Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Clarification

Caricato da

ashrachDescrizione originale:

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Clarification

Caricato da

ashrachCopyright:

Formati disponibili

Clarification

Introduction

Water clarification is the process of removing suspended solids from water. In this chapter, factors

governing the destabilization, coagulation and removal of suspended solids from water are reviewed.

Important concepts of this section include:

1. Stable solids suspensions in water%he mechanisms involved in keeping solids suspended in water

2. Chemical treatmentsow organic polymers and inorganic coagulants work to counteract solids

stabilization mechanisms and enhance removal of solids from water

3. The function of clarification unit operationsow these units work and how chemical treatment

enhances their performance

After reading this chapter, you should have the basic information required to begin onsite investigations

of water clarification processes. You should be able to define and discuss coagulation, flocculation,

chemical treatment and clarification processes as applied to the physical treatment of surface waters.

$ubsidence

While a degree of clarification can be accomplished by subsidence (settling), most industrial processes

require better quality water than can be obtained from subsidence only. Most of the suspended matter in

water would settle, given enough time, but in most cases the amount of time required would not be

practical. %he time required for settling is dependent on many factors, including:

1. Weight of the particle

2. Shape of the particle

3. Size of the particle

4. Viscosity and/or frictional resistance of the water, which is a function of temperature

%he settling rates of various size particles at 50 F (10 C) is illustrated in %able 6.1.

TABLE 6.1

$ettling Rates by Particle $ize

Diameter of Particle

(in mm)

Types of Particles(by order ofParticle

(mm) magnitude)

Time Required to$ettle

One Foot

10.0 Gravel 0.3 seconds

1.0 Coarse sand 3.0 seconds

0.1 Fine sand 38.0 seconds

0.01 Silt 33.0 minutes

0.001 Bacteria 35.0 hours

0.0001 Clay particles 230.0 days

0.00001 Colloidal particles 63.0 years

$tokes' Law

Settling velocities may be calculated from Stokes' Law.

Where V = Velocity of fall (ft/sec)

D = Diameter of particle (in)

S1= Density of particle (lb/ft3)

S2= Density of fluid (lb/ft3)

z = Viscosity (centipoises)

In this equation it is assumed that the particles are spherical, failing under viscous resistance, and that

they have no electrostatic charges. %his is, of course, never true under actual conditions. Most

suspended solids smaller than 0.1 mm found in surface waters carry negative electrostatic charges. %his

charge causes the particles to repel each other, increasing their stability and thus increasing their

tendency to remain suspended. Chemicals are often added to water to neutralize particle charge and

enhance particle settling. Chemicals used to promote suspended particle subsidence in the clarification

process are commonly called coagulants; the particle charge neutralization process is called coagulation.

Coagulation

Coagulation, the first step in complete clarification, is the neutralization of the electrostatic charges on

colloidal particles. Because most of the smaller suspended solids in surface waters carry a negative

electrostatic charge, the natural repulsion of these similar charges causes the particles to remain

dispersed almost indefinitely. %o allow these small suspended solids to agglomerate, the negative

electrostatic charges must be neutralized. %his is accomplished by using inorganic coagulants (water

soluble inorganic compounds), organic cationic polymers or polyelectrolytes.

Inorganic Coagulants

%he most common inorganic coagulants are:

1. Alumaluminum sulfateAl

2

(SO

4

)

3

2. Ferric sulfateFe

2

(SO

4

)

3

3. Ferric chlorideFeCl

3

4. Sodium aluminatea

2

AI

2

0

4

Inorganic salts of metals work by two mechanisms in water clarification. %he positive charge of the

metals serves to neutralize the negative charges on the turbidity particles. %he metal salts also form

insoluble metal hydroxides which are gelatinous and tend to agglomerate the neutralized particles. %he

most common coagulation reactions are as follows:

Coagulation Reactions

Al

2

(SO

4

)

3

+ 3Ca(CO

3

)

