Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

526607N DD Install USw

Caricato da

Sonit HandaDescrizione originale:

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

526607N DD Install USw

Caricato da

Sonit HandaCopyright:

Formati disponibili

R

I NSTA LLATI ON I NSTRUCTI ONS

(NOTE: FOR INTEGRATED PANEL PREPARATION INSTRUCTIONS REFER TO SUPPLIED SHEET)

part number 526607 N

05/ 2005

(page 1 of 12)

US CA

NOTE TO THE INSTALLER

1. Read t hese inst ruct ions complet ely and carefully.

2. Inst allat ion of t his DishDraw er requires basic

mechanical and elect rical skills.

3. Be sure t o leave t hese Inst ruct ions w it h t he Cust omer.

4. At t he complet ion of t he DishDraw er inst allat ion, t he

Inst aller must perform Final Check List as per Sect ion 12

of t hese Inst allat ion Inst ruct ions.

5. Remove all packaging mat erials supplied w it h t he

DishDraw er .

6. This dishw asher is manufact ured for indoor use only.

NOTE TO THE CUSTOMER

Keep these Installation Instructions with your User Guide

for future reference. The DishDrawer must be securely

anchored before it is operated.

WARNING!

Before i nstal l i ng the Di shDrawer , remove the house fuse or open

the ci rcui t breaker. Ensure al l water connecti ons are turned OFF. It i s

the responsi bi l i ty of the pl umber and el ectri ci an to ensure that each

i nstal l ati on compl i es wi th al l Codes and Regul ati ons.

Import ant !

These i nstructi ons must be fol l owed preci sel y to ensure correct

venti ng and operati on of the Di shDrawer . In the event of a faul t

rel ated to the i ncorrect i nstal l ati on, the i nstal l er wi l l be l i abl e for any

repai rs.

Import ant !

The Di shDrawer MUST be i nstal l ed to al l ow for future removal

from the encl osure i f servi ce i s requi red.

Import ant !

Improper i nstal l ati on i s not covered under the Warranty.

Import ant !

If the Di shDrawer i s to be rel ocated from one i nstal l ati on to

another i t must be kept upri ght to avoi d damage from water spi l l age.

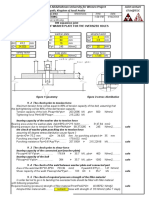

DOUBLE DD603 MODELS

DD603 PREFINISHED (show n left )

DD603 FLAT DOOR (not show n)

DD603I INTEGRATED (show n right )

SINGLE DS603 MODELS

DS603 PREFINISHED (show n left )

DS603 FLAT DOOR (not show n)

DS603I INTEGRATED (show n right )

BEFORE YOU START - DOUBLE & SINGLE MODELS

PARTS SUPPLIED

DOUBLE MODELS

Drain Hose

Support (1)

Drain Hose

Joiner (1)

Wire

Clips (2)

Installation Tabs (2)

Phillips 16mm

Screws (7)

Prefinished

Toe Kick (1)

White prefinished toe kick kit p/ n 526678

or Black prefinished toe kick kit p/ n 526679

or Iridium prefinished toe kick kit p/ n 527109

Moisture

Protection

Tape (1)

p/ n 527208

Drain Hose

Support (1)

Drain Hose

Joiner (1)

Wire

Clip (1)

Phillips 16mm

Screws (5)

Moisture

Protection

Tape (1)

p/ n 527208

SINGLE MODELS

TOOLS NEEDED

Wooden Chopping Board Drill & No.2 Phillips Bit

Tape Measure No.2 Phillips Screw driver

Spirit Level Flat Screw driver

Safet y Glasses Adjust able Wrench or M5 Socket

Ut ilit y Knife 1

1

/

2

(38mm) Hole Saw

Pencil Side Cut t ing Pliers

Sandpaper

SPARE PARTS INSTALLATION KIT FOR SINGLE & DOUBLE MODELS: p/ n 526676

INSTALLATION PREPARATION

ELECTRICAL PREPARATION

A) The sw it ched pow er out let must be out side t he DishDraw er

cavit y so t hat it is accessible aft er inst allat ion.

B) The sw it ched pow er out let must be bet w een 6 (150mm) and

18 (450mm) from t he DishDraw er cavit y.

C) Refer t o Page 9, St ep 5 for elect rical connect ion opt ions.

Import ant !

The services hole in t he DishDraw er cavit y needs t o be large

enough f or t he plug on t he pow er supply cord t o f it t hrough, but MUST

NOT be more t han 1

1

/

2

(38mm).

PLUMBING & DRAINAGE PREPARATION

A) A readily accessible valve must be inst alled in t he w at er supply pipe.

B) If t he supply pressure exceeds 145 psi (1000kPa), t hen a pressure

limit ing valve must be used.

C) Review Plumbing Opt ions on pages 4 or 6. Choose a met hod t hat best

suit s your needs.

D) A Drain Hose ext ension Kit P/ N 525798 w ill ext end t he drain hoses

by 141

3

/

4

(3.6m). The kit is available from t he nearest Fisher&Paykel

Aut horized Service Agent . DO NOT ext end beyond t his limit .

E) This Dishw asher s maximum drain height is 37

1

/

2

(950mm).

CAVITY PREPARATION

A) It is recommended t hat all cabinet ry surrounding t he DishDraw er

(including t he underside of t he count ert op) is sealed w it h an oil based

paint or moist ure-proof polyuret hane t o prevent possible st eam

damage. The air in t he cavit y can get very hot and humid (sat urat ed

at 122

o

F/ 50

o

C)

B) The self-adhesive moist ure prot ect ion t ape must be applied t o t he

underside of t he count ert op t o prevent moist ure damage, (refer t o

cavit y diagram pg 3 or 5). Be sure surfaces are dry and dust -free

prior t o applicat ion.

