to Belt Cleaning Equipment Resistance Forces Upper Run Resistance Forces Lower Pun Total Resistance Forces Starting

m br mb

1.15 9.90

Kg/m2mm Kg/m

Datum no 08 m b =(B/1000)*(m br *(Th u +Th l )+m bc )

Du Dl n ru n rl mm qu ql Fd Fs Fm Fv F pu F pl q du q dl

108 108 407 407 120.76 291.36 1.03 1.10 1.00 0.97 0.65 1.00 1,112 311

mm mm rpm rpm Kg/m N

according to Table no 09 according to Table no 09 n ru =(v*1000*60)/(D* ) , check acc to Table no 10 n rl =(v*1000*60)/(D* ) , check acc to Table no 10 m m =(1000*Q v * )/(3600*v) q u =g*a u *(m b +m m ) q l =g*a l *m b according to Table no 11 according to Table no 12 according to Table no 13 according to Table no 13 according to Table no 14 according to Table no 14

1,509.61 N

N N

q du =q u *F d *F s *F m *F pu q dl =q l *F v *F s *F m *F pl

mb mm m uis m lis m ui m li Lc f Cq Ct v0 F NF h F NC F NS Fu Fl F

9.90 120.76 17.8 13.3 15.11 4.43 150.75 0.017 1.50 1.00 0.00 639 0.20 508 1,500 25,847 582 26,429

Kg/m Kg/m Kg Kg Kg/m Kg/m m

m b =(B/1000)*(m br *(Th u +Th l )+m bc ) (6.7) m m =(1000*Q v * )/(3600*v) (7.5) according to Table according to Table mui=muis/au mli=mlis/al L c =(L 2 +H 2 ) 1/2 according to Table according to Table according to Table

m/s N m N N N N N

Datum F NF =(1000*Q m )*(v-v 0 )/3600 Datum F NC =2000*v 2 *h 2 * F NS =(1500*B)/1000 F u =f*Cq*Ct*L c *[m ui +(m b +m m )*cos( )]*g+(m b +m m )*H*g+F NF +F NC F l =f*Cq*Ct*L c *[m li +m b cos( )]*g-m b *H*g+F Ns F=F u +F l

m iredu m iredl 9.1 9.2 Reduced Idler Mass per Meter of Conveyor Length Acceleration m ired as F us F ls 9.3 10.0 10.3 10.4 10.5 10.6 10.7 Required Force at starting Power Motor Efficiency Transmition Efficiency Overall Efficiency Required Power at Constant Operation Required Power at Starting Po Ps

m t

13.60 3.99 17.59 0.5 36,721 1,629 38,349

Kg/m Kg/m Kg m/s N N N

m iredu =0,9*m ui m iredl =0,9* m li m ired =0,9*(m ui +m li ) according to Table F us =a s *(m m +m b +m iredu )*L c +F u F ls =a s *(m b +m iredl )*L c +F l F s =a s *(m m +2*m b +m ired )*L c +F

Fs

0.95 0.95 0.90 67.4 97.7 KW KW =

m

P =(F *v)/( *1000) P s =(F s *v)/( *1000)

10.8 10.9 11.0 11.1 11.2 11.3 11.4 11.4 11.5 12.0 12.1 12.2 12.3 12.4 12.5 12.6 12.7 12.8 12.9 12.10 12.11

Required Nominal Power Selected Motor Power Tensioning Mimimum Necessary Tention for 2% Deflection Mimimum Necessary Tention for 1.5% Deflection Mimimum Necessary Tention for 1.0% Deflection Strength of the Belt Maximum Permisible Stain at Normal Operation Maximum Permisible Strain at Start Up Belt Tensions Case 01 Friction Coefficient Contant angle Factor c1 Factor c2 Normal Operation

Pr P

81.4 90.0

KW KW

P r =P s /1.2 according to Table

T 0,2 T 0,1.5 T 0,1 Tb T op T st

9,614 12,921 19,227 31,500 47,250

N N N N N

T 0,2 =6,25*(m b +m m )*a nu *g T 0,1.5 =8,4*(m b +m m )*a nu *g T 0,1 =12,5*(m b +m m )*a nu *g T b =B*T s T op =0,10*T b T st =0,15*T b