2

= 2Al(O)

3

+ 3CaSO

4

+ 6CO

2

Al

2

(SO

4

)

3

+ 3a

2

CO

3

+ 3

2

O = 2AI(O)

3

+ 3a

2

SO

4

+ 3CO

2

Al

2

(SO

4

)

3

+ 6aO = 2AI(O)

3

+ 3a

2

SO

4

Al

2

(SO

4

)

3

(4)2SO4 + 3Ca(C03) = 2AI(O)3 + (

4

)

2

SO4 + 3CaSO

4

+ 6CO

2

Al

2

(SO

4

)

3

K

2

SO

4

+ 3Ca(CO

3

)

2

= 2AI(O)

3

+ K

2

SO

4

+ 3CaSO

4

+ 6CO

2

a

2

AI

2

0

4

+ Ca(CO

3

)

2

+

2

0 = 2AI(O)

3

+ CaCO

3

+ a

2

CO

2

Fe(SO4)

3

+ 3Ca(O)

2

= 2Fe(O)

3

+ 3CaSO

4

4Fe(O)

2

+ O

2

+ 2

2

O = 4Fe(O)

3

Fe

2

(SO

4

)

3

+ 3Ca(CO

3

) = 2Fe(O)

3

+ 3CaSO

4

+ 6CO

2

Coagulant Equivalents

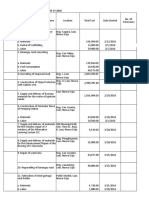

%he effectiveness of inorganic coagulants is dependent upon water chemistry (p and alkalinity), and

their addition usually alters that chemistry. %able 6.2 illustrates the effect of the addition of 1 ppm of the

various inorganic coagulants.

TABLE 6.2

Coagulant, Acid and $ulfate-1 ppm Equivalents

1 ppm Formula of

Chemical

ppm

Alkalinity

Reduction

ppm

SO

4

Increase

ppm

a

2

SO

4

Increase

ppm

CO

2

Increase

ppm

%otal

Solids

Increase

Filter Alum Al

2

(SO

4

)

3

182O 0.45 0.45 0.64 0.40 0.16

Ammonia alum Al

2

(SO

4

)

3

(

4

)

2

SO

4

24

2

O 0.33 0.44 0.63 0.29 0.27

Potash alum Al

2

(SO

4

)

3

K

2

SO

4

24

2

O 0.32 0.43 0.60 0.28 0.30

Copperas (ferrous

sulfate)

FeSO

4

7

2

O 0.36 0.36 0.61 0.31 0.13

Chlorinated

Copperas

FeSO

4

7

2

O+(Cl

2

) 0.54 0.36 0.51 0.48 0.18

Ferric Sulfate

(100% Fe

2

(SO

4

)

3

)

Fe

2

(SO

4

)

3

0.76 0.76 1.07 0.64 0.27

Sulfuric acid96%

2

SO

4

1.00 1.00 1.42 0.88 0.36

Sulfuric acid

93.2% (66 Be)

2

SO

4

0.96 0.95 1.36 0.84 0.34

Sulfuric acid

77.7% (60 Be)

2

SO

4

0.79 0.79 1.13 0.70 0.28

Salt cake95% a

2

SO

4

0.64 0.95 1.00

Sodium

aluminate88%

a

2

Al

2

O

4

Increase

0.54

Reductio

n 0.47

0.90

Alkalinity Relationships

Aluminum salts are most effective as coagulants in a 5.58.0 p range. Because they react with the

alkalinity in the water, it may be necessary to add additional alkalinity in the form of lime or soda ash.

Iron salts, on the other hand, are most effective as coagulants at higher p ranges (810). Iron salts

also depress alkalinity and p levels; therefore, additional alkalinity must be added. Sodium aluminate

increases the alkalinity of water, so care must be taken not to exceed p and alkalinity guidelines. As is

evident from the reactions discussed above, a working knowledge of the alkalinity relationships of water

is mandatory.

