Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Salicylic Acid Tablets Lot Q0 D200

Caricato da

Tarek ShadyDescrizione originale:

Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Salicylic Acid Tablets Lot Q0 D200

Caricato da

Tarek ShadyCopyright:

Formati disponibili

USP Salicylic Acid Tablets RS Lot Q0D200 (300 mg nominal salicylic acid content per tablet) USP DISSOLUTION

CALIBRATOR, NON-DISINTEGRATING TYPE This USP Dissolution Calibrator is provided for use in the Apparatus Suitability Test for USP Apparatus 1 and 2 in the USP General Test Chapters on DISSOLUTION <711> and DRUG RELEASE <724>. Do not expose the tablets to excessive humidity. Dissolution Medium- We recommend preparing the medium as follows: Transfer a 41-g portion of monobasic potassium phosphate into a 6-L volumetric flask, and dissolve in 5.8 L of water. Add portions of sodium hydroxide solution 50% (w/w) to obtain a pH of 7.4 0.05. Dilute this solution with water to volume. Readjust the pH if necessary with sodium hydroxide or phosphoric acid. Another method to prepare a pH 7.4 Phosphate Buffer Solution is described in the USP Chapter for Solutions. Deaerate the Dissolution Medium with a technique validated for 37. One method of deaeration is described in the USP General Test Chapter on DISSOLUTION <711>. Procedure- [See DISSOLUTION <711> and DRUG RELEASE <724> in the current USP.] Determine the quantity of salicylic acid, C7H6O3, dissolved at thirty minutes, in each vessel, expressed as percent of the labeled amount. Use 900 mL of 0.05M Phosphate Buffer pH=7.4 0.05 (pH tested at room temperature) as the Dissolution Medium and conduct the test at 37. Operate each apparatus at 100-rpm speed. Measure the amount of salicylic acid dissolved from filtered portions of the sample aliquots withdrawn and suitably diluted with Dissolution Medium if necessary at 296 nm (the approximate wavelength of maximum absorbance) in comparison with a solution of known concentration of USP Salicylic Acid Reference Standard. Test Interpretation - the apparatus is suitable if each of the individual calculated values for each apparatus is within the specified ranges shown in the Table. Notes: An amount of alcohol not to exceed 1% of the total volume of the standard solution may be used to bring the salicylic acid standard into solution prior to dilution with Dissolution medium. The filtering method must not cause adsorptive loss of drug. Bias introduced by automated methods is to be avoided. Cracked, capped, or severely chipped tablets should not be used. However, tablets with minor surface flaws are generally acceptable for use. Powder on the surface of tablets should be removed prior to use of the tablets. If equipment is dedicated for use with only one apparatus (basket or paddle), then the calibration is only required for that apparatus. See other side for helpful suggestions.

These values apply only to Lot Q0D200

Apparatus Percentage of the labeled amount of salicylic acid dissolved at 30 minutes at 100 rpm 23-30 17-25

1 2

Founded in 1820, the United States Pharmacopeial Convention comprises representatives from colleges and national and state organizations of medicine and pharmacy. It revises and publishes The United States Pharmacopeia and The National Formulary, the legally recognized compendia of standards for drugs.

Salicylic Acid Tablets: Calibration Notes

Dissolution equipment that has been routinely used for a number of years (three-five) should be serviced if out-of-range values are obtained. Any dissolution equipment that is used routinely should be calibrated at regular intervals. Relocation of apparatus always requires recalibration. Some USP Dissolution tests require 2-L vessels or speeds other than 50 and 100 rpm. The equipment is suitable for these other conditions if it passes the calibration tests.