C) Be sure t he cavit y provides sufficient mat erial t o secure t he DishDraw er

using t he mount ing t abs (refer t o st ep 1, page 7). If t here is

not hing t o screw t o, add a brace. See page 3 or 5 for screw locat ions.

D) The services hole MUST be immediat ely adjacent t o t he rear low er

corner of t he cabinet ry. If not , t he hoses w ill prevent t he

DishDraw er being pushed back int o t he cavit y all t he w ay. The hole

can be locat ed on eit her side depending on t he locat ion of t he

services.

E) Be sure t he cavit y sides are plumb (vert ical) as t his w ill assist w it h

levelling t he DishDraw er .

F) Minimum clearances:

ELECTRICAL INFORMATION

POWER SUPPLY CORD

A) Care should be t aken w hen t he appliance is inst alled or

removed t o reduce t he likelihood of damage t o t he pow er

supply cord.

B) If t he pow er supply cord is damaged, it must be replaced by

t he Manufact urer, Service Agent or a similarly qualified person

in order t o avoid a hazard.

GROUNDING INSTRUCTIONS

A) This appliance must be grounded. In t he event of malfunct ion or

breakdow n, grounding w ill reduce t he risk of elect ric shock by

providing a pat h of least resist ance for elect ric current .

2

WARNING!

Improper connect ion of t he equipment -grounding conduct or can result

in a risk of elect ric shock. Check w it h a qualif ied elect rician or

service represent at ive if you are in doubt as t o w het her t he appliance

is properly grounded.

B) This appliance is equipped w it h a pow er supply cord having an

equipment -grounding conduct or and an eart hing plug. The pow er

supply plug must be plugged int o an appropriat e out let t hat is inst alled

and eart hed in accordance w it h all local Codes and Ordinances.

WARNING!

Do not modif y t he pow er supply plug provided w it h t he appliance - if

it w ill not f it t he out let , have a proper out let inst alled by a qualif ied

elect rician. Do not use an ext ension cord, adapt or plug or mult iple

out let box.

R

Washer

(1)

Clamp

(1)

Edge Protector (1)

Flexible Extrusion

for Sides (2)

Flexible Extrusion

for Top (1)

Edge

Protector (1)

Flexible Extrusion for Sides (2)

Clamp (1) Washer (1)

1

/

8

(2.5mm)

1

/

8

(2.5mm)

1

/

2

(13mm)

DOUBLE MODELS

SERVICES SPECIFICATIONS

TOE KICK DEPTH

Prefinished & Flat Door 2 -4

3

/

8

(50-110mm);

Integrated 5 (127mm) less t he Toe Kick Panel t hickness. Minimum Panel

t hickness using t he supplied screw s is

3

/

8

(9mm).

# DOOR FRONT HEIGHT

Prefinished & Flat Door 30

5

/

64

(764mm);

Integrated 28

1

/

4

(717.5mm) minimum.

THE CAVITY

23

5

/

8

" (600mm)

Mih thickhess

of cavity sides

is

5

/

8

" (16mm)

Screw

w (14mm)

from froht of cabihetry

+

90

+

Moisture

Frotectioh

Tape

4

"

(

1

0

0

m

m

)

4

5

/

16

"

(109.5mm)

3

2

3

/

8

"

-

3

4

3

/

4

(

8

2

2

.

5

-

8

8

2

.

5

m

m

)

22

7

/

8

" (580mm)

throughout cavity

3

13

/

16

"

(97mm)

1

9

7 /8

"

(

5

0

5

m

m

)

2

5

1

3

/

3

2

"

(

6

4

5

.

5

m

m

)

1

1

/

2

" (38mm)

services hole

immediately

adjaceht to corher,

cah be either side

ccon|e||c

mc/s|o|e

|c|ec|/cn

|ae

w(13mm)

w

(13mm)

NOTE: All dept h measurement s are t aken

from t he front face of t he adjacent cabinet ry.

WARNING!

Be sure t he edges of t he services hole

are smoot h or covered. If t he services

hole is t hrough a met al part it ion t he hole

must be prot ect ed w it h t he Edge Prot ect or

provided t o prevent damage t o t he pow er

cord or hoses.

WATER CONNECTION

Recommended HOT

(Maximum 140F/ 60C).

Supplied hose t o suit

3

/

8

(9mm)

male compression fit t ing.

WATER SOFTENER MODELS

Refer t o your DishDraw er User Guide for

how t o set up your w at er soft ener.

WATER PRESSURE

DRAIN CONNECTION

Drain Hose Joiner t o suit

3

/

4

5

/

64

,

5

/

8

5

/

64

and

1

5

/

64

w ast e t ees.

ELECTRICAL CONNECTION

110-120 VAC pow er out let , 9 Amps Minimum.

LENGTH OF SERVICES (FROM PRODUCT EXIT POINT)

Drain hose - 88

9

/

16

(2250mm)

Inlet hose - 68

7

/

8

(1750mm)

Pow er supply cord - 44 (1125mm)

NOTE: Services approximat ely exit product 7

7

/

16

(189mm) from left ;

21

5

/

8

(550mm) from front ; 31

1

/

4

(793mm) from t op.

3

R

Maximum Minimum

Wat er Soft ener Models 145 p.s.i. (1000kPa) 14.5 p.s.i. (100kPa)

Ot her Models 145 p.s.i. (1000kPa) 4.3 p.s.i. (30kPa)

20

15

/

32

"

(520mm)

Drawer Opeh

3

0

5

/

6

4

"

(

7

6

4

m

m

)

22

7

/

16

"

(570mm)

23

7

/

16

"

(595mm)

3

2

1

/

4

"

-

3

4

5

/

8

"

(

8

1

9

.

5

-

8

7

9

.

5

m

m

)

2" - 4

3

/

8

"

(50-110mm)

Side View

22

7

/

16

"

(570mm)

3

2

1

/

4

"

-

3

4

5

/

8

"

(

8

1

9

.

