Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Ecm 128

Caricato da

Balmukund AgarwalDescrizione originale:

Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Ecm 128

Caricato da

Balmukund AgarwalCopyright:

Formati disponibili

Datasheet

36320

MotoHawkControlSolutions

Microprocessor: Freescale MPC565, 56 MHz Memory: 1M Flash, 548K RAM, 8K Serial EEPROM, 64Kx8 Parallel EEPROM Operating Voltage: 932 Vdc Operating Temperature: 40 to +105 C (in benchmark marine engine application) Sealed connectors operable to 10 ft (3 m) submerged Inputs: 30 Analog 4 Low Frequency Digital 4 VR Frequency 2 Wide Range O2 (l) SensorInputs (Bosch LSU4.2) Dual Lambda Sensor Interface (switch type) 2 Dual Sensor Wide Band Knock Detector Input Outputs: 6x 3 A Peak/1 A Hold Injector Drivers 6x 7 A/3 A or 3 A/1 A Peak/Hold Inj. Drivers 16x TTL Level Ignition System 10x 3 A Low Side PWMs 1x 1.5 A Tachometer Output 2x 5 A H-Bridge PWMs 1x 10 A H-Bridge PWM 1x Relay Driver (Main Power) Datalinks: 2 CAN 2.0B Channels 1 ISO 9141 Channel (KWP2000/HWP2000, 10.4 kbps) 1 RS-485 Channel

ECM05651280701C

EngineControlModule (PartNo.82371238) Description

Presenting the ECM-0565-128-0701-C engine control module from Woodwards new MotoHawk Control Solutions product line. This rugged embedded controller is capable capable of operating in harsh automotive, marine, and off-highway applications. Numerous marine applications have proven the capability of this module. Based on the Freescale MPC565 family of microprocessors, the ECM-0565128-0701-C modules are capable of delivering complex control strategies. The onboard floating-point unit and high clock frequency allow software to be executed in shorter times. The CAN 2.0B datalink ensures interoperability with other vehicle systems. The ECM-0565-128-0701-C module is part of the ControlCore family of embedded control systems. MotoHawk Control Solutions ControlCore operating system, MotoHawk code-generation product, and MotoHawks suite of development tools enable rapid development of complex control systems. Woodward does not warranty this ECM based on information supplied in this datasheet, but only with an express and specific production supply agreement based on customers operating mode. Information in this datasheet is subject to change without prior notice. Please contact MotoHawk Control Solutions sales for more information.

Woodward 36320 p.2

1Input Signal Conditioning

1.1 KEY_SW (J1-B2), BATT (J1-B8), DRVG A (J2-A16), DRVG B (J2-A24), DRVG C (J2-A15), DRVG D (J2-B9), XDRG_A (J1-B24), XDRG_B (J1-A24), EST_RTN (J2-A22)

See Freescale MPC565 Datasheet for description of processor resources.

c

KEY_SW J1-B2 0.01uF 3.3K 16.5K 2.21K 1.0uF

51.1K 0.01uF ADC

3.3K

BATT J1-B8 0.01uF DRVG C J2-A15 DRVG A J2-A16 DRVG B J2-A24 DRVG D J2-B9 X DRG_A J1-B24

47uH

e

68uF

68uF

68uF

b c

ADCs WAKE REG

DRVG is connected to Battery Ground, XDRG is the transducer return. 1.2 DRVP (J2-A18, J2-A19) This is the source for the H-Bridges (via the Main Power Relay). The DRVP monitor is scaled for 42.5 V 12 V = 290 counts. 1.3 XDRP_A, XDRP_B (J1-B11, J1-A11) The XDRP monitors are scaled for 10 V 5 V = 512 counts.

AGND DGND

X DRG_B J1-A24 EST_RTN J2-A22

XDRG

PWR RF INJ GND GND GND

1.4 AN1M, AN2M, AN3M (J1-A14, J1-A18, J1-A8) These inputs are 10-bit 05 V ADCs, = 1 ms They are intended for potentiometers 1.5 AN4M (J1-A2) This input is a 10-bit 05 V ADCs, = 100 s. It is intended for a MAP sensor. 1.6 AN5MAN12M (J1-A30, J1-A6, J1-A21, J1-A17, J1-A25, J1-A16, J1-A26, J1-A15) These inputs are 10-bit 05 V ADCs, = 1 ms. They are intended for pressure sensors. 1.7 AN13M, AN26MAN28M (J1-A10, J1-C12, J1-C15, J1-C7) These inputs are 10-bit 05 V ADCs, =1 ms. They are intended for variable-resistance sensors such as thermistors.

Woodward 36320 p.3

1Input Signal Conditioning

1.8 AN14MAN25M (J1-A28, J1-A5, J1-A27, J1-A7, J1-C10, J1-C11, J1-C9, J1-C2, J1-C4, J1-C5 ,J1-C1, J1-C3) These input are 10-bit 05 V ADCs, =1 ms. They are intended for variable-resistance sensors such as thermistors.

(continued)

1.9 AN29M, AN30M (J1-C6, J1-C8) These inputs are 10-bit 05 V ADCs, =1 ms. They are intended for switch type Oxygen sensors.

1.10 EGO1P, EGO1N, EGO2P, EGO2N (J1-B3, J1-B4, J1-B5, J1-B6)

1.10.1 DG1M (J1-B7) Digital switch input; VIL=2.0 V max., VIH=2.5 V min.,

=5.1 s.