Sources of Error in Calibration Testing

Deaeration of medium. Improper deaeration is a common problem. This formulation has been demonstrated to be sensitive to dissolved gases in the medium. One method of deaeration is as follows: Heat the medium, while stirring gently, to about 41, and filter under vacuum through a 0.45-m-porosity membrane into a suitable filtering flask, equipped with a stirring device. Seal the flask and continue to apply vacuum while stirring for an additional five minutes. Do not allow the temperature of the Dissolution Medium to fall below 37 prior to the initiation of the test. Gently transfer the medium directly to the vessel. Rotating the Apparatus 2 shafts to speed equilibration to 37 is discouraged. Use medium promptly after it is equilibrated. Vessels. Vessels must be clean. Use of an unacceptable vessel is a systematic error. Vibration and mechanical problems. When not properly examined and maintained, factors such as dissolution head coplanarity, shaft perpendicularity, tension on the drive chain or belt, centering, and operating condition of the gear plates can adversely affect dissolution. Digital rpm readings may not necessarily represent individual spindle speeds. Visual inspection may be needed to observe surging of the separate spindles. To minimize vibration effects, the dissolution equipment should be on a stable bench top or table. Other mechanical equipment using fans, pumps, or other vibration sources should be removed from the area or isolated in some other way. Turbulence in the water bath caused by circulation patterns can affect results in one or more vessels. Automation. Always validate the automated method, including the analytical method and sampling method, by performing a parallel manual analysis, withdrawing test samples at the same times, and comparing to the automated results. Filter probes may become clogged, absorb the active ingredient, or generate additional turbulence through the air-purging step. Be alert to the possibility of carryover among samplings. Automated systems may not account for dilution and the absorbance reading may be over 1.0 absorbance units. Linearity above 1.0 absorbance should be established with a standard curve. Tablets. The Calibrator Tablets should be stored in the original containers in a dry place. Avoid excess humidity. When testing, take the tablets from the blister pack and begin the dissolution test immediately. Reference Standard. Use the current lot of USP Reference Standard and follow any drying instructions on the label. Prepare the standard solution on the day of use. Filtering. Do not centrifuge sample. The sample aliquot should be filtered immediately after the sample is drawn. The filters should be tested for interference from leachables or by adsorption of the drug. A separate clean syringe and filter should be used for sampling each vessel. Paddles and baskets. The shafts of both apparatuses should be straight. A simple test of this is to roll the shaft on the bench top with the paddle blade or prongs for the basket hanging over the edge. The shaft should roll evenly like an arrow shaft. Baskets should be straight and not frayed. Routine use in hydrochloric acid Medium causes deterioration of the stainless steel baskets. Baskets should attach firmly to the shaft prongs. Evaporation lids should be used. Inspect them for fit or warping.

Potrebbero piacerti anche

- Materials Properties Handbook Titanium Alloys CompressDocumento788 pagineMaterials Properties Handbook Titanium Alloys CompressJordan PowellNessuna valutazione finora

- Membrane CleaningDocumento5 pagineMembrane CleaningKamal ChokshiNessuna valutazione finora

- Dissolution TestingDocumento23 pagineDissolution TestingAnushka AgrawalNessuna valutazione finora

- BSW Laboratory and Field TestDocumento4 pagineBSW Laboratory and Field TestRonald Figo Torres EcheNessuna valutazione finora

- 09935289A MHS 15 Mercury Hydride System Quick ReferenceDocumento18 pagine09935289A MHS 15 Mercury Hydride System Quick Referencekariliz15Nessuna valutazione finora

- Understanding Motor Controls 3rd Edition Herman Test BankDocumento4 pagineUnderstanding Motor Controls 3rd Edition Herman Test BankDebits100% (5)

- Junkers Monobloc Planning Guide English PDFDocumento184 pagineJunkers Monobloc Planning Guide English PDFReInvieNessuna valutazione finora

- Dissolution Test For Solid Oral Dosage FormsDocumento8 pagineDissolution Test For Solid Oral Dosage FormsPedro Marcelo Alva PlasenciaNessuna valutazione finora

- Hach 8009 Zinc Ed 08Documento6 pagineHach 8009 Zinc Ed 08Beth AlvaradoNessuna valutazione finora

- Nessler Ammonia HACHDocumento6 pagineNessler Ammonia HACHMesut GenişoğluNessuna valutazione finora

- Cleaning & Monitoring: ProceduresDocumento6 pagineCleaning & Monitoring: Proceduresumi_hayyatNessuna valutazione finora

- Salivary Cortisol: Expanded Range High SensitivityDocumento21 pagineSalivary Cortisol: Expanded Range High Sensitivityerik gunawanNessuna valutazione finora