315,000 N

0.35 200 c1 c2 T 0,2 Fu Fl T3 T2 T1 A T 0,2 F us F ls T3 T2 T1 A 1.42 0.42 9,614 25,847 582 9,614 9,032 35,460 -0.53 9,614 36,721 1,629 9,614 7,985 46,334 -2.41 N N N N N N N N N N N N

Datum according to Table Datum according to Table c 1 =1+1/(e c 2 =1/(e -1) -1)

T 3 =T 0,2 T 3 =T 2 +F l T 1 =T 3 +F u A=e 1/ 2 0

(?)

12.12 During Start Up 12.13 12.14 12.15 12.16 12.17 12.18 12.19 13.1 13.2 13.2 13.3 13.4 13.5 13.6 13.7 13.8 13.9 13.10 13.11 13.12 During Start Up 13.13 13.14 13.15 13.16 13.17 13.18 13.19 14.0 14.1 Belt Tensions Case 03 Friction Coefficient 0.35 Datum according to Table T 0,1.5 F us F ls T3 T2 T1 A 12,921 36,721 1,629 12,921 11,292 49,641 -1.00 N N N N N N T 3 =T 0,1.5 T 3 =T 2 +F l T 1 =T 3 +F u A=e 1/ 2 0

T 3 =T 0,2 T 3 =T 2 +F l T 1 =T 3 +F u A=e 1/ 2 0

(?)

Belt Tensions Case 02 Friction Coefficient Contant angle Factor c1 Factor c2 Normal Operation c1 c2 T 0,1,5 Fu Fl T3 T2 T1 A 0.35 200 1.42 0.42 12,921 25,847 582 12,921 12,339 38,767 0.25 N N N N N N T 3 =T 0,1.5 T 3 =T 2 +F l T 1 =T 3 +F u A=e 1/ 2 0

Datum according to Table Datum according to Table c 1 =1+1/(e c 2 =1/(e -1) -1)

(?)

(?)

14.2 14.3 14.4 14.5 14.6 14.7 14.8 14.9 14.10 14.11

Contant angle Factor c1 Factor c2 Normal Operation c1 c2 T 0,1 Fu Fl T3 T2 T1 A T 0,1 F us F ls T3 T2 T1 A

200 1.42 0.42 19,227 25,847 582 19,227 18,645 45,074 0.98 19,227 36,721 1,629 19,227 17,598 55,948 0.21

Datum according to Table c 1 =1+1/(e c 2 =1/(e -1) -1)

N N N N N N T 3 =T 0,1 T 3 =T 2 +F l T 1 =T 3 +F u A=e N N N N N N T 3 =T 0,1 T 3 =T 2 +F l T 1 =T 3 +F u A=e 1/ 2 0

1/

2 0

(?)

14.12 During Start Up 14.13 14.14 14.15 14.16 14.17 14.18 14.19

(?)

Potrebbero piacerti anche

- Saddle Support Calculation PD 5500,2000 Annex.G)Documento26 pagineSaddle Support Calculation PD 5500,2000 Annex.G)Neeraj Kumar33% (3)

- Coupled CFD-DEM Modeling: Formulation, Implementation and Application to Multiphase FlowsDa EverandCoupled CFD-DEM Modeling: Formulation, Implementation and Application to Multiphase FlowsNessuna valutazione finora

- JSW Toranagallu 24m Gallery DesignDocumento5 pagineJSW Toranagallu 24m Gallery DesignvivekNessuna valutazione finora

- Conveyor CalculationDocumento40 pagineConveyor CalculationAnonymous 5XvUbWynnNessuna valutazione finora

- Belt Conveyor Capacity CalculatorDocumento5 pagineBelt Conveyor Capacity CalculatorramsaiNessuna valutazione finora