1.11 DG2M (J1-C16) Digital switch input; VIL=2.0 V max., VIH=2.5 V min.,

=1 ms.

1.12 DG3M, DG4M (J1-A19, J1-A9) Digital switch inputs; VIL=2.0 V max., VIH=2.5 V min., =5.1 s. They may be used for high speed MAF sensors.

Woodward 36320 p.4

1Input Signal Conditioning

1.13 CRANK, CNK_VR(J1-A13, J1-A2) CRANK input may be used with a Hall-Effect or Variable Reluctance sensor.

(continued)

1.14 CAM, CAM_VR(J1-A20, J1-A31) CAM input may be used with a Hall-Effect or Variable Reluctance sensor

1.15 SPD1, SPD2, SPD(J1-A1, J1-A12, J1-A32) Speed inputs may be used with a Hall-Effect or Variable Reluctance sensor.

1.16 EK1P, EK1N, EK2P, EK2N, EK3P, EK3N, EK4P, EK4N (J1-C19, J1-C20, J1-C21, J1-C22, J1-C23, J1-C24, J1-C13, J1-C14) These inputs are intended for wide-band piezoelectric knock sensors. 1.16.1 DG5, DG6 (J1-C23, J1-C24) Digital switch inputs; VIL=2.0 V max., VIH=2.5 V min., =5.1 s. They may be used for high-speed MAF sensors.

1.17 LSU1_UN, LSU1_IA, LSU1_IP, LSU1_VM, LSU2_UN, LSU2_IA, LSU2_IP, LSU2_VM (J1-B21, J1-B15, J1-B14, J1-B1, J1-B12, J1-B16, J1-B17, J1-B13) This circuit is compatible with the Bosch LSU4.2 sensor.

Woodward 36320 p.5

2Output Signal Conditioning

2.1 XDRP_A (J1-B11) Independent 5 V, 300 mA transducer power.

2.2 XDRP_B (J1-A11) Independent 5 V, 300 mA transducer power.

2.3 LSO1/LSUH1, LSO2/LSUH2 (J1-B20, J1-B19) These are low side drivers intended to drive heaters for the Lambda Sensing Units (1.17), 10 A continuous, 3 A PWM. LSO1 and 2 each use one leg of a 6 A dual diode part so average PWM current between the two can not exceed 6 A. The corresponding average load current allowed depends on the duty cycle. The higher the duty cycle, the less current will flow through the diode. 2.4 LSO 5 LSO 10 (J2-B12, J2-B15, J2-B17, J2-B19, J2-B18, J2-B20) These are low side drivers intended to.drive inductive loads, 4 A continuous, 3 A PWM.

2.5 LSO 3, LSO4 (J1-A23, J2-B21) These are low side drivers with current feedback, 4 A continuous, 3 A PWM.

Woodward 36320 p.6

2Output Signal Conditioning

2.6 H1+, H1-, H2+, H2(J2-A9, J2-A17, J2-B22, J2-B23) These outputs are high current drivers intended for loads that may be operated in either polarity such as DC motors.

(continued)

2.7 H3+, H3(J2-B16, J2-B24) These outputs are high current drivers intended for loads that may be operated in either polarity such as DC motors.

2.8 MPRD (J1-B18) This is a 1.5 A low side driver intended to drive a relay coil (1.1) that supplies DRVP used by the loads and H-Bridges (see above).

2.9 TACH (J1-A22) This is a 1.5 A low side driver intended to drive a tachometer.

2.10 EST1...EST12, EST13/LAMP1...EST16/LAMP4 (J2-A12, J2-A13, J2-A14, J2-A20, J2-A10, J2-A11, J2-A21, J2-A23, J2-B14, J2-B13, J2-B11, J2-B10, J2-B6, J2-B5, J2-B7, J2-B8) These are TTL level outputs intended for intelligent coil modules. Notes: Short circuit protection, open circuit and short circuit detection. Since EST_RTN (not shown) is a direct path to the ECM ground care must be taken not to introduce ground loops. EST_RTN is not designed to carry any significant current; it is a reference only. It should be open circuit unless the smart coil electronics provides an isolated logic ground reference. Care must also be taken not to introduce noise on EST_RTN. Electrical transients on EST_RTN can cause module upsets. EST13/LAMP1...EST16/Lamp4 may be used to drive resistive loads requiring up to 1.5 A.

5 V 130K

uP TPU PORT

EST_CTRL 100

EST

uP PORT

EST_LS_DIS DIAG (see notes)

EST_CTRL EST DWELL SPARK TRIGGER

Woodward 36320 p.7

2Output Signal Conditioning

2.11 INJ04, INJ05, INJ07...INJ09, INJ12 (J2-A6, J2-A8, J2-A2, J2-A4, J2-B3, J2-B1) Notes: When the injector output is on (duration) the current is regulated to either the peak or hold level, which is determined by the Current Select signal. Current regulation is implemented via a chopper drive and the recirculation path is via DRVP. If the output is off there is no leakage path to DRVP and flyback energy is dissipated via low-side avalanche.