It is important to note, at this point, that the use of metal salts for coagulation may increase the

quantity of dissolved solids. One must consider the downstream impact of these dissolved solids. In

addition, the impact of carryover of suspended Al

+++

and Fe

+++

compounds and their related effect on

downstream processes must be considered.

For example, if the alum demand of water is 50 ppm, the sulfate increase in the effluent water would be

50 ppm x .45, or 22.5 ppm. If an equivalent amount of lime had to be added, the dissolved solids

content of the water would be further increased by

It must also be pointed out that using inorganic coagulants produces a voluminous, lowsolids sludge

that dewaters and dries very slowly.

TABLE 6.3

Alkali and Lime 1 ppm Equivalents

Compound - 1 ppm

Formula

(1 ppm)

Alkalinity

Increase

(1 ppm)

Free CO2

Reduction

(1 ppm)

Hardness as

CaCO3

Increases

Sodium bicarbonate aCO

3

0.60

Soda ash (56% a

2

99.16% a

2

CO

3

) a

2

CO

3

0.94 .41

Caustic soda (76% a

2

O98.06% a

2

CO

3

) aO 1.23 1.08

Chemical lime (Ouicklimeusually 90% CaO) CaO 1.61 1.41 1.61

ydrated lime (usually 93% Ca(O)

2

) Ca(O)

2

1.26 1.11 1.36

Organic Coagulants - Polymers

While these coagulants serve the same function as the inorganic metal salts, the process is simpler

because the charge neutralization reaction is the only concern. Polymer addition has no effect on p or

alkalinity, so no supplemental chemical feed is required to control either.

Polymers can be envisioned as long chains with molecular weights of 1000 or less to 5,000,000 or more.

Along the chain are numerous charged sites. In primary coagulants, these sites are positively charged.

%he sites are available for adsorption onto the negatively charged particles in the water. %o accomplish

optimum polymer dispersion and polymer/particle contact, initial mixing intensity is critical. %he mixing

must be rapid and thorough. Polymers used for charge neutralization cannot be overdiluted or over

mixed. %he farther upstream in the system these polymers can be added, the better their performance.

Because most polymers are viscous, they must be properly diluted before they are added to the influent

water. Special mixers such as static mixers, mixing tees and specially designed chemical dilution and

feed systems are all aids in polymer dilution.

Flocculation - The $econd $tep of the Coagulation Process

Once the negative charges of the suspended solids are neutralized, flocculation begins. Charge reduction

increases the occurrence of particleparticle collisions, promoting particle agglomeration. Portions of the

polymer molecules not absorbed protrude for some distance into the solution and are available to react

with adjacent particles, promoting flocculation. Bridging of neutralized particles can also occur when two

or more turbidity particles with a polymer chain attached come together. It is important to remember

that during this step, when particles are colliding and forming larger aggregates, mixing energy should

be great enough to cause particle collisions but not so great as to break up these aggregates as they are

formed.

In some cases flocculation aids are employed to promote faster and better flocculation. %hese

flocculation aids are normally high molecular weight anionic polymers. Flocculation aids are normally

necessary for primary coagulants and water sources that form very small particles upon coagulation. A

good example of this is water that is low in turbidity but high in color (colloidal suspension).

Color Removal

By far the most difficult impurity to remove from most surface waters is color (from dissolved or

colloidal suspensions of decayed vegetation) and other colloidal suspensions.

Color in surface water normally is a result of its contact with decayed vegetation and is composed of

tannins and lignins, the components that hold together the cellulose cells in vegetation. In addition to

their undesirable appearance in drinking water, these organics can cause serious problems in

downstream water purification processes. For example:

1. Expensive demineralizer resins can be irreversibly fouled by these materiais.

2. Some of these organics have chelated trace metals, such as iron and manganese within their

structure, which can cause serious deposition problems in a cooling system.

