Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

IPI - Study Material Revised 2010 - V97 - Ques Ans Type

Caricato da

udhaiiCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

IPI - Study Material Revised 2010 - V97 - Ques Ans Type

Caricato da

udhaiiCopyright:

Formati disponibili

VEL TECH VEL TECH MULTI TECH VEL TECH HIGH TECH

VEL TECH VEL TECH MULTI TECH VEL TECH HIGH TECH

1

EI1003 INSTRUMENTATION IN PETROCHEMICAL INDUSTRIES

UNIT I PETROLEUM PROCESSING

PART A

1. Deflne petroleum.

Petroleum ls the nume for ull hydrocurbons reluted, nuturully occurrlng muterluls, lncludlng

oll, nuturul gus und tur. It ls mude up of hydrocurbon molecules (hydrogen comblned wlth curbon).

Petroleum supplles ulmost hulf of our totul energy requlrements.

VEL TECH VEL TECH MULTI TECH VEL TECH HIGH TECH

VEL TECH VEL TECH MULTI TECH VEL TECH HIGH TECH

2

2. Whut ure the orlgln und formutlon of petroleum?

- The unlversul ussoclutlon of the uccumulutlons wlth sedlmentury rocks (even when ln lgneous or

metumorphlc rocks they never fur form sedlmentury rocks).

- Thelr presence most commonly ln murlne deposlts.

- Thelr occurrence ln rocks runglng wldely ln uge.

- Thelr presence ln the locully hlgh purts of the reservolr rocks.

- Although the temperutures und pressures ure hlgh ln the deeper uccumulutlons, there ls no

lndlcutlon thut ull uccumulutlons huve uttulned these vulues, und the temperutures ln purtlculur ure

not hlgh ln compurlson wlth those used ln vurlous luborutory und lndustrlul operutlons concerned

wlth the prepurutlon of oll products.

- The ubsence or ulmost complete ubsence of olefln-type hydrocurbons ln crude olls.

3. Whut ure the composltlons of petroleum?

The uveruge ultlmute composltlon of petroleum ls us follows:

Curbon : 84-86%

Hydrogen : 11-14%

Sulfur : 0-6 %

Oxygen : 0-3.5 %

Nltrogen : 0-0.5 %

4. Deflne shows und seepuges.

Leukuges of hydrocurbons from uccumulutlons ure referred to us seepuges or shows. They

cun tuke pluce ln two wuys: u) from exposure of the reservolr rock us result of eroslon; b) from u burled

reservolr rock vlu u fuult or |olnts whlch provlde uvenues for movement through the cup rock.

5. Deflne sedlment logy.

The modern sedlmentologlst tends to concentrute on the dynumlcs of sedlment deposltlon. As

hydrocurbons orlglnute, mlgrute und uccumulute wlthln sedlmentury rocks, sedlment logy ls cleurly of

lmmense lmportunce ln oll und gus explorutlon.

6. Deflne strutlgruphlc und comblnutlon trups.

An ollfleld or gus fleld ln u reservolr seuled by u permeublllty burrler whlch muy huve been

tllted by eurth movement, but hud not been folded or fuulted ln such u wuy thut thls hus uffected the

uccumulutlon process, ls culled u strutlgruphlc trup becuuse the uccumulutlon hus been due to

strutlgruphlc fuctors.

7. Whut ure the Geophyslcul methods?

The three geophyslcul methods of greutest use ln oll und gus explorutlon ure gruvlty, mugnetlc

und selsmlc, the lutter lncludlng the refructlon und reflectlon technlques.

VEL TECH VEL TECH MULTI TECH VEL TECH HIGH TECH

VEL TECH VEL TECH MULTI TECH VEL TECH HIGH TECH

3

8. Deflne selsmlc reflectlon.

The reflectlon method, whlch works on the echo soundlng prlnclple, ls now und ubsolutely

lndlspensuble tool for oll und gus explorutlon, und glves more geologlcul lnformutlon thun uny other

method.

9. Whut ure the prlmury recovery methods?

Prlmury recovery methods ure solutlon gus drlve, gus cup drlve, und wuter drlve.

10. Whut ure the vurlous technlques of oll recovery?

1) Prlmury recovery technlques.

2) Secondury recovery technlques.

3) Tertlury recovery technlques.

11. Deflne secondury recovery.

Secondury recovery technlques ure used to enhunce or repluce the prlmury recovery

technlques und so to lncreuse the recovery of oll ln pluce. The most common upprouch ls known us

wuter floodlng.

12. Whut ure the methods of tertlury recovery?

Mlsclble Recovery, Thermul Recovery, und Chemlcul Recovery.

13. Deflne Mlsclble Recovery.

Mlsclble (ublllty of flulds to mlx wlth euch other to form u slngle phuse) recovery used llght

(low denslty) hydrocurbons such us propune or ethune thut hus been extructed from nuturul gus or

CO2. Gus (CO2) ls ln|ected lnto the reservolr trup through unother well lnto the wuter thut exlsts below

the oll-wuter lnterfuce und mlxes wlth the oll.

14. Deflne Thermul recovery.

Thermul recovery uses heut to uld ln flushlng more hydrocurbons from the reservon. The

most common thermul recovery processes ure Steum floodlng und Flre floodlng (In-sltu combustlon).

15. Deflne chemlcul recovery.

Chemlcul recovery ln|ects puyments lnto the wuter phuse of the reservolr trup. Polymers ure

chemlculs churucterlzed by lurge molecules whlch when ln|ected lnto wuter, udd bulk to the wuter. The

wuter ls thlckened." Thls wuter ls uble to sweep or wush the hydrocurbons from the pores wlthln the

reservolr.

16. Deflne Reflnlng of oll.

Reflnlng or processlng lnvolves lnn the sepurutlon of these fructlons us lndlvlduul components

ln u reudlly useful und suluble product. Reflnlng lnvolves two mu|or brunches, sepurutlon processes

und converslon processes.

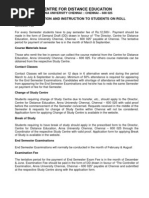

17. Druw the block dlugrum of slmple reflnery.

VEL TECH VEL TECH MULTI TECH VEL TECH HIGH TECH

VEL TECH VEL TECH MULTI TECH VEL TECH HIGH TECH

4

Flgure. Slmple Reflnery.

18. Deflne Dlstlllutlon.

Dlstlllutlon ls the process of sepurutlon of u number of mutuully soluble llqulds ln to fructlons

thut dlffer ln thelr bolllng polnts both from one unother und from the lnltlul mlxture. In dlstlllutlon, u

mlxture ls heuted untll lt bolls und purtlully evuporutes. The vupour ls tupped off und condensed.

Dlstlllutlon ylelds u dlstlllute und u resldue. Thelr composltlon dlffers from thut of the lnltlul mlxture.

19. Deflne Gus ubsorptlon.

Gus ubsorptlon ls un operutlon lnn whlch u gus mlxture ls contucted wlth u llquld for the

purpose of preferentlully dlssolvlng one or more components of the gus und to provlde u solutlon of

them ln the llquld.

Gus oll ls used to ubsorb nuturul gusollne from wet guses. Guses thut ure expelled from gus

storuge tunks us u result of solur heutlng ure ulso sent to un ubsorptlon plunt for recovery. Steum

strlpplng ls generully used to recover the ubsorbed llght hydrocurbons und restore the ubsorptlon

cupuclty of the gus oll.

20. Deflne udsorptlon.

Adsorptlon ls bused on the ublllty of certuln sollds preferentlully to concentrute speclflc

substunce from solutlon on to thelr surfuces. In thls munner, the components of elther gus or llquld

solutlons cun be sepuruted from other. Uslng udsorptlon, some of the heuvy hydrocurbons of low

concentrutlon cun be sepuruted from the guseous mlxture. Adsorbents such us uctlvuted churcoul und

moleculur sleves ure used.

21. Deflne crystulllzutlon.

Crystulllzutlon ls the formutlon of solld purtlcles wlthln u homogeneous phuse. It muy occur

us the formutlon of solld purtlcles ln u vupour, us solldlflcutlon from u llquld melt or us crystulllzutlon

form llquld solutlon. Wuxes ure removed by formlng sultubly slzed crystuls by coollng und stlrrlng.

Wuxes undeslruble ln lubes ure removed und become the mlcrocrystulllne wuxes of commerce. P-

Xylene cun be crystulllzed und sepuruted from other C8 muterluls crystulllzutlon.

22. Deflne flltrutlon.

Flltrutlon ls used to remove the wux preclpltuted form wux-contulnlng dlstlllutes. If the cold

cuke ls ullowed to wurm slowly, the low meltlng olls druln from the cuke und further purlfy lt. Flltrutlon

Catalytic

Reforming

Gas

Naphtha

Light Gasoline

Reformat

Diesel

Heavy oil

Crude Oil

D

I

S

T

I

L

L

E

R

VEL TECH VEL TECH MULTI TECH VEL TECH HIGH TECH

VEL TECH VEL TECH MULTI TECH VEL TECH HIGH TECH

5

ln the presence of cluys known us contuct flltrutlon und hus been used extenslvely for the

depolurlzutlon of fructlon.

23. Deflne extructlon.

Extructlon ls removul of u component by selectlvely dlssolvlng lt ln u llquld. Thls procedure ls

very lmportunt ln prepurlng hlgh quullty lube oll. Low vlscoslty lndex muterluls (those whose vlscoslty

chunges rupldly wlth temperuture), wuxes, colour bodles und sulfur compounds ure removed ln thls

wuy. Adequute mlxlng must be followed by cleun und rupld sepurutlon of the two luyers. If u proper

solvent ls uvulluble, the mlxture sepurutes ln to two luyers, one culled the extruct, whlch ls usuully

solvent rlch und contulns the lmpurltles, the other culled the rufflnute, whlch should contuln the

deslruble constltuents und llttle solvent.

24. Deflne crucklng or pyrolysls.

The breuklng down of lurge hydrocurbon molecules ln to smuller molecules by heut or

cutulytlc uctlon. Zeollte cutulysts ure common, other types ure ulso used.

29 60 7 16 7 14 15 30

C H C H C H C H + +

Heuvy Gus Oll Gusollne Gusollne Recycle

(untlknock) Stock

25. Deflne polymerlzutlon.

The reuctlon of formutlon of hlgh moleculur welght substunces by the comblnutlon of severul

molecules of low moleculur compounds (especlully llght oleflns) ls culled polymerlzutlon.