(continued)

BATTERY

MAIN PWR RLY MPRD DIAG ( see notes)

uP MPIO PORT uP TPU PORT uP GPIO PORT

CURRENT SELECT

DRVP INJ

I N J E C T O R

DURATION

INJ CTRL

PEAK/! HOLD

DURATION PEAK/! HOLD INJECTOR ON PEAK TIME ( ~ 7/3 A) HOLD TIME ( ~ 3/1 A)

2.11.1 INJ01, ...INJ03, INJ06, INJ10, INJ11 (J2-A1, J2-A3, J2-A7, J2-A5, J2-B2, J2-B4) Notes: When the injector output is on (duration) the current is regulated to either the peak or hold level. Current regulation is implemented via a chopper drive and the recirculation path is via DRVP. If the output is off there is no leakage path to DRVP and flyback energy is dissipated via low-side avalanche.

BATTERY

MAIN PWR RLY MPRD DRVP DIAG (see notes) INJ

I N J E C T O R

uP TPU PORT

DURATION

INJ CTRL

uP PORT

PEAK/!HOLD

DURATION PEAK/!HOLD INJECTOR ON PEAK TIME (~ 3 A) HOLD TIME (~ 1 A)

3Communications

3.1 CAN1+, CAN1-, CAN2+, CAN2(J1-B9, J1-B10, J1-C17, J1-C18) 3.2 RS-485+, RS-485(J1-B22, J1-B23) 3.3 ISO 9141-K, ISO 9141-L (J1-A3, J1-A4) CAN 2.0B, Standard or Extended ID, up to 1 MBd. RS-485, programmable baud rate 1200 - 57600. 8 Bits, No parity, 1 Stop Bit KWP2000/HWP2000, 10.4 kBd

Woodward 36320 p.8

4Connector Pinouts

Pin # ECM J1-A1 J1-A2 J1-A3 J1-A4 J1-A5 J1-A6 J1-A7 J1-A8 J1-A9 J1-A10 J1-A11 J1-A12 J1-A13 J1-A14 J1-A15 J1-A16 J1-A17 J1-A18 J1-A19 J1-A20 J1-A21 J1-A22 J1-A23 J1-A24 J1-A25 J1-A26 J1-A27 J1-A28 J1-A29 J1-A30 J1-A31 J1-A32 ControlCore Resource Name SPD1 CNK_VRISO_9141_K ISO_9141_L AN15M AN6M AN17M AN3M DG4 AN13M XDRP_B SPD2 CNK AN1M AN12M AN10M AN8M AN2M DG3 CAM AN7M TACH LSO3 XDRG AN9M AN11M AN16M AN14M AN4M AN5M CAM_VRSPDFunction Auxiliary Speed Input Return for CRANK VR sensor Serial Data Link Variable Resistance Input Pressure Input Variable Resistance Input Pressure Input Discrete Switch, Frequency Potentiometer Input Transducer Power B (5 V) Auxiliary Speed Input Crank Position Signal Pressure Input Pressure Input Pressure Input Pressure Input Pressure Input Discrete Switch, Frequency Cam Position Signal Pressure Input Tachometer Output PWM with current feedback Transducer Ground Pressure Input Pressure Input Variable Resistance Input Variable Resistance Input Pressure Input Pressure Input Return for CAM VR sensor Return for SPD VR sensors ISO 9141 Compliant 1K Pull Up 51K Pull Down 1K Pull Up 220K Pull Down 1K Pull Up 2.2K Pull Up Transducer Power VR or HALL Effect VR or HALL Effect 220K Pull Down 51K Pull Down 51K Pull Down 51K Pull Down 220K Pull Down 1K Pull Up VR or HALL Effect 51K Pull Down 4.75K Pull Up 4 A continuous, 3 A PWM Return for Transducers 51K Pull Down 51K Pull Down 1K Pull Up 1K Pull Up 51K Pull Down 51K Pull Down Notes VR or HALL Effect Wire Color purple/white white/yellow yellow blue/black white/orange light blue/white white/yellow brown/white yellow/pink red/pink white white/red tan/orange tan tan/green green brown white/dark blue black/red yellow/orange dark blue black/orange purple/yellow red/purple light blue/black pink/black orange/pink dark blue/white white/light blue white/black yellow brown Wire # 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32

Woodward 36320 p.9

4Connector Pinouts

Pin # ECM J1-B1 J1-B2 J1-B3 J1-B4 J1-B5 J1-B6 J1-B7 J1-B8 J1-B9 J1-B10 J1-B11 J1-B12 J1-B13 J1-B14 J1-B15 J1-B16 J1-B17 J1-B18 J1-B19 J1-B20 J1-B21 J1-B22 J1-B23 J1-B24 ControlCore Resource Name LSU1_VM KEY_SW EGO1P EGO1N EGO2P EGO2N DG1 BATT CAN1+ CAN1XDRP_A LSU2_UN LSU2_VM LSU1_IP LSU1_IA LSU2_IA LSU2_IP MPRD LSO2/LSUH2 LSO1/LSUH1 LSU1_UN SCL+ SCLXDRG

(continued) Function Lambda Sensing Unit ECM Wake Notes See datasheet for Bosch LSU4.x and CJ125. Wake Up Module Wire Color black/green green/black gray/dark blue LM9040 EGO yellow/purple white white/purple 1K Pull Up light blue/black yellow/black Terminating Resistance Required 300 mA Source for Transducers green/purple green/brown orange gray red See datasheet for Bosch LSU4.xand CJ125. white/brown black/blue orange/black red/blue Wire to Coil of Main Power Relay 10 A continuous, 3 A PWM red/blue yellow/white pink/light blue Wire # 33 34 35 36 37 38 39 40 41 42 43 44 45 46 47 48 49 50 51 52 53 54 55 56

