Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

California Walnut

Caricato da

tersane1995Descrizione originale:

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

California Walnut

Caricato da

tersane1995Copyright:

Formati disponibili

CALIFORNIA WALNUT: BACKGROUNDER

In a nutshell The State of California's mild climate and deep fertile soils provide the ideal growing conditions for the world's premium walnuts. Harvested at their peak, California walnuts are carefully sorted, cleaned, dried and prepared for shipping. The California Walnut Commission (CWC) is deeply committed to ensuring that its walnuts are consistently of the highest quality, excelling in both taste and appearance, through high growing and handling standards. Freshness is of key importance to the CWC. Significant variance in global growing standards has resulted in disparity in the quality of walnuts imported into Canada. The CWC seeks to remedy negative consumer opinion by adhering to a rigorous growing and processing program that ensures the excellence of its product. Canadians are quickly recognizing the consistently superior flavour and quality of California walnuts. Since 2000, California walnut shipments to Canada have nearly doubled totaling 15,089,360 million pounds in 2007. California walnuts can be described as: o being large and plump; tan in colour o possessing a rich, sweet nutty flavour o readily lending flavour and texture to any number of dishes, from salads to desserts and main courses. In addition to their superior flavour, California walnuts are packed with good nutrition and provide appetite satisfaction. For additional information on walnut nutrition, please refer to A Hearty Handful Fact Sheet. There are 37 varieties of walnuts grown in California, however, four varieties account for over 80 per cent of total production: Chandler, Hartley, Payne and Serr.

California Walnut Industry: A Short History The first commercial walnut plantings in California began in 1867 when Joseph Sexton, an orchardist and nurseryman in the Santa Barbara County town of Goleta, planted English walnuts. For several years, walnuts were predominantly planted in the southern areas of California. Some 70 years after Sexton's first planting, the centre of Californias walnut production moved northward to the Stockton area in one of the most dramatic horticultural moves in history. Better growing areas, improved irrigation and better pest control methods in the north resulted in increasingly larger yields. The Central Valley of California is now the state's prime walnut growing region. Its mild climate and deep fertile soils provide ideal growing conditions for the California walnut. California walnuts account for 99 per cent of the commercial U.S. supply and two-thirds of the worlds supply.

Growing California Walnuts Walnuts are commercially grown throughout the Central Valley of California and in the Coastal Valleys, from Redding in the north, to Bakersfield in the south. Current walnut acreage tops more than 200,000 acres with more than 4,000 growers contributing to the states $540 million walnut industry. After an orchard is planted, it takes approximately six to eight years until its first yield. Constant attention is given to each tree every step of the way from pruning, spraying and fertilizing to irrigation to ensure a healthy orchard. Once a walnut tree has been planted and stabilized, it will continue to bear fine quality fruit for as long as a century. In late August, boughs of California walnut trees hang heavy with walnuts. The harvest begins when the protective green hulls split, signaling that the nuts are ready to be removed from the trees. The harvesting methods used depend on the size of the orchard and the equipment and crew available to the grower. The harvest season usually continues into early November. Harvesting operations are largely automated. First, the orchard floor is rolled or dragged clean of twigs, rocks and other orchard debris. Then the nuts are removed from the tree by a mechanical shaker. After they have been shaken to the ground, walnuts are blown into a row to allow mechanical harvesters to pick them up for cleaning and hulling.

Processing: Drying After hulling and washing, the walnuts are transferred from the mechanical harvester into a hopper where they are mechanically dehydrated (air-dried) to the desirable eight-per-cent moisture level. This prevents deterioration of the nut and protects its quality during storage. Mechanical dehydration quick, thorough and scientifically controlled represents a major improvement over the sun-drying method formerly used.

Processing: In-shell Walnuts Walnuts with desirable traits, such as big beautiful shells, are selected for the in-shell market. The walnut is cleaned, dried and readied for markets around the world where holiday cracking of walnuts is an age-old tradition. In-shell walnuts are classified as "Jumbo," "Large," "Medium" or "Baby" according to USDA standards.