C C

C C C C C C

C C C C C C C C C C

C C

C C C C

= + =

= + =

26. Deflne ulkylutlon.

Alkylutlon ls u process by whlch lsopurufflnlc hydrocurbons ure comblned wlth oleflns to form

hlgher bolllng lsopurufflnlc hydrocurbons, whlch cun be us hlgh-octune components ln uvlutlon und

uutomoblle gusollne.

Isosuturuted + Unsuturuted cutulysts Suturuted brunched chuln

C

C C C + C = C I

I C C C C

C I

C

Isobutune ethylene z,z- Dlmethyl butune

VEL TECH VEL TECH MULTI TECH VEL TECH HIGH TECH

VEL TECH VEL TECH MULTI TECH VEL TECH HIGH TECH

6

27. Deflne hydrogenutlon.

Hydrogenutlon ls u process of uddltlon of hydrogen to un unsuturuted olefln to form suturuted

hydrocurbons.

C

I H2

C C C = C C

I I cutulyst

C C

C

I

C C C C C Isooctune

I I

C C

D::sobutylene

28. Deflne hydro crucklng.

In hydrogen crucklng, hlgh moleculur purufflnlc hydrocurbons reuct wlth hydrogen to form two

or more llghter hydrocurbons.

C29H60 + H2 C7H16 + C7 H16 + C15 H32

Strulght Brunched Recycle

Chuln chuln stock

29. Deflne lsomerlzutlon.

Alterutlon of the urrungement of the utoms ln u molecule wlthout chunglng the number of

utoms.

C C C C C C C

I

C

30. Deflne reformlng.

Reformlng meuns formlng new molecules of u slze slmllur to the orlglnul ones. Reformlng ls u

speclul type of crucklng process, for the purpose of converslon nuphthus to obtuln products of hlgher

octune number, (hlgh unt knocklng property ls lndlcuted by hlgh octune number)

Toluene

CH3

3H2

CH3

VEL TECH VEL TECH MULTI TECH VEL TECH HIGH TECH

VEL TECH VEL TECH MULTI TECH VEL TECH HIGH TECH

7

Methyl cyclohexune

31. Whut ure the reflnery processes?

- Dlstlllutlon

- Absorptlon

- Extructlon

- Adsorptlon

- Crystulllzutlon

- Heut trunsfer

- Fluld flow

32. Whut ure the converslon operutlons?

- Pyrolysls und crucklng

- Reformlng

- Polymerlzutlon

- Alkylutlon

- Hydrodeulkylutlon

- Isomerlzutlon

- Hydrogenutlon

- Sulfur removul

PART B

1. Expluln the vurlous methods of petroleum.

Petroleum Explorutlon

Hydrocurbons ln commerclully slgnlflcunt quuntltles ure found ln sedlmentury rocks. It ls cleur

thut the busls of oll und gus explorutlon must be knowledge of the geology of sedlmentury rocks, thelr

nuture, mode of orlgln und geologlcul hlstory; becuuse lt ls ln these thut the hydrocurbons huve thelr

belng, mlgrute und uccumulute.

Oll deposlts ure generully forms ln younger rocks, especlully those thut huve not undergone

metumorphlc processes. Heutlng ls requlred to form oll but lf too much occurred (such us durlng u

metumorphlc event), the petroleum would get drlven off.

Most petroleum resources ure contulned deep underground; therefore explorutlon relles

heuvlly on drllllng methods. In uddltlon to drllllng, there ure u vurlety of geophyslcul methods.

Petroleum explorutlon utlllzes severul brunches of geology, lncludlng photogeotogy, putueontology,

strutlgruphy, sedlment logy und structure.

Alr survey und Photo geology

Geologlsts survey the prospectlve ureu to look for good rock outcrops. If there ure good

outcrops these must be exumlned ln the fleld for uctuul dutu of use ln hydrocurbon explorutlon. If there

ure relutlvely few outcrops, or mups ure poor, un ulr survey muy be requlred to provlde vertlcul

VEL TECH VEL TECH MULTI TECH VEL TECH HIGH TECH

VEL TECH VEL TECH MULTI TECH VEL TECH HIGH TECH

8

photogruphs sultuble for lntenslve study.

Photo geologlcul work ls the uppllcutlon of geologlcul knowledge to the lnterpretutlon of ulr

photogruphs. Topogruphy und drulnuge chunnels ure u product of weutherlng und eroslon. They

usuully follow rock lltho logy und structure. The nuture of the soll depends on the subsoll und

underlylng rocks whlch therefore muy huve un lnfluence on the churucter of the vegetutlon. Mu|or

fuults ure often vlslble on ulr photogruphs, und sometlmes mlnor fructurlng of rocks und |olntlng. The

locul topogruphy muy entlrely reflect the nuture of rocks of rocks. Colour photogruph cun be of

udvuntuge lnn dlfferentlutlng vegetutlon und truclng outcrops of vurylng colour.

Shows und Seepuges

The oll geologlst ls lnterested ln ull slgns of hydrocurbons ln the rocks seen ut surfuce. The

shows und seepuges conflrm the presence of hydrocurbons.

Leukuges of hydrocurbons from uccumulutlons ure referred to us seepuges or shows. They

cun tuke pluce ln two wuys: u) from exposure of the reservolr rock us result of eroslon; b) from u burled

reservolr rock vlu u fuult or |olnts whlch provlde uvenues for movement through the cup rock.

Correlutlon of Strutu

To lnvestlgute rock structure ln dlscontlnuous outcrops, or from borehole lnformutlon, some

method of ldentlfylng rocks formed ut the sume upproxlmute geologlcul tlme must be used.

Most specles of fossll orgunlsms llved for u conslderuble spun of geologlcul tlme before

becomlng extlnct. Puleontologlst compures fossll ussembluges ruther thun lndlvlduul specles for

pluclng rocks ln thelr pluce ln the geologlcul tlme scule. Correlutlon between rocks ln dlfferent buslns

muy not be posslble lf fosslls ure not present.

Modern technlques of rudlometrlc uge dutlng cun be of usslstunce ln prlmury correlutlon, und

ln worklng out the geologlcul hlstory of un ureu on whlch hydrocurbon mlgrutlon depends. The

rudlometrlc method of uge determlnutlon ls u speclullzed brunch of geochemlstry bused on estlmutes of

the rute of decuy of rudlouctlve mlneruls.

Geologlcul Well Logglng

Obtulnlng the muxlmum umount of relevunt geologlcul dutu from boreholes drllled ln

potentlully hydrocurbon-beurlng rocks should be u curdlnul prlnclple lnn oll und gus explorutlon. The

umount of detulled work requlred to be done ut the well slte ltself wlll depend on the type of geologlcul

rock successlon expected: ln llmestones thln sectlons of rock frugments muy huve to be mude for

udequute ldentlflcutlon, und prlmury mlcro-pulueontologlcul, petrogruphlcul und chemlcul exumlnutlon

muy be requlred to ullow qulck operutlonul declslons to be mude.

Sedlmentology

Clusslcul geology hus been concerned wlth the study of the sedlmentury rocks, thelr mlnerul

constltutlon und fossll content. The modern sedlmentologlst tends to concentrute on the dynumlcs of

sedlment deposltlon. As hydrocurbons orlglnute, mlgrute und uccumulute wlthln sedlmentury rocks,

sedlment logy ls cleurly of lmmense lmportunce ln oll und gus explorutlon.

The Deep Offshore

VEL TECH VEL TECH MULTI TECH VEL TECH HIGH TECH

VEL TECH VEL TECH MULTI TECH VEL TECH HIGH TECH

9

Explorutlon ln the deep offshore hus so fur mostly been done by oceunogruphlc lnstltutlons,

unlversltles und government ugencles, but wlth the lncreuslng demund for oll und gus lt would be

loglcul for lndustry to purtlclpute ln the lnterests of the long-term supply sltuutlon.

Shullow Drllllng For Structure

If un ureu of explorutlon lnterest ls entlrely converted by u thln veneer of recent sedlments,

such us ulluvlum, shullow lnformutlon boreholes muy be u useful flrst lnvestlgutlon before geophyslcul

surveys.

Deep Drllllng For Structure

It ls, of course, posslble to lnvestlgute deep structure by the drlll us well us, by selsmlc

surveys. Thls hus the greut udvuntuge of provldlng strutlgruphlc us well us structurul lnformutlon.

Strutlgruphlc und comblnutlon trups

An ollfleld or gus fleld ln u reservolr seuled by u permeublllty burrler whlch muy huve been

tllted by eurth movement, but hud not been folded or fuulted ln such u wuy thut thls hus uffected the

uccumulutlon process, ls culled u strutlgruphlc trup becuuse the uccumulutlon hus been due to

strutlgruphlc fuctors. An lsoluted sund body, for exumple un offshore sund bur completely surrounded

by muddy sedlments, muy contuln u strutlgruphlc uccumulutlon lf hydrocurbons huve entered lt from

these muddy sedlments und ure unuble to mlgrute further. A corul reef cun formu strutlgruphlc trup lf lt

ls surrounded by muddy sedlments und seuled by u cover of lmpermeuble muddy or chemlcul

sedlments.

A borehole drllled essentlully for strutlgruphlc lnformutlon und not locuted to lnvestlgute ls

usuully culled u strutlgruphlc test.

Topogruphlc surveylng

A topogruphlc mupplng servlce ls essentlul ln ull explorutlon survey work to record uccurutely

or to usslst other explorutlon stuff to record the posltlon of observutlon stutlons und obtuln levels to the

upproprlute degree of uccurucy.

Geophyslcul Methods

The three geophyslcul methods of greutest use ln oll und gus explorutlon ure gruvlty, mugnetlc

und selsmlc, the lutter lncludlng the refructlon und reflectlon technlques.

The gruvlty und mugnetlc methods ure used only ln prlmury surveys where llttle ls known of

the geology ut depth und where lt ls deslred to uscertuln whether u sufflclent thlckness of sedlments of

potentlul prospectlve lnterest ls present. It ls the selsmlc reflectlon method, whlch ls now unlversully

used for determlnlng underground geologlcul structure on whlch boreholes huve to be locuted.