- Homocysteine ELISA KIT PDFDocumento14 pagineHomocysteine ELISA KIT PDFRidwan AndragunaNessuna valutazione finora

- PhosphateDocumento8 paginePhosphateUmi NazaliaNessuna valutazione finora

- Oxygen Demand, ChemicalDocumento10 pagineOxygen Demand, ChemicalPetrovic NenadNessuna valutazione finora

- Chlorine Free DPDDocumento8 pagineChlorine Free DPDEndang SupriyatnaNessuna valutazione finora

- DOC316.53.01099 Ed10Documento10 pagineDOC316.53.01099 Ed10zvjesosNessuna valutazione finora

- SRB Test InstructionsDocumento1 paginaSRB Test InstructionsAbie RexoMenNessuna valutazione finora

- (Intended Use) : Instruction ManualDocumento8 pagine(Intended Use) : Instruction ManualTPNessuna valutazione finora

- (Intended Use) : Instruction ManualDocumento8 pagine(Intended Use) : Instruction ManualNitin KeshavNessuna valutazione finora

- 44-74841TCH FIASAnalyticalConditionsDocumento11 pagine44-74841TCH FIASAnalyticalConditionsIrvingDavalosNessuna valutazione finora

- Doc316 53 01113Documento6 pagineDoc316 53 01113pothanNessuna valutazione finora

- Pharmacopoeial Standards For TabletDocumento17 paginePharmacopoeial Standards For TabletRohitPatelNessuna valutazione finora

- Method 3520C Continuous Liquid-Liquid ExtractionDocumento8 pagineMethod 3520C Continuous Liquid-Liquid ExtractionridermateNessuna valutazione finora

- Norepinephrine (Research) ELISA: For The Quantitative Determination of Norepinephrine in Various Sample Types and VolumesDocumento7 pagineNorepinephrine (Research) ELISA: For The Quantitative Determination of Norepinephrine in Various Sample Types and Volumesnomi_intanNessuna valutazione finora

- Core Sampling Recommended ProceduresDocumento16 pagineCore Sampling Recommended ProceduresAgus Wahyu SetiawanNessuna valutazione finora

- Instruction 18-1060-44 ACDocumento12 pagineInstruction 18-1060-44 ACpalkybdNessuna valutazione finora

- DissolutionDocumento7 pagineDissolutionAbdullah DoulaNessuna valutazione finora

- Compendial Methods of Dissolution and Biopharmaceutic Considerations in Drug Product DesignDocumento31 pagineCompendial Methods of Dissolution and Biopharmaceutic Considerations in Drug Product DesignGiovanne BuendiaNessuna valutazione finora

- Homap Health & OTC Manufacturing Associates Pakistan: IslamabadDocumento11 pagineHomap Health & OTC Manufacturing Associates Pakistan: IslamabadHafiz Ali shanNessuna valutazione finora

- VeenaDocumento37 pagineVeenaVeena Reddy SingamNessuna valutazione finora

- Chevron - EPA Method - 413 - 2-HydrocarbonDocumento3 pagineChevron - EPA Method - 413 - 2-HydrocarbonErvie J CauncaNessuna valutazione finora

- ELISA Kit For Fetoprotein Alpha (AFP) E90153BoDocumento8 pagineELISA Kit For Fetoprotein Alpha (AFP) E90153BoRo KohnNessuna valutazione finora

- 8.4 - Extraction and Washing Guide: OverviewDocumento4 pagine8.4 - Extraction and Washing Guide: OverviewDhruv PatelNessuna valutazione finora

- 788 - Particulate Material - Usp MonographDocumento6 pagine788 - Particulate Material - Usp MonographVanessa CarreraNessuna valutazione finora

- 2007 07 10 Methods Method 180 1 TurbidityDocumento10 pagine2007 07 10 Methods Method 180 1 Turbidityrohmen042Nessuna valutazione finora

- Disintegration TestDocumento13 pagineDisintegration TestVesh Chaurasiya100% (1)

- Protocolo de ELISA - IL-1 BetaDocumento6 pagineProtocolo de ELISA - IL-1 BetamllboxNessuna valutazione finora

- Content Uniformity, Dissolution Test and QC of CaPsDocumento48 pagineContent Uniformity, Dissolution Test and QC of CaPsgul rehmanNessuna valutazione finora

