Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Iso 842

Caricato da

Rone Da-anoyDescrizione originale:

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Iso 842

Caricato da

Rone Da-anoyCopyright:

Formati disponibili

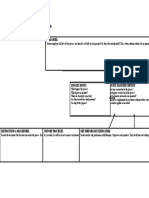

WHAT

Material What are the supplied materials? Do they contribute to the making of nonconforming materials? How do you know the supplied parts are meeting requirements? Process Equipment/Tools How were the equipment/tools selected for the process? Are the equipment/tools for the job adequate and available when needed? How are equipment/tools for the job identified, controlled and maintained? What else needs to be in place prior to commencing the job?

WHO

Directly Involved Parties Who is setting the job up? Who is producing product? Who is determining the (inspection) status of the product? Who is determining the disposition of nonconforming product? Who is the process owner (responsible for managing the process)? Linkages/Interfaces with Other Involved Parties What Support Process personnel are involved? How? What supplier, customer or other external personnel are involved? How? How is competency determined for all parties involved?

OUTPUT INPUT

Identify what the customer wants/needs.

PROCESS

Name/Description List COP or Other Process Title

Identify what the customer gets.

Output Requirements (criteria and records) Input Requirements (specifications) List sources of product requirements (i.e. customer, organization & regulatory requirements documents). How were these requirements collected and reviewed for accuracy and completeness? Steps/Activities List Key Process Steps/Activities What output criteria are used to determine if what should have been produced has been produced? What measures are used to demonstrate or ensure product compliance? (see measures) Consider: - ppm - delivery performance - response time - time for returned product test/analysis - quality cost

MEASURES

Who decides what measures to use to judge this process? What are the metrics used to show if the process is effective? Why were these measures selected? How is data collected? Who does the analysis? How is it reported? How is data used to identify and resolve/prevent problems? What actions are taken based on the data collected? How are actions tracked to assess their impact? Has the corrective action worked?

HOW

Procedures/Control Documents How are the process control conditions defined (i.e. what work instructions, inspection instructions, control plans, procedures governing the control of nonconforming material, etc., exists)? Are they available and used? Where is the control methodology breaking down ? Support Processes What processes/systems are needed to support the work? (i.e. maintenance, housekeeping, logistics, storage, packaging, measuring, data analysis, etc.) Have any nonconforming materials been traced to support processes

WI 8.4-2 Turtle Guide Rev: 0 12/31/2010

Potrebbero piacerti anche

- BS en Iso 00787-5-1995 (2000)Documento10 pagineBS en Iso 00787-5-1995 (2000)Donig FermanianNessuna valutazione finora

- HSM 461en1Documento174 pagineHSM 461en1Mtunzi MzamoNessuna valutazione finora

- En 15662 2008Documento81 pagineEn 15662 2008Александра КостенкоNessuna valutazione finora

- ISO TS 10020 Revision OverviewDocumento12 pagineISO TS 10020 Revision OverviewalfredorozalenNessuna valutazione finora

- Food Contact Materials and Packaging Legislation OverviewDocumento4 pagineFood Contact Materials and Packaging Legislation Overviewdd11rrttyyNessuna valutazione finora

- Catálogo HutchinsonDocumento58 pagineCatálogo Hutchinsonsandruska72Nessuna valutazione finora

- Iso 4630 1 2004 en FR PDFDocumento6 pagineIso 4630 1 2004 en FR PDFAnthony MaputiNessuna valutazione finora

- ISO 6743-7 - 1986 - Part. 7 - Family M - MetalworkingDocumento8 pagineISO 6743-7 - 1986 - Part. 7 - Family M - MetalworkingMassimiliano VolaNessuna valutazione finora

- BA121576-121579 NPK09-en006 0314Documento24 pagineBA121576-121579 NPK09-en006 0314Yew LimNessuna valutazione finora

- 20210630-Public-Private Cape Fear Memorial Replacement ProposalDocumento23 pagine20210630-Public-Private Cape Fear Memorial Replacement ProposalBen SchachtmanNessuna valutazione finora

- GSO 142/2010 (E) Tableware made from melamine plasticsDocumento8 pagineGSO 142/2010 (E) Tableware made from melamine plasticsMarwaNessuna valutazione finora