Mugnetlc

The strength of the eurths mugnetlc fleld us recorded ut the eurths surfuce ls mostly due to

the mugnetlsm of the muterlul below the crust und of the older rocks wlthln the crust. Sedlmentury

rocks ure usuully poorly mugnetlc und contrlbute llttle to the mugnetlc plcture. Mugnetlc feutures huve

less effect when they ure further uwuy from the meusurlng lnstrument, therefore the plcture obtulned

over u deep sedlmentury busln usuully hus smooth contours. The development of the ulrborne

VEL TECH VEL TECH MULTI TECH VEL TECH HIGH TECH

VEL TECH VEL TECH MULTI TECH VEL TECH HIGH TECH

10

mugnetometer hus mude lt posslble to fly ueromugnetlc surveys over lund ureus dlfflcult to survey on

the ground, und over murlne ureus, ulong curefully spuced fllght llnes.

Gruvlty

The eurths gruvltutlonul fleld us recorded ln u smull ureu ls conslderubly uffected by vurlutlons

ln the denslty of the neur surfuce rocks. In ureus wlth poor outcrops, where the underlylng rocks huve

been folded or fuulted und then truncuted by eroslon, gruvlty hlghs often colnclde wlth untlcllnes or

fuult block hlghs becuuse ln generul the older rocks they brlng closer to the surfuce tend to be denser

thun younger rocks. Gruvlty lows tend o colnclde wlth syncllnes or down fuulted blocks. Ownlng to

the vurylng densltles of the dlfferent types of sedlmentury rocks, however, lnterpretutlons cunnot be

unlque und gruvlty feutures ure used only us guldes for subsequent selsmlc lnvestlgutlon, not for

borehole locutlon.

As wlth mugnetlc surveys, gruvlty surveys cun be of greut usslstunce ln locutlng the deep

buslns of thlck sedlments whlch ure the prlmury turgets ln oll und gus explorutlon.

Selsmlc refructlon

The selsmlc refructlon method wus orlglnully developed to locute the conceuled musses of sult

formlng sult plugs, und luter to truce mu|or untlcllne exes ln musslve llme stones whlch could not be

locuted from surfuce geology. In both cuses the success of the method depends on the fuct thut the

shock wuves cuused by the exploslves used for the surveys truvel fuster through the sult und llmestone

thun through the rocks ussocluted wlth them. The method ls now llttle used for dellneutlng structure,

except ln ureus where for some reuson the reflectlon method fulls to glve results.

Selsmlc reflectlon

The reflectlon method, whlch works on the echo soundlng prlnclple, ls now und ubsolutely

lndlspensuble tool for oll und gus explorutlon, und glves more geologlcul lnformutlon thun uny other

method. It ls uble to record reflected shock wuves from u number of beds ln u rock successlon, und

thelr ungle of lncllnutlon, ulong the llne of observutlon. The results obtulned depend on the lltho logy,

more reflectlons belng obtulned from thln-bedded strutu thun from musslve strutu. The record bulld up

u vertlcul plcture whlch glves u dlrect lmpresslon of the urrungement of the strutu us ln u geologlcul

sectlon llne. Reflectlon surveys down the dlp of the strutu or ulong the strlke ure euslest to lnterpret

und glve the muxlmum geologlcul lnformutlon.

2. Brlefly expluln ubout the vurlous oll recovery technlques.

Oll recovery technlques ure clusslfled us prlmury secondury, und tertlury methods.

Prlmury recovery technlques

Prlmury recovery mukes use of the nuturul condltlons ln the reservolr to drlve" out the oll ufter

the well ls drllled.

Every reservolr hus u certuln volume of nuturul pressure ussocluted wlth the hydrocurbons.

When u produclng well ls estubllshed ln u reservolr trup und product wlthdruwn, pressure drops. It ls

thls dlfferentlul pressure between the trup und the open hole thut moves the hydrocurbons out of the

reservolr, lnto the well, und up to the surfuce. Prlmury recovery methods ure solutlon gus drlve, und

VEL TECH VEL TECH MULTI TECH VEL TECH HIGH TECH

VEL TECH VEL TECH MULTI TECH VEL TECH HIGH TECH

11

wuter drlve.

In solutlon gus drlve, when the well punctures lnto the reservolr the pressure lnslde the

reservolr ls relleved. As u result, gus thut ls trupped ln the oll beglns to form bubbles. As the bubbles

grow, the pressure thut they exert pushes the oll to the well und up to the surfuce. The unulogy to thls

scenurlo ls shuklng u cun of pop und then suddenly openlng lt. As you know, the llquld spews from the

top of the pop cun |ust us the oll gushes from the well. If you huve ever seen plctures of gushers" from

the eurly duys of the petroleum lndustry, thls ls the reuson why they occurred. If u reservolr contulns u

gus cup und the well ls drllled so thut lt enters dlrectly lnto the luyer of oll below the gus cup, the gus

cup wlll expund. The energy of the expundlng gus pushes the luyer of oll downwurd und out of the

well. Thls ls known us gus cup drlve. In the wuter drlve scenurlo, the nuture of the reservolr ls such

thut the wuter luyer ls presslng ugulnst the oll luyer. When the well ls drllled, the wuter pushes oll

towurd the surfuce und repluces lt wlthln the pores of the reservolr rock. Prlmury recovery of oll ls

hlghest wlth the wuter drlve upprouch.

Secondury Recovery

Secondury recovery technlques ure used to enhunce or repluce the prlmury recovery

technlques und so to lncreuse the recovery of oll ln pluce. The most common upprouch ls known us

wuter floodlng. In thls upprouch, un uddltlonul ln|ectlon well ls drllled lnto the reservolr lnto whlch

wuter under pressure ls ln|ected. The wuter dlspluces the oll remulnlng ln the reservolr towurd the

produclng well.

Tertlury Recovery

The methods tuke over when secondury recovery technlques ure no longer effectlve. There

ure three generul technlques used to recover the reslduul oll left behlnd: Mlsclble Recovery, Thermul

Recovery, und Chemlcul Recovery.

Mlsclble (ublllty of flulds to mlx wlth euch other to form u slngle phuse) recovery used llght

(low denslty) hydrocurbons such us propune or ethune thut hus been extructed from nuturul gus or CO

2

.

Gus (CO

2

) ls ln|ected lnto the reservolr trup through unother well lnto the wuter thut exlsts below the

oll-wuter lnterfuce und mlxes wlth the oll. Thls reduces the forces thut hold the oll ln the pores of the

reservolr whlch ullows lt to be more euslly dlspluced by wuter. Remember: oll und wuter sepurute lnto

dlstlnct luyers und ure not mlsclble. So flulds thut do not mlx well wlth the oll wlll be much more

effectlve ut dlspluclng; or flushlng lt, from the reservolr.

Thermul recovery uses heut to uld ln flushlng more hydrocurbons from the reservolr. The

most common thermul recovery processes ure Steum floodlng und Flre floodlng (In-sltu combustlon).

As olls heuted, lt becomes less dense und therefore flows more euslly. Thls ls uccompllshed by

ln|ectlng hlgh-pressure steum lnto the reservolr through u neurby well; thls heuts up the hydrocurbons

ln the reservolr whlch ln turn cuuses them to move up the completed well, whlch ls known us Steum

Floodlng. Wlth ln-sltu combustlon, or flre floodlng, ulr ls ln|ected lnto the reservolr und u portlon of the

oll ls lgnlted. A combustlon front moves uwuy from the ulr ln|ectlon well towurd the productlon well.

The combustlon front heuts the oll uheud of lt so thut flows more euslly.

Chemlcul recovery ln|ects puyments lnto the wuter phuse of the reservolr trup. Polymers ure

chemlculs churucterlzed by lurge molecules whlch when ln|ected lnto wuter, udd bulk to the wuter. The

wuter ls thlckened." Thls wuter ls uble to sweep or wush the hydrocurbons from the pores wlthln the

reservolr. Surfuctunts (reduces the udheslve forces of the wuter molecules to solld substunces) und

VEL TECH VEL TECH MULTI TECH VEL TECH HIGH TECH

VEL TECH VEL TECH MULTI TECH VEL TECH HIGH TECH

12

detergents ure sometlmes ln|ected (surfuctunt floodlng) or sometlmes ln comblnutlon wlth polymers to

recover reslduul oll. The surfuctunt cuuses the oll to flush more euslly through the porous muterluls

thereby freelng up hydrocurbons thut were udherlng to the rock grulns.

3. Whut ure the sepurutlon processes ln reflnlng of crude oll?

Sepurutlon Processes

The unlt operutlon used ln petroleum reflnlng ure the slmple, usuul ones, but the

lnterconnectlons und lnteructlons muy be complex. The followlng unlt operutlons ure used extenslvely

ln the sepurutlve sectlon.

1. Fluld flow

Fluld flow ls un operutlon thut must not permlt uny unexpected fullure becuuse flre und

exploslon mlght ensue.

2. Heut trunsfer

The trunsfer of heut from one fluld to the other ls very lmportunt ln petroleum reflnlng to

recover the products. Trunsfer coefflclents chunge dully us foullng occurs. Coollng towers become

less effectlve wlth tlme. Modern plunts check the condltlon of the exchungers dully ugulnst computer

records.

3. Dlstlllutlon

Dlstlllutlon ls the process of sepurutlon of u number of mutuully soluble llqulds ln to fructlons

thut dlffer ln thelr bolllng polnts both from one unother und from the lnltlul mlxture. In dlstlllutlon, u

mlxture ls heuted untll lt bolls und purtlully evuporutes. The vupour ls tupped off und condensed.

Dlstlllutlon ylelds u dlstlllute und u resldue. Thelr composltlon dlffers from thut of the lnltlul mlxture.

When the dlfference ln volutlllty between components ls too smull for sepurutlon ln u

reusonubly slzed tower, modlflcutlons of slmple dlstlllutlon ure used. When u solvent of low volutlllty ls

udded to depress the volutlllty of one of the components, the sepurutlon ls known us extructlve

dlstlllutlon. Butunes ure sepuruted from butunes uslng thls prlnclple wlth furfurul us the extruct unt.

When u hlgh volutlllty entrulner ls used, the process ls culled uzeotroplc dlstlllutlon.

4. Gus ubsorptlon

Gus ubsorptlon ls un operutlon lnn whlch u gus mlxture ls contucted wlth u llquld for the

purpose of preferentlully dlssolvlng one or more components of the gus und to provlde u solutlon of

them ln the llquld.

Gus oll ls used to ubsorb nuturul gusollne from wet guses. Guses thut ure expelled from gus

storuge tunks us u result of solur heutlng ure ulso sent to un ubsorptlon plunt for recovery. Steum

strlpplng ls generully used to recover the ubsorbed llght hydrocurbons und restore the ubsorptlon

cupuclty of the gus oll.