5

-

8

7

9

.

5

m

m

)

5

/

64

"

(2mm)

Tab

5

/

16

"

(8mm)

#

*

These marks indicat e mount ing t ab screw

locat ions (refer t o st ep 1 page 7)

Prefinished model show n

* For an Int egrat ed DishDraw er t he

product dept h is specified w it h an

11

/

16

(18mm) Int egrat ed Panel t hickness.

* * Dept h of product excludes Curvat ure (1

3

/

16

(30mm) Prefinished only,)

or Handle.

* *

M

A

X

h

e

i

g

h

t

t

o

t

o

p

o

f

A

I

R

B

R

E

A

K

(

c

o

u

n

t

e

r

t

o

p

o

r

w

a

l

l

-

m

o

u

n

t

e

d

)

3

7

3

/

8

(

9

5

0

m

m

)

DOUBLE MODELS

PLUMBING OPTIONS

OPTION 1

DishDraw er and St andpipe 1

1

/

2

(38mm) w it h Air Gap.

OPTION 2

DishDraw er w it h Wast e Disposal.

2

9

1

/

2

-

3

4

3

/

4

(

7

5

0

m

m

-

8

8

2

.

5

m

m

)

OPTION 3

DishDraw er using Air Break w it h Drain Hose Joiner.

4

R

NOTE: Prefinished Model is shown. There is no variation

in plumbing between models. Option 1 is the preferred

option. Drains will need to be separated to satisfy Kosher

requirements. We suggest you confirm acceptability with

your local Rabbi in respect to Kosher installations.

2

9

l

/

2

-

3

4

3

/

4

(

7

5

0

m

m

-

8

8

2

.

5

m

m

)

WATER CONNECTION

Recommended HOT

(Maximum 140F/ 60C).

Supplied hose t o suit

3

/

8

(9mm) male

compression fit t ing.

WATER SOFTENER MODELS

Refer t o your DishDraw er User Guide

for how t o set up your w at er soft ener.

WATER PRESSURE

DRAIN CONNECTION

Drain Hose Joiner t o suit

3

/

4

5

/

64

and

5

/

8

5

/

64

w ast e t ees.

ELECTRICAL CONNECTION

110-120 VAC pow er out let , 4.5 Amps Minimum.

WEIGHT

Full 93 lb (42kg) Prefinished

Empt y 62 lb (28kg) Prefinished

SINGLE MODELS

1

6

3

/

3

2

(

4

0

9

m

m

)

22

7

/

16

"

(570mm)

5

/

64

"

(2mm)

Tab

5

/

16

"

(8mm)

Side View

20

15

/

32

"

(520mm)

Drawer Opeh

22

7

/

16

(570mm)

23

7

/

16

"

(595mm)

16

3

/

32

(409mm)

ccon|e||c

mc/s|o|e

|c|ec|/cn

|ae

w(13mm)

w

(13mm)

+

Mihimum

thickhess of

cavity sides

is

5

/

8

" (16mm)

90

1

1

/

2

" (38mm) services

hole immediately

adjaceht to corher,

cah be either side

+ +

+

Moisture

Frotectioh Tape

4

"

(

1

0

0

m

m

)

23

5

/

8

" (600mm)

22

7

/

8

" (580mm)

throughout cavity

2

5

/

8

"

(67mm)

3

13

/

16

"

(97mm)

1

6

7

/

3

2

"

(

4

1

2

m

m

)

1

9

7

/8

"

(5

0

5

m

m

)

R

SERVICES SPECIFICATIONS

LENGTH OF SERVICES (FROM PRODUCT EXIT POINT)

Drain hose - 88

9

/

16

(2250mm)

Inlet hose - 68

7

/

8

(1750mm)

Pow er supply cord - 44 (1125mm)

NOTE: Services approximat ely exit product 7

7

/

16

(189mm) from left ;

21

5

/

8

(550mm) from front ; 15

1

/

2

(393mm) from t op.

Maximum Minimum

Wat er Soft ener Models 145 p.s.i. (1000kPa) 14.5 p.s.i. (100kPa)

Ot her Models 145 p.s.i. (1000kPa) 4.3 p.s.i. (30kPa)

THE CAVITY

NOTE: All dept h measurement s are t aken

from t he front face of t he adjacent cabinet ry.

WARNING!

Be sure t he edges of t he services hole

are smoot h or covered. If t he services

hole is t hrough a met al part it ion t he

hole must be prot ect ed w it h t he Edge

Prot ect or provided t o prevent damage t o

t he pow er cord or hoses.

NOTE: To align draw er front t o adjacent

cabinet ry, t he product t o count ert op

clearance can be increased from

1

/

8

(3mm).

Import ant !

Adj acent cabinet ry must

not ext end above

cavit y base.

5

R

These marks indicat e mount ing

t ab screw locat ions

(refer t o st ep 1 page 7)

**

*

Prefinished model show n

* For an Int egrat ed DishDraw er t he product dept h is specified w it h an

11

/

16

(18mm) Int egrat ed Panel t hickness.

* * Dept h of product excludes Curvat ure (1

3

/

16

(30mm) -

prefinished only), or Handle.

SINGLE MODELS

OPTION 1

DishDraw er and St andpipe 1

1

/

2

(38mm) w it h Air Gap.

OPTION 2

DishDraw er w it h Wast e Disposal.

M

A

X

h

e

i

g

h

t

t

o

t

o

p

o

f

A

I

R

B

R

E

A

K

(

c

o

u

n

t

e

r

t

o

p

o

r

w

a

l

l

-

m

o

u

n

t

e

d

)

3

7

3

/

8

(

9

5

0

m

m

)

2

9

l

/

2

-

3

4

3

/

4

(

7

5

0

m

m

-

8

8

2

.

5

m

m

)

2

9

l

/

2

-

3

4

3

/

4

(

7

5

0

m

m

-

8

8

2

.