%here are many ways of optimizing color removal in a clarifier:

1. Prechlorination (before the clarifier) significantly improves the removal of organics as well as reducing

the coagulant demand.

2. %he proper selection of polymers for coagulation has a significant impact on organic removal.

3. Color removal is affected by p. Generally, organics are less soluble at low p.

Should organic removal prove to be a problem, a relatively simple test procedure is available to

determine removal efficiency. (Refer to ench Testing Procedures Handbook.)

Clarification Process (Mechanical)

Conventional Clarification

%he simplest form of clarification uses a large tank or horizontal basin for sedimentation of flocculated

solids, as shown in Figures 6.1 and 6.2. %he basin may contain separate chambers for rapid mix, slow

mix and settling. %he first two steps are important for good clarification. An initial period of turbulent

mixing is necessary for contact between the coagulant and the suspended matter, followed by a period

of gentle stirring to increase collisions between particles and increase floc size. %ypical retention times

are 35 minutes for rapid mix, 15 to 30 minutes for flocculation. and 46 hours for settling.

%he coagulant is added to the waste water in the rapid mix chamber or just upstream, and the water

passes through the mix chambers into the settling basin. As the water passes along the length of the

basin (or out to the circumference in the case of a circular clarifier), the flocculated particles settle to the

bottom and are scraped into a sludge collection basin for removal and disposal. Clear water flows over a

weir and is usually held in a tank called a clearwell.

FIGURE 6.1

Large Tank Clarifier

FIGURE 6.2

Horizontal Basin Clarifier

Upflow Clarification

It is often advantageous to employ a zone of high solids contact to achieve a better quality effluent. %his

is accomplished in an upflow clarifier, so called because the water flows upward through the clarifier as

the solids settle to the bottom. Most upflow clarifiers are either solidscontact or sludgeblanket type

clarifiers, which differ somewhat in theory of operation. Crosssections of these two types of units are

shown in Figures 6.3 and 6.4. Both units have an inverted cone within the clarifier. Inside the cone is a

zone of rapid mixing and a zone of high solids concentration. %he coagulant is added either in the rapid

mix zone or somewhere upstream of the clarifier.

FIGURE 6.3

$olids-Contact Clarifier

FIGURE 6.4

$ludge-Blanket Clarifier

The $olids-Contact Clarifier

In the solidscontact clarifier, raw water is drawn into the primary mixing zone, where initial coagulation

and flocculation take place. %he secondary mixing zone is used to produce a large number of particle

collisions so that smaller particles are entrained in the larger floc. Water passes out of the inverted cone

into the settling zone, where solids settle to the bottom and clarified water flows over the weir. Solids

are drawn back into the primary mixing zone, causing recirculation of the large floc. %he concentration

of solids in the mixing zones is controlled by occasional or continuous blowdown of sludge.

The $ludge-Blanket Clarifier

%he sludgeblanket clarifier goes one step further, by passing the water up from the bottom of the

clarifier through a blanket of suspended solids that acts as a filter. %he inverted cone within the clarifier

produces an increasing crosssectional area from the bottom of the clarifier to the top. %hus, the upward

velocity of the water decreases as it approaches the top. At some point, the upward velocity of the water

exactly balances the downward velocity of a solid particle and the particle is suspended, with heavier

particles suspended closer to the bottom. As the water containing flocculated solids passes up through

this blanket, the particles are absorbed onto the larger floc, which increases the floc size and drops it

down to a lower level. It eventually falls to the bottom of the clarifier to be recirculated or drawn off.

Troubleshooting Tips

Problems normally show up as floc or turbidity carryover from the clarifier. %his problem can be caused

by many factors, some of which are listed in %able 6.4.

Application Pointers

1. Always read the clarifier equipment manual for information about how the unit should be operated.

2. Remember that primary coagulants thrive on mixing.

3. %ry different feed points.