Processing: Shelled Walnuts Clean and dried walnuts are stored until ready to be cracked by state-of-the-art equipment to produce what are called "shelled" walnuts (shell-removed). Only top quality walnuts enter the processing channels, all of which are designed to exacting processing, sanitation and quality control standards. Walnuts for both consumer and industrial use are removed from storage as needed and sent to a shelling department where they are cracked. Cracking is done mechanically. Next, the shelled walnuts are screened, separating kernels into a series of sizes. Kernels are then air-separated to remove shell fragments. By bucket elevator and conveyor systems, kernels are then moved to electronic colour separators and laser sorters. Finally, walnuts are hand-sorted by trained inspectors for quality, and are ready for packaging in clear film bags or bulk cartons.

Quality Standards All walnuts must meet or exceed the standards set by the Walnut Marketing Board. Enforced by the Dried Fruit and Tree Nut Association of California (DFA), they ensure that California walnuts are truly the worlds finest. Consumers and foodservice companies are encouraged to look for the Product of California/USA designation on the label when purchasing walnuts to ensure the best in taste and freshness.

- 30 -

For further information, please contact: Natalie Pavlenko Faye Clack Communications [t] 905-206-0577 ext. 231 [e] npavlenko@fayeclack.com

Potrebbero piacerti anche

- Technical Information KitDocumento16 pagineTechnical Information KitMauricio Ulloa MoralesNessuna valutazione finora

- Nut Grower's Guide: The Complete Handbook for Producers and HobbyistsDa EverandNut Grower's Guide: The Complete Handbook for Producers and HobbyistsNessuna valutazione finora

- Avocados: From The Farm To Your TableDocumento18 pagineAvocados: From The Farm To Your Tablegstewart05Nessuna valutazione finora

- Canned Citrus Processing: Techniques, Equipment, and Food SafetyDa EverandCanned Citrus Processing: Techniques, Equipment, and Food SafetyNessuna valutazione finora

- Makin 2Documento7 pagineMakin 2Nirmal SharmaNessuna valutazione finora

- Australian Chocolates, History in The MakingDocumento4 pagineAustralian Chocolates, History in The MakingelaineediblejourneysNessuna valutazione finora

- Pineapple Jai PrakashDocumento61 paginePineapple Jai PrakashJai Prakash100% (1)

- Cocoa SlideshowDocumento21 pagineCocoa SlideshowKshirod Kumar DashNessuna valutazione finora

- FCOC Growers Guide v11Documento64 pagineFCOC Growers Guide v11makda mulugetaNessuna valutazione finora

- Cocoa Bean (Also Cacao BeanDocumento9 pagineCocoa Bean (Also Cacao BeanVillaci5Nessuna valutazione finora

- Canola 1Documento3 pagineCanola 1Jaime Li AliNessuna valutazione finora

- Harvest and Post Harvest Handling of BananaDocumento22 pagineHarvest and Post Harvest Handling of BananaShanthanu KrishnakumarNessuna valutazione finora

- Adlai ProductionDocumento80 pagineAdlai ProductionPhilip Alfred Barsalote100% (1)

- Best Practices For APRICOT Production and Marketing in Afghanistan, Roots of Peace ROPDocumento28 pagineBest Practices For APRICOT Production and Marketing in Afghanistan, Roots of Peace ROPMaftei MariusNessuna valutazione finora

- Avocado Production in The PhilippinesDocumento20 pagineAvocado Production in The Philippinescutieaiko100% (1)

- Medicinal Properties of CassavaDocumento9 pagineMedicinal Properties of CassavaJohn AmazingNessuna valutazione finora

- Musa Group No 2Documento6 pagineMusa Group No 2maswimusa25Nessuna valutazione finora

- Pineapple BookletDocumento17 paginePineapple BookletKaren Lambojon BuladacoNessuna valutazione finora

- A G Brochure 2010Documento2 pagineA G Brochure 2010ahijah12Nessuna valutazione finora

- Chemical and Sensory Evaluation of Peanut ButterDocumento55 pagineChemical and Sensory Evaluation of Peanut Buttersscy94qsfbNessuna valutazione finora