- High Performance Liquid Chromatography SystemDocumento12 pagineHigh Performance Liquid Chromatography SystemHarvinder SinghNessuna valutazione finora

- How To Make HPLC Columns Last LongerDocumento7 pagineHow To Make HPLC Columns Last LongerMubarak PatelNessuna valutazione finora

- Compendial Methods For DissolutionDocumento9 pagineCompendial Methods For Dissolutionmm75% (4)

- Scrubber ManualDocumento41 pagineScrubber ManualRahul Sonkamble100% (1)

- Developing A Discriminating Dissolution Procedure For A Dual Active Pharmaceutical Product With Unique Solubility CharacteristicsDocumento5 pagineDeveloping A Discriminating Dissolution Procedure For A Dual Active Pharmaceutical Product With Unique Solubility CharacteristicsparinafernsNessuna valutazione finora

- ELISA Kit For Angiotensin II (AngII) E90005RaDocumento8 pagineELISA Kit For Angiotensin II (AngII) E90005RaTan Jie HuiNessuna valutazione finora

- Dissolution TestingDocumento37 pagineDissolution Testingampay ayubNessuna valutazione finora

- About ApparaatusDocumento18 pagineAbout Apparaatusachi_cantikNessuna valutazione finora

- Troubleshooting For Increased PressureDocumento5 pagineTroubleshooting For Increased PressureMubarak PatelNessuna valutazione finora

- Nitrogen, Ammonia: Direct ISE Method Method 10001 0.1 To 10.0 MG/L NH - N Ammonia ISEDocumento8 pagineNitrogen, Ammonia: Direct ISE Method Method 10001 0.1 To 10.0 MG/L NH - N Ammonia ISEPablo Vladimir Millanao FuentesNessuna valutazione finora

- Size Exlusion ProteinsDocumento7 pagineSize Exlusion Proteinscristhian10_00Nessuna valutazione finora

- Cianeto - Met 8027 - DOC316.53.01040Documento10 pagineCianeto - Met 8027 - DOC316.53.01040Claudia Telles BenattiNessuna valutazione finora

- Hach 8021 Cloro Residual Ed 09Documento8 pagineHach 8021 Cloro Residual Ed 09Beth AlvaradoNessuna valutazione finora

- TOC Usp Metodo de AnálisisDocumento2 pagineTOC Usp Metodo de AnálisisdaniellemaqNessuna valutazione finora

- Moist 02Documento8 pagineMoist 02Raja VeluNessuna valutazione finora

- Procedure For Laboratory Jar TestDocumento2 pagineProcedure For Laboratory Jar TestManuel Gabriel GonzalesNessuna valutazione finora

- Abbot Traninig ReportDocumento105 pagineAbbot Traninig ReportAhsan AliNessuna valutazione finora

- Hydroxyl Value (Hindered Hydroxyls) : Lubrizol Standard Test ProcedureDocumento3 pagineHydroxyl Value (Hindered Hydroxyls) : Lubrizol Standard Test Procedurecarlos_bautista_55Nessuna valutazione finora

- 711 Dissolution PDFDocumento15 pagine711 Dissolution PDFRajesh AkkiNessuna valutazione finora

- Flow charts of pharmaceutical quality control tests for different dosage formsDa EverandFlow charts of pharmaceutical quality control tests for different dosage formsNessuna valutazione finora

- Quality Control OF Bulk Drug FormulationsDa EverandQuality Control OF Bulk Drug FormulationsNessuna valutazione finora

- Design and Manufacture of Pharmaceutical TabletsDa EverandDesign and Manufacture of Pharmaceutical TabletsValutazione: 3.5 su 5 stelle3.5/5 (6)

- Lexicon of Pharmacy: A Concise up-to-date referenceDa EverandLexicon of Pharmacy: A Concise up-to-date referenceNessuna valutazione finora

- A Comprehensive Book on Experimental PharmaceuticsDa EverandA Comprehensive Book on Experimental PharmaceuticsValutazione: 5 su 5 stelle5/5 (1)

- Pip Ctse1000-2018Documento82 paginePip Ctse1000-2018John BuntalesNessuna valutazione finora