4. Don't feed polymers too close to chlorine or other oxidants.

5. Use dilution water with polymers.

6. Optimize all variables (sludge bed depth, turbine speed, etc.).

7. Split up feeding of polymers.

8. Remember the sludge bed level will drop when polymer is first added. Watch the blowdown closely.

9. Learn to watch the centerwell for troubleshooting and to observe quickly the effect of any chemical

dosage changes.

TABLE 6.4

Floc Problems and $olutions

Problem Possible Cause(s) Corrective Action

Excessive Floc

Carryover

ydraulic overload; flow surges Equalize flow (meter flow of clarifier) to

eliminate surges

%hermal currents Equalize flow

Shortcircuiting Use tracer dye to confirm problem

Check clarifier internals (mixing baffles, etc.)

Low density floc Increase coagulant/flocculant dose

Sludge bed level too high Decrease sludge bed height

Chemical feed problem (e.g.,

no chemical feed)

Check pump settings

Confirm that settings correspond with

anticipated chemical feed rate

o floc in

centerwell

Chemical underfed Check operation of feed pump

Check punp settings

Sludge bed recirculation lost Increase recirculation (very slowly)

Potrebbero piacerti anche

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (121)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (399)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- 6th Central Pay Commission Salary CalculatorDocumento15 pagine6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (73)

- Microturbine GeneratorsDocumento126 pagineMicroturbine GeneratorsProphx BliziceNessuna valutazione finora

- English SentencesDocumento262 pagineEnglish SentencesTess Williams100% (3)

- Piping Stress AnalysisDocumento51 paginePiping Stress Analysissandygo100% (4)

- Role of Designers EthicsDocumento13 pagineRole of Designers EthicsBibilal VijayadevNessuna valutazione finora

- UFC 3-230-12A Water Desalination (01!16!2004)Documento118 pagineUFC 3-230-12A Water Desalination (01!16!2004)Bob VinesNessuna valutazione finora

- Thrust Restraint Design For DI PipeDocumento24 pagineThrust Restraint Design For DI PipefazyroshanNessuna valutazione finora

- Department of The NavyDocumento29 pagineDepartment of The Navymrgoniea100% (1)

- Basic Pipe Stress TutorialDocumento24 pagineBasic Pipe Stress TutorialoanzarNessuna valutazione finora

- Energy Saving Using Mitsubishi VFDDocumento4 pagineEnergy Saving Using Mitsubishi VFDkashinathNessuna valutazione finora

- Compact Water TreatmentDocumento22 pagineCompact Water TreatmentCHEMSTRONG100% (1)

- Green HouseDocumento78 pagineGreen HouseDiplima SarmahNessuna valutazione finora

- C-PPBIO1 Laboratory ManualDocumento45 pagineC-PPBIO1 Laboratory ManualPauline Lyzell G. FranciscoNessuna valutazione finora

- DTSS Ph2 18feb2016Documento82 pagineDTSS Ph2 18feb2016scegtsNessuna valutazione finora

- Stall QB English New PDFDocumento27 pagineStall QB English New PDFAmit Gangwar100% (1)

- Hdpe PP Butterfly ValveDocumento1 paginaHdpe PP Butterfly ValveashrachNessuna valutazione finora

- Stall QB English New PDFDocumento27 pagineStall QB English New PDFAmit Gangwar100% (1)

- Stall QB English New PDFDocumento27 pagineStall QB English New PDFAmit Gangwar100% (1)

- Stall QB English New PDFDocumento27 pagineStall QB English New PDFAmit Gangwar100% (1)

- Viking Johnson Flexlock Brochure EnglishDocumento9 pagineViking Johnson Flexlock Brochure EnglishCSNessuna valutazione finora

- Pivot TablesDocumento18 paginePivot TablesAdil Akbar JanjuaNessuna valutazione finora

- PVQuickStart 2015Documento66 paginePVQuickStart 2015ashrachNessuna valutazione finora