Discrete Switch, Frequency, IRQ Battery Connection Serial Communications Transducer Power A (5 V) Lambda Sensing Unit2 Lambda Sensing Unit1 Lambda Sensing Unit2 Main Power Relay Driver PWM Output/ LSU Heater Lambda Sensing Unit1 RS-485 HI RS-485 LO Transducer Ground

See datasheet for Bosch LSU4.x orange/white and CJ125. pink/dark blue black/yellow Return for Transducers purple/pink

Woodward 36320 p.10

4Connector Pinouts

Pin # ECM J1-C1 J1-C2 J1-C3 J1-C4 J1-C5 J1-C6 J1-C7 J1-C8 J1-C9 J1-C10 J1-C11 J1-C12 J1-C13 J1-C14 J1-C15 J1-C16 J1-C17 J1-C18 J1-C19 J1-C20 J1-C21 J1-C22 J1-C23 J1-C24 ControlCore Resource Name AN24M AN21M AN25M AN22M AN23M AN29M AN28M AN30M AN20M AN18M AN19M AN26M EK4P/DG7 EK4N/DG8 AN27M DG2 CAN2+ CAN2EK1P EK1N EK2P EK2N EK3P/DG5 EK3N/DG6

(continued) Function Variable Resistance Input Variable Resistance Input Variable Resistance Input Variable Resistance Input Variable Resistance Input High Impedance Input Potentiometer Input High Impedance Input Variable Resistance Input Variable Resistance Input Variable Resistance Input Potentiometer Input Knock Sensor Positive Knock Sensor Negative Potentiometer Input Notes 1K Pull Up 1K Pull Up 1K Pull Up 1K Pull Up 1K Pull Up 5.1M Pull Up, 1M Pull Down 2.2K Pull Up 5.1M Pull Up, 1M Pull Down 1K Pull Up 1K Pull Up 1K Pull Up 2.2K Pull Up Compatible with the Motorola PROSAK IC 2.2K Pull Up 1K Pull Up Terminating Resistance Required Wire Color yellow/orange brown/white red/white brown/yellow brown/white pink/black green/orange green/blue yellow/red yellow/white pink/brown green/red green/white green/yellow black black gray/white gray/red yellow/pink green/white pink/purple Compatible with the Motorola PROSAK IC light blue/white pink/orange black Wire # 57 58 59 60 61 62 63 64 65 66 67 68 69 70 71 72 73 74 75 76 77 78 79 80

Discrete Switch, Frequency, IRQ Serial Communications Knock Sensor Positive Knock Sensor Negative Knock Sensor Positive Knock Sensor Negative Knock Sensor Positive/ Discrete Input Knock Sensor Negative/ Discrete Input

Woodward 36320 p.11

4Connector Pinouts

Pin # ECM J2-A1 J2-A2 J2-A3 J2-A4 J2-A5 J2-A6 J2-A7 J2-A8 J2-A9 J2-A10 J2-A11 J2-A12 J2-A13 J2-A14 J2-A15 J2-A16 J2-A17 J2-A18 J2-A19 J2-A20 J2-A21 J2-A22 J2-A23 J2-A24 ControlCore Resource Name INJ01 INJ07 INJ02 INJ08 INJ06 INJ04 INJ03 INJ05 H1+ EST5 EST6 EST1 EST2 EST3 DVRG DVRG H1DRVP DRVP EST4 EST7 EST_RTN EST8 DVRG

(continued) Function Injector 1 Driver Injector 7 Driver Injector 2 Driver Injector 8 Driver Injector 6 Driver Injector 4 Driver Injector 3 Driver Injector 5 Driver H-Bridge Output Notes 3 A/1 A peak/hold 7 A/3 A or 3 A/1 A peak/hold 3 A/1 A peak/hold 7 A/3 A or 3 A/1 A peak/hold 3 A/1 A peak/hold 7 A/3 A or 3 A/1 A peak/hold 3 A/1 A peak/hold 7 A/3 A or 3 A/1 A peak/hold High Current (5 A) Wire Color pink/light blue pink/orange yellow/black white white/ dark blue black/red yellow/orange light blue tan/light blue gray dark blue Electronic Spark Timing TTL dark blue/white white/ light blue white/black Driver Ground H-Bridge Output Driver Power (VBATT) Electronic Spark Timing Low Current Return Electronic Spark Timing Driver Ground TTL Connect to Battery Ground Connect to Battery Ground High Current (5 A) Power to H-Bridges and Loads TTL black/yellow black/white pink/purple pink/brown orange orange/white black/blue yellow/purple red/blue black/white Wire # 81 82 83 84 85 86 87 88 89 90 91 92 93 94 95 96 97 98 99 100 101 102 103 104

Woodward 36320 p.12

4Connector Pinouts

Pin # ECM J2-B1 J2-B2 J2-B3 J2-B4 J2-B5 J2-B6 J2-B7 J2-B8 J2-B9 J2-B10 J2-B11 J2-B12 J2-B13 J2-B14 J2-B15 J2-B16 J2-B17 J2-B18 J2-B19 J2-B20 J2-B21 J2-B22 J2-B23 J2-B24 ControlCore Resource Name INJ12 INJ10 INJ09 INJ11 EST14/LAMP2 EST13/LAMP1 EST15LAMP3 EST16/LAMP4 DVRG EST12 EST11 LSO5 EST10 EST9 LSO6 H3+ LSO7 LSO9 LSO8 LSO10 LSO4 H2+ H2H3-

