Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Manual

Caricato da

befoaCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Manual

Caricato da

befoaCopyright:

Formati disponibili

MUSASHI SOUTH CAROLINA

AMENDMENTS

Page 45 of 2

DOC NO:MSC-QM1 SECTION: AMENDMTS

TS Manual Amendment Record

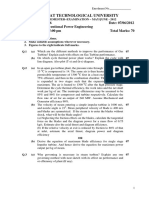

REVISION REVISION DATE NUMBER CLAUSE 7/30/03 1 5- Mgmt. Resp. 7/6/04 2 5- Mgmt. Resp. 9/13/04 1 Forward 3/1/05 3 5- Mgmt. Resp. 5/3/05 1 1-Scope 8/31/05 4 5- Mgmt. Resp. APPROVED BY RSS RSS RSS RSS RSS RSS

CHANGE Updated for organization changes Updated for organization changes Distribution list revised to post on "S" Updated for organization changes Revised scope statement, & expanded 7.3 Product design exclusion detail Updated for organization changes of responsibilities

Issued by: Ralph Sulser Approved by: Keith Shepard

Edition: 01 Date: 04/02/03 Rev. 0

MUSASHI SOUTH CAROLINA

INTRODUCTION

Page 3 of 45

DOC NO.:MSC-QM1 SECTION#: 00

SECTION NO.

0

TITLE Introduction

CL. REF.

REVISION NO.

0

NO. OF PAGES

5

Table of Contents 0.1 Foreword 0.2 Structure of the Manual 0.3 Manual Issue Procedure 0.4 -Manual Revision, Updating & Amendment Procedure 0.5 Company Profile Distribution List + 0.6 -0.7 1

1 0 1

Scope

General Application (Exclusions, if any)

1 1.1 1.2 3 4 4.1 4.2 4.2.1 4.2.2 4.2.3 4.2.4

3 4

Terms and Definitions Quality Management System

General Requirement Documentation requirement General Quality Manual Control of Documents Control of Records

0 0

1 3

+May not be part of the "Uncontrolled Copy of this Manual which is meant for distribution to External Agencies.

SECTION NO.

TITLE

CL. REF.

REVISION NO.

3 Updated positions resp. 3/01/05

NO. OF PAGES

Management Responsibility

- Management Commitment - Customer Focus - Quality Policy Planning Quality Objectives Quality Management System Planning - Responsibility, Authority & Communication Responsibility & Authority of Managers Management Representative Internal Communication Management Review General Review Inputs - Review Outputs

5 5.1 5.2 5.3 5.4 5.4.1 5.4.2 5.5 5.5.1 5.5.2 5.5.3 5.6 5.6.1 5.6.2 5.6.3

Resource Management

Provision of Resources Human Resources General Competence, Awareness & Training Infrastructure Working Environment

6 6.1 6.2 6.2.1 6.2.2 6.3 6.4

Note: Printed documents are not controlled copies-check master computer files for latest revisions

Issued by: Ralph Sulser Approved by: Keith Shepard

Edition : 01 Date: 09/13/04 Rev. 1

MUSASHI SOUTH CAROLINA

INTRODUCTION

Page 4 of 45

DOC NO.:MSC-QM1 SECTION#: 00

SECTION NO.

7

TITLE Product Realization

CL. REF.

REVISION NO.

0

NO. OF PAGES

7

7 - Planning of Product Realization 7.1 - Customer Related Processes 7.2 - Determination of requirements related to the product 7.2.1 -Review of Requirements related to the product 7.2.2 - Customer Communication 7.2.3 Design & Development 7.3 Purchasing 7.4 Purchasing Process 7.4.1 Purchasing Information 7.4.2 Verification of Purchased Product 7.4.3 Production & Service Provision 7.5 Control of production and service provision 7.5.1 *Validation of processes for 7.5.2 production and service provision Identification & Traceability 7.5.3 Customer Property 7.5.4 Preservation of product 7.5.5 -Control of Monitoring and Measuring Devices 7.6 Measurement system analysis 7.6.1 Calibration/verification records 7.6.2 Laboratory requirements 7.6.3 Internal Laboratory 7.6.3.1

SECTION NO.

8

TITLE

CL. REF.

8 8.1 8.2 8.2.1 8.2.2 8.2.3 8.2.4 8.3 8.4 8.5 8.5.1 8.5.2 8.5.3

REVISION NO. OF NO. PAGES

0 3

Measurement, Analysis and Improvement

General Monitoring & Measurement Customer Satisfaction Internal Audit Monitoring & Measurement of Processes Monitoring & Measurement of Products Control of Non-conforming Product Analysis of Data Improvement Continual Improvement Corrective Action Preventive Action

9 10

Section 2- Customer Specific requirements Amendment Record Product Process Flow Chart , Process Approach Charts Organization Chart 0 0

1 1 4 1 36

Annex Annex

Note: Printed documents are not controlled copies-check master computer files for latest revisions

Issued by: Ralph Sulser Approved by: Keith Shepard

Edition : 01 Date: 09/13/04 Rev. 1

MUSASHI SOUTH CAROLINA

INTRODUCTION

Page 5 of 45

DOC NO.:MSC-QM1 SECTION#: 00

Introduction 0.2

FOREWORD

This Quality Manual describes the Quality Management System Requirements adopted by Musashi South Carolina. The Manual lists the Procedures and measures stipulated for ensuring the quality of products manufactured by this unit.

The Quality Management System has been formulated on the basis of ISO/TS 16949:2002(E) for MSC. This Section titled "Introduction" explains the Structure, Issue and Updating procedure of the Quality System Manual. This Manual and the information incorporated herein are the property of Musashi South Carolina. It must not be reproduced in whole or in part or otherwise disclosed without prior consent in writing from MSC.

0.3

STRUCTURE OF THE MANUAL

This Quality Manual is structured as shown in the content pages of the Manual. Different sections are arranged sequentialy as per clause number of ISO/TS 16949:2002(E) and ISO 9001: 2000 (herein after called QMS Standard). The main clause number of QMS Standard has also been indicated along with title of each Section. For all Sections, relevant sub-clause numbers under the main clause of QMS Standard have been indicated in the text. Quality System Manual pages are numbered serially with page number indication. All pages of the Master Copy of each Section of the manual contain electronic signature(s) of the Issuing and Approving Authority of the manual. The current revision numbers and edition numbers on each page is also indicated. Revision no. 0 has been given to first issue of the Section. This master manual is available in English Language only, and copies may be available in Japanese if required

0.4

MANUAL ISSUE PROCEDURE

The TS16949 Coordinator/Management Representative is authorized by the Quality Control Manager, and the President to carry out the activities of preparing, issuing, maintaining and updating of this Quality System Manual. The distribution of the Manual and the amendment(s) are con-trolled and the TS16949 Coordinator/ Management Representative carries out this activity.