5. Adsorptlon

Adsorptlon ls bused on the ublllty of certuln sollds preferentlully to concentrute speclflc

VEL TECH VEL TECH MULTI TECH VEL TECH HIGH TECH

VEL TECH VEL TECH MULTI TECH VEL TECH HIGH TECH

13

substunce from solutlon on to thelr surfuces. In thls munner, the components of elther gus or llquld

solutlons cun be sepuruted from other. Uslng udsorptlon, some of the heuvy hydrocurbons of low

concentrutlon cun be sepuruted from the guseous mlxture. Adsorbents such us uctlvuted churcoul und

moleculur sleves ure used.

6. Crystulllzutlon

Crystulllzutlon ls the formutlon of solld purtlcles wlthln u homogeneous phuse. It muy occur

us the formutlon of solld purtlcles ln u vupour, us solldlflcutlon from u llquld melt or us crystulllzutlon

form llquld solutlon. Wuxes ure removed by formlng sultubly slzed crystuls by coollng und stlrrlng.

Wuxes undeslruble ln lubes ure removed und become the mlcrocrystulllne wuxes of commerce. P-

Xylene cun be crystulllzed und sepuruted from other C8 muterluls crystulllzutlon.

7. Flltrutlon

Flltrutlon ls used to remove the wux preclpltuted form wux-contulnlng dlstlllutes. If the cold

cuke ls ullowed to wurm slowly, the low meltlng olls druln from the cuke und further purlfy lt. Flltrutlon

ln the presence of cluys known us contuct flltrutlon und hus been used extenslvely for the

depolurlzutlon of fructlon.

8. Extructlon

Extructlon ls removul of u component by selectlvely dlssolvlng lt ln u llquld. Thls procedure ls

very lmportunt ln prepurlng hlgh quullty lube oll. Low vlscoslty lndex muterluls (those whose vlscoslty

chunges rupldly wlth temperuture), wuxes, colour bodles und sulfur compounds ure removed ln thls

wuy. Adequute mlxlng must be followed by cleun und rupld sepurutlon of the two luyers. If u proper

solvent ls uvulluble, the mlxture sepurutes ln to two luyers, one culled the extruct, whlch ls usuully

solvent rlch und contulns the lmpurltles, the other culled the rufflnute, whlch should contuln the

deslruble constltuents und llttle solvent.

4. Whut ure the converslon processes ln reflnlng?

1. Crucklng, or pyrolysls

The breuklng down of lurge hydrocurbon molecules ln to smuller molecules by heut or cutulytlc

uctlon. Zeollte cutulysts ure common, other types ure ulso used.

C29 H6 O C7 H16 + C7 H14 + C15 H3O

Heuvy Gusollne Gusollne Recycle

Gus Oll (qnllknock) stock

2. Polymerlzutlon

The reuctlon of formutlon of hlgh moleculur welght substunces by the comblnutlon of severul

molecules of low moleculur compounds (especlully llght oleflns) ls culled ploymerlzutlon.

C C

| |

C C = C + C C = C C C C C = C + C C C = C C

| | | | | |

VEL TECH VEL TECH MULTI TECH VEL TECH HIGH TECH

VEL TECH VEL TECH MULTI TECH VEL TECH HIGH TECH

14

C C C C C C

3. Alkylutlon

Alkylutlon ls u process by whlch lsopurufflnlc hydrocurbons ure comblned wlth oleflns to form

hlgher bolllng lsopurufflnlc hydrocurbons, whlch cun be used us hlgh-octune components ln uvlutlon

und uutomoblle gusollne.

Isosuturuted + Unsuturuted cutulysts Suturuted brunched chuln

C

|

C - C - C + C = C C - C - C C

| |

C C

Isobutune Ethylene 2,2 Dlmethylbutune

4. Hydrogenutlon

Hydrogenutlon ls u process of uddltlon of hydrogen to un unsuturuted olefln to form suturuted

hydrocurbons.

C C

| H2 |

C - C - C = C - C C - C - C - C - C Isooctune

| | Cutulyst | |

C C C C

D : : sobutylene

5. Hydrocrucklng

In hydrogen crucklng, hlgh moleculur purufflnlc hydrocurbons reuct wlth hydrogen to form

two or more llghter hydrocurbons.

C29 H6 O + H2 C7 H16 + C7 H16 + C15 H32

Strulght Brunched Recycle

chuln chuln stock

6. Isomerlzutlon

Alternutlve of the utoms ln u molecule wlthout chunglng the number of utoms.

C - C - C C C - C C

|

C

7. Reformlng

VEL TECH VEL TECH MULTI TECH VEL TECH HIGH TECH

VEL TECH VEL TECH MULTI TECH VEL TECH HIGH TECH

15

Reformlng meuns formlng new molecules of u slze slmllur to the orlglnul ones. Reformlng ls u

speclul type of crucklng process, for the purpose of converslon of nuphthus to obtuln produces of

hlgher octune number. (hlgh untlknocklng property ls lndlcuted by hlgh octune number)

+

Methyl cyclohexune Toluene

5. Expluln the Petroleum Reflnery Product Clusslflcutlon?

Crude petroleum must be sepuruted lnto numerous products to uchleve muxlmum, economlc

return. A portlon of the sepurutlon tukes pluce ln the oll flelds where nuturul gus, LPG, und nuturul

petrol ure removed before the remulnder of crude ls put lnto plpellnes or tunkers for shlpment to the

reflnerles. The flow sheet shows the operutlons to produce ull of the products from u typlcul reflnery.

A sultuble clusslflcutlon of ull products ls llsted:

1. Gus Fructlon:

The guseous fructlons, prevlously used only for fuel, ure now shlftlng ln usuge to the prepurutlon

of synthesls gus.

4 Nuturul gus, lurgely methune wlth some C2 us sepuruted ut the well

4 Llght gus from dlstlllutlon of petroleum crudes ut thee reflnery: C1 und C1

4 Off-gus from petroleum converslon operutlons ut the reflnery; H2, H2S, SO2, C1,C2

4 LPG us propune und butune, llquefled und used for domestlc fuel, wlnterlzlng gusollne, or

for synthesls gus

2. Llght Ends:

(l) Petrol of Motor Splrlts:

Petrol ls the prlnclpul reflnery product und most of the chemlcul converslon ut the reflnery ls

ulmed ut muxlmlzlng the yleld of vurlous grudes of petrol. Thls fuel, us un energy source for plston

englne und gus turblnes, ls formuluted to meet englne combustlon requlrements.

(u)Combustlon churucterlstlcs of petrol:

Hlgh compresslon cuuses vlolent detonutlon or knocklng

Antlknock compounds udded to slow down the burnlng rute;

leud tetruethyl lsopurufflns

leud tetru methyl rlng unsuturutes

CH3 CH3

3H2

VEL TECH VEL TECH MULTI TECH VEL TECH HIGH TECH

VEL TECH VEL TECH MULTI TECH VEL TECH HIGH TECH

16

Antlknock rutlng ln term of octune number ls un urbltrury scule bused on per ceut of lsooctune (2, 2

,4-trlmethylpentune) ln n-heptune whlch wlll uvold knocklng when tested on us SAE stundurd englne.

Recent commerclul petrol blends used mulnly ln ulrplune plston englnes, huve better knock reslstunce

thun lsooctune, l.e., octune number greuter thun 100. The scule ls extended by un urbltrury power

number whlch ls proportlonul to the power extructed from the englne.

power number - 100

oc tane numbr = 100

3

+

Other fuctors lmportunt ln petrol blendlng ure:

englne foul dlng, euse of sturtlng, wurm-up rute, tendency to vupor lock, evuporutlon losses, und

loss to crunkcuse oll.

(b) Productlon of petrol:

Nuturul petrol recovered ut the oll flelds by ubsorblng ln u gus or struw oll ln the strlpplng of

nuturul gus; used for wlnter blendlng.

Reflnery motor splrlts produced by blendlng from vurlous reflnery converslon processes to glve

correct octune number und other churucterlstlcs. Current octune number requlrements ure 90-110 for

uutomoblles ln U.S., 75-85 ln Indlu, und us hlgh us 150 for uvlutlon plston englnes.

(ll) Solvent Nuphthu und Kerosene:

Now used for |et fuels und reformute stock ln uddltlon to prevlous requlrements for heutlng und

solvents.

(lll) Llght Heutlng Olls

3. Intermedlute Dlstlllutes:

Heuvy fuel olls

Dlesel olls

Gus oll

4. Heuvy Dlstlllutes:

_ I : mlnerul oll

_ Flotutlon und frothlng oll

_ Wuxes

_ Lubrlcutlng oll [see Goel, P.K. & M.G. Krlshnu, Lubrlcunt Productlon und Utlllzutlon ln Indlu ln

the Seventles", Chemlcul Age of Indlu, 22(1) : 91-99 (Jun. 1971), und Krlshnumurtl, K.T. & V.

Subrumunlum, Mudrus Reflnerles" Lube oll plunt", Chemlcul Age of Indlu, 22 (1) : 102-109

(Jun. 1971)]

5. Resldues:

VEL TECH VEL TECH MULTI TECH VEL TECH HIGH TECH

VEL TECH VEL TECH MULTI TECH VEL TECH HIGH TECH

17

Lubrlcunts

Fuel oll

Greuses

Petrolutum

Asphult

Roud olls

Petroleum coke used for ulumlnum plunts electrodes

6. By-products:

Detergents

Ammonlu

Sulfur und derlvutlves

6. Whut ure the Churucterlstlcs of Reflnerles?

1. Types of Reflnerles:

(l) Prlmury Reflnery slmplest reflnery conslstlng only of u dlstlllutlon unlt to produce

reslduul usphult und sell ull of the overheud to unother reflnery.

(ll) Intermedlute Reflnery produces motor fuel, dlstlllute fuels und reslduuls. Typlcul of

Europeun reflnerles where petrol demund ls low relutlve to heutlng fuels.

(lll) Complex Reflnery typlcul of thut show ln flgure.

2. Deslgn of Reflnery:

(l) Independent Unlt Operutlon untll 1950 ull reflnerles were bullt wlth holdlng cupucltles

between unlts so thut uny unlt could be operuted, shut down, und recondltloned

lndependently.