(continued) Function Injector 12 Driver Injector 10 Driver Injector 9 Driver Injector 11 Driver Electronic Spark Timing/ Low Side Lamp Driver Electronic Spark Timing/ Low Side Lamp Driver Driver Ground Electronic Spark Timing PWM Output Electronic Spark Timing PWM Output H-Bridge Output PWM Output PWM Output PWM Output with current feedback H-Bridge Output Notes 7 A/3 A or 3 A/1 A peak/hold 3 A/1 A peak/hold 7 A/3 A or 3 A/1 A peak/hold 3 A/1 A peak/hold High Current (1 A) High Current (1 A) Connect to Battery Ground TTL 4 A continuous, 3 A PWM TTL 4 A continuous, 3 A PWM High Current (10 A) 4 A continuous, 3 A PWM 4 A continuous, 3 A PWM 4 A continuous, 3 A PWM Wire Color black/orange tan yellow dark blue/pink red/pink white white/green brown/white gray/red orange/black blue/black white/orange white/yellow tan/green green/yellow green/red black/green purple tan/purple light blue/white purple/yellow tan/white High Current (10 A) green/black green/blue Wire # 105 106 107 108 109 110 111 112 113 114 115 116 117 118 119 120 121 122 123 124 125 126 127 128

Woodward 36320 p.13

4.1Additional Development Harness Wires

Highlighted wires are not directly accessible.

Additional Harness Wires Wire # 129 130 131 132 133 134 135 136 137 138 139 140 141 142 143 144 145 FUNCTION SC GND BATTERY + FUSED PWR SC PWR FUSED PWR COIL PWR DRVP DRVP BATTERY GND CONN KEYSWITCH BOOT CKT BOOT CKT BOOT CKT BOOT CKT FUSED PWR GROUND COLOR BLACK RED RED RED RED RED RED RED BLACK BLACK FROM SPL01 C09 C08 SPL04 C06 C06 C06 SPL03 SPL02 SPL01 PIN A -A B 30 85 87 B A A A C A A E F A TO C07 C08 SPL04 C07 SPL04 SPL04 SPL03

OUTPUT

PIN B B A A B C A --A F B C B B ---

C10 SPL02 C07 C12 SPL06 SPL06 C11

OUTPUT OUTPUT

GRN-BLK SPL05 GRN-BLK SPL05 YEL-BLK YEL-BLK RED RED BLACK C11 C12 SPL04 SPL04 SPL02

Woodward 36320 p.14

5Physical Dimensions

All dimensions are in millimeters.

Woodward 36320 p.15

5.1Block Diagram

Development Harness Connections (HARN-P128-002)

Woodward 36320 p.16

6Environmental Ratings

6.1 GENERAL: The ECM is designed to meet automotive industry standard under hood environmental requirements for 12 volt and 24 volt systems, and also meets marine industry environmental requirements. Validation tests included extreme operating temperatures (40 to +105 C), thermal shock, humidity, salt spray, salt fog, immersion, fluid resistance, mechanical shock, vibration, and EMC. It is the responsibility of the application engineer to assure that the application does not exceed the demonstrated capabilities of the unit; vibration or thermal. It may be necessary to perform additional tests to validate the unit in the application. 6.2 STORAGE TEMPERATURE: 6.3 OPERATING TEMPERATURE: 6.4 THERMAL SHOCK: 6.5 FLUID RESISTANCE: 6.6 HUMIDITY RESISTANCE: 6.7 SALT FOG RESISTANCE: 6.8 IMMERSION: 6.9 MECHANICAL SHOCK: 6.10 DROP: 6.11 VIBRATION: 40 to +125 C 40 to +105 C 40 to +125 C transition within 10 s for 500 cycles Two stroke motor oil, Four-stroke motor oil, Unleaded gasoline, ASTM Reference 'C' fuel 85% humidity at 85 C for 1000 hours of operation 1000 hours Submersible in 8% saltwater solution to 10 ft (3 m) 50 hours of 50 g's Random drop tests on concrete from 6 ft (1.8 m) Engine mountable and tested to high-performance levels

Examples of Acceptable ECU Vibration Profiles

20 18 16

Extreme race engine vibration

ECU Acceleration(G's)

14 12 10 8 6 4 2 0 0 200 400 600 800 1000 1200 1400 1600 1800 2000

Production engine vibration

Frequency(Hz)

6.12 ABNORMAL SUPPLY VOLTAGE RESISTANCE: Conditions Reverse Battery Abnormal Alternator Output Minimum Battery Supply Voltage 24 Vdc 36 Vdc 6 Vdc Time 5 Minutes 5 Minutes Indef.

Woodward 36320 p.17

7Using a Boot Key/Cable

Errors in configuration, logic and/or other programming made during program development for this module (via .srz file), can cause a persistent loss of CAN communications with the module under development. If this happens, apply the boot key to force the module into reboot mode, reloading the module with functional program code (a known, valid .srz file) in order to allow resumption of module communication. Follow the steps listed in this section. Refer to diagram below for connections. Remove the ECU from direct control connections before performing the reboot procedure, as outputs are set to defaults or undefined states, with unpredictable and possibly hazardous results if applied.