The Master Copy contains the electronic signature of the approving and issuing authority in original. The Master files are in the controlled in the TS16949 Coordinators computer files, with restricted access. Printed Controlled Copies are red stamped "Controlled Document" on the first page. Uncontrolled copies issued to designated individual s (as per distribution list) are legibly photocopied from the Master Copy. Printed documents are not controlled copies-check master computer files for latest revisions.

Additional copies of the Manual, required by external agencies, if any, are issued by the TS16949 Coordinator/Management Representative and such copies of the Manual issued are not stamped in red. This indicates that the copies are not controlled by virtue of the non-red stamp due to the copy process. These uncon-trolled copies do not come under the control of the document amen-dment procedure, and are used for reference only, and are not used within the Company.

The TS16949 Coordinator / Management Representative maintains a record of the distribu-tion list of the Quality System Manual. This list is used as reference for updating of the respective controlled copies.

Note: Printed documents are not controlled copies-check master computer files for latest revisions

Issued by: Ralph Sulser Approved by: Keith Shepard

Edition : 01 Date: 09/13/04 Rev. 1

MUSASHI SOUTH CAROLINA

INTRODUCTION

Page 6 of 45

DOC NO.:MSC-QM1 SECTION#: 00

0.5 MANUAL REVISION, UPDATING AND AMENDMENT PROCEDURE

The TS16949 Coordinator/ Management Representative in consultation with the related departments reviews the Quality System Manual periodically. No revision is implemented unless it has been approved by the Senior Manager Quality Control, then formally issued. Each revision is introduced formally by the TS16949Coordinator/ Management Represen-tative by issue of revised section(s) for each of the copies as per the Distribution List.

When revisions take place, the revisions are indicated by the revision number in each of the revised sections and recorded in the Amendment Sheet (Refer Amendment Sheet) supplied with the controlled copies of the Manual. If there are more than 20 revisions, the complete manual is revised to the next edition number.

The insertion of the additional/amended sections and the removal of the old sections in the individual controlled copies as per the distribution list of the Manual are the responsibility of the person holding the individual copy. All old sections so removed are crossed with an inscription of the marking "OBSOLETE" and returned to the TS16949 Coordinator/ Management Representative who ensures that the same are destroyed. The TS16949 Coordinator/Management Representative retains one copy of the earlier version of the Section(s) in archives for Five Years.

0.6

COMPANY PROFILE

In 1938, Musashi Seimitsu Industry Co. LTD, Toyohashi, Japan started its first Manufacturing operation in Musashino City, Tokyo. Business flourished and they soon became a major supplier of precision automotive components worldwide. Musashi Seimitsu has grown to include facilities in the United States, Thailand, United Kingdom, Brazil, Indonesia and Canada.

Musashi South Carolina, Inc. was established on October 25th, 1999, and started production in 2001. The 120,000 square foot main plant and 10,000 square foot assembly plant were built on 40.4 acres of land near Bennettsville, South Carolina. MSC produces ATV gears and assemblies and automotive differential gears. MSC is dedicated to the Team Philosophy. Teamwork is essential, and open communication is the cornerstone of all our processes. MSC's production areas are supported by several departments, including General Administration, Human Resources, Purchasing, Engineering, E/H/S, Quality Control, Maintenance and Tool and Die.

QUALITY, CUSTOMER FOCUS, AND CUSTOMER SATISFACTION is a way of life at Musashi South Carolina. Our products are sold in the international automotive and ATV markets. Musashi products have an established reputation in the world market for excellence in quality, and customer focus. Musashi continually upgrades technology and customer focus for quality, to optimize product performance, superior in international world-class quality expectations.

Note: Printed documents are not controlled copies-check master computer files for latest revisions

Issued by: Ralph Sulser Approved by: Keith Shepard

Edition : 01 Date: 09/13/04 Rev. 1

MUSASHI SOUTH CAROLINA

INTRODUCTION

Page 7 of 45

DOC NO.:MSC-QM1 SECTION#: 00

DISTRIBUTION LIST

(Distributed uncontrolled copy by electronic e-mail)

Posted on the "shared" computer file

TS16949 Coordinator (Printed Controlled copy)

Master Copy

Note: Printed documents are not controlled copies-check master computer files for latest revisions

Issued by: Ralph Sulser Approved by: Keith Shepard

Edition : 01 Date: 09/13/04 Rev. 1

MUSASHI SOUTH CAROLINA 1 1.1 SCOPE General

SCOPE

8 of 45

DOC NO.:MSC-QM1 SECTION# :1

MSC has adopted Technical Specification, ISO/TS 16949:2002(E) and Visteon Customer Specific Requirements, which specifies the requirements for a Quality Management System in order to:

Manufacture of Gears, and Gear Assemblies for the Automotive Industry

Application

a) Demonstrate ability to consistently provide product(s) that meet(s) customers standards, and applicable regulatory requirements, and

b) Enhance customer satisfaction through the effective application of the system, including the processes for continual improvement of the system and the assurance of conformity to customer and applicable regulatory requirements.

The established system is applicable to the activities of the company plant located at One Musashi Drive, Bennettsville, SC. The scope of implementation of this standard is as given below:

1.2

The following ISO/TS16949:2002 requirement is not applicable to MSC QMS, and therefore excluded from our scope: Clause 7.3 activities related to Product Design and Development. MSC does not have product design responsibility. All products are manufactured to customer drawings.

Note: Printed documents are not controlled copies-check master computer files for latest revisions

Issued by: Ralph Sulser Approved by: Keith Shepard

Edition: 01 Date: 05/03/05 Rev. 1

MUSASHI SOUTH CAROLINA TERMS and DEFINITIONS

9 of 45

DOC NO.:-QM1 SECTION#:3

3.0

TERMS, DEFINITION & ABBREVIATIONS

In this Quality System Manual and related procedures / instructions, following terms / definitions and abbreviations have been used: 3.1 Terms and definitions: Organization: Musashi South Carolina (MSC) Supplier: Organizations supplying the materials, parts and /or services to MSC Customer: The Customer /end user who buys the MSC products. It is also used for Internal Customers Abbreviations: QMS OPI T/L PC MT PC MGT SP Quality Management System Operator Process Instructions Team Leaders Production Control Maintenance Production Control Management Standard procedure NC FMEA PPAP APQP PH PD CP CAR Non-conformance Failure Mode Effect Analysis Production Part Approval Process Advanced Product Quality Planning Purchasing Production Control Plan Corrective Action Request

3.2

Note: Printed documents are not controlled copies-check master computer files for latest revisions