5

m

m

)

6

PLUMBING OPTIONS

R

NOTE: Prefinished Model is shown. There is no variation

in plumbing between models. Option 1 is the preferred

option. Drains will need to be separated to satisfy Kosher

requirements. We suggest you confirm acceptability with

your local Rabbi in respect to Kosher installations.

OPTION 3

DishDraw er using Air Break w it h Drain Hose Joiner.

PLEASE NOTE: Your model of DishDraw er may differ from t he model show n in t he inst allat ion

diagrams. Inst allat ion is similar for all models for eit her Single or Double models. Informat ion referring

t o Single models only is highlight ed in blue. Inst allat ion diagrams have been simplified t o enable

clearer inst ruct ion. FOR INTEGRATED PRODUCTS FOLLOW THE INTEGRATED PANEL PREPARATION

INSTRUCTIONS P/ N 526608, BEFORE MOVING THE PRODUCT INTO THE CAVITY.

R

READ THESE INSTRUCTIONS

COMPLETELY AND CAREFULLY.

Import ant !

DO NOT push

middle of draw er(s).

MOUNTING TAB OPTIONS

The mount ing t abs are in pairs, one on each side of t he product . They are

used t o secure t he product t o t he cavit y sides. Inst allat ion requires t w o

set s of t ab pairs be used. DOUBLE MODELS ONLY - A and B t ab pairs

OR B and C t ab pairs may be used. All t abs w ould be opt imum.

If t he t op inst allat ion t abs C are t o be used, fit t o t he chassis by

insert ing int o t he t op slot s as show n. Ensure t he t abs are fully

locked in place.

Opt ional Flexible Ext rusion

If t he cavit y is 24 x 34

1

/

2

(610mm x 876mm) flexible ext rusions

can be at t ached along t he t op and sides of t he product . Open t he

draw er(s) t o expose t he chassis t rim. Remove ext rusion backing

and adhere t o t he side and t op of DishDraw er . Refer t o t he

draw ing for correct placement .

Be sure t hat ext rusions do not prevent t he draw er from closing

complet ely.

Check cavit y for any obst ruct ions t hat may int erfere w it h sliding

t he product back. DOUBLE MODELS ONLY - loosen t he feet first .

Push product int o cavit y t o suit adjacent cabinet ry. Do not push

middle of draw er(s). Be sure inlet , drain hose(s) and pow er supply

cord are not rest rict ed or damaged by carefully pulling all excess

lengt h t hrough t he services hole, w hile t he product is being pushed

back int o t he cavit y.

FOR SINGLE MODELS, check t hat t he base of t he product is not

bow ed. Do not rest single models on your knee w hen moving t hem

int o t he cavit y.

1

2

3

Import ant ! (SINGLE MODELS ONLY).

The product may move. Mark chassis posit ion on cavit y.

SINGLE MODELS ONLY. Gent ly open t he draw er and mark t he

chassis posit ion on t he cavit y, before removing t he t ub.

Open t he draw er (bot t om draw er in DOUBLE MODELS). Release

t he t ub by depressing t he right hand t ub clip and pushing it back

1

3

/

16

(30mm). Repeat on t he left hand side.

Lift t he t ub up off t he draw er runners.

Slide bot h runners back int o t he product .

Place t he t ub ont o t he floor.

For SINGLE MODELS, depending on t he height of t he cavit y, t he t ub

w ill need t o be support ed, eg on a chair.

6

7

1

3

2

5

9

7

6

8

9

8

INSTALLATION INSTRUCTIONS

STEP 1: MOVING THE PRODUCT INTO THE CAVITY

WARNING!

Be caref ul of

sharp edges.

STEP 2: REMOVING THE TUB

5

7

4

4

SINGLE MODELS ONLY

Check t he posit ion of t he chassis is st ill w here marked on t he cavit y,

before securing t he product .

There are four

5

/

8

(16mm) round holes, t w o on t he left and t w o on

t he right hand side in t he sound insulat ion. These provide access t o

t he mount ing t abs.

To secure t he product t o t he cabinet ry use a

5

/

8

(16mm)

Phillips screw in each mount ing t ab.

Make sure t he sound insulat ion is posit ioned correct ly before

cont inuing inst allat ion.

DOUBLE MODELS ONLY

Screw t he t w o t op t abs t o t he underside of bench. Use t he supplied

Phillips

5

/

8

(16mm) screw s. Tabs can accommodat e a maximum of

3

/

4

(19mm) vert ical gap.

DOUBLE MODELS ONLY

Adjust t he height of t he product t o suit t he cabinet ry, by t urning t he

feet from inside t he product using a w rench or M5 socket .

TIP - gent ly t ake t he load off each foot using t he slide and

t hen t urn by hand.

NOTE: For integrated products, the upper panel may be

aligned with the top of the adjacent cabinetry, provided

a minimum

3

/

16

(5mm) clearance from the counter is

maintained.

Import ant !

The product must be levelled t o w it hin

3

/

32

(2.5mm) f rom f ront t o

back, and side t o side.

Import ant !

The product should NOT support any part of t he kit chen cabinet ry.

TIP - Place a spirit level on t he drawer runners t o level t he

product .

R

INSTALLATION INSTRUCTIONS

STEP 4: SECURING THE PRODUCT

STEP 3: ADJUSTING THE FEET (DOUBLE MODELS ONLY)

11

12

13

11

12

13

8

10

10

3

/

16

(5mm)

R

INSTALLATION INSTRUCTIONS

STEP 5: ELECTRICAL CONNECTION

To refit t he t ub, make sure bot h of t he lat ches at t he rear of each

draw er runner are facing forw ard. Ensure hoses are hooping

upw ard. Place t he t ub on t he half open draw er runners and close

t he draw er.

Import ant !