Use Boot Key and Reprogram the Module

Remove other ECUs from CANbus for this procedure. 1. Connect the module for programming via necessary cables, CAN converter, etc. 2. Select a known, valid .srz file for programming. 3. With key off, disconnect battery power from module. With module power off, initiate programming of the module using MotoTune. 4. When the Looking for an ECU prompt appears in the dialog, reconnect Battery, and then turn key on, to power up and wake-up ECU. The module must wake-up (KEYSW on) with the boot key or cable connections applied as described in order to initiate a reboot and to absorb the selected program.

Woodward 3 36320 p.18

PO Box 1519, Fort Collin CO, USA 805 ns 522-1519 East Drake Road, Fort Collins CO 80525 O 1000 E Tel.: +1 (9 970) 482-5811 Fax: +1 (970) 498-3058 mcsinfo@ @woodward.com mcs.woodw ward.com dward.com www.wood Distributor & Service rs Woodw ward has an inte ernational networ of distributors and service facilities. rk For yo nearest repre our esentative, call th Fort Collins plant or see the he Worldw wide Directory on our website.

This do ocument is distribut for informationa purposes only. It is not to be constr ted al rued as creating or becoming part of any Woodward Governor Compan contractual or w t ny warranty en obligation unless expressly stated in a writte sales contract.

For more informa ation contact:

Wo oodward 2008, All Rights Rese erved

2010/5/Fort Collins

Potrebbero piacerti anche

- Generator 307 USERDocumento54 pagineGenerator 307 USERLiviu PopaNessuna valutazione finora

- ECU-AIM Logger 110 EngDocumento56 pagineECU-AIM Logger 110 EngHabib GürbüzNessuna valutazione finora

- Throttle Body Explanation and CalibrationDocumento2 pagineThrottle Body Explanation and CalibrationReynaldo FloresNessuna valutazione finora

- Honda CityDocumento20 pagineHonda CityAlimi JasmanNessuna valutazione finora

- ECU Minco-F2 Manual enDocumento12 pagineECU Minco-F2 Manual enVerona MedinaNessuna valutazione finora

- Vdo Ecu PinDocumento3 pagineVdo Ecu PinjjoehairyNessuna valutazione finora

- Cables For AUTOCOM CDP For TrucksDocumento2 pagineCables For AUTOCOM CDP For TrucksOscar VillaseñorNessuna valutazione finora

- PowerWizard 1 (GB) (0208) PDFDocumento2 paginePowerWizard 1 (GB) (0208) PDFايمن الهدام100% (1)

- ABS (TMMMS Made), Brake Assist (TMMMS Made)Documento12 pagineABS (TMMMS Made), Brake Assist (TMMMS Made)Albert BriceñoNessuna valutazione finora

- Ipd 66031Documento42 pagineIpd 66031HannOtto StoreNessuna valutazione finora

- Diagnostic Codes: MitsubishiDocumento12 pagineDiagnostic Codes: Mitsubishiน้องกอย่า วงศ์เครือNessuna valutazione finora

- GPM 22Documento2 pagineGPM 22Khalid SaddikNessuna valutazione finora

- Manual de Reparacion para Transmision Automatica Modelo 5R55EDocumento120 pagineManual de Reparacion para Transmision Automatica Modelo 5R55EGerardo GallardoNessuna valutazione finora

- Система управления двигателемDocumento3 pagineСистема управления двигателемEdik Bonifacio MamaniNessuna valutazione finora

- 03 大众车系与自主品牌汽车电脑维修图集Documento64 pagine03 大众车系与自主品牌汽车电脑维修图集Kwun Hok ChongNessuna valutazione finora

- PDFDocumento5 paginePDFJohn Mark CorralesNessuna valutazione finora

- 636 Green Machine Operator ManualDocumento85 pagine636 Green Machine Operator Manualnenad100% (1)

- Engine RPM Measurement Using Timer 1 (Embedded C Programming and The Atmel Avr)Documento2 pagineEngine RPM Measurement Using Timer 1 (Embedded C Programming and The Atmel Avr)dinamik2t100% (1)

- TC1724 DS v12-785810Documento135 pagineTC1724 DS v12-785810balajiboss005Nessuna valutazione finora

- Mitsubishi E500 Series ManualDocumento225 pagineMitsubishi E500 Series ManualtoanchiNessuna valutazione finora

- Generic With Curtis 1268 5411 ControlDocumento6 pagineGeneric With Curtis 1268 5411 Controlpavli999Nessuna valutazione finora

- T TC014 06Documento2 pagineT TC014 06mario100% (1)

- ECDocumento339 pagineECulisse_Nessuna valutazione finora

- Alternator: Engine:: BF6M 1013 FCG2 ECP38-2SNDocumento7 pagineAlternator: Engine:: BF6M 1013 FCG2 ECP38-2SNalutttNessuna valutazione finora

- XTuner E3 User Manual V8.0Documento60 pagineXTuner E3 User Manual V8.0carlosve87Nessuna valutazione finora