Issued by: Ralph Sulser Approved by: Keith Shepard

Edition: 01 Date: 04/02/03 Rev. 0

MUSASHI SOUTH CAROLINA

QUALITY MANAGEMENT SYSTEM Page 10 of 45

DOC NO.:MSC-QM1 SECTION#: 4

4.0 Quality Management System 4.1 General Requirements

The MSC has established, documented, and implemented a Quality Management System. The company maintains and continually improves the effectiveness of our QMS in accordance with the requirements of ISO/TS 16949:2002 MSC has therefore: a) identified the processes needed for the quality management system, and their application throughout MSC, except for the exclusion as mentioned at Section 1.0 (Refer 1.2), The outsource processes, if any, that affect product conformity with requirements, have also been identified. Apart from their identification, the Company has also identified the controls over their processes in order to ensure product conformity. b) determined the sequence and interaction of these processes (QC-PM-001 &001b) , and a typical bevel gear Process Flow Diagram(s) shown in each parts PPAP/QAV booklet. (located in the front of manual) c) determined the criteria and the methods needed to ensure that both the operation and control of these processes are effective. This has been done while planning for the processes. (Refer Section 7.1). d) ensured the availability of resources and information necessary to support the operation and monitoring of these processes (Refer Section 6 & 7.1). These have been determined and verified at the time of planning the e) decided to monitor, measure and analyze the above identified processes (Refer Section 8), and f) implemented actions necessary to achieve the planned results and deciding, the continual improvement of these processes. These processes are managed by MSC in accordance with the requirements of the QMS Standard. 4.1.1 MSC assures control over any outsourced processes and responsibility of same conforming to all customer requirements.

Note: Printed documents are not controlled copies-check master computer files for latest revisions

Issued by: Ralph Sulser Approved by: Keith Shepard

Edition: 01 Date: 04/02/03 Rev. 0

MUSASHI SOUTH CAROLINA

QUALITY MANAGEMENT SYSTEM Page 11 of 45

DOC NO.:MSC-QM1 SECTION#: 4

4.2 4.2.1

Documentation Requirements General

The Quality Management System documentation of the MSC includes:

a) Documented statement of Quality Policy and Quality Objectives, (Refer Section 5.3 & 5.4.1 of this Manual) b) Quality System Manual, c) Documented procedures wherever required by ISO/TS 16949:2002 and where the absence of these procedures can affect the quality of the product. d) Applicable documents needed by the Company to ensure the effective planning, operation and control of its processes, and e) Quality Records specified by this standard required for demonstrating the objective evidence of having carried out the activity. The Company has developed document structure as given below: Level Level Level 1- Quality System Manual 2- Standard Procedures 3 -Operator Process Instructions Work Instructions Process Flow Diagrams Drawings / Specifications 4- Checksheets, Charts, Forms, Tags

Level

MSC has established procedures to conform with those specified in the Standard and identified as Documented Procedures. These have been established, documented, implemented and maintained. While planning for the processes, apart from the required procedures, other procedures and guidelines / work instructions have also been identified based on the type of the activity, complexity of the processes and the existing competence of the personnel.

Note: Printed documents are not controlled copies-check master computer files for latest revisions

Issued by: Ralph Sulser Approved by: Keith Shepard

Edition: 01 Date: 04/02/03 Rev. 0

MUSASHI SOUTH CAROLINA

QUALITY MANAGEMENT SYSTEM Page 12 of 45

DOC NO.:MSC-QM1 SECTION#: 4

4.2.2

Quality Manual

MSC has established and maintains a Quality Manual that includes the applicable Scope of the Quality Management System (Refer Section 1.1) . Procedures established have been referenced in the relevant Sections. Wherever no procedures are required, the required methodology as adopted and implemented to meet the requirement of the standard have been explained in the Manual itself. The interaction between the processes(QCPM-001) of the Quality Management System have also been described in the Manual and by including the Process Flow Diagram(s) of the product(s) processed by the Company.

4.2.3

Control of Documents

Documents required by Quality Management Systems (refer documentation structure under 4.2.1) are controlled. The Company has established a Documented Procedure which defines the controls needed to effectively implement the Quality Management Systems. The controls defined in the procedure include the methods: a) To approve documents for adequacy prior to issue, from designated approving authorities, b) To review and update, as necessary, as a part of improvement of the management systems and re-approve the documents after modifications by the designated approving authorities, c) To ensure that changes and the current revision status of documents are identified through establishing distribution and maintaining revision / issue number. d) To ensure that relevant versions of applicable documents are available at the points of use. e) To ensure that documents, while distributing and use, remain legible and are readily identifiable by their document numbers, revision status and/or titles, f) To ensure that documents of external origin like customer drawings, international / other national standards are identified and updated periodically and their distribution controlled. g) To prevent the unintended use of obsolete documents by eliminating same and substituting with revised version, and to apply suitable identification to them if they are retained for any legal / reference purposes. 4.2.3.1 A system has been established and maintained to assure timely review distribution and implementation of all customers engineering standards/specifications and changes. Timely review shall not exceed two working weeks. A record will be maintained of the date each change is implemented, and corresponding document changes Procedure No.: QC SP 003 -Document Control

4.2.4

Control of Quality Records

While planning for the processes (Refer Section No. 7.1), the MSC has determined, established and maintained applicable Quality Records which provide evidence of conformity to requirements [including regulatory and customer requirements] and of the effective operation of the Quality Management System. These quality records serve as the objective evidence and are part of the Quality Management Systems. Quality records are maintained in such a manner that these remain legible, readily identifiable and retrievable. MSC has established a documented procedure which defines the controls needed for identification, storage, protection, retrieval, retention time, and disposition of records. 4.2.4.1 Records retention controls shall satisfy regulatory, and customer requirements if these differ from MSC company policies. Procedure No.: QC SP 004 - Control of Records

Note: Printed documents are not controlled copies-check master computer files for latest revisions

Issued by: Ralph Sulser Approved by: Keith Shepard

Edition: 01 Date: 04/02/03 Rev. 0

MUSASHI SOUTH CAROLINA

MANAGEMENT RESPONSIBILITY

Page 13 of 45

DOC. NO.;MSC-QM1 SECTION #: 5

5.0 Management Responsibility

5.1 Management Commitment

The MSC management is committed to the development and implementation of the quality management system and continually improve its effectiveness by: a) Communicating to all employees of the company: the importance of meeting customer as well as statutory and regulatory requirements through regular training programs, display of documents and departmental meetings, communication meetings, and manag b) Establishing the quality policy based on the improvement objectives, c) Ensuring that quality objectives are established, d) Conducting regular management reviews, and e) Ensuring the availability of resources for improvements when required. f) Product realization process and support processes are reviewed for their effectiveness and efficiency