- Production DepartmentDocumento26 pagineProduction DepartmentannuNessuna valutazione finora

- WatermelonDocumento7 pagineWatermelonRyza MartizanoNessuna valutazione finora

- Peanut ButterDocumento10 paginePeanut Butterjopeco2010100% (1)

- 2 Subtrop Banana BysDocumento11 pagine2 Subtrop Banana BysjhvkhgvNessuna valutazione finora

- Saging Ging Ging Ging GingDocumento31 pagineSaging Ging Ging Ging GingElissa PagulayanNessuna valutazione finora

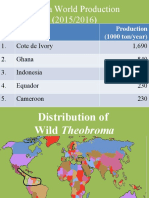

- Cocoa World Production (2015/2016) : No. Country Production (1000 Ton/year)Documento80 pagineCocoa World Production (2015/2016) : No. Country Production (1000 Ton/year)AvinashRaiNessuna valutazione finora

- OkraDocumento2 pagineOkraChinAfricaineNessuna valutazione finora

- Bibliografia 8 - TraducirDocumento10 pagineBibliografia 8 - Traducirjuan clarosNessuna valutazione finora

- Avocado Cultivation Information GuideDocumento8 pagineAvocado Cultivation Information GuidesupreNessuna valutazione finora

- Avocado Cultivation Information GuideDocumento8 pagineAvocado Cultivation Information GuidesupreNessuna valutazione finora

- Babycarrot PDFDocumento3 pagineBabycarrot PDFapa_aNessuna valutazione finora

- Perform Harvest and Post-Harvest ActivitiesDocumento39 paginePerform Harvest and Post-Harvest ActivitiesRegie MacayaNessuna valutazione finora

- Dennis Kangethe Chapter OneDocumento5 pagineDennis Kangethe Chapter OnebonfaceNessuna valutazione finora

- Activity 1-4 (Midterms)Documento75 pagineActivity 1-4 (Midterms)Arnel SisonNessuna valutazione finora

- Acceptability of Breadfruit Candy 2Documento33 pagineAcceptability of Breadfruit Candy 2Chummy Annea Princillo SajordaNessuna valutazione finora

- Language Center of National University of El Santa (Ceiduns)Documento3 pagineLanguage Center of National University of El Santa (Ceiduns)Lars Paredes NonatoNessuna valutazione finora

- Cocoa Production, Chemistry, and UseDocumento6 pagineCocoa Production, Chemistry, and UseFranco CapeloNessuna valutazione finora

- LC BananasDocumento1 paginaLC BananasSiddharta GauthamaNessuna valutazione finora

- Group-3 Postharvest Losses - OatsDocumento42 pagineGroup-3 Postharvest Losses - OatsRichelle EspinedaNessuna valutazione finora

- Ipr 1Documento3 pagineIpr 1PrajnaNessuna valutazione finora

- Cultivando Grano de CacaoDocumento14 pagineCultivando Grano de CacaoEDUARD MIGUEL CHAVEZ AREDONessuna valutazione finora

- Quinoa Group 4Documento62 pagineQuinoa Group 4Richelle EspinedaNessuna valutazione finora

- Desiccated Coconut Coconut Milk or Cream Instant Coconut Milk Powder Coconut Sap and Products. Desiccated CoconutDocumento12 pagineDesiccated Coconut Coconut Milk or Cream Instant Coconut Milk Powder Coconut Sap and Products. Desiccated CoconutRajalingamNessuna valutazione finora

- Sisal FiberDocumento3 pagineSisal FiberTheSmartSEO7Nessuna valutazione finora

- Peanut ProcessingDocumento80 paginePeanut Processingprasad sanjayaNessuna valutazione finora

- 5 - Cocoa 2019Documento61 pagine5 - Cocoa 2019Qiun LeeNessuna valutazione finora

- Arabica Coffee VarietiesDocumento72 pagineArabica Coffee VarietiesYalina Aguilar PeraltaNessuna valutazione finora

- Arabica Coffee Varieties PDFDocumento72 pagineArabica Coffee Varieties PDFtheblueserenadeNessuna valutazione finora