Bef ore ref it t ing t he t ub, be sure t he hoses are not t w ist ed and t he

lat ches at t he rear of each draw er runner are f acing f orw ard.

Import ant !

Be sure t he t ub clips on bot h sides are reset .

Check t he t ub clips have reset on bot h sides of t he t ub. If not , pull

t he t ub clips forw ard unt il t he t ub clip but t on is reset .

STEP 6: REFITTING THE TUB

16

16

9

14

15

WARNING!

The product MUST NOT be

plugged in at t his st age.

WARNING!

If permanent ly connect ing be

sure t he pow er is isolat ed.

Be sure t here is a pow er out let in reach of t he supplied pow er cord.

If t here is not a suit able out let available t hen have one inst alled by a

qualified elect rician.

Do not use an ext ension cord.

14

Alt ernat ively, t he DishDraw er may be permanent ly connect ed t o a

flexible conduit .

Remove t he pow er supply cord. Remove round knock-out for cable

clamp. Fit suit able cable clamp for t he conduit and t erminat e t he

w iring as show n. Terminat e t he ground w ire using t he saddle t hat

w as used on t he exist ing eart h.

15

17

17

This view show s t he bot t om left -hand rear corner w it h t he cover removed

WARNING!

This must only be done by a cert if ied person.

At t ach t he Drain Hose Support t o t he cabinet ry (w it h t he screw

supplied) t o prevent siphoning and t o keep t he drain hose(s)

from kinking. If required, t he Drain Hose(s) may be t rimmed t o a

suit able lengt h.

2

9

1

/

2

-

3

4

3

/

4

(

7

5

0

m

m

-

8

8

2

.

5

m

m

)

2

9

1

/

2

-

3

4

3

/

4

(

7

5

0

m

m

-

8

8

2

.

5

m

m

)

DishDraw er w it h Hose Joiner (see Plumbing Opt ions).

Remember to slip the wire clip(s) on the drain hose(s) first.

Import ant !

Minimum hole size t o be connect ed t o t he w ast e t ee is

1

/

2

(12.7mm).

Be sure t he Drain Hose(s) are f ully ext ended t o prevent sagging

(see diagram t o t he lef t ).

The Drain Hose support must be used.

Drain Hose j oiner must not support w eight of hoses. Keep

excess lengt h of Drain Hose on t he DishDraw er side of t he

Drain Hose support or t rim t o suit .

When using t he st andpipe opt ion (see Plumbing Opt ions), hose(s)

should not ext end furt her t han 4

3

/

4

(120mm) dow n t he st andpipe,

in order t o prevent siphoning.

Slip a w ire clip over each drain hose, t hen push t he hoses int o

t he Drain Hose Joiner firmly, 5 clicks. Posit ion t he w ire clip(s)

bet w een t he t w o posit ioning ribs on t he Drain Hose Joiner.

At t ach t he Drain Hose Joiner t o t he w ast e t ee (see Plumbing

Opt ions). Ensure a snug fit . If required a hose clamp may be used.

R

INSTALLATION INSTRUCTIONS

STEP 7: CONNECTING THE DRAIN HOSE(S)

NOTE: SINGLE MODELS DO NOT HAVE A TOE KICK TO

INSTALL. PROCEED TO STEP 12 FINAL CHECK LIST.

WARNING!

DO NOT plug t he product in

at t his st age.

Import ant !

DO NOT cut t he inlet hose.

19

Connect t he Inlet Hose t o t he w at er supply. Be sure t he sealing

w asher is in place. The hose coupling must be t ight ened a furt her

half t urn aft er seal cont act .

TIP - Turn the water valve ON to check for any leaks.

Alt ernat ively flexible st ainless st eel hose can be plumbed direct ly t o

t he inlet valve using a

3

/

8

brass adapt or (p/ n 526161) available from

t he nearest Fisher & Paykel Aut horized Service Agent .

18a

19

20

STEP 8: CONNECTING THE INLET HOSE

10

18a

18b

18b

WATER

SUPPLY

20

On t he chosen groove cut dow n t he vert ical ribs at t he cent re and

t he ends using a knife. Cut along full lengt h w it h a knife. Turn Toe

Kick over, bend and t hen cut from front . Sand or scrape bot t om edge

t o remove rough pat ches.

Import ant !

Bef ore cut t ing ensure t he Toe Kick is posit ioned on a w ooden

chopping board t o avoid damage t o surrounding area.

WARNING!

Remove all sharp edges

To avoid a cut t ing hazard remove all sharp edges aft er t rimming.

Remove Toe Kick t abs by snapping t hem off.

Part ially open t he bot t om draw er. Turn Prefinished Toe Kick

upside dow n and hold vert ically against t he bot t om edge of t he

Tub side (not t he draw er front ).

Mark t he posit ion of t he bot t om edge of t he Tub side on t he Toe Kick.

Choose t he nearest groove t o t he pencil mark w hich w ill result

in t he short est Toe Kick.

Bot t om edge

of t ub si de

R

INSTALLATION INSTRUCTIONS

STEP 9: MEASURING THE TOE KICK (DOUBLE MODELS ONLY)

21

22

21

24

22

23

STEP 10: TRIMMING THE TOE KICK (DOUBLE MODELS ONLY)

23

24

11

R

INSTALLATION INSTRUCTIONS

Be sure product is level, securely fast ened t o t he cabinet ry and

opens and closes freely. The DishDraw er must be free t o close

w it h no resist ance from t he cabinet ry.

Be sure t he inlet hose t o valve connect ion is t ight ened a furt her half

t urn aft er seal cont act .

Be sure any knock-out s or plugs in drain connect ion have been

drilled out and drain connect ion has been made.

Turn ON t he pow er and w at er supply. The DishDraw er should

beep and light up.

Open t he draw er(s) and check operat ion of Wash Program Cont rol

Panel and check t he sprayarm(s) are in place and free t o rot at e.