5.2

Customer Focus

The Top Management of MSC ensures that customer requirements are determined and fulfilled with the aim of enhancing customer satisfaction. While reviewing the requirements, the implied needs and expectation of the customer are also identified. These are conveyed to the respective functions for ensuring that they are met. As a part of Management Review (Refer 5.6 below) , a focus is made for communicating the customer requirements to all functions and ensuring product conformance. Methods of determining customer requirements, expectations and satisfactions are defined in the procedures MGT SP 001 QC SP 023 QC-SP-007 Contract Review (Product Requirement Review) APQP (Planning for product realization) Failure Mode And Effect Analysis

5.3

Quality Policy

The Management of the company has defined the quality policy ensuring that the quality policy a) is appropriate to the purpose and organizational goals of the company, b) includes a commitment to comply with requirements and continually improve the effectiveness of the quality management system, c) provides a framework for establishing and reviewing quality objectives, d) e) is communicated to all employees of the company and is understood at all levels in the company, is periodically reviewed for continuing suitability.

Note: Printed documents are not controlled copies-check master computer files for latest revisions

Issued by: Ralph Sulser Approved by: Keith Shepard

Edition: 01 Date: 08/31/05 Rev. 4

MUSASHI SOUTH CAROLINA

MANAGEMENT RESPONSIBILITY

Page 14 of 45

DOC. NO.;MSC-QM1 SECTION #: 5

The Policy of the company has been displayed at strategic locations and also distributed to all employees. Periodic Training Programs are held for understanding by all the functions through out the organization. Quality Policy distribution and display records are maintained. The policy of Musashi South Carolina is to achieve total customer satisfaction by delivering products and providing services that meet or exceed customer quality requirements and expectations. Deliver on time, and at the most competitive prices in domestic and export market for our entire product range. It is implied that all people at all levels in our organization be committed to comply with requirements and continually improve the effectiveness of the Quality Management System and their performance. Ultimate goal of working towards achieving zero defects. Necessary measures are also taken towards product safety, and environmental needs to minimize potential risks to employees, and subsequent end users. Our mission is to make Musashi South Carolina a synonym for a world-class organization excelling in gear, and gear assembly manufacturing. MSC Senior Management, Department Managers, Assistant Managers, and area Team Leaders shall ensure that this policy is understood, implemented and maintained by all personnel in their respective division / department / section.

QUALITY POLICY

MSC will continually strive to produce quality products that meet or exceed customer expectations, cost competitiveness, and timely deliveries QCD (Quality, Cost, Delivery) through exercise of continual improvement, employee support, and customer communication.

Dated: 03/20/2003

S. Okubo

President

Process interactions of achieving product realization are described on QC-PM-001. Outlined below are typical duties, and inputs of the department management to focus on objectives, and customer satisfaction. Current plant organizational charts are on file in H.R.

Note: Printed documents are not controlled copies-check master computer files for latest revisions

Issued by: Ralph Sulser Approved by: Keith Shepard

Edition: 01 Date: 08/31/05 Rev. 4

MUSASHI SOUTH CAROLINA

MANAGEMENT RESPONSIBILITY

Page 15 of 45

DOC. NO.;MSC-QM1 SECTION #: 5

5.4 Planning

5.4.1 Quality objectives Top management ensures that quality objectives, including those needed to meet requirements for product [see 7.1 a)] are established at relevant functions and levels within the organization. The quality objectives are measurable and consistent with the quality policy. Top management defines quality objectives and measurements that are included in the business plan and used to deploy the quality policy. Quality objectives address customer expectations and achievement goals within a defined time period. 5.4.2 Quality management system planning Top management ensures that a) the planning of the quality management system is carried out in order to meet the requirements given in 4.1, as well as the quality objectives, and b) the integrity of the quality management system is maintained when changes to the quality management system are planned and implemented.

5.5 Responsibility, authority and communication

5.5.1 Responsibility and authority Top management ensures that the responsibilities and authorities are defined and communicated within the organization.

1.

President - Musashi South Carolina

The senior most executive at the plant and designated as President, and has responsibility for the entire operation.. Approves customer and supplier contract review actives. Approves the company's policies and gives directions for managing the objectives, and company activities. Approves the MSC's quality policy and objectives. Responsible for providing essential resources and personnel for implementation of the quality policy, and quality management system. Responsible for effective implementation of the quality management system. Through leadership and actions, the President creates an environment where people are fully involved, and in which a QMS can operate effectively. Reviews customer scorecards for Visteon, and other customers, on their web sites Chairman of the Management Review Committee.

2.

Senior Manager Engineering/Maintenance

Overall responsibility for planning, coordinating & managing activities related to functions of Manufacturing Engineering, Maintenance, Projects. Preventive/Predictive Maintenance, Tool/Die, Mechanical, Electrical, Compressor, pump house and LPG and all utilities Manages, and coordinates any modifications to be carried out in the existing operations or enhancing the efficiency of the plant. Responsible for building the required competency level in the employees reporting to him. Assisted by Manufacturing Engr. Mgr, Maint. Manager. Authorized for approval of production processes in the plant. Authorized for taking corrective & preventive action in case of deviations in the operations. Authorized to STOP PRODUCTION if systems are not being implemented. Developing facilities, processes and equipment, and contingency plans. Supporting QMS activities including regulatory requirement if any, for the products. Reports to the Plant President.

Note: Printed documents are not controlled copies-check master computer files for latest revisions

Issued by: Ralph Sulser Approved by: Keith Shepard

Edition: 01 Date: 08/31/05 Rev. 4

MUSASHI SOUTH CAROLINA

MANAGEMENT RESPONSIBILITY

Page 16 of 45

DOC. NO.;MSC-QM1 SECTION #: 5

3.

Senior Manager Quality Control

Responsible for quality systems, procedures, and instructions for the plant Monitoring the Process for outputs. Providing Test Status on In-coming, In-process and Finished Products Documenting trends in quality and current quality levels. Controlling of non-conforming products. Authorized for dispositioning deviations on Non-conforming products for use at next stages. Authorized for release of finished product. Obtaining waivers from customer on non-conforming finished products. Developing and implementation of plans for customer complaint resolution. Assessment of Preliminary (Ppk) and on going process capabilities (Cpk). Preparing details for Production Part Approval Process. Inspection and testing at incoming, in process and final stages Controlling the procedures for In-coming, In-process and Final Inspection Stages Calibration of all identified inspection, measuring and test equipment. Authorized for providing inspection and test status on all products. Identifying and implementing statistical technical techniques for process and product. Verifying the effectiveness of corrective and preventing actions. Issuing and maintaining originals and withdrawal of obsolete APQP documents, process standards, drawing and documents of external origin. Production Part Approval Process (PPAP&PSW) and liaison with customers for same Establishing, and maintaining customer communication channels. Monitoring and Measuring Customer Satisfaction metrics. Representing the needs of the customer in internal functions in addressing the ISO/TS 16949 requirements. Assisted by Quality Control Mgr. QC, QC Technicians, QC Associates, TS16949 Coordinator Reviews and maintains scorecards for Visteon, and other customers, weekly on their web sites Designated as Customer Representative to ensure customer requirement are met, and contact for quality issues.