- Beam Deflection CalculationDocumento2 pagineBeam Deflection CalculationAriful IslamNessuna valutazione finora

- 123Documento29 pagine123Pravin Narkhede100% (1)

- M 275 ContentDocumento40 pagineM 275 ContentAnonymous DQ4wYUmNessuna valutazione finora

- Chain Conveyors Design Calculation 400 TDocumento3 pagineChain Conveyors Design Calculation 400 TAbderrahim AbarayNessuna valutazione finora

- Apron Weigh FeederDocumento4 pagineApron Weigh FeederRaji SuriNessuna valutazione finora

- Chain Conveyor ExampleDocumento4 pagineChain Conveyor ExampledeeptidhaNessuna valutazione finora

- Ball Screw Selection ExerciseDocumento7 pagineBall Screw Selection ExercisemaddyaugNessuna valutazione finora

- Rumus BucketDocumento4 pagineRumus BucketBimahsNessuna valutazione finora

- Conveyor Design Summary ReportDocumento53 pagineConveyor Design Summary ReportTotok ChemScoutNessuna valutazione finora

- BELT CONVEYOR DESIGN FORMULASDocumento3 pagineBELT CONVEYOR DESIGN FORMULASwidyaditya8Nessuna valutazione finora

- Conveyor Design Summary ReportDocumento1 paginaConveyor Design Summary ReportAlejandro Castro0% (1)

- Screw ConveyorDocumento4 pagineScrew ConveyorRaji SuriNessuna valutazione finora

- Conveyor CalculationDocumento46 pagineConveyor CalculationBuditama Chandranegara100% (1)

- Belt Conveyor CalcsDocumento3 pagineBelt Conveyor Calcspandu_chemengNessuna valutazione finora

- Apron FeederDocumento2 pagineApron FeederRaji Suri100% (1)

- Belt Conveyor CalculationDocumento8 pagineBelt Conveyor CalculationFarrahxviiiNessuna valutazione finora

- Appendix A1Documento5 pagineAppendix A1Thomas Stephen100% (1)

- Design of Belt ConveyorsDocumento5 pagineDesign of Belt ConveyorsYashrajNessuna valutazione finora

- Conveyor Screws PDFDocumento9 pagineConveyor Screws PDFldavilaluceralNessuna valutazione finora

- RENOLD CHAIN DOUBLE PITCH SPROCKET DESIGN SPECIFICATIONSDocumento1 paginaRENOLD CHAIN DOUBLE PITCH SPROCKET DESIGN SPECIFICATIONSWaris La Joi Wakatobi0% (1)

- Belt Selection CalculationDocumento29 pagineBelt Selection CalculationElwathig BakhietNessuna valutazione finora

- Design and Analysis of Screw Conveyor at Inlet of Ash/Dust ConditionerDocumento6 pagineDesign and Analysis of Screw Conveyor at Inlet of Ash/Dust ConditionerMohd HafizzNessuna valutazione finora

- Conveyor Design DraftDocumento25 pagineConveyor Design DraftDxFxNessuna valutazione finora

- Bucket Elevator Design StudyDocumento24 pagineBucket Elevator Design StudyIrfan AhmedNessuna valutazione finora

- CHAIN PULL AND POWER CALCULATION FOR HORIZONTAL AND INCLINED CONVEYORDocumento2 pagineCHAIN PULL AND POWER CALCULATION FOR HORIZONTAL AND INCLINED CONVEYORdeddy ariyanto100% (1)

- Belt Tension CalculationDocumento5 pagineBelt Tension Calculationmanoj983@gmail.comNessuna valutazione finora

- Calculate Bucket Elevator CapacityDocumento2 pagineCalculate Bucket Elevator CapacityBùi Hắc HảiNessuna valutazione finora

- BELT FEEDER Preliminary Dimension IngDocumento29 pagineBELT FEEDER Preliminary Dimension IngoscarjofkNessuna valutazione finora

- Conveyor Chains TsubakiDocumento184 pagineConveyor Chains Tsubakitepu msosaNessuna valutazione finora