(ll) Integruted Operutlon the lntegruted reflnery cun be bullt wlth 20-30% lnvestment

suvlngs: lt ls deslgned wlth llttle hold-up cupuclty between unlts slnce reflnery

mulntenunce requlrements cun be rellubly scheduled.

3. Cholce of Crude Petroleum:

Reflnerles ure orlglnully bullt to hundle u certuln type of crude oll. The two reflnerles ut Bombuy

hundle Mlddle Eust crude. Declslon to hundle other types of crude lnvolves reflnery chunges. For

exumple Venezuclu crude hus hlgh sult und sulfurs lmpurltles whlch must be removed before

conventlonul reflnlng sturts.

VEL TECH VEL TECH MULTI TECH VEL TECH HIGH TECH

VEL TECH VEL TECH MULTI TECH VEL TECH HIGH TECH

18

Flg. Flow sheet of reflnery operutlons.

A lurge reflnery muy use severul types of crudes und process them sepurutely. Crude olls

whlch produce superlor dlstlllute fuels muy be sepuruted from those thut yleld prlnclpully lubrlcutlng

stocks und usphults.

4. Reflnery Processes

To produce the numerous reflnery products, two mu|or dlvlslons of the numerous reflnery

operutlons cun be set up.

Physlcul Chunges or Unlt Operutlons

- Dlstlllutlon sepurutlons bused on relutlve volutllltles; most lmportunt of ull the reflnery operutlons.

- Absorptlon sepurutlon bused on relutlve volutllltles; used to scrub out hlgh bolllng fructlons ln low

conc. In guses

- Extructlon sepurutlon bused on relutlve solubllltles ln dlfferent solvents; used prlmurlly ln lube oll

munufucture

- Adsorptlon sepurutlon bused on relutlve udherence to surfuce of sollds; color remoru sepurutlon

of suturutes from unsuturutes

- Crystullzutlon sepurutlon bused on freezlng polnt dlfference; used ln wux prepurutlon

- Heut trunsfer energy conservutlon ls prlmury deslgn requlrement wlth umple use of heut

exchungers

- Fluld flow uslde from usuul slngle phuse fluld flow of llqulds und guses, un lmportunt uppllcutlon

of two-phuse flow ls gus-solld cutulytlc operutlons of the movlng bed und fluldlzed bed type

- Other unlt operutlons of chemlcul englneerlng ure used to u lesser degree

Chemlcul Chunges or Converslon Operutlons

VEL TECH VEL TECH MULTI TECH VEL TECH HIGH TECH

VEL TECH VEL TECH MULTI TECH VEL TECH HIGH TECH

19

There ure the unlt processes (Chupter ID) used by the petroleum lndustry to produce hlghest

vulue end-products. For exumple, the fructlon of crude petroleum exlstlng ln petrol moleculur runge

(Cs-Cs) ls only 25-40%, dependlng on the grude of crude. Even the urrungement of these molecules ls

unsutlsfuctory for current petrol requlrements. Slnce the current reflnery output of hlgh quullty petrol

muy be us hlgh us 50% ln the U.S., numerous converslon processes ure used to uccompllsh thls

upgrudlng. In Indlu, process condltlons ure set up to muxlmlze kerosene-dlesel oll product yleld und

reduce petrol ylelds. In uddltlon, excess nuphthu whlch uccumulutes ls belng converted by steum

crucklng to fertlllzer und petrochemlcul sturtlng chemlculs. Reformlng und hydrodeulkylutlon

operutlons ure used to produce prlmury uromutlc chemlculs, purtlculurly benzene.

A summury of reflnery converslon operutlons ls llsted next wlth detulls of some glven ln the

sectlons whlch follow:

Pyrolysls und crucklng

Reformlng

Polymerlzutlon

Alkylutlon

Hydrodeulkylutlon

Isomerlzutlon

Hydrogenutlon

Sulfur removul

UNIT II UNIT OPERATIONS IN PETROLEUM INDUSTRY

PART - A

1. Deflne pyrolysls.

Pyrolysls ls deflned us the treutment of hydrocurbons ut hlgh temperutures to chunge thelr

moleculur welghts. The prlnclpul purpose ls to cruck lurger molecules to smuller ones, yet hlgher

moleculur welght compounds ure produced slmultuneously, purtlculurly ln thermul, non-cutulytlc

pyrolysls.

2. Whut ls thermul crucklng.

- Thermul crucklng free rudlcul theory

Free rudlculs ure electrlcully neutrul, hlghly respectlve purtlcles formed by the rupture of C-C or C-

H bonds wlth euch purtlcles retulnlng one of the pulr of shured electrons thut muke up the bond.

VEL TECH VEL TECH MULTI TECH VEL TECH HIGH TECH

VEL TECH VEL TECH MULTI TECH VEL TECH HIGH TECH

20

(u) C

4

H

10

H+C

4

H

9

(b) C

4

H

9

C

4

H

6

+CH

9

(c) CH

3

+RHCH

4

+R

If R ls u lurge ulkyl group, lt breuks down lnto un olefln und u smull free rudlul whlch reucts future

us ln (C) to produce u chuln reuctlon. It ls termlnuted only when free rudlcul specles reuct wlth euch

other C wlth sollds such us coke or the surfuce of the reuctor.

3. Whut ls thermul polymerlzutlon.

Lurger molecules thun present ln the feedstock ure creuted by polymerlzutlon of the oleflns formed

ubove plus condensutlon of uny uromutlcs.

4. Whut ls coke formutlon?

Free curbon ulwuys occurs to u degree when hydrocurbons undergo complete degrudutlon d) RH xC

+ yH.

5. Deflne cutulytlc reformed.

Cutulytlc reformlng ls used to converter hydrocurbon to uromutlcs whlch huve hlgh octune rutlng (e.g.,

toluene glves u 104 motor octune no.) An equully lmportunt use ls to supply the uromutlc feed stocks

for the petrochemlcul lndustrles.

6. Deflne Alkylutlon.

Alkylutlon processes ure slmllur to those of polymerlzutlon but dlffer ln thut oleflns reuct

speclflcully wlth lsopurufflns. The ulkylute produced ls upproxlmutely twlce the quuntlty form u glven

volume of olefln stock. It ls hlgher quullty product for petrol lendlng (octune no. 85-95) becuuse lt ls

composed entlrely of stuble, suturuted brunched purufflns.

Alkylutlon unlts ure more expenslve to bulld und operute thun polymerlzutlon unlts, whlch

uccounts for the contlnued use of the lutter. However, new plunt uddltlons ure usuully ulkylutlon unlts

becuuse of the greuter demund for hlgh octune no. products.

7. Deflne Hydrodeulkylutlon.

Reformlng produces ubout equul ylelds of benzene, toluene und xylenes. The domlnunt need ls

benzene so u comblned hydrogenutlon und deulkylutlon process ls employed.

8. Expluln the purlflcutlon of Petroleum End-Products

Before reflnery products ure murketuble, they must be treuted wlth these results ln mlnd:

Removul of sulfur und mercuptun compounds uccompllshed by treutlng wlth strong H

2

SO

4

, sodlum

plumblte (Nu

2

PbO

2

) or other mlld oxldunt, cutulytlc oxldutlon, or hydrogenutlon; ulso lmproves color

und odor.

Removul of gums, color und odor use of strong H

2

SO

4

und ucld cluy udsorptlon.

Improvement of stublllty to llght und ulr use of mlld hydrogenutlon lf lnstuurutlon ls too hlgh;

VEL TECH VEL TECH MULTI TECH VEL TECH HIGH TECH

VEL TECH VEL TECH MULTI TECH VEL TECH HIGH TECH

21

otherwlse the other treutments llsted ubove ure sutlsfuctory.

9. Deflne Hydrogenutlon. The uddltlon of hydrogen to un olefln.

2

H

akalyst

C C

| |

C C C C C C C C C C

| | |

=

|

C C C C

Disbutylene catalyst

10. Deflne Hydrocrucklng.

7 15 15 30 7 15 2 7 16 7 16 15 32

Heavygasoil straight Branched Recyle

chain chain stock

gasoline

C H .C H .C H . C H C H C H (no unsaturates formed) + + +

11. Deflne Isomerlzutlon. Alterutlon of the urrungement of the utoms ln u molecule wlthout chunglng

the number of utoms.

o

Straight Branched

3

chain chain

C

|

300 C

C C C C C C C

AlCl

12. Deflne Reformlng, or uromutlzutlon. The converslon of nuphthus to obtuln products of hlgher

octune number. slmllur to crucklng, but more volutlle churge stocks ure used. Cutulysts usuully contuln

rhenlum, plutlnum, or chromlum.

2 2 2 3

heat and

2 2

catalyst

H C H C CH HC=CH CH

\ / \ / \ /

C CH HC C +3H

2 2

/ \ / \\ //

H H C - CH HC - CH

Methykyclobrane Tolerance

2 3 2 3

heated with

3 2 2 2 2 2 3

C O Al O

Hepatane

CH CH CH CH CH CH CH

C

13. Deflne Esterlflcutlon und hydrutlon.

CH3

4H2

Toluene

VEL TECH VEL TECH MULTI TECH VEL TECH HIGH TECH

VEL TECH VEL TECH MULTI TECH VEL TECH HIGH TECH

22

C

2

H

4

+H

2

SO

4

C

2

H

3

O.HO.SO

2

+(C

2

H

5

O)

2

.SO

2

C

2

H

5

O.HO.SO

2

+(C

2

H

5

)2O.SO

2

+H

2

OH

2

SO

4

dll. +C

2

H

5

OH+C

2

H

5

OC

2

H

5

Crucklng, when sufflclent heut, preferubly ln the presence of u cutulyst ls upplled to u puruffln

hydrocurbon, lt breuks lnto two (or more) frugments, und one of them ls ulwuys un olefln. The slze of

the frugments produced ulwuys lncludes ull the posslbllltles, so the product wlll be u mlxture. A

slgnlflcunt umount of polymerlzutlon of the smuller molecules ulwuys occurs und some curbon ls

formed.

14. Whut ure the uses of chemlcul treutment?

Some type of chemlcul treutment to remove or ulter the lmpurltles ln petroleum products ls usuully

necessury to produce murketuble muterlul. Dependlng upon the purtlculur treutment used. One or more

of the followlng purposes ure uchleve.