Representing the needs of the customer in internal functions addressing the product realization planning (APQP) for

ISO/TS 16949 requirements (e.g. selection of special characteristics, setting quality parameters. Develops manufacturing process design quality controls including Process Flow Diagram, FMEAs, Control Plans and Process Standards, and Inspection Standards. Authorized to STOP PRODUCTION if systems are not being implemented. Reports to the Plant President

Note: Printed documents are not controlled copies-check master computer files for latest revisions

Issued by: Ralph Sulser Approved by: Keith Shepard

Edition: 01 Date: 08/31/05 Rev. 4

MUSASHI SOUTH CAROLINA

MANAGEMENT RESPONSIBILITY

Page 17 of 45

DOC. NO.;MSC-QM1 SECTION #: 5

4. Senior Manager Production/Production Control/New Sales

Overall responsibility for planning, coordinating & managing activities related to functions of Production Purchasing of manufacturing materials, and supplier monitoring. Production scheduling of all products Control of customer-supplied products, and packaging Receiving, storage and issue of products, and packaging. Reviewing, approving and maintaining effectiveness of the procedures for the above activities. Disposal of scrap, and waste. Handling storage, preservation, identification and test status of all products during receipt, storage, Ensuring 100% on time delivery to customer. Inventory management of purchased products, WIP and finished product. Checking adequacy of FIFO. Supplier performance tracking Supporting QMS requirements related to these functional areas. Assisted by Production Control Manager, and Coordinators. Reviews customer scorecards for Visteon, and other customers, on their web sites Preparing and submitting the quotation offer to customers. Receipt of order / dispatch schedules from customer. Review of customers order for correctness. Resolving any differences between the inquires and potential orders. Communicating customers requirement to concerned personnel in the company. Interaction with Customer for product development and all contract review activities Also responsible for EHS, ISO14001 and assisted by the EHS Administrator Assisted by Managers, and Assistant Managers for Forging, Lathing, Heat Treat/Assembly, for these activities. Guiding and supporting QMS activities including regulatory requirement if any, for the products. Reviews customer scorecards for Visteon, and other customer rating systems Authorized for approval of production processes in the plant. Authorized for taking corrective & preventive action in case of deviations in the operations. Authorized to STOP PRODUCTION in his area, if systems are not being implemented. Reports to the Plant President

5.

Accounting Manager

Overall responsibility for all accounting, finance, and supplies purchasing functions in the plant. Assists in guiding and supporting QMS related activities in those functions such as purchased supplies, tooling, and stores. Assisted by the, Assistant Manager of Accounting, and the Assistant Manager Purchasing/Buyer, Accounting Coordinator, and IT Administrator for these activities. Reports to the Plant President.

6.

Manager Human Resources

Responsible for coordinating with departmental heads to obtain staffing. Determine the training needs related to managers, staff, associates, temporaries, probationers, and trainees. Identifies, and implements training, and employee motivation needs. Also responsible for public affairs, and industrial relations to enhance productivity. Assisted by the H.R. Assistant, and Payroll Coordinator. Reports to the Plant President.

Note: Printed documents are not controlled copies-check master computer files for latest revisions

Issued by: Ralph Sulser Approved by: Keith Shepard

Edition: 01 Date: 08/31/05 Rev. 4

MUSASHI SOUTH CAROLINA

MANAGEMENT RESPONSIBILITY

Page 18 of 45

DOC. NO.;MSC-QM1 SECTION #: 5

7. MSI Engineering- Japan

Reviewing, recommending and providing guideance for effectiveness of the procedures on Product requirement Review Manufacturing Process Designing and Development; Plant Facilities and Equipments Provisioning, Developing guidelines of new products planning. Reviewing customer engineering specifications and standards.

8.

President - Sales and Marketing-Musashi North America, Detroit, MI

Receipt of Inquiries from the customers, review, and passes thyrough to Musashi South Carolina Coordinating with MSI, MSC President for planning future business Assists in assessments of customer satisfaction. Reports to President Musahi North America

9.

Management Representative ( Ref. 5.5.2 )

The Management of the company has appointed the TS16949 Coordinator, as Management Representative, who, irrespective of other responsibilities, has the responsibility and authority that includes: Management Representative (MR) / TS16949 Coordinator, Quality Controlare responsible for Establishing, implementing and maintaining quantity system in accordance with ISO/TS 16949:2002 (E) Reporting the performance of the Quality System for Management Review, which forms the basis for improvement of Quality System. Liaison with internal and external parties on matters relating to Quality System. Ensuring timely management review of the Quality System. Organizing Audit Summary Report, and summary of the Preventive Actions for Management Review. Approving and ensuring effectiveness of procedures on Document Control, Quality Management System Auditing and Records Control. Preparation and issue of Quality System, and Procedures Manuals Maintaining original documents and their master lists and issue of Quality System Manual, all Quality System Procedures, all work instructions, and samples of all formats Identification of training needs for building a team of internal quality auditors

5.5.1.1 Responsibility and authority of managers Managers with responsibility and authority for corrective action are promptly informed of products or processes that do not conform to requirements. Personnel responsible for product quality have the authority to stop production to correct quality problems. Production operations across all shifts are staffed with personnel in charge of, or delegated responsibility for, ensuring product quality. 5.5.2 Management representative Top management has appointed the TS16949 Coordinator-Quality Control who, irrespective of other responsibilities, has the responsibility and authority that includes: a) ensuring that processes needed for the quality management system are established, implemented and maintained, b) reporting to top management on the performance of the quality management system and any need for improvement, and c) ensuring the promotion of awareness of customer requirements throughout the organization. d) liaison with external parties on matters relating to the quality management system.

Note: Printed documents are not controlled copies-check master computer files for latest revisions

Issued by: Ralph Sulser Approved by: Keith Shepard

Edition: 01 Date: 08/31/05 Rev. 4

MUSASHI SOUTH CAROLINA

MANAGEMENT RESPONSIBILITY

Page 19 of 45

DOC. NO.;MSC-QM1 SECTION #: 5

5.5.2.1 The Sr. Manager-Quality Control has been designated as Customer Representative to assure customer requirements are addred within MSC. Visteron will be notified of any changes to customer rep., or senior mgmt. 5.5.3 Internal communication The Management of the MSC ensures that appropriate communication processes are established within the company and that communication takes place regarding the effectiveness of the quality management system, and actions to be taken on nonconformances encountered in the activities including customer communication.