- Cashew Nut ProcessingDocumento8 pagineCashew Nut ProcessingSunil ParikhNessuna valutazione finora

- (En Ligne)Documento2 pagine(En Ligne)Sara Amazrhar100% (1)

- Zintek 200 Spec SheetDocumento6 pagineZintek 200 Spec SheetellisforheroesNessuna valutazione finora

- Instruction Manual EntoleterDocumento11 pagineInstruction Manual Entoleter(Doc - Bto) Renato Alejandro Andara Escalona100% (1)

- 1939 DIN EN - EnglischDocumento17 pagine1939 DIN EN - EnglischZmeulZmeilorNessuna valutazione finora

- As NZS ISO 8980.1-2011 Ophthalmic Optics - Uncut Finished Spectacle Lenses Specifications For Single-Vision ADocumento8 pagineAs NZS ISO 8980.1-2011 Ophthalmic Optics - Uncut Finished Spectacle Lenses Specifications For Single-Vision ASAI Global - APACNessuna valutazione finora

- Stabilizers Acidified Milk Drinks PDFDocumento6 pagineStabilizers Acidified Milk Drinks PDFthanhtl_hugolataNessuna valutazione finora

- Manual Sampling of Petroleum and Petroleum Products: Standard Practice ForDocumento18 pagineManual Sampling of Petroleum and Petroleum Products: Standard Practice ForKhoai Sai GonNessuna valutazione finora

- FMEADocumento51 pagineFMEAELAMPARITHINessuna valutazione finora

- Boeco LaboratoryEquipmentDocumento30 pagineBoeco LaboratoryEquipmentdjonycsNessuna valutazione finora

- Iso 13302 en (Odour)Documento11 pagineIso 13302 en (Odour)Tushar NathNessuna valutazione finora

- PVC 57ger01Documento1 paginaPVC 57ger01rajesh patelNessuna valutazione finora

- Iso 1Documento33 pagineIso 1Sujith Suj0% (2)

- Iso TS 27265-2009Documento16 pagineIso TS 27265-2009Farhad British WingsNessuna valutazione finora

- StarDesignPower CargillBeauty PresentationDocumento28 pagineStarDesignPower CargillBeauty PresentationJames WuNessuna valutazione finora

- Metal Shark® 2 Metal Shark® 2 Metal Shark® 2 Metal Shark® 2Documento88 pagineMetal Shark® 2 Metal Shark® 2 Metal Shark® 2 Metal Shark® 2RAFLY SYAHNessuna valutazione finora

- Fulltext 12088 PDFDocumento83 pagineFulltext 12088 PDFWilbert FatahNessuna valutazione finora

- Din Iso 8130-3Documento6 pagineDin Iso 8130-3Carlos Ernesto NataliNessuna valutazione finora

- Installation and Operational Qualification: Prepared by .. . DateDocumento6 pagineInstallation and Operational Qualification: Prepared by .. . DateEkkawit Wangkanklang0% (1)

- Seta Verification Materials: STVM MTVMDocumento2 pagineSeta Verification Materials: STVM MTVMdchyNessuna valutazione finora

- Iso/fdis 14644-14Documento28 pagineIso/fdis 14644-14Mostafa AfifyNessuna valutazione finora

- Calsol Process OilsDocumento5 pagineCalsol Process OilsBen Karthiben NathanNessuna valutazione finora

- Viscometer Falling Ball Viscometer, Viscotester, AccessoriesDocumento8 pagineViscometer Falling Ball Viscometer, Viscotester, Accessoriesعلي مؤيد مطشر صدامNessuna valutazione finora

- Food Contant MaterialsDocumento142 pagineFood Contant MaterialsAnonymous oTrMzaNessuna valutazione finora

- Manual Book Drying OvenDocumento32 pagineManual Book Drying OvenJauhariNessuna valutazione finora

- Polymer GuideDocumento15 paginePolymer GuidetalhawasimNessuna valutazione finora

- HSE-Reg On Push+pull MHDocumento66 pagineHSE-Reg On Push+pull MHNg RickyNessuna valutazione finora