- Flow ConDocumento8 pagineFlow ConKumaresan SithurajNessuna valutazione finora

- Health and Development NexusDocumento6 pagineHealth and Development NexusashrachNessuna valutazione finora

- Demountable FlatpackDocumento12 pagineDemountable FlatpackashrachNessuna valutazione finora

- P BlockDocumento1 paginaP BlockashrachNessuna valutazione finora

- Demountable FlatpackDocumento12 pagineDemountable FlatpackashrachNessuna valutazione finora

- Java Interview Questions: 1 Muralidhar, MCADocumento51 pagineJava Interview Questions: 1 Muralidhar, MCAkishoreramanaNessuna valutazione finora

- Purposive Ni CyDocumento3 paginePurposive Ni CyCj CantilloNessuna valutazione finora

- Warning: Read Carefully Before Use - Save These InstructionsDocumento2 pagineWarning: Read Carefully Before Use - Save These InstructionsPadmini KunaparajuNessuna valutazione finora

- Sanika - There Are Different Sepration Techniques Involved in Sewage Treatment PlantDocumento3 pagineSanika - There Are Different Sepration Techniques Involved in Sewage Treatment PlantSANIKA TALATHINessuna valutazione finora

- A Compendium of Concrete Aggregates Used in SW EnglandDocumento136 pagineA Compendium of Concrete Aggregates Used in SW EnglandPetrolabNessuna valutazione finora

- Thesis FinalDocumento16 pagineThesis FinalabcdefNessuna valutazione finora

- Plant PigmentsDocumento12 paginePlant PigmentsvazsonzijuliaNessuna valutazione finora

- 12 - Safe Handling of Sharps - March 3 - Low ResDocumento2 pagine12 - Safe Handling of Sharps - March 3 - Low ResRasheda PickettNessuna valutazione finora

- PPAs 2016Documento28 paginePPAs 2016Jonson PalmaresNessuna valutazione finora

- Msds KafeinDocumento6 pagineMsds KafeinNovia Arinda Pradisty100% (1)

- PerugudidumpyardpaperDocumento14 paginePerugudidumpyardpaperShakthiVelNessuna valutazione finora

- Cable Sizing of Ass1Documento5 pagineCable Sizing of Ass1Achint singhNessuna valutazione finora

- Absorption Heat PumpDocumento4 pagineAbsorption Heat PumpMaisa UlfahNessuna valutazione finora

- Rockdonnell Presentation - INSSDC 2018Documento47 pagineRockdonnell Presentation - INSSDC 2018Not FakeNessuna valutazione finora

- Commercial Buidlings SWM Guideline Manual PDFDocumento163 pagineCommercial Buidlings SWM Guideline Manual PDFzaheeruddin_mohdNessuna valutazione finora

- Sanitary Landfills: Under Solid and Hazardous Waste ManagementDocumento11 pagineSanitary Landfills: Under Solid and Hazardous Waste ManagementRiddhiNessuna valutazione finora

- Lag Atta 1997Documento9 pagineLag Atta 1997linoficNessuna valutazione finora

- NEWAH EWB Challenge Design Brief PDFDocumento20 pagineNEWAH EWB Challenge Design Brief PDFRagesh OdungattuNessuna valutazione finora

- OS SMART Green Treatment SystemDocumento4 pagineOS SMART Green Treatment Systemexecutive engineerNessuna valutazione finora

- Tashveen 11Documento3 pagineTashveen 11T THEVEN A/L TARMALINGAM MoeNessuna valutazione finora

- Safety Data Sheet For PhiX174 RF I DNADocumento9 pagineSafety Data Sheet For PhiX174 RF I DNANabilahNessuna valutazione finora

- Minimum and Peak Flows of WastewaterDocumento26 pagineMinimum and Peak Flows of WastewaterSteven Joseph IncioNessuna valutazione finora

- NYF 2023 Brochure 2Documento20 pagineNYF 2023 Brochure 2Abhishek V BendreNessuna valutazione finora