5.6 Management review

5.6.1 General Top Management of MSC reviews the companys quality management system, at planned intervals to ensure its continuing suitability, adequacy and effectiveness. The Quality Management System of the company is reviewed by the Management Review Team that comprises all Managers of Departments under the Chairmanship of the President. The review includes assessing opportunities for improvement and the need for changes to the quality management system, including the quality policy and quality objectives. Management Representative maintains records of management reviews. 5.6.1.1 Quality Management System Performance-Input All requirements of the quality management system, performance, and trends for continual improvement. Monitoring quality objectives Regular reporting and evaluation of cost of poor quality Evidence of achieving: quality objective specified in the business plan Evidence of customer satisfaction with products supplied 5.6.1 Review input The input to management review in the form of Agenda for Management Review Team meeting includes information for the period under review on sections of applicable QMS STANDARDS. However, more focus is placed on the following: a) Business Plan/Quality objectives b) Cost of poor quality c) Customer satisfaction, feedback, (Customer perceptions & Complaints) d) Analysis of actual and potential field failures and their impact on quality, safety or the environment e) Follow-up actions from previous management reviews, f) Results of internal/external audits including the trends, g) Process performance and product conformity, h) Status of preventive and corrective actions, i) Planned changes that may affect the quality management system, and j) Recommendations for improvement especially for product / process characteristics, k) Status and results of Quality objectives and Quality Improvement Programs, l) Performance of Suppliers, e.a., monthly ratings for quality, and delivery 5.6.2.1 Additional Review Inputs a) Management analysis of actual and potential field failures, and their impact on quality, safety, or the environment. b) Measurements at specified stages of design and development will be defined, analyzed, and reported with summary results. Items such as quality risks, costs, lead times, critical paths, and others as appropriate. 5.6.3 Review output The minutes of the management review meeting are recorded and maintained for a specified period. The output from the management review in the form of minutes of meeting and action plans include any decisions and actions related to: a) Improvement of the effectiveness of the quality management system and its processes, b) Improvement of product related to customer requirements, and c) Resource needs support Procedure No. QC SP 001 Management Review Management Review Form: QC-F-MR418

Note: Printed documents are not controlled copies-check master computer files for latest revisions

Issued by: Ralph Sulser Approved by: Keith Shepard

Edition: 01 Date: 08/31/05 Rev. 4

MUSASHI SOUTH CAROLINA

RESOURCE MANAGEMENT

Page 20 of 45

DOC NO.: MSC-QM1 SECTION#: 6

6

6.1

Resource Management

Provision of Resources

MSC determines and provides the resources, such as competent personnel, proper working environment and adequate infrastructure needed to implement and maintain the Quality Management System and continually improve its effectiveness. Equipment and instruments needed for work and verification are identified, procured. Procedures are issued to ensure that these are fit for use in carrying out work and verification activities. Department Managers identify the resources required for implementing, performing and verification activities related to MSCs quality management systems. These are further examined, reviewed and provided as and when required to enhance customer satisfaction by meeting customer requirements. These resources are identified at the time of planning for product realization and periodically reviewed (Refer Section No. 7.1 ). Necessary identified resources are planned and provided to meet the requirements.

6.2

6.2.1

Human Resources

General

MSC has identified the competence level required for the personnel carrying out the activities in different areas of operations and production departments. The Job Description (Profiles) for all functions have been defined on the basis of requirements related to appropriate education, training, skills and experience for the specific jobs. Hence the personnel performing such work, which affects product quality, are assigned the tasks on the basis of defined competence. The job descriptions are also used for identifying the training needs of the personnel to ensure they are competent to do their assigned activities. 6.2.2 Competence, Awareness and Training

MSC has established a documented procedure for Training. Through this procedure, the training needs of personnel are identified to ensure competence for carrying out their activities. The controls exercised for making the personnel competent are: a) To determine the required minimum competence for the personnel performing work affecting product quality in terms of criticality of the process through defined Job Description (Profiles) (Refer Section 6.2.1 above), For process design responsible personnel this includes competence on design tools and techniques a) To provide structured / unstructured training (i.e. technical college courses, on job training / coaching under the supervision of their seniors) to the identified personnel to satisfy and meet their training needs. On the job training is provided to all the personnel including temporary/contract personnel whenever there is any new or modified job/process affecting product quality is incorporated. During this training, associates are informed of the consequences to the customer of non-conformity to quality requirements. b) To evaluate, after a defined period, the effectiveness of the structured / unstructured training provided, toward progress in their achievements: c) To ensure that the MSC associates are fully aware of the relevance and the importance of their activities including their involvement and contribution to the achievement for the identified quality objectives. d) To maintain records of education, training, skills and experience of all associates as quality records. These records also help in determining the need for multi-skill training requirements, if any. (Refer to Skill Maps for each department) f) A documented procedure has been established and maintained for employee motivation and empowerment for achieving quality objectives, continual improvement and promote innovation. A process is in place to ensure that personnel are aware of the relevance and importance of their activities and contribution in achieving quality objectives. Procedure: HR SP 001 Training HR SP 002 Resource Management

Note: Printed documents are not controlled copies-check master computer files for latest revisions

Issued by: Ralph Sulser Approved by: Keith Shepard

Edition: 01 Date: 04/02/03 Rev.: 0

MUSASHI SOUTH CAROLINA

RESOURCE MANAGEMENT

Page 21 of 45

DOC NO.: MSC-QM1 SECTION#: 6

6.3

Infrastructure

MSC identifies and determines, with a multidisciplinary approach, the required infrastructure at the time of Planning for Product Realization (Refer Section No. 7.1 ). The infrastructure considered during planning includes: a) adequate buildings for storage, processing, inspections b) adequate workspace for working and house keeping, processing and storage c) required associated utilities like power, compressors, water supply, fuel supply, utilities etc.; d) required process equipment / machinery (both hardware and software) which can meet needs for converting the inputs into required outputs at relevant stages of processing, and can meet the customer requirements. e) supporting services, such as transport for movement within and outside of MSC and required means of communication. f) Plant layout is developed in such a way so that it optimizes material travel; handling and value added use of floor space, and facilitates a synchronous flow of material. A system is in place to evaluate and monitor the effectiveness of existing operation. g) A contingency plan is prepared and followed in all manufacturing departments to ensure supply of products in the event of emergency such as utility interruptions, labor shortage, key equipment failure and field returns.