- Roduction of Sugar: Tamkanat Saad Redha Khalid Uswa Zahid Kaneez FizzaDocumento35 pagineRoduction of Sugar: Tamkanat Saad Redha Khalid Uswa Zahid Kaneez FizzaMudassir Mehmood yousafNessuna valutazione finora

- Process Audit Turtle Diagram: Equipment & Facilities: Personnel: Control ProcessesDocumento1 paginaProcess Audit Turtle Diagram: Equipment & Facilities: Personnel: Control Processesmamk77Nessuna valutazione finora

- Process Audit DiagramDocumento1 paginaProcess Audit Diagramcertifiq8213Nessuna valutazione finora

- Process Audit DiagramDocumento1 paginaProcess Audit Diagramsmadi.adiNessuna valutazione finora

- Process Audit Turtle DiagramDocumento1 paginaProcess Audit Turtle DiagramJoel Alcantara100% (3)

- TurtleTemplateISO Audit ChecklistDocumento1 paginaTurtleTemplateISO Audit ChecklistMarcela GonçalvesNessuna valutazione finora

- Process Audit ChecklistDocumento15 pagineProcess Audit Checklistmulachu100% (1)

- ISO 9001 Process Audit Turtle DiagramDocumento1 paginaISO 9001 Process Audit Turtle DiagramEusbesio McvarroNessuna valutazione finora

- Process-Based Auditing - ASQDocumento5 pagineProcess-Based Auditing - ASQSelvaraj SimiyonNessuna valutazione finora

- Auditoria Com Abordagem de ProcessoDocumento5 pagineAuditoria Com Abordagem de ProcessoANTONIO CARLOS LINO MACHADONessuna valutazione finora

- Process Metrics and Continuous ImprovementDocumento9 pagineProcess Metrics and Continuous ImprovementnovgoranNessuna valutazione finora

- Super Turtle Process DiagramDocumento4 pagineSuper Turtle Process DiagramJohn OoNessuna valutazione finora

- All Processes ChecklistDocumento8 pagineAll Processes ChecklistcosmicbunnyNessuna valutazione finora

- Process Audit Turtle Diagram TemplateDocumento1 paginaProcess Audit Turtle Diagram TemplateUsman HameedNessuna valutazione finora

- Streamline Quality Management ProcessesDocumento15 pagineStreamline Quality Management ProcessesPoorna Chandra GaralapatiNessuna valutazione finora

- Audit Process ChecklistDocumento3 pagineAudit Process ChecklistBAlaNessuna valutazione finora

- BPOM 2013 Risa Anwar PharnacovigilanceDocumento28 pagineBPOM 2013 Risa Anwar PharnacovigilanceYulis AdrianaNessuna valutazione finora

- Free IATF Audit Checklist For Manufacturing ProcessesDocumento14 pagineFree IATF Audit Checklist For Manufacturing ProcessesvidushiNessuna valutazione finora

- ISO9001ChkDemo ProcessDocumento6 pagineISO9001ChkDemo ProcessreshmamalluNessuna valutazione finora

- All Processes ChecklistDocumento9 pagineAll Processes ChecklistAndy Le GrangeNessuna valutazione finora

- Guidance: Process Audit ChecklistDocumento16 pagineGuidance: Process Audit ChecklistnadeemkarimiNessuna valutazione finora

- Testing Tool Guide: Categories, Benefits, Risks and SelectionDocumento16 pagineTesting Tool Guide: Categories, Benefits, Risks and SelectionYONG LONG KHAWNessuna valutazione finora

- Tarah Viviano Revised Resume 2016Documento2 pagineTarah Viviano Revised Resume 2016api-314537209Nessuna valutazione finora

- Perceptual Learning: An IntroductionDocumento476 paginePerceptual Learning: An IntroductionVíctor FuentesNessuna valutazione finora

- Grade 8 Learners' Difficulties in Writing ParagraphsDocumento26 pagineGrade 8 Learners' Difficulties in Writing ParagraphsBetel Niguse100% (2)

- Ch02 Why Waterfall Model FailDocumento12 pagineCh02 Why Waterfall Model Failetl_manNessuna valutazione finora