- Can Bus PDFDocumento73 pagineCan Bus PDFmohanNessuna valutazione finora

- 5 - 12 Section 5 - Diagnosis J-1 ECM Connector Identification (1 of 2 J-1)Documento8 pagine5 - 12 Section 5 - Diagnosis J-1 ECM Connector Identification (1 of 2 J-1)MyBriggsNessuna valutazione finora

- FlaDocumento553 pagineFlacalvarez_5100% (1)

- Fusilera Peugeot 308 Mk2 2013-15Documento3 pagineFusilera Peugeot 308 Mk2 2013-15skpppNessuna valutazione finora

- Removing Mitsubishi Pajero ECUDocumento2 pagineRemoving Mitsubishi Pajero ECUJose GilmerNessuna valutazione finora

- 043 Man TruckDocumento4 pagine043 Man TruckFilipposNessuna valutazione finora

- 1 4runner Electrical Wiring DiagramDocumento35 pagine1 4runner Electrical Wiring DiagramEverardo Pineda ParraNessuna valutazione finora

- 321 Aim Pectel T6 100 EngDocumento5 pagine321 Aim Pectel T6 100 EngmisdeismoNessuna valutazione finora

- Grand Am Continental Tire Sports Integrating ECU PDFDocumento31 pagineGrand Am Continental Tire Sports Integrating ECU PDFsenthilvlNessuna valutazione finora

- Datasheet Alternator: - General CharacteristicsDocumento10 pagineDatasheet Alternator: - General Characteristicsnguyenbinh20Nessuna valutazione finora

- DVB - Nl5101d Set Top BoxDocumento5 pagineDVB - Nl5101d Set Top BoxSrinivasa Raju KNessuna valutazione finora

- Pinout-Schematic DiagramsDocumento14 paginePinout-Schematic DiagramsIvan RdzNessuna valutazione finora

- InteliNano NT Datasheet 2012-3 CPLENANODocumento6 pagineInteliNano NT Datasheet 2012-3 CPLENANOsdiaman100% (1)

- WairingDocumento6 pagineWairingDiecky ChristiawanNessuna valutazione finora

- Quick Reference TransistorDocumento125 pagineQuick Reference TransistorLuis Alonso Rosero VelezNessuna valutazione finora

- Avensis Intake System PDFDocumento19 pagineAvensis Intake System PDFMladen VidovićNessuna valutazione finora

- Multiport Fuel System (Mfi) : Group 13ADocumento64 pagineMultiport Fuel System (Mfi) : Group 13Ajagjitemir6014Nessuna valutazione finora

- Corolla Engine ControlDocumento12 pagineCorolla Engine ControlPatricio ValenciaNessuna valutazione finora

- V850ESDocumento6 pagineV850ESVictor Ramalho100% (1)

- Engine Immobiliser System (LHD W/O Smart Key System) : 244 LS430 (EWD435F) LS430 (EWD435F) 245Documento1 paginaEngine Immobiliser System (LHD W/O Smart Key System) : 244 LS430 (EWD435F) LS430 (EWD435F) 245Tomy100% (1)

- CDS61236 Ethernet Superseal Connector Cable 1.8M (Rev A and Rev B)Documento2 pagineCDS61236 Ethernet Superseal Connector Cable 1.8M (Rev A and Rev B)JAVIER ROMERONessuna valutazione finora

- Cip0340 CHECKING VVT SENSOR PDFDocumento5 pagineCip0340 CHECKING VVT SENSOR PDFDoDuyBacNessuna valutazione finora

- Global GuideDocumento292 pagineGlobal GuideGiangDoNessuna valutazione finora

- 97 Legacy GT ECU PinoutDocumento2 pagine97 Legacy GT ECU PinoutBen MonsonNessuna valutazione finora

- Civic IdleDocumento4 pagineCivic IdlexmariachiNessuna valutazione finora

- DC Motor Speed Control BC201Documento24 pagineDC Motor Speed Control BC201ROSEMARIO PORFIRIONessuna valutazione finora

- Instruments: Instrument Panels, PositionDocumento45 pagineInstruments: Instrument Panels, Positionssinokrot100% (1)

- Ecm 0555 080 0703Documento17 pagineEcm 0555 080 0703Anderson megusta el juegoNessuna valutazione finora

- Iri-Pro V2Documento8 pagineIri-Pro V2Arun KumarNessuna valutazione finora

- (DOM) Kobold FRT12 ManualDocumento12 pagine(DOM) Kobold FRT12 Manualvallolet_sb5185Nessuna valutazione finora

- L99DZ100G, L99DZ100GPDocumento197 pagineL99DZ100G, L99DZ100GPVenezuela is the 51st stateNessuna valutazione finora

- LMD18201 3A, 55V H-Bridge: Literature Number: SNVS092CDocumento14 pagineLMD18201 3A, 55V H-Bridge: Literature Number: SNVS092CIrfan AbbasiNessuna valutazione finora

- Quad Differential Drivers Bdg1A, Bdp1A, Bdgla, Bpnga, Bpnpa, and BppgaDocumento16 pagineQuad Differential Drivers Bdg1A, Bdp1A, Bdgla, Bpnga, Bpnpa, and Bppgacatsoithahuong84Nessuna valutazione finora

- AP2182Documento17 pagineAP2182ابراهيم السعيديNessuna valutazione finora

- Energy Metering Ic With Pulse Output: DescriptionDocumento7 pagineEnergy Metering Ic With Pulse Output: DescriptionvungocduongNessuna valutazione finora