As per the identified requirements, MSC provides the infrastructure needed to achieve conformity to product requirements. MSC has also established a documented procedure, and preventative maintenance schedule matrix for maintaining the above infrastructure by conducting preventive, condition monitoring and break-down maintenance in order to ensure continuing suitability. The data related to maintenance is analyzed and maintenance objectives are established for continual improvements. Procedure: QC SP 024 Contingency Plan MT-SP-001- Procedure for Preventative Maintenance(update-CG)

6.4

Work Environment

MSC determines and manages the required work environment needed to achieve conformity to product requirements as per documented process. At the time of planning for Product Realization (Refer Section No. 7.1 ), the requirements of Work Environment are considered and examined and wherever required, reviewed upgrading. The following applicable work environment factors are considered at the time of planning:

Temperature, humidity, vibration, air quality, noise, lighting, as appropriate to the nature of the work being performed.

6.4.1 Personnel safety to achieve product quality Product safety and means to minimize potential risks to employees, and customers are addressed by MSC, especially in the design and development process and in manufacturing process activities.

Human factors such as ergonomics (space required for effective working), and need for the use of personal protective equipment (PPE).

6.4.2 Cleanliness of premises MSC maintains the premises in a state of order, cleanliness, and repair consistent with the product and manufacturing needs. Cleanliness of premises is maintained using 5S check lists to ensure the premises in a state of order, cleanliness and repair. The work conditions and environment are continually improved for meeting the product requirements. These requirements are met by providing the adequate facilities and conducting regular maintenance for their upkeep.

Note: Printed documents are not controlled copies-check master computer files for latest revisions

Issued by: Ralph Sulser Approved by: Keith Shepard

Edition: 01 Date: 04/02/03 Rev.: 0

MUSASHI SOUTH CAROLINA 7.0 Product Realization 7.1 Planning of Product Realization

PRODUCT REALIZATION

Page 22 of 45

DOC NO.:MSC-QM1 SECTION#: 7

MSC uses a multi-disciplinary approach for Planning for the products realization [using advance product quality process]. While Planning for product realization, it is ensured that the requirements of the other processes of the Quality Management System (see 4.1) are consistent with the anticipated requirements. Product and process regulatory requirements are also given due consideration during the development and preparation of relevant Process Control Documents. The resources, infrastructure, work environment and competency of required personnel are identified. 7.1.1 Customer requirements and references or differences to the specified technical specifications are included in the planning. The following are considered, as appropriate, at the time of development, updating / modification for improvement in the existing process: a) identified quality objectives and requirements for the product; [7.1.2 Acceptance criteria are defined by the company, and approved by the customer if required. The acceptance level for attribute data sampling is always zero defects.] b) the need to establish processes, documents, and provide resources specific to meet the requirements of the product; c) required verification, validation, monitoring, inspection and test activities specific to the products processed at relevant stages of processes and the criteria for the product acceptance; Acceptance criteria for attribute data sampling is zero defects. d) 7.1.3 Confidentiality of customer contracted product/projects and related product information. e) records needed to provide objective evidence that the realization processes and resulting product fulfill requirements. The business risks, the FMEAs (failure modes), their current status (i.e. Severity, Occurrence, Detection criteria) are studied and the required controls are identified. If upgrades are required for improvements, then action plans are initiated. The output of this planning in the form of a Control Plan, FMEA, Operator Process Instructions, or process control standards (PCS), quality inspection plans are made and provided at the relevant stages of processing for implementation. 7.1.4 A system is in place to control and react to changes that impact product realization. Assessment, verification, validation is done for the changes including the changes by the supplier. Procedure No. MGT-SP-001 Contract Review Procedure No. QC SP 023 Advanced Product Quality Planning

7.2 Customer Related Processes

7.2.1 Determination of Requirements Related to Product The organization has established a documented procedure to determine: requirements related to product including those specified by the customer, not stated by the customer and statutory and regulatory requirements; conformity to customer requirements for designation, documentation, and control of special characteristics; review of requirements related to product prior to supply and resolving any differences; amendments of relevant documents if product requirements are changed; investigating, conforming and documenting the manufacturing feasibility of the proposed product determining and implementing effective arrangements with the customer; and ability to communicate necessary information in customer specified language and format 7.2.1.1 Customer designated special characteristics are identified for conformance according to customer requirements of the designation, documented and controlled

7.2.2

Review of Requirements Related to Product

MSC reviews the requirements related to the product. This review is conducted via a check list prior to the organization's commitment to supply products to the customer and ensures that: a) Product requirements including delivery schedules, packing requirements are clearly defined. Where the customer provides no documented requirements, the customer requirements are confirmed before acceptance by: phone calls, e-mails, meetings, letters. b) Contract or order requirements differing from those previously expressed are resolved, and

Note: Printed documents are not controlled copies-check master computer files for latest revisions

Issued by: Ralph Sulser Approved by: Keith Shepard

Edition: 01 Date: 04/02/03 Rev. 0

MUSASHI SOUTH CAROLINA

PRODUCT REALIZATION

Page 23 of 45

DOC NO.:MSC-QM1 SECTION#: 7

c) MSC has the ability to meet the defined requirements. d) Manufacturing feasibility including risk analysis is investigated, confirmed and documented before contracting. e) In case any formal review of the contract is not applicable, prior authorization from the customer is obtained before proceeding with the contract. Records of the results of the review and actions arising from the review as quality records are also maintained. If any amendments to product requirements are received from the customer, MSC ensures that these are reviewed for ability to supply, and the relevant documents are amended accordingly. The modified documents are conveyed to relevant functions for making them aware of the changed requirements for immediate compliance. Procedure No. MGT-SP-001 Contract Review Procedure No. QC SP 023 APQP

7.2.3

Customer communication

MSC has determined and assigned responsibilities for implementing effective arrangements for communicating with customers in relation to: a) Product information through customer visits, meetings, letters, e-mails, and web site. b) Inquiries, contracts or order handling, including amendments, and c) Customer feedback, including resolving customer complaints. Such feedbacks from customer are reviewed and analyzed for root cause of the problems through problem solving techniques. The decisions taken for corrective and preventive actions including further improvements in the products / processes. d) Where required by the customer, necessary information including data is communicated to customers in their specified language and format. (web sites, e-mail, electronic data exchange) Procedure No. MGT SP 001 - Procedure for Contract Review QC SP 019 - Corrective Action (Includes Customer complaint response) QC SP 011 - Procedure for internal & External Customer Satisfaction