On t he Wash Program Cont rol Panel select Rinse and close t he

draw er(s). St art t he program by pressing t he St art / Pause but t on.

Aft er t he Rinse program has finished, be sure t he machine has run

and drained correct ly.

Check w at er supply and drainage connect ion for leakage.

Repeat for each Drawer.

LEAVE ALL LITERATURE WITH CUSTOMER.

TROUBLE SHOOTING

Excessive w at er remaining above t he filt er plat e, aft er t he

rinse cycle; check for kinked drain hoses or blocked w ast e

connect ion.

No w at er supply; check w at er is connect ed, ON and t here is

t he specified w at er pressure.

DishDraw er does not light up w hen t he t ub is opened;

be sure pow er is connect ed and is sw it ched ON.

Wat er around w at er supply and drainage connect ions -

check connect ions, exist ing plumbing and hoses for leaks.

If a fault occurs, consult t he Fault Code Sect ion of t he

User Guide.

If unable t o resolve, cont act your Cust omer Care Cent re.

If you have any quest ions concerning t he inst allat ion of t his DishDraw er ,

please cont act your Fisher & Paykel Aut horized Service Agent .

FOR THE UNITED STATES OF AMERICA (USA) & CANADA

Fisher & Paykel Appliances

5900 Skylab Road

Hunt ingt on Beach

CA 92647

PHONE TOLL FREE 1888 9 FNP USA

1888 9 367 872

w w w . us a. f i s h e r p ay k e l . c o m

STEP 11: FITTING THE TOE KICK TO THE PRODUCT (DOUBLE MODELS ONLY)

STEP 13: CUSTOMER CARE

12

Import ant !

DO NOT over t ight en screw s.

Overt ight ening w ill damage t he plast ic mount ing det ail.

Part ly open bot t om draw er. Posit ion Toe Kick behind door and slide

ont o t he mount ing rails on t he underside of t ub.

Close bot t om draw er, check if flush w it h adjacent cabinet ry.

If required open draw er and adjust .

Note: Clearance between Toe Kick and floor must be

15

/

32

(12mm) minimum.

When Toe Kick is in posit ion, open bot t om draw er and gent ly fast en

t he Toe Kick screw s, on each side.

STEP 12: FINAL CHECKLIST (DOUBLE AND SINGLE MODELS)

25

25

26

26

Toe kick

mount ing rails

Potrebbero piacerti anche

- Ultimate Guide: Wiring, 8th Updated EditionDa EverandUltimate Guide: Wiring, 8th Updated EditionValutazione: 3.5 su 5 stelle3.5/5 (4)

- 16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsDa Everand16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsValutazione: 4 su 5 stelle4/5 (1)

- Washer PlateDocumento2 pagineWasher PlateНемања Караклајић100% (2)

- Article 312 Inspection and Repair of Shell and Tube Heat ExchangersDocumento12 pagineArticle 312 Inspection and Repair of Shell and Tube Heat ExchangersasifNessuna valutazione finora

- Training Duet-By WhirlpoolDocumento52 pagineTraining Duet-By Whirlpoolnibble1974Nessuna valutazione finora

- Seismic Design of RC Structures - SaatciogluDocumento146 pagineSeismic Design of RC Structures - SaatciogluAl MamunNessuna valutazione finora

- Manual3620 Pro-Grid DE Filter HaywardDocumento12 pagineManual3620 Pro-Grid DE Filter HaywardAries Roxas Enriquez AntonioNessuna valutazione finora

- Critical Section For Moment Critical Section For Shear and TorsionDocumento7 pagineCritical Section For Moment Critical Section For Shear and TorsionShashank Srivastava0% (1)

- Inspection & Testing Requirements Scope:: Test and Inspection PerDocumento2 pagineInspection & Testing Requirements Scope:: Test and Inspection PerdheenasweetNessuna valutazione finora

- Structural Design From First Principles by Michael Byfield (Solution Manual)Documento26 pagineStructural Design From First Principles by Michael Byfield (Solution Manual)Law AnsonNessuna valutazione finora

- Concrete Basements The New Design GuideDocumento38 pagineConcrete Basements The New Design Guideletuananhb100% (3)

- Info RASCHIG Column Internals-1101Documento100 pagineInfo RASCHIG Column Internals-1101Frits32100% (3)

- Split System Air Conditioners ManualDocumento20 pagineSplit System Air Conditioners ManualGiuseppe MaioranaNessuna valutazione finora

- Dtac100f1wdb Dtac120f1wdb Efsom 20190122Documento32 pagineDtac100f1wdb Dtac120f1wdb Efsom 20190122Jeffrey MacFarlaneNessuna valutazione finora

- User Manual Whirlpool Awm 235 3 eDocumento4 pagineUser Manual Whirlpool Awm 235 3 eZauf SatrapicusNessuna valutazione finora

- DU1055XTVS8Documento40 pagineDU1055XTVS8mrcmhNessuna valutazione finora

- Installation and Start-Up Instructions: 38YCC-50 HZ Split System Heat PumpDocumento8 pagineInstallation and Start-Up Instructions: 38YCC-50 HZ Split System Heat PumpAflredo FloresNessuna valutazione finora

- Installation Instructions - 8546448Documento32 pagineInstallation Instructions - 8546448sfkidNessuna valutazione finora

- Installation Manual TTD/TTT: Multi-Split System Condensing Unit 18,000-36,000 Btuh Models 50/60 HZDocumento16 pagineInstallation Manual TTD/TTT: Multi-Split System Condensing Unit 18,000-36,000 Btuh Models 50/60 HZchitak_80Nessuna valutazione finora

- Installation Instruction Sheet: Cassette TypeDocumento2 pagineInstallation Instruction Sheet: Cassette TypepepondeAvilesNessuna valutazione finora

- NFP Piston Series 5Documento12 pagineNFP Piston Series 5Elois grimonNessuna valutazione finora