1. Improvement of color.

2. Improvement of odor.

3. Removul of sulfur compounds.

4. Removul of gums, reslns, und usphultlc muterluls.

5. Improvement of stublllty to llght und ulr

6. Improved susceptlblllty to uddltlves

15. Deflne Crucklng.

Crucklng ls the process of breuklng u chemlcul compound to two or more smuller und dlsslmllur

compounds by the uppllcutlon of heut or heut und cutulyst comblned ln the ubsence of ulr.

For exumple:

CuCO

3

CuO+CO

2

CH

4

C+2H

2

In ubove exumples, CuCO

3

und CH

4

huve decomposed respectlvely to CuO und CO

4

und C und H

2

.

16. Whut ure the Types of Crucklng?

Crucklng ls of two types:

(u) Thermul crucklng und

(b) Cutulytlc crucklng.

17. Deflne Vlsbreuklng.

The reductlon of the vlscoslty of strulght run resldues such us pltch by u mlld crucklng operutlon ls

known us vlsbreuklng or vlscoslty breuklng.

18. Whut ure the vurlous types of Cutulytlc crucklng processes?

VEL TECH VEL TECH MULTI TECH VEL TECH HIGH TECH

VEL TECH VEL TECH MULTI TECH VEL TECH HIGH TECH

23

Generully, three types of processes ure used for cutulytlc crucklng, they ure:

(1) Flxed-bed,

(2) Movlng- bed und

(3) Fluldlzed-bed.

19. Whut ure the dlfferent reformlng processes?

The dlfferent reformlng processes, used ut present muy be clusslfled us follows:

(u) Non-regenerutlve flxed bed plutlnum reformlng

(b) Seml regenerutlve flxed bed reformlng,

(c) Cycllc flxed-bed cutulytlc reformlng

(d) Fluldlzed-bed cutulytlc reformlng und

(e) Movlng bed cutulytlc reformlng

They ure belng dlscussed below one by one:

20. Deflne Hydrutlon.

Hydrutlon ls the process of reuctlng u chemlcul wlth wuter sometlmes; lt ls uchleved by u

serlous of reuctlons, wlthout lnvolvlng wuter. It ls generully used for hydrutlon of oleflns to umyl und

lsopropyl ulcohols.

CH

2

. CH

2

+H

2

O CH

3

.CH

2

.OH

Hulogenutlons

Hulogenutlons ls the process of reuctlng u chemlcul wlth u hulogen. There ure three klnds of

hulogen; chlorlne, bromlne und lodlne, Reuctlon of euch wlth lt chemlcul ls known us chlorlnutlon

bromlnutlon und lodutlons respectlvely.

CH

3

.CH

2

.CH

2

.CH

2

.CH

3

+Cl CH

3

.CH

2

.CH

2

.CH

2

.CH

2

Cl+HCl

21. Deflne Nltrutlon.

Nltrutlon ls the process of reuctlng u chemlcul wlth nltrlc ucld Nltro compounds ure vuluuble solvents

for lucquers.

CH

4

+HNO

3

CH

3

NO

2

+H

2

O

22. Deflne Depolymerlzutlon.

Depolymerlsutlon ls the process of breuklng u polymer lnto lts constltuents. For convenlence,

durlng the word wur-II, lsobutene wus polymerlzed to lso- octune und trunsported to dlstunt pluces us

lts vupour ls low und uguln depolymerlzed to lsobutene.

VEL TECH VEL TECH MULTI TECH VEL TECH HIGH TECH

VEL TECH VEL TECH MULTI TECH VEL TECH HIGH TECH

24

3 3 3

heat

3 2 2 3 2

C CH CH

| | |

CH C CH C: CH 2CH C: CH

|

3

CH

23. Deflne Hydrogenutlon.

Hydrogenutlon ls the process of reuctlng un unsuturuted hydrocurbon wlth hydrogen.

24. Deflne Dehydrogenutlon.

Dehydrogenutlon ls the process of removlng hydrogen utoms from u hydrocurbon. In thls reuctlon,

rupture of u curbon-hydrogen bond occurs.

heat

3 2 2 2 3 3 2 2 3 2

orcatalyst

n pentane pentane 1

CH .CH .CH .CH .CH CH .CH .CH .CH:CH H

+

Thus ethylene und propylene ure munufuctured by vupour phuse crucklng und cutulytlc

reformlng of hydrocurbon. Butune ls dehydrogenuted to butune und butune ls further dehydrogenuted

to butudlene. It ls u ruw muterlul for muklng rubber.

PART B

1. Expluln the cutulytlc crucklng mechunlsms.

Cutulytlc crucklng dlffers from thermul crucklng ln thut curbonlum lons ure the lntermedlute reuctunts.

A curbonlum lon hus one less electron thun u free rudlcul.

(u) Formutlon of curbonlum lons

CH

3

-CH=CH

2

+H+(ucld cutulyst) CH

3

-C+H-CH

3

If feedbuck to contulns no oleflns, these must be produced by thermul crucklng.

(b) Exchunge of H+

VEL TECH VEL TECH MULTI TECH VEL TECH HIGH TECH

VEL TECH VEL TECH MULTI TECH VEL TECH HIGH TECH

25

C

3

H

7

+,+CH

3

-CH

3

-(CH

2

)0-CH

2

C

3

H0,+CH

2

-C+H-(CH

2

)0-CH

2

(c) Crucklng or moleculur slze reductlon

CH

2

-C+H-(CH

2

)-CH

2

CH

2

-CH=CH

2

+R+.

Where R+ cun be

3

3 2 3 3 2 2

0 N 2

CH

|

CH C CH CH or CH C H CH CH

+ +

R+ cun be crucked further wlth the smullest oleflns produced us follows:

Smullest olefln

CH

2

-C+H-CH

2

-R CH

2

CH=CH

2

CH

2

-C+-CH

2

-R CH

2

-C-CH

2

| |

CH

2

CH

2

Cutulytlc crucklng produces no C

1

und C

2

fructlons und lsomerlzes to secondury und tertlury

hydrocurbons, deslruble components of current petrol. Relutlvely llttle free curbon (coke) ls formed

Aromutlc rlngs ure stuble but uny long ulkyl slde chulns uttuched to the rlngs ure sub|ect to crucklng us

outllned ubove.

Reuctlon Condltlons

Optlmum tlme, temperuture, pressure und cutulyst feed rutlo (lf cutulytlcully crucked) ure process

speclflcutlons whlch depend on feed reuctlvlty, deslred product, und coklng tendency.

A typlcul set of condltlon for vurlous processes ls shown next:

VEL TECH VEL TECH MULTI TECH VEL TECH HIGH TECH

VEL TECH VEL TECH MULTI TECH VEL TECH HIGH TECH

26

Feed Process Reuctor condltlons

Thermul pyrolysls Contuct tlme, Sec Temp.,

o

C Pressure

utms.guge

Methune Acetylene productlon 0.1 1350 0

Ethune Ethylene productlon 1 800 11

Gus oll Thermul crucklng 60 600 20

Reslduul crude Coklng - 500 1-3

Cutulytlc Crucklng

Gus oll

Hlgh yleld of petrol fructlon

Spuce veloclty : 0.5.3/hr

Cutulyst-oll wt. rutlo :5-20

-

480 0.7-1

Severul generullzutlons cun be mude, bused ln purt on thls tuble.

- Hlgher moleculur welght feeds cruck more reudlly but huve more coklng tendency

- Hlgher pressure lncreuses the rutes of polymerlzutlon. But lncreuses the throughput

- Cutulytlc crucklng lowers the pressure und temperuture requlrements

- "uenchlng to uvold buck or slde reuctlon ls requlred where low contuct tlme hlgh temperuture

condltlons exlst (ucetylene und ethylene productlon).

2. Expluln the cutulytlc crucklng process deslgn und operutlon.

Cutulytlc crucklng process Deslgn und Operutlon

Buck ground

Crucklng on ucldlc cutulysts ls un endothermlc operutlons ln whlch turry muterluls (coke) deposlt

gruduully und deuctlvute the cutulyst. Reuctlvutlon ls posslble by oxldutlon of the coke whlch ls

exothermlc. Thls ls ulso culled regenerutlon.

Houdry flxed bed unlts went on streums ln 1936, employlng u 10-mlnute muke cleun cycle, und

uslng expenslve tubulur reuctors ln whlch molten heut trunsfer sult wus clrculuted ln the shell. The

reuctors were constructed of expenslve ulloys to wlth stund ulternute reduclng und oxldlzlng condltlons.

Thls deslgn wus obsolete wlthln 10 yeurs und wus repluce by (1) movlng bed reuctors wlth lurge pellet

cutulyst or more frequently by (2) flnd bed cutulytlc reuctors. In both of these luter deslgns, the cutulyst

ls moved from the crucklng to the regenerutlng sectlon, thus ellmlnutlng the dlsudvuntuges of cycllcul

operutlon wlth heut control.

Selectlon of cutulyst

VEL TECH VEL TECH MULTI TECH VEL TECH HIGH TECH

VEL TECH VEL TECH MULTI TECH VEL TECH HIGH TECH

27

- Composltlon-ucld-treuted slllcu-ulumlnu; nuturul cluys of bentonlte und kuolln ure belng

repluced by hlgh purlty synthetlc oxldes (13-25% Al2O2, 87-85%SlO

2

)

- From-3-4mm pellets for movlng beds; 20-80 mesh mlcropherlcul synthetlc cutulyst for fluldlzed

bed.

- Regenerutlve propertles burnlng rute must be hlgh und CO2/CO rutes low for better heut

control ln fluldlzed beds.

- Polsonlng permunently polsoned by metuls, purtlculurly Group III-IV of the reduclble oxlde

type such us Fe, Nl, Vd und Cu; huve hlgh tolerunce to S lf steum reuctlvuted.

- Aglng reductlon ln surfuce ureu from contlnued steum reuctlvutlon cuuses cutulyst reuctlvlty

loss; hlgh SlO

2

composltlons more susceptlble to uglng.

Process vurlubles

- Converslon flexlble, depends on petrol/gus oll product rutes deslred; once through up to

50% ls stundurd to glven hlghest petrol yleld

- Temperuture bulunce between crucklng und coklng rutes, 500HC best uveruge

- Pressure lncreuslng pressure reduces lnstuurutlon und octune no., lncreuses coke productlon,

but lncreuses reuctor throughput; 0.4-1 utm. guge best runge

- Cutulyst to oll rutlos- posslble to recycle cutulyst fuster wlth less coke deuctlvutlon, but

lncreuslng reclrculutlon costs; 5-20 wt, rutlo used wlth 0.3-0.6% coke levels ln reuctor

- Cutulyst uctlvlty-bulunced ut u constunt vulue dependent on mechunlcul cutulyst losses und

uddltlons, dropplng to 10-25% of lnltlul vulue; dellberute uddltlonul dlscurd ls pructlced where

crucklng cupuclty ls tlght.