- Research Paper About AvocadoDocumento7 pagineResearch Paper About Avocadogafuz0zewez3100% (1)

- Cash Crop Technology-1Documento195 pagineCash Crop Technology-1Food science and technologyNessuna valutazione finora

- Cassava GroupDocumento17 pagineCassava GroupTOLA ABENessuna valutazione finora

- CHAPTER 1 3.docxkhamiDocumento12 pagineCHAPTER 1 3.docxkhamikhamigaelNessuna valutazione finora

- Revised CBLMDocumento7 pagineRevised CBLMTesda SfistNessuna valutazione finora

- Notes On Harvesting and Handling Melons: Tony Bratsch, Extension Specialist, Department of Horticulture Virginia TechDocumento2 pagineNotes On Harvesting and Handling Melons: Tony Bratsch, Extension Specialist, Department of Horticulture Virginia TechfodoNessuna valutazione finora

- 1the Bean Bar 1-8Documento62 pagine1the Bean Bar 1-8Rey Mart PerezNessuna valutazione finora

- Arabica Coffee Varieties PDFDocumento75 pagineArabica Coffee Varieties PDFpaulNessuna valutazione finora

- Coconut: Cocos NuciferaDocumento169 pagineCoconut: Cocos NuciferaRachel BrionesNessuna valutazione finora

- Sweet CornDocumento31 pagineSweet Cornmanisha prasadNessuna valutazione finora

- Gherkin ProcessingDocumento6 pagineGherkin ProcessingParvez Sheikh100% (1)

- Pollen Pellet Colour PosterDocumento7 paginePollen Pellet Colour PosterAleksandar VukovicNessuna valutazione finora

- K10 GRS 2000Documento2 pagineK10 GRS 2000Dilon FernandoNessuna valutazione finora

- Landscape ReportDocumento4 pagineLandscape ReportMun Munirah MuniNessuna valutazione finora

- Acidic Vs Alkaline SoilDocumento4 pagineAcidic Vs Alkaline SoiljumelisaNessuna valutazione finora

- 02 037Documento8 pagine02 037agrosergio2010920Nessuna valutazione finora

- Storey Publishing Fall 2017 CatalogDocumento108 pagineStorey Publishing Fall 2017 CatalogStorey PublishingNessuna valutazione finora

- Vacuum Wood Kiln May2003webDocumento10 pagineVacuum Wood Kiln May2003webFrankcw1Nessuna valutazione finora

- December 2016 Wren Online EditionDocumento30 pagineDecember 2016 Wren Online EditionAlanNessuna valutazione finora

- Yuji Yoshimura Giovanna MDocumento297 pagineYuji Yoshimura Giovanna MRinno100% (3)

- Nelson/Salmo Pennywise Sept. 29, 2015Documento48 pagineNelson/Salmo Pennywise Sept. 29, 2015Pennywise PublishingNessuna valutazione finora

- Permaculture Guilding and Companion Planting - UpisfDocumento327 paginePermaculture Guilding and Companion Planting - UpisfSkanavi62d100% (4)

- Describing A Tree1Documento3 pagineDescribing A Tree1Everest Lim Yong KeanNessuna valutazione finora

- Short Conversation Between Two FriendsDocumento11 pagineShort Conversation Between Two Friendsapi-343063076Nessuna valutazione finora

- 10 Lessons We Can Learn From HoneybeesDocumento2 pagine10 Lessons We Can Learn From HoneybeesPhil ChandlerNessuna valutazione finora

- Sylhet CuisineDocumento5 pagineSylhet CuisineZiauddin ChoudhuryNessuna valutazione finora

- The Wildlife-Friendly Vegetable Gardener - A Sneak PeekDocumento15 pagineThe Wildlife-Friendly Vegetable Gardener - A Sneak PeekStorey PublishingNessuna valutazione finora

- Easter CactusDocumento9 pagineEaster CactusDragana MuncanNessuna valutazione finora

- Essay On School PicnicDocumento2 pagineEssay On School PicnicAnil Shelar100% (1)