- Datasheet RefDem58219080-3400-30 en 120V 60Hz-2Documento7 pagineDatasheet RefDem58219080-3400-30 en 120V 60Hz-2Floyd PriceNessuna valutazione finora

- Sikagrout - 214: High Performance, Non Shrink, Expanding Cementitious Grouting MortarDocumento3 pagineSikagrout - 214: High Performance, Non Shrink, Expanding Cementitious Grouting MortarSulaim Al KautsarNessuna valutazione finora

- Pulp and PaperDocumento226 paginePulp and PaperAktharNessuna valutazione finora

- Punching, Perforating, Blanking, NibblingDocumento2 paginePunching, Perforating, Blanking, NibblingTtrraanneeOonneeNessuna valutazione finora

- Elastomeric Bearing Design ExampleDocumento14 pagineElastomeric Bearing Design ExampleTan Nguyen Cong100% (2)

- Welded Wire Reinforcement Manual of Standard PracticeDocumento38 pagineWelded Wire Reinforcement Manual of Standard PracticemarmusmanNessuna valutazione finora

- Newcon Suggested Specifications Rev 100715Documento1 paginaNewcon Suggested Specifications Rev 100715saroat moongwattanaNessuna valutazione finora

- Design and Fabrication of Portable Rotating Machinery Fault SimulatorDocumento48 pagineDesign and Fabrication of Portable Rotating Machinery Fault SimulatorAdib Fikri0% (1)

- 3 Methods of Determining Workability of ConcreteDocumento4 pagine3 Methods of Determining Workability of Concretesuryakantame100% (1)

- Jurnal SanitasiDocumento12 pagineJurnal SanitasiAnnisa FadlilahNessuna valutazione finora

- Application of Spiral Heat Exchangers in Heavy Oil Service External PDFDocumento27 pagineApplication of Spiral Heat Exchangers in Heavy Oil Service External PDFProcess EngineerNessuna valutazione finora

- A 250Documento1 paginaA 250AnuranjanNessuna valutazione finora

- Cours 4 Et Exercices Anglais TechDocumento5 pagineCours 4 Et Exercices Anglais TechÁł ÃăNessuna valutazione finora

- C Compact EUROMOLDDocumento40 pagineC Compact EUROMOLDWalter CahuanaNessuna valutazione finora

- Thermination Atau TerminasiDocumento31 pagineThermination Atau TerminasiRasyidjarazNessuna valutazione finora

- Characteristics of Iron OreDocumento4 pagineCharacteristics of Iron OreNathan SwamiNessuna valutazione finora

- Equipment List Corn Oil Update Terbaru 01-10-2011Documento8 pagineEquipment List Corn Oil Update Terbaru 01-10-2011ayiep1202Nessuna valutazione finora

- Hall Sensors Selection GuideDocumento2 pagineHall Sensors Selection GuideMiltongrimi GrimilNessuna valutazione finora

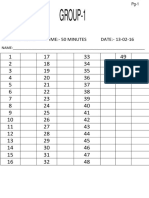

- Chemical Kinetics Mcqs Group 1Documento11 pagineChemical Kinetics Mcqs Group 1zafarchem_iqbalNessuna valutazione finora

- EZ Clean 1500Documento4 pagineEZ Clean 1500sebasalinashjNessuna valutazione finora

- Hardness TestDocumento10 pagineHardness Testbadawi2Nessuna valutazione finora

- Tutorial IIDocumento5 pagineTutorial IIMushtansir AnsariNessuna valutazione finora

- Bromine New PDFDocumento1 paginaBromine New PDFSuhasNessuna valutazione finora

- Spot Weld Growth On 304L Austenitic Stainless Steel For Equal and Unequal ThicknessesDocumento9 pagineSpot Weld Growth On 304L Austenitic Stainless Steel For Equal and Unequal ThicknessesAmin MojiriNessuna valutazione finora

- Powder 1Documento84 paginePowder 1Nyanda MadiliNessuna valutazione finora

- Wire Rope Splice and Method of Making The SameDocumento3 pagineWire Rope Splice and Method of Making The SameFiqri AnraNessuna valutazione finora