- Honeywell Portable Air Conditioner MN Series ManualDocumento32 pagineHoneywell Portable Air Conditioner MN Series ManualKovacs JozsefNessuna valutazione finora

- Instruction Manual Central Vacuum Cyclovac Tradition Archive-2Documento105 pagineInstruction Manual Central Vacuum Cyclovac Tradition Archive-2ficioruNessuna valutazione finora

- Emerson ES3Documento40 pagineEmerson ES3SanjitDasguptaNessuna valutazione finora

- Cable Termination - Installation Instructions - 755LR - IsDocumento5 pagineCable Termination - Installation Instructions - 755LR - Isvladimir_71Nessuna valutazione finora

- Hotpoint Dishwasher - Model BFV62 ManualDocumento20 pagineHotpoint Dishwasher - Model BFV62 ManualMartin Lee SmithNessuna valutazione finora

- Project: Brooklyn School of Inquiry (K) Site: 50 Avenue P, Brooklyn, Ny 11204 CONTRACT NO: C000014965Documento8 pagineProject: Brooklyn School of Inquiry (K) Site: 50 Avenue P, Brooklyn, Ny 11204 CONTRACT NO: C000014965Rahul PillaiNessuna valutazione finora

- Pressure Transmitter Information & Installation Manual (M374)Documento10 paginePressure Transmitter Information & Installation Manual (M374)gusmilexaNessuna valutazione finora

- Tyco - Alarmno ZvonoDocumento4 pagineTyco - Alarmno ZvonoMuhidin KozicaNessuna valutazione finora

- BMRX Series Rotary Level Control: Operating InstructionsDocumento10 pagineBMRX Series Rotary Level Control: Operating Instructionstono notoNessuna valutazione finora

- Craftsman Wet/Dry Vacuum Owner's ManualDocumento11 pagineCraftsman Wet/Dry Vacuum Owner's Manualb0beiiiNessuna valutazione finora

- Dishwasher Installation Instructions: Import Ant!Documento14 pagineDishwasher Installation Instructions: Import Ant!Dmitriy SemakovNessuna valutazione finora

- LG HB965DF PDFDocumento151 pagineLG HB965DF PDFboroda2410100% (1)

- Manual de Servicio TV LCD Polaroid Modelos FLM-323B FLM-373B FLM-2632 FLM-2634 FLM-3232Documento52 pagineManual de Servicio TV LCD Polaroid Modelos FLM-323B FLM-373B FLM-2632 FLM-2634 FLM-3232Angel ContrerasNessuna valutazione finora

- Sony Kdl-40-52nx803 CH Az1hDocumento47 pagineSony Kdl-40-52nx803 CH Az1hIsmael CosgayaNessuna valutazione finora

- Installation Instructions - 8573715Documento20 pagineInstallation Instructions - 8573715oakvillecanadaNessuna valutazione finora

- LG BP335W PDFDocumento85 pagineLG BP335W PDFboroda2410100% (1)

- Washing Mashine Manual To Use W1A101Documento16 pagineWashing Mashine Manual To Use W1A101Paula PaulaNessuna valutazione finora

- US801453-TX9200-9500 Install and Service Manaul SW - 9 2Documento63 pagineUS801453-TX9200-9500 Install and Service Manaul SW - 9 2Rickz2k8Nessuna valutazione finora

- Karcher b102 Plus Operation User S Manual 20Documento20 pagineKarcher b102 Plus Operation User S Manual 20SALAH NETNessuna valutazione finora

- Instrument InstallationDocumento4 pagineInstrument InstallationadelmnrNessuna valutazione finora

- cv86 MeDocumento17 paginecv86 MeRakesh DashNessuna valutazione finora

- Service Manual Dishwashers Type: DW70Documento33 pagineService Manual Dishwashers Type: DW70ZeigtNessuna valutazione finora

- FisherPaykel 113584988 FP InstallGuide en HP60IDCHX3 HP90IDCHX3 IntegratedInsertRangehood 0 105938BDocumento23 pagineFisherPaykel 113584988 FP InstallGuide en HP60IDCHX3 HP90IDCHX3 IntegratedInsertRangehood 0 105938BArunBhutaNessuna valutazione finora

- Precautions For Proper Use of Air Conditioner: More User Manuals OnDocumento16 paginePrecautions For Proper Use of Air Conditioner: More User Manuals OnLeonardoNessuna valutazione finora

- Therma Flow Inst and Oper. Maint. ManualDocumento41 pagineTherma Flow Inst and Oper. Maint. ManualJOSUE FERNANDO FERNANDEZNessuna valutazione finora

- Terminales Termocontractiles PDFDocumento18 pagineTerminales Termocontractiles PDFcbeltranochoaNessuna valutazione finora

- Instructions For Use: Washer-DryerDocumento14 pagineInstructions For Use: Washer-DryerMurali Venkat NagNessuna valutazione finora

- Trane FWDDocumento12 pagineTrane FWDFrinaru CiprianNessuna valutazione finora

- Polaroid FLM Series 40 42 ServiceManual 20070415Documento52 paginePolaroid FLM Series 40 42 ServiceManual 20070415Edilberto AvilaNessuna valutazione finora

- Operating Instructions TH-42PWD5: Progressive Wide Plasma DisplayDocumento44 pagineOperating Instructions TH-42PWD5: Progressive Wide Plasma DisplayCookie MonstaNessuna valutazione finora

- Sony kdl32 40 46 52 60-Ex700 Chassis Az1-LDocumento76 pagineSony kdl32 40 46 52 60-Ex700 Chassis Az1-Ljordache81Nessuna valutazione finora

- BR-D95U: Instructions Video Cassette RecorderDocumento76 pagineBR-D95U: Instructions Video Cassette RecordercaroltanasescuNessuna valutazione finora

- Description: A B C DDocumento6 pagineDescription: A B C DNhuan NguyenNessuna valutazione finora