- KQG Newsletter June 2014Documento5 pagineKQG Newsletter June 2014Gloria ReibinNessuna valutazione finora

- Designing Pier Footings PDFDocumento7 pagineDesigning Pier Footings PDF63ragtopNessuna valutazione finora

- Tips Upsr-EnglishDocumento30 pagineTips Upsr-EnglishrifaqaireenNessuna valutazione finora

- Hardy Geranium 07 HiDocumento20 pagineHardy Geranium 07 HiDan DanutNessuna valutazione finora

- Method Statement For Turfing WorkDocumento2 pagineMethod Statement For Turfing WorkMohd Syaril Mohd AliNessuna valutazione finora

- AmorphophallusDocumento25 pagineAmorphophallusCarey Anne SantosNessuna valutazione finora

- AKM Bahasa Inggris 1Documento2 pagineAKM Bahasa Inggris 1Pipit Rochmayanti PuspitaningtyasNessuna valutazione finora

- Arrogant Interloper-Catherine GeorgeDocumento67 pagineArrogant Interloper-Catherine GeorgeErlinda Sandel100% (7)

- Design: LandscapeDocumento16 pagineDesign: LandscapeAnuradhaKannanNessuna valutazione finora

- Bike Off! Jordan House Bicycle Project: Pages 6 and 7Documento12 pagineBike Off! Jordan House Bicycle Project: Pages 6 and 7muccilauandeNessuna valutazione finora

- Nelson/Salmo Pennywise September 18, 2018Documento32 pagineNelson/Salmo Pennywise September 18, 2018Pennywise PublishingNessuna valutazione finora

- Progress Test UNIT 3: GrammarDocumento5 pagineProgress Test UNIT 3: GrammarMaytezeroNessuna valutazione finora

- Root to Leaf: A Southern Chef Cooks Through the SeasonsDa EverandRoot to Leaf: A Southern Chef Cooks Through the SeasonsValutazione: 4.5 su 5 stelle4.5/5 (3)

- The Hidden Life of Trees: What They Feel, How They CommunicateDa EverandThe Hidden Life of Trees: What They Feel, How They CommunicateValutazione: 4 su 5 stelle4/5 (1002)

- Wild Witchcraft: Folk Herbalism, Garden Magic, and Foraging for Spells, Rituals, and RemediesDa EverandWild Witchcraft: Folk Herbalism, Garden Magic, and Foraging for Spells, Rituals, and RemediesValutazione: 5 su 5 stelle5/5 (32)

- A Girl and Her Greens: Hearty Meals from the GardenDa EverandA Girl and Her Greens: Hearty Meals from the GardenValutazione: 3.5 su 5 stelle3.5/5 (7)

- Gardening Hacks: 300+ Time and Money Saving HacksDa EverandGardening Hacks: 300+ Time and Money Saving HacksValutazione: 5 su 5 stelle5/5 (1)

- The Encyclopedia of Spices & Herbs: An Essential Guide to the Flavors of the WorldDa EverandThe Encyclopedia of Spices & Herbs: An Essential Guide to the Flavors of the WorldValutazione: 3.5 su 5 stelle3.5/5 (5)

- Mini Farming: Self-Sufficiency on 1/4 AcreDa EverandMini Farming: Self-Sufficiency on 1/4 AcreValutazione: 4 su 5 stelle4/5 (76)

- Miraculous Abundance: One Quarter Acre, Two French Farmers, and Enough Food to Feed the WorldDa EverandMiraculous Abundance: One Quarter Acre, Two French Farmers, and Enough Food to Feed the WorldValutazione: 4.5 su 5 stelle4.5/5 (54)

- The Intelligent Gardner: Growing Nutrient-Dense FoodDa EverandThe Intelligent Gardner: Growing Nutrient-Dense FoodValutazione: 4.5 su 5 stelle4.5/5 (8)

- Permaculture for the Rest of Us: Abundant Living on Less than an AcreDa EverandPermaculture for the Rest of Us: Abundant Living on Less than an AcreValutazione: 4.5 su 5 stelle4.5/5 (33)