7.3.2

Design and Development Planning

MSC only manufactures products from customer provided designs and specifications, and therefore performs only manufacturing process design and development activities in conjunction with Planning for product Realization. Upon receiving a Letter of Intent (LOI) or Purchase Order (PO) from the customer the organization develops a process design and development plan defining the development stages design review, verification and validation requirements and responsibilities / authorities for design and development. 7.3.2.1 The organization uses cross-functional teams for manufacturing process design and development. The team carries out feasibility studies, prepares process flow diagrams, PFMEA, (process failure mode and effective analysis), develops Control Plans and identifies special characteristics for products giving due care to product safety, utilizing appropriate mistake proofing methodologies with efforts on defect prevention rather than detection and, creating internal awareness on safety considerations. 7.3.2.2 The design and development inputs are then identified, documented and reviewed based on product and customer requirements and experience from previous developments. Control Plans are developed at the system, sub system and component levels for the products supplied at the different phases via Prototype, Pre-launch and Production as appropriate including listing all controls used for process control. 7.3.2.3 Manufacturing design outputs consist of process control guidelines, i.e., FMEAs, Control Plans, Process Standards and Operator Process Instructions. These are marked with the customers special characteristics symbols, if specified by the customer on the drawings/documents supplied. All production processes, which directly affect the quality of products, are considered during quality planning. Control Plans are reviewed and updated if the product or process changes, or becomes in-capable / unstable. Inspection methods, and frequencies are also revised if necessary. Process approval acceptance criteria data for quality, reliability, maintainability and measurability results of error-proofing activities. Methods of rapid detection and feed back of manufacturing process non conformities are defined, as appropriate as an output, of the design and development activity in the form of procedures, work instructions or process standards. Programs of design and development is monitored at defined stages / frequency, analyzed and reported with summary results in the management reviews.

Note: Printed documents are not controlled copies-check master computer files for latest revisions

Issued by: Ralph Sulser Approved by: Keith Shepard

Edition: 01 Date: 04/02/03 Rev. 0

MUSASHI SOUTH CAROLINA

PRODUCT REALIZATION

Page 24 of 45

DOC NO.:MSC-QM1 SECTION#: 7

7.3.6.3 A procedure has also been established for production part approval process (PPAP) addressing the following activities as applicable: -identification of need for submission / preparation of PPAP -decision on submission level -Preparation of Part Submission Warrant and submitting a copy of PPAP document / sample to customer, as appropriate -Maintaining original PPAP documents / records -Maintaining master sample (s) -Incorporating changes required by customer in the documents and processes Part approval process is used for suppliers. The system ensures that the engineering changes are properly validated. Review, verification and validation of the newly designed and developed manufacturing process is carried out at sample / prototype, production part approval and pre-launch stages of production respectively. Developed product is reviewed at sample / prototype stage, verified and validated after production part approval. Records of results of reviews, verification and validation of manufacturing process design and development activities are maintained. Procedure No. QC SP 009 Parts Submission Warrant/PPAP

7.4

7.4.1

Purchasing

Purchasing process

MSC has established a documented procedure to ensure that purchased products conform to specify purchase requirements [including conformity to applicable regulatory requirements]. The type and extent of control applied to the supplier and the purchased product depends upon the effect of the purchased product on subsequent product realization or the finished / final product. The Company evaluates and selects suppliers based on their ability to supply product in accordance with the Companys requirements [where specified by the customer, purchasing is done from customer approved sources only unless waived by the customer. Criteria for selection, evaluation and periodical re-evaluation have been established [monitoring of the supplier is done using documented process which considers the indicators like quality, delivery schedule performance, premium freight, field return and special status, customer notification]. Records of the results of evaluations and any necessary actions arising from the evaluation at company or supplier end are maintained. MGT-SP- 001 Contract Review (Sr. Manager Production Control and President) PH-QP- 4.6 Purchasing Materials/Components (Production Control Manager) PH-SP- 002 Approved Supplier List

7.4.2

Purchasing information

MSC has established criteria for detailing adequate Purchasing Information in the Purchase Documents (in hard copies / through emails ) for the products to be procured. The product and supplier details are described in Purchase Documents or e-mails, including where applicable: a) Requirements for approval of product, procedures, processes, and equipment, b) Requirements for qualification of personnel, and Quality management system requirements. The authorized Production Control Manager or Purchasing Manager reviews the purchase information to ensure the adequacy of specified purchase requirements prior to their communication or issue to the suppliers. MGT-SP- 001 Contract Review (Sr. Manager Production Control and President) PH-QP-4.6 Purchasing-Materials/Components (Production Control Manager) PH- SP- 005 Purchasing Indirect Materials, Tooling, Supplies (Purchasing Manager)

Note: Printed documents are not controlled copies-check master computer files for latest revisions

Issued by: Ralph Sulser Approved by: Keith Shepard

Edition: 01 Date: 04/02/03 Rev. 0

MUSASHI SOUTH CAROLINA

PRODUCT REALIZATION

Page 25 of 45

DOC NO.:MSC-QM1 SECTION#: 7

A goal has been established for quality management system development of suppliers That goal is eventual supplier conformity with ISO/TS 16949-2002. As a first phase suppliers are encougred to pursue and obtain third party certification to ISO 9001-2000 and finally to ISO/TS16949-2002 if applicable.

7.4.3

Verification of Purchased Product

a) MSC has established a documented procedure for implementing the Inspection / Testing or Verification of the products, as necessary, for ensuring that purchased products meet the specified purchase requirements. The company ensures that through this procedure for receiving inspection and testing, all material at incoming stage are inspected, tested/verified for conformance to the specified requirements. b) During verification of purchase product one of the methods as given below are followed: Receipt and evaluation of statistical data Receiving inspection and testing on the basis of sampling Assessment of supplier by customer or third party supported through acceptable product quality record. (Rec.Insp.) Test Report from accredited laboratory. Other methodology as advised by the customer. c) If contractually agreed, the company also allows its customers or their representatives to verify that the purchased materials at supplier end for ensuring materials conformance to specified requirements. When it is proposed to verify the purchased product at the supplier's premises by either customer or companys representatives, the verification arrangements and the method of product release are specified in the purchase order or its attachments. Procedure No. QC SP 014 Receiving Inspection-Bar Stock Work Instruction PD-WI-017 Receiving Steel Bars Work Instruction PD-WI-HF-109 Receiving and inspection of ATV Billets

7.5

Production and service provision

7.5.1 Control of Production and Service Provision Servicing, and Appearance Items are not currently a contractual part of Musashi South Carolina customer requirements, and not part of MSCs current manufacturing operations. If in the future these become a requirement, we will address them in accordance with the applicable specification, and/or standards. Production is controlled by way of preparing and implementing Operator Process Instructions, Work Instructions, Check Sheets, and X bar & R Charts. Suitable equipment, and monitoring and measuring devices are provided and maintained. Release and delivery activities are implemented