- JLPT Sensei - n5 Grammar List v2Documento3 pagineJLPT Sensei - n5 Grammar List v2Łukasz ZiomekNessuna valutazione finora

- Linking The Van Hiele Theory To Instruction 2015Documento11 pagineLinking The Van Hiele Theory To Instruction 2015Oliver IpoNessuna valutazione finora

- Grasps FilipinoDocumento7 pagineGrasps FilipinoLeslie JimenoNessuna valutazione finora

- MIT Technology Review, Vol. 126.5 (September-October 2023)Documento92 pagineMIT Technology Review, Vol. 126.5 (September-October 2023)themagnum202Nessuna valutazione finora

- Diaz - Science 1 - Learning Packet - Week 04Documento6 pagineDiaz - Science 1 - Learning Packet - Week 04Maloucel DiazNessuna valutazione finora

- Bryson Yurkemik: Employment ObjectiveDocumento2 pagineBryson Yurkemik: Employment Objectiveapi-345358688Nessuna valutazione finora

- Commercial building floor plan layoutDocumento1 paginaCommercial building floor plan layoutjitu9918Nessuna valutazione finora

- BJCP Study GuideDocumento77 pagineBJCP Study GuideCarlos BarrientosNessuna valutazione finora

- Discipline and Ideas QuestonaireDocumento3 pagineDiscipline and Ideas QuestonaireShaira Mae Pasion Erdaje100% (1)

- Get the Most Out of Your Nutanix Cloud Platform TrainingDocumento12 pagineGet the Most Out of Your Nutanix Cloud Platform TrainingJohramoNessuna valutazione finora

- Attestation Process ChecklistDocumento2 pagineAttestation Process ChecklistConcepcion MpsNessuna valutazione finora

- School Learning and Development Plan For Head TeachersDocumento3 pagineSchool Learning and Development Plan For Head TeachersLiza Bacudo100% (1)

- Session Plan FBSDocumento17 pagineSession Plan FBSorabelle punoNessuna valutazione finora

- Shermila DissertationDocumento305 pagineShermila DissertationRangothri Sreenivasa SubramanyamNessuna valutazione finora

- The Brain Fitness Book Activities and Puzzles To Keep Your Mind Active and Healthy (Rita Carter) (Z-Library)Documento192 pagineThe Brain Fitness Book Activities and Puzzles To Keep Your Mind Active and Healthy (Rita Carter) (Z-Library)Richard Wokard100% (1)

- Non-Verbal Communication: by V P BhagatDocumento14 pagineNon-Verbal Communication: by V P BhagatSat SharmaNessuna valutazione finora

- Visualization Without VisionDocumento21 pagineVisualization Without Vision11Dewi Meiliyan Ningrum dewimeiliyan.2020Nessuna valutazione finora

- Anallisis Lagu Lewis CapaldiDocumento7 pagineAnallisis Lagu Lewis CapaldiIta PratiwiNessuna valutazione finora

- JATBMSBBAFIABAHonsBusinessEconomics ResDocumento863 pagineJATBMSBBAFIABAHonsBusinessEconomics RespuneetNessuna valutazione finora

- (2010) Handbook Strategy As PracticeDocumento367 pagine(2010) Handbook Strategy As PracticeViniciusNessuna valutazione finora

- Dr. Sarbari Guha Physics ProfileDocumento5 pagineDr. Sarbari Guha Physics Profilevishwas gaurNessuna valutazione finora

- Chapter 8 - Nervous SystemDocumento12 pagineChapter 8 - Nervous SystemlalaNessuna valutazione finora

- UGFN1000 Student Learning OutcomesDocumento3 pagineUGFN1000 Student Learning Outcomestutorial TaipoNessuna valutazione finora

- APC Boosts Polypropylene OperationDocumento6 pagineAPC Boosts Polypropylene OperationJuan AlejandroNessuna valutazione finora

- B.tech Apjktu (2019 Scheme)Documento21 pagineB.tech Apjktu (2019 Scheme)Amarnath RajeshNessuna valutazione finora

- Articulo EstereotiposDocumento20 pagineArticulo EstereotiposEriEscobarNessuna valutazione finora