- TS10 - TS3000Documento65 pagineTS10 - TS3000Serrefriair Garcia RefriNessuna valutazione finora

- Owner'S Manual Dual Submerged Suction Outlet Frames & CoversDocumento8 pagineOwner'S Manual Dual Submerged Suction Outlet Frames & CoversnurfansyahNessuna valutazione finora

- Maquina Lavar e Secar Roupa INDESIT IWDC6105Documento16 pagineMaquina Lavar e Secar Roupa INDESIT IWDC6105Humberto MendesNessuna valutazione finora

- Sharp Lc-26ad22u SMDocumento86 pagineSharp Lc-26ad22u SMhuitlamenNessuna valutazione finora

- Installation & Maintenance Information IF 1721: ApplicationDocumento12 pagineInstallation & Maintenance Information IF 1721: ApplicationAndres VillacisNessuna valutazione finora

- Carver Cascade2 RapideDocumento8 pagineCarver Cascade2 Rapidepetrica laurentiuNessuna valutazione finora

- Advantage: Owner'S Manual Installation, Operation & PartsDocumento10 pagineAdvantage: Owner'S Manual Installation, Operation & PartsRetep Nhoj SelipamidNessuna valutazione finora

- BT-LH2550P BT-LH2550E: Operating InstructionsDocumento56 pagineBT-LH2550P BT-LH2550E: Operating InstructionsgfxtoolsczNessuna valutazione finora

- User's Manual: WS-4830SS WS-4836SSDocumento16 pagineUser's Manual: WS-4830SS WS-4836SSMarco TosiniNessuna valutazione finora

- Radio Shack TRS-80 Expansion Interface: Operator's Manual Catalog Numbers: 26-1140, 26-1141, 26-1142Da EverandRadio Shack TRS-80 Expansion Interface: Operator's Manual Catalog Numbers: 26-1140, 26-1141, 26-1142Nessuna valutazione finora

- Delco Manuals: Radio Model 633, Delcotron Generator Delco Radio Owner's Manual Model 633, Delcotron Generator InstallationDa EverandDelco Manuals: Radio Model 633, Delcotron Generator Delco Radio Owner's Manual Model 633, Delcotron Generator InstallationNessuna valutazione finora

- Delco Radio Owner's Manual Model 633; Delcotron Generator InstallationDa EverandDelco Radio Owner's Manual Model 633; Delcotron Generator InstallationNessuna valutazione finora

- Epolam 5015Documento2 pagineEpolam 5015Eduardo JoseNessuna valutazione finora

- Solar B.E.S.T.Documento24 pagineSolar B.E.S.T.Μιχάλης ΠολυδώρουNessuna valutazione finora

- Sustainable Materialization of Responsive ArchitectureDocumento20 pagineSustainable Materialization of Responsive ArchitectureAlexander TeohNessuna valutazione finora

- Chem Lab (Interpretation)Documento2 pagineChem Lab (Interpretation)CyberR.DomingoNessuna valutazione finora

- Price ListDocumento11 paginePrice ListJacy Maricor Reabad100% (1)

- Pump Performance Curve - XPS230-SS-VTSDocumento1 paginaPump Performance Curve - XPS230-SS-VTSjosephNessuna valutazione finora

- 4 Frictional ResistanceDocumento35 pagine4 Frictional Resistancebr1404Nessuna valutazione finora

- Machine Design r13 PaperDocumento13 pagineMachine Design r13 PaperyogeshwararaoNessuna valutazione finora

- Chapter 2 Literature ReviewDocumento26 pagineChapter 2 Literature ReviewSalvatory Lyakurwa67% (3)

- Fence Engineering ManualDocumento30 pagineFence Engineering ManualvklsNessuna valutazione finora

- Permeable PavementsDocumento16 paginePermeable PavementsPatricia MilesNessuna valutazione finora

- Earthcote Tradition Product Datasheet 4 July 2012 V3Documento2 pagineEarthcote Tradition Product Datasheet 4 July 2012 V3guidogiglioNessuna valutazione finora

- Istruct 2019 Bamboo PDFDocumento17 pagineIstruct 2019 Bamboo PDFNiamul IslamNessuna valutazione finora

- Ningbo Jinglefast Imp & Exp Co., LTD: Test CertificateDocumento1 paginaNingbo Jinglefast Imp & Exp Co., LTD: Test CertificateDennis Carlos Cueva MontufarNessuna valutazione finora

- Geotechnical Characteristics of An Erodible Soil Stabilised by LiDocumento229 pagineGeotechnical Characteristics of An Erodible Soil Stabilised by LiRatan KumarNessuna valutazione finora

- Augustin - A Contribution To The Design of Ribbed PlatesDocumento10 pagineAugustin - A Contribution To The Design of Ribbed Platesm2auNessuna valutazione finora

- Gold AlloysDocumento16 pagineGold AlloyscoldmailhotmailNessuna valutazione finora

- Roquette Industry Paper Board Brochure Corrugating PDFDocumento36 pagineRoquette Industry Paper Board Brochure Corrugating PDFsyifa latifa zahidaNessuna valutazione finora

- Design GuideDocumento3 pagineDesign GuidegvmindiaNessuna valutazione finora

- UNITEN ICCBT 08 Mechanical Properties of Foamed ConcreteDocumento10 pagineUNITEN ICCBT 08 Mechanical Properties of Foamed ConcreteLim Han JianNessuna valutazione finora

- Rme Pec Module 3 - Sept 2015Documento2 pagineRme Pec Module 3 - Sept 2015Bianca SañezNessuna valutazione finora

- Overview of EN and ISO Window Thermal Performance Standards: Calculation Methods Measurement MethodsDocumento1 paginaOverview of EN and ISO Window Thermal Performance Standards: Calculation Methods Measurement MethodsBojan BjelajacNessuna valutazione finora