- Kicks: This Brochure Reflects The Product Information For The 2020 Kicks. 2021 Kicks Brochure Coming SoonDocumento8 pagineKicks: This Brochure Reflects The Product Information For The 2020 Kicks. 2021 Kicks Brochure Coming SoonYudyChenNessuna valutazione finora

- Preventive Maintenance - HematologyDocumento5 paginePreventive Maintenance - HematologyBem GarciaNessuna valutazione finora

- 133 The Science and Understanding of TheDocumento14 pagine133 The Science and Understanding of TheCarlos RieraNessuna valutazione finora

- Nisha Rough DraftDocumento50 pagineNisha Rough DraftbharthanNessuna valutazione finora

- RetrieveDocumento8 pagineRetrieveSahian Montserrat Angeles HortaNessuna valutazione finora

- Manuscript - Batallantes &Lalong-Isip (2021) Research (Chapter 1 To Chapter 3)Documento46 pagineManuscript - Batallantes &Lalong-Isip (2021) Research (Chapter 1 To Chapter 3)Franzis Jayke BatallantesNessuna valutazione finora

- CH 2 Nature of ConflictDocumento45 pagineCH 2 Nature of ConflictAbdullahAlNoman100% (2)

- Tendernotice 1Documento42 pagineTendernotice 1Hanu MittalNessuna valutazione finora

- Types of MemoryDocumento3 pagineTypes of MemoryVenkatareddy Mula0% (1)

- Starkville Dispatch Eedition 12-9-18Documento28 pagineStarkville Dispatch Eedition 12-9-18The DispatchNessuna valutazione finora

- Introduction To AirtelDocumento6 pagineIntroduction To AirtelPriya Gupta100% (1)

- Presentation - Prof. Yuan-Shing PerngDocumento92 paginePresentation - Prof. Yuan-Shing PerngPhuongLoanNessuna valutazione finora

- Majalah Remaja Islam Drise #09 by Majalah Drise - Issuu PDFDocumento1 paginaMajalah Remaja Islam Drise #09 by Majalah Drise - Issuu PDFBalqis Ar-Rubayyi' Binti HasanNessuna valutazione finora

- Portfolio Report Zarin Tasnim Tazin 1920143 8Documento6 paginePortfolio Report Zarin Tasnim Tazin 1920143 8Fahad AlfiNessuna valutazione finora

- Data Book: Automotive TechnicalDocumento1 paginaData Book: Automotive TechnicalDima DovgheiNessuna valutazione finora

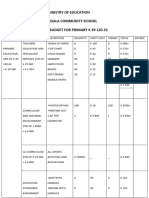

- Ministry of Education Musala SCHDocumento5 pagineMinistry of Education Musala SCHlaonimosesNessuna valutazione finora

- Ticket Udupi To MumbaiDocumento2 pagineTicket Udupi To MumbaikittushuklaNessuna valutazione finora

- Careem STRATEGIC MANAGEMENT FINAL TERM REPORTDocumento40 pagineCareem STRATEGIC MANAGEMENT FINAL TERM REPORTFahim QaiserNessuna valutazione finora

- INTERNSHIP PRESENTATION - Dhanya - 2020Documento16 pagineINTERNSHIP PRESENTATION - Dhanya - 2020Sanitha MichailNessuna valutazione finora

- Health Informatics SDocumento4 pagineHealth Informatics SnourhanNessuna valutazione finora

- Aluminium Extrusion Industry in IndiaDocumento3 pagineAluminium Extrusion Industry in Indiakalan45Nessuna valutazione finora

- WHO Partograph Study Lancet 1994Documento6 pagineWHO Partograph Study Lancet 1994Dewi PradnyaNessuna valutazione finora

- BPL-DF 2617aedrDocumento3 pagineBPL-DF 2617aedrBiomedical Incharge SRM TrichyNessuna valutazione finora

- Outage Analysis of Wireless CommunicationDocumento28 pagineOutage Analysis of Wireless CommunicationTarunav SahaNessuna valutazione finora

- La Salle Lipa Integrated School Senior High School Community 1 Quarter Summative Assessment Earth Science AY 2021-2022 Household Conservation PlanDocumento4 pagineLa Salle Lipa Integrated School Senior High School Community 1 Quarter Summative Assessment Earth Science AY 2021-2022 Household Conservation PlanKarlle ObviarNessuna valutazione finora

- Sangeetahealingtemples Com Tarot Card Reading Course in UsaDocumento3 pagineSangeetahealingtemples Com Tarot Card Reading Course in UsaSangeetahealing templesNessuna valutazione finora

- Reference: Digital Image Processing Rafael C. Gonzalez Richard E. WoodsDocumento43 pagineReference: Digital Image Processing Rafael C. Gonzalez Richard E. WoodsNisha JosephNessuna valutazione finora

- Allplan 2006 Engineering Tutorial PDFDocumento374 pagineAllplan 2006 Engineering Tutorial PDFEvelin EsthefaniaNessuna valutazione finora

- Marley Product Catalogue Brochure Grease TrapsDocumento1 paginaMarley Product Catalogue Brochure Grease TrapsKushalKallychurnNessuna valutazione finora

- Risk Analysis and Management - MCQs1Documento7 pagineRisk Analysis and Management - MCQs1Ravi SatyapalNessuna valutazione finora