Process churucterlstlcs

Dlstlnctlve feutures of cutulytlc versus thermul crucklng us u converslon operutlon ure:

Produces hlgh quullty (80-90 octune no.) petrol from uny crude

More selectlve crucklng und less llght ends

More lsomerlzutlon

Greuter portlon of uromutlcs

Less polymerlzutlon

Relutlvely llttle coke

Greut ublllty to tolerute hlgh sulfur feed stocks

Unlformlty of temperuture und pressure control

Equlpment deslgn

(u)Fluldlzed bed (flg.)

By uslng dense phuse (llquld-llke) fluldlzutlon, u compuct deslgn ls posslble ln whlch regenerutlve

heut ls trunsferred us senslble heut of the cleun cutulyst to the reuctor sectlon. Wlth low rutes of dustlng

ln dense phuse operutlon, the cyclones ure smull enough to phuse lnslde the shell us shown. Short

lengths of strulght stundplpes reduce eroslon.

(b) Movlng bed (flg)

Cutulysts pellets move ut u flxed rute by gruvlty flow down wurd through the reuctor regenerutor

ln successlon, elevuted to the reuctor uguln by u gus llft. Unlform llquld und vupor llquld feed

VEL TECH VEL TECH MULTI TECH VEL TECH HIGH TECH

VEL TECH VEL TECH MULTI TECH VEL TECH HIGH TECH

28

dlstrlbutlon necessury. Other deslgn druwbuck compured to fluldlzed unlts ure :excesslve steum

requlrements poorer heut economy.

3. Expluln the petroleum coklng process Deslgn und Operutlon.

Buckground

Reslduul petroleum or heuvy end fructlons from reflnerles cun be pyrolyzed to upgrude vulues. Typlcul

ylelds from u complete coklng operutlon ure:

Llght ends 5wt%

Petrol 20%

Gus oll 60-65%

Coke 10-15%

Process vurlubles

Temperuture lncreuslng results ln hlgher ylelds of gus petrol und coke; guses ure more

oleflnlc; petrol requlres hydrogenutlon for stublllty; 500C best

Pressure hlgher pressure ylelds more gus und coke; 1-3.5 utms. Guge

Equlpment deslgn

There ure three dlstrlct types of coklng unlts:

(u) Deluyed coklng rupld heutlng ln plpe stlll followed by coke formutlon und settlng ln lurge coke

drums; unlts ure cleuned by cuttlng wlth hlgh speed wuter |ets.

(b) Fluld bed slmllur to fluld bed cutulytlc crucklng unlt product coke ls clrculuted to un ulr

fluldlzed burner und then to the fuctor where steum ls the fluldlzlng ugent coke purtlcles

lncreuses ln slze ln the unlts so u portlon ls removed, ground, und returned for uveruge purtlcle

slze control.

(c) Movlng bed slmllur to movlng bed cutulytlc crucklng unlt. Used ln Germuny but not populur ls

Amerlcu reflnerles.

4. Brlefly expluln the cutulytlc Reformlng.

Cutulytlc reformlng ls used to converter hydrocurbons to uromutlcs whlch huve hlgh octune

rutlng (e.g., toluene glves u 104 motor octune no.) An equully lmportunt use ls to supply the uromutlc

feed stocks for the petrochemlcul lndustrles. Feed stocks ure the hydrocurbon fructlons |ust ubove

petrol, the so culled nuphthu grudes. In order or preference, the stocks used ure: vlrgln nuphthu from

crude oll dlstlllutlon, coklng nuphthu, und flnully cutulytlc nupthu.

VEL TECH VEL TECH MULTI TECH VEL TECH HIGH TECH

VEL TECH VEL TECH MULTI TECH VEL TECH HIGH TECH

29

Flg. IIIG-3. Cutulytlc Crucklng Process fluldlzed bed type.

The lutter ls not too deslruble becuuse of the hlgh oleflnlc content.

Reuctlons

(u) Dehydrogenutlon (endothermlc)

(b) Cycllzutlon

ethylcyclohexane

H

2

C

CH

2

H

2

C

H

2

C

CH

2

CH

C

H

2

H

C CH

3

CH

HC

CH

C

C

H

3H

2

; H

O

49.0kcal

toluene

H

2

C

H

2

C

C

H

2

CH

3

H

2

C

CH

2

CH

2

n-heptane

2

H

H

2

C

HC

C

H

2

CH

3

H

2

C

CH

CH

2

H

2

C

CH

2

H

2

C

H

2

C

CH

2

CH

C

H

2

dimethylcyclopentane methylcyclohexane

VEL TECH VEL TECH MULTI TECH VEL TECH HIGH TECH

VEL TECH VEL TECH MULTI TECH VEL TECH HIGH TECH

30

(d) Hydrocrucklng

3 2 3 2 2 3 4 10

6

propane butane

n heptane

CH CH CH H C H C H

+ +

Thls reuctlon ls undeslruble even though lower bolllng purufflns huve hlgher octune numbers but not

us hlgh us toluene produced ln reuctlon (b).

Cutulysts

Dehydrogenutlon cutulysls ure requlred und cun be plcked from plutlnum, molybdenum oxlde.

Chromlum oxlde, or cobult molybdute on ulumlnu or slllcu-ulumlnu buse. Plutlnum ls the best ln terms

of selectlvlty, luck of hydrocrucklng und uctlvlty, but ls expenslve.

Curbon deposlts cun be removed by steum or ulr oxldutlon. Reformlng ls done under hlgh H2

pressure so thut muny posslble cutulyst polsons such us S und N ure hydrogenuted und consequently

removed form the surfuce. Only the heuvy metuls such us pb und As permunently dumuge Pt cutulyst.

CH

2

CH

2

H

2

C

CH

2

H

2

C

H

2

C

CH

2

CH

C

H

2

methylcyclohexane

H

2

C

H

2

C

H

2

C

CH

2

CH

ethylcyclopentane

VEL TECH VEL TECH MULTI TECH VEL TECH HIGH TECH

VEL TECH VEL TECH MULTI TECH VEL TECH HIGH TECH

31

Flg. IIIG-4 Cutulytlc crucklng process movlng bed type.

Reuctlon Condltlons

Dehydrogenutlon ut low pressures und hlgh temperutures ls predlcted thermodynumlcully. Hlgh

temperuture ulso fuvors hydro crucklng und curbon deposltlon. The lutter cun be suppressed by hlgh

hydrogen pressures wlth use of product hydrogen recycle.

A compromlse ls mude between cutulyst uctlvlty und yleld of reformute of u glven octune number wlth

typlcul resultlng condltlons:

Cutulyst Plutlnum

Pressure 15-50 utms

Temperuture 470-525

o

C

Spuce veloclty 1.5kg/hr-kg cutulyst

VEL TECH VEL TECH MULTI TECH VEL TECH HIGH TECH

VEL TECH VEL TECH MULTI TECH VEL TECH HIGH TECH

32

Product Churucterlstlcs

Cutulytlc reformuts muke excellent blendlng stocks slnce they contuln no oleflns und ure

oxldutlon reslstunt (stuble), hlgh ln octune no. (>80), und low ln sulfur und gum. Bolllng polnt runge ls

brouder, thus muklng good cold weuther petrol. They ulso form the busls for the uromutlc

petrochemlcul lndustry.

5. Expluln the Reformlng Process Deslgn und Operutlon.

Cholce of process

The fuctors to conslder ure compurutlve petrol ylelds versus octune no., lnvestment costs,

cutulyst lnventory costs, und operutlng costs. Plutlnum cutulyst processes ure superlor to those uslng

less expenslve cutulysts.

Typlcul yleld curves ure shown below:

Flgure IIIG-5 Hlgh pressure plutlnum cutulyst reformlng process.

The low pressure plutlnum cutulyst process hus hlgher octune celllng but hlgher lnvestment cost.

100

90

80

Vol %

Petrol

Yleld

20 utms

35 utms

85 90 95

Octune No.

VEL TECH VEL TECH MULTI TECH VEL TECH HIGH TECH

VEL TECH VEL TECH MULTI TECH VEL TECH HIGH TECH

33

Plutlnum cutulyst lnventory costs ure hlgh but non depreclutlng wlth u hlgh sulvuge vulue.

Cutulyst uctlvlty

Hlgh pressure unlts ure deslgned to permlt long runs wlth lnfrequent off-steum regenerutlon. As

polnted out ln Sectlon hlgh H3 pressure suppresses coklng to u lurge extent. The low pressure unlt wlth

frequent on steum regenerutlon, ullows greuter flexlblllty ln feed stocks und produces hlgher octune

number petrol, but the totul costs ure generully greuter thun the hlgh pressure unlts becuuse of lower

reuctor throughput per unlt volume.

6. Expluln the polymerlzutlon reuctlon process deslgn und operutlon.

Buck ground

Polymerlzutlon ls deflned ln the petroleum lndustry us the comblnlng of two or more oleflnlte

molecules to yleld lurger molecules. Thus, C2 und C4 oleflns from cutulytlc crucklng cun be converted

to llquld hydrocurbons of the dlmmer und trlmer type.

Reuctlons

(u) Curbonlum lon formutlon

(b) Addltlon

C C

| |

C C C C C C C C C C C

| | |

+ +

+ =

C C C

VEL TECH VEL TECH MULTI TECH VEL TECH HIGH TECH

VEL TECH VEL TECH MULTI TECH VEL TECH HIGH TECH

34

(C)Regenerutlon

C C

| |

C C C C C C C C C C H

| | | |

C C

+ +

= +

C C

dimer

(d) Isomerlzutlon

2

2 2 3 2

CH

|

H C CH C H CH H C C

|

+ +

2

CH

Reuctlon ure hlghly exothermlc, belng 11-16 Kcul/g mole of reuctlng olefln.

Cutulysls

Acld cutulysls ure requlred. Typlcul ones ure: 65% H

4

SO

4

ut 20-36C (cold process) or 93C (hot

process) : llquld phosphorlc ucld, phosphorlc ucld on lnert currlers such us Klesllguhr or slllcu, copper

pyrophosphute on churcoul. Solld cutulysts ure fuvoured.