- BELT CONVEYOR - Discharge TrajectoryDocumento1 paginaBELT CONVEYOR - Discharge TrajectoryEslam FaroukNessuna valutazione finora

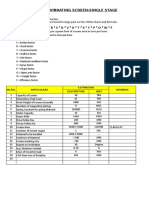

- Vibrating ScreensDocumento3 pagineVibrating ScreensvinodsnNessuna valutazione finora

- BELT CONVEYOR POWER ESTIMATEDocumento7 pagineBELT CONVEYOR POWER ESTIMATEgullipalli srinivasa raoNessuna valutazione finora

- Screw Conveyor CalculationDocumento1 paginaScrew Conveyor Calculation113314Nessuna valutazione finora

- CONVEYOR CALCULATION SHEET DraftDocumento24 pagineCONVEYOR CALCULATION SHEET DraftRaghava0% (1)

- Belt Conveyor Drive Sizing CalculationsDocumento3 pagineBelt Conveyor Drive Sizing Calculationsmishra_1982Nessuna valutazione finora

- Conveyor Belt Scale Data SheetDocumento2 pagineConveyor Belt Scale Data SheetEDUARDONessuna valutazione finora

- Belt Bucket Elevator DesignDocumento14 pagineBelt Bucket Elevator Designking100% (1)

- TS of Travelling TripperDocumento10 pagineTS of Travelling TripperShashank HegdeNessuna valutazione finora

- 45 TPH DRAG CHAIN CONVEYOR DESIGNDocumento7 pagine45 TPH DRAG CHAIN CONVEYOR DESIGNImam SampoernoNessuna valutazione finora

- BELT CONVEYOR - Discharge TrajectoryDocumento3 pagineBELT CONVEYOR - Discharge TrajectorySergio Diaz DuarteNessuna valutazione finora

- Conveyor 01Documento2 pagineConveyor 01kmatsNessuna valutazione finora

- Conveyor CalculationDocumento32 pagineConveyor CalculationsutanuprojectsNessuna valutazione finora

- Data Sheet Jet Pulse Bag FilterDocumento1 paginaData Sheet Jet Pulse Bag FilterHassan SleemNessuna valutazione finora

- Belt Conveyor Take Up DesignDocumento4 pagineBelt Conveyor Take Up DesignKroya HunNessuna valutazione finora

- Belt Conveyor PowerDocumento10 pagineBelt Conveyor PowerRyukiNessuna valutazione finora

- Slat ConveyorDocumento8 pagineSlat ConveyorpkjddjsydNessuna valutazione finora

- Chain Conveyor Design Calculation for 400 TPH Drag ConveyorDocumento3 pagineChain Conveyor Design Calculation for 400 TPH Drag Conveyorsudip giriNessuna valutazione finora

- Pneumatic Transport Pressure Loss CalculationDocumento2 paginePneumatic Transport Pressure Loss CalculationMugurelVasilescuNessuna valutazione finora

- Screw ConveyorsDocumento4 pagineScrew ConveyorsAshish SharmaNessuna valutazione finora

- Belt Conveyor CapacityDocumento4 pagineBelt Conveyor CapacityPurnima ArkalgudNessuna valutazione finora

- System Characteristic Curve Shows Ventilation System Pressure LossDocumento5 pagineSystem Characteristic Curve Shows Ventilation System Pressure LossMichael LagundinoNessuna valutazione finora

- 3 Date 2 1 0 R e V I S I o N Checked by Checked by Approve DbyDocumento2 pagine3 Date 2 1 0 R e V I S I o N Checked by Checked by Approve DbyidilfitriNessuna valutazione finora

- Conveyor ChainsDocumento184 pagineConveyor ChainsAchinNessuna valutazione finora

- EISA504 IMO9471886 Preliminary Test ConditionsRev2 57334319 57226253Documento93 pagineEISA504 IMO9471886 Preliminary Test ConditionsRev2 57334319 57226253islimaNessuna valutazione finora

- ProblemsDocumento22 pagineProblemsSuresh GoudNessuna valutazione finora