- The Native American Herbalist's Bible 9 Books in 1: Find Out Thousands of Herbal Remedies and Recipes, Grow Your Personal Garden of Magic Herbs and Build Your First Herb Lab at HomeDa EverandThe Native American Herbalist's Bible 9 Books in 1: Find Out Thousands of Herbal Remedies and Recipes, Grow Your Personal Garden of Magic Herbs and Build Your First Herb Lab at HomeNessuna valutazione finora

- Soil: The Story of a Black Mother's GardenDa EverandSoil: The Story of a Black Mother's GardenValutazione: 4.5 su 5 stelle4.5/5 (16)

- In Bloom: Growing, Harvesting and Arranging Homegrown Flowers All Year RoundDa EverandIn Bloom: Growing, Harvesting and Arranging Homegrown Flowers All Year RoundValutazione: 5 su 5 stelle5/5 (1)

- Teaming With Microbes: The Organic Gardener's Guide to the Soil Food WebDa EverandTeaming With Microbes: The Organic Gardener's Guide to the Soil Food WebValutazione: 4.5 su 5 stelle4.5/5 (34)

- Houseplant HortOCCULTure: Green Magic for Indoor SpacesDa EverandHouseplant HortOCCULTure: Green Magic for Indoor SpacesNessuna valutazione finora

- The Well-Gardened Mind: The Restorative Power of NatureDa EverandThe Well-Gardened Mind: The Restorative Power of NatureValutazione: 4 su 5 stelle4/5 (3)

- The Pint-Sized Guide to Organizing Your HomeDa EverandThe Pint-Sized Guide to Organizing Your HomeValutazione: 4.5 su 5 stelle4.5/5 (2)

- Wild Witchcraft: Folk Herbalism, Garden Magic, and Foraging for Spells, Rituals, and RemediesDa EverandWild Witchcraft: Folk Herbalism, Garden Magic, and Foraging for Spells, Rituals, and RemediesValutazione: 5 su 5 stelle5/5 (3)

- The Well-Gardened Mind: The Restorative Power of NatureDa EverandThe Well-Gardened Mind: The Restorative Power of NatureValutazione: 4.5 su 5 stelle4.5/5 (43)

- The Green Witch's Garden: Your Complete Guide to Creating and Cultivating a Magical Garden SpaceDa EverandThe Green Witch's Garden: Your Complete Guide to Creating and Cultivating a Magical Garden SpaceValutazione: 5 su 5 stelle5/5 (18)

- Square Foot Gardening: How To Grow Healthy Organic Vegetables The Easy WayDa EverandSquare Foot Gardening: How To Grow Healthy Organic Vegetables The Easy WayValutazione: 5 su 5 stelle5/5 (3)

- The Lean Micro Farm: How to Get Small, Embrace Local, Live Better, and Work LessDa EverandThe Lean Micro Farm: How to Get Small, Embrace Local, Live Better, and Work LessValutazione: 5 su 5 stelle5/5 (2)

- The Orchid Thief: A True Story of Beauty and ObsessionDa EverandThe Orchid Thief: A True Story of Beauty and ObsessionValutazione: 3.5 su 5 stelle3.5/5 (686)

- Nature's Best Hope: A New Approach to Conservation that Starts in Your YardDa EverandNature's Best Hope: A New Approach to Conservation that Starts in Your YardValutazione: 5 su 5 stelle5/5 (42)

- Midwest-The Lost Book of Herbal Remedies, Unlock the Secrets of Natural Medicine at HomeDa EverandMidwest-The Lost Book of Herbal Remedies, Unlock the Secrets of Natural Medicine at HomeNessuna valutazione finora

- Plant Based Sauces and Dips Recipes: Beginner’s Cookbook to Healthy Plant-Based EatingDa EverandPlant Based Sauces and Dips Recipes: Beginner’s Cookbook to Healthy Plant-Based EatingValutazione: 4.5 su 5 stelle4.5/5 (20)

- Grow Bag Gardening - The New Way to Container GardeningDa EverandGrow Bag Gardening - The New Way to Container GardeningValutazione: 5 su 5 stelle5/5 (1)