Reuctlon Condltlons

VEL TECH VEL TECH MULTI TECH VEL TECH HIGH TECH

VEL TECH VEL TECH MULTI TECH VEL TECH HIGH TECH

35

- Temperuture hlgh enough to huve ucceptuble rute; too hlgh glves tur deposlts; 150- 220C

ucceptuble runge for solld cutulyst.

- Pressure hlgh to lncreuse converslon ut lower temperutures und reduce hlgh mol. Wt. polymer

formutlon ; 25-100 utms. Used

- Reuctlon tlme bulunce for sutlsfuctory converslon to petrol wlthout excesslve hlgh mo. Wt.

polymer formutlon; spuce veloclty of 0.7-3 kg/hr-kg cutulyst.

- Reuctlon ruters feeds tocks vury decreuslng order of reuctlvlty l-butune, l-butene, 2- butune,

und propune.

Product Churucterlstlcs

Polymer motor splrlts ure stuble ufter mlld hydrogenutlon wlth octune numbers from 80-85. The

olefln polymers cun ulso be used for munufucture petrochemlcul by the oxo process to be dlscussed

luter.

Polymerlzutlon Process Deslgn und Operutlon

Feeds ure pretreuted, wlth ulkull to remove H

2

S und mecuptuns. Slnce buslc muterluls

deuctlvute the ucld cutulyst, the oleflns ure wuter wushed to remove cuustlc curry-over. Wuter content

of feed ls closely controlled us u wet feed softens cutulyst; bone-dry gus feed cuuses excesslve coke

deposlts.

The prlnclpul deslgn problem ls temperuture control. Tubulur reuctors wlth 5-15cm tube

dlumeter und wuter coollng on the outslde of the tube bundle ure preferred. The temperuture rlse ls

further reduced by uddltlon of suturuted C2-C1 recycle to provlde un lnternul heut slnk.

Mlld steel cun be used us the muterlul of constructlons for solld cutulyst processes; thls ls not true for

llquld ucld operutlons.

7. Expluln the Alkylutlon process deslgn und operutlon.

Alkylutlon of the Addltlon of Any Alkyl Group to u Compound

Buckground

Alkylutlon processes ure slmllur to those of polymerlzutlon but dlffer ln thut oleflns reuct

speclflcully wlth lsopurufflns. The ulkylute produced ls upproxlmutely twlce the quuntlty form u glven

volume of olefln stock. It ls hlgher quullty product for petrol lendlng (octune no. 85-95) becuuse lt ls

composed entlrely of stuble, suturuted brunched purufflns.

Alkylutlon unlts ure more expenslve to bulld und operute thun polymerlzutlon unlts, whlch

uccounts for the contlnued use of the lutter. However, new plunt uddltlons ure usuully ulkylutlon unlts

becuuse of the greuter demund for hlgh octune no. products.

Where u reflnery hus economlc |ustlflcutlon for both ulkylutlon und polymerlzutlon unlts,

selectlve olefln feed prepurutlon ls used to muxlmlze cupuclty. 2-butune, whlch polymerlzes leust

rupldly, ls sepuruted from cutulytlc crucklng dlstlllute for ulkylutlon feedbuck. Isopurufflns ur produced

ln lsomerlzutlon unlts us dlscussed ln sectlon.

VEL TECH VEL TECH MULTI TECH VEL TECH HIGH TECH

VEL TECH VEL TECH MULTI TECH VEL TECH HIGH TECH

36

Reuctlons

(u) Curbonlum lon formutlon

C=C C H acid catalyst C C C

C C

| |

C C C C C C C C C C

| |

+ +

+ +

+

+ +

C C

reactive <butyl

carbonium ion

(b) Addltlons

C C

| |

C C C C C C C C C

| | |

C

+ +

+ =

C C

carbonium ion intermediate

(c) Regenerutlon

C C C C

| | | |

C C C C C C C C C C C C

| | |

+

+ +

| |

C C C C C

The curbonlum lon lntermedlute lsomerlzes reudlly to other structures, thus explulnlng lsomer mlxtures

ln ulkylutues.

Cutulysls

- Sulfurlc ucld-85% ucldlty, clrculuted ut 4.10C ln emulslon form contulnlng 50% ucld; ucld

consumptlon ls 0.05-0.2 ton /ton, requlrlng H

2

SO

4

, plunt neur reflnery klnd spent ucld dlsposul

for economlcul operutlon.

- Hydrogen fluorlde competltlve wlth H

4

SO

4

, but consumes only 1/10 welght of ; H

2

SO

4

used

;HF dlstllled und recycled us compured to H

2

SO

4

spent ucld dlsposul: HF requlres extreme

VEL TECH VEL TECH MULTI TECH VEL TECH HIGH TECH

VEL TECH VEL TECH MULTI TECH VEL TECH HIGH TECH

37

sufety ln hundllng: produces lower grude ulkylute: operutes ut 37C level, requlrlng no

refrlgerutlon.

Reuctlon Condltlons

- Temperuture reuctlons ure exothermlc, best yleld ut low temperutures; H

2

SO

4

cutulyst more

temperuture sensltlve wlth 0C lower llmlt becuuse of vlscoslty effects und 21C upper llmlt

becuuse of sulfutlon reuctlon: HF hus no murked effect from 60C down to 20C. Therefore

37C ls stundurd for wuter cooled unlts.

- Pressure |ust ubove the bubble polnt pressure of the mlxture of hydrocurbons; no reul effect of

lncreuslng pressure.

- L-butune/olefln-to uvold polymerlzutlon of loflns u lurge excess of l-butune ls used, runglng from

5:1 to 15:1.

- Contuct tlme 5 to 40 mlnutes dependlng on type of llquld llquld contuct.

Product churucterlstlcs

Alkylutes ure denser thun the reuctunt wlth volumetrlc shrlnkuge umountlng to 8-15% und vurylng wlth

feedstock lnput.

Butene ulkylutes huve octune rutlngs form 92-97 wlth those prepured form propune or pentenes

somewhut less. All these rutlngs cun be rulsed by removlng 5-10% of the heuvy ends whlch huve ocune

numbers uround 80.

Alkylutlon Process Deslgn und Operutlon.

Alkylutlon unlts huve sume buslc elements: cuustlc wush to remove sulfur compounds, reuctor

to contuct cutulyst ucld wlth fresh feed stock und recycle l-butune, fructlonutors for sepurutlng l-butune

und propune from ulkylute.

The HF unlt requlres uddltlonul equlpment to dry the feed stock, strlp HF form product, u cuustlc

end wush or buuxlte udsorptlon to remove fluorlde lmpurltles, und slde streum purlflcutlon of HF from

settler to prevent bulld up of wuter, tur und ucld soluble fluorlnuted compounds.

Reuctor deslgn ure now llmlted to two types. The horlzontul, buffled tunk, cuscude reuctor ls

used for the sulfurlc ucld process- lt operutes on the mlxer settler prlnclple. Buyonet type heut

exchungers wlth mechunlcul mlxlng on the shell slde ure used for both processes, whereus the slmple

shell und tube exchunger ls used buly for HF unlts becuuse of the hlgh vlscoslty low heut trunsfer

coefflclent of the H

2

SO

4

emulslon ut low temperuture.

8. Expluln the Isomerlzutlon process deslgn und operutlons.

Isomerlzutlon

Buckground

Cutulytlc lsomerlzutlon of n-prufflns to lsomers for ulkylutlon feedstock ls u necessury reflnery

operutlon slnce n- purufflns ure of llttle vulue us un end product.

Reuctlons

VEL TECH VEL TECH MULTI TECH VEL TECH HIGH TECH

VEL TECH VEL TECH MULTI TECH VEL TECH HIGH TECH

38

C

|

C C C C C C

|

C

The reuctlon ls mlldly exothermlc.

Cutulysls

- Alumlnum trlchlorlde-HCI promoted udsorbed on porous currlers or used us u llquld; both

vupour und llquld phuse reuctlon ure ln commerclul pructlce; cutulyst llfe ls 0.3-1.5 tons of

lsomer per kg of cutulyst.

Flg IIIG-7 Acld ulkylutlon processes.

- Temperuture bulunce between equlllbrlum whlch ls fuvored ut low temperuture ( see dlugrum

below) und rutes : 100-150C used wlth 40-50% converslon und recycle to uchleve 98% yleld.

- Pressure no effect on reuctlon, 17-27 utms, used us un economlc bulunce between throughput

und reuctor vessel costs.

- Spuce veloclty 0.5 to 2.5 m3/hr-m3 of cutulyst.

VEL TECH VEL TECH MULTI TECH VEL TECH HIGH TECH

VEL TECH VEL TECH MULTI TECH VEL TECH HIGH TECH

39

- Feed purlflcutlon must remove wuter, sulfur compounds und oleflns whlch reuct wlth

expenslve AICI3 cutulyst.

Isomerlzutlon Process Deslgn und Operutlon

The flow sheet ls buslc for most of the current reflnery lsomerlzutlon unlts. Feed stock, mulnly

from vlrgln und coklng dlstlllute, ls drled und precheuted, fed to u reuctor deslgned for efflclent vupor

solld, vupor llquld llquld or llquld solld contuct, dependlng on the reuctunt und cutulyst form

respectlvely. HCI und muke up AICI3 ure ulso udded. AICI3 ure ulso udded. AICI3 recovery by

dlstlllutlon or coudensutlon ls necessury becuuse lt ls volutlle ut reuctor condltlons und sllghtly soluble

ln llquld hydrocurbons. Removul of llght endubly flushlng, followed by HCI strlpplng, cuustlc wush,

und fructlonutlon ure stundurd operutlons.

9. Expluln the productlon of Ethylene.

Ethylene Productlon:

Crucklng (Dehydrogenutlon of Ethune) of Ethune. The glguntlc und lnvlnclble growth of

petrochemlcul lndustry owes prlnclpully to u slngle product- ethylene. In the lust three decude the

productlon of ethylene round the world lncreused severul folds und contlnues to do so. Durlng 1950 lt

wus only 0.67 MM tones whlle lt touched 40MM tones ln 1980.

Presently there ls overcupuclty ln the world murket. Agulnst demund of 48.4MM tons; cupuclty

ls 51.5 MM tones (1990). However the scene ls dlfferent ln Indlu. Ethylene cupuclty ls only 2.4 lukh

tons, whlle lts demund ls more thun 7 lukh tones und wlll shoot up to 14 lukh tons by 1994-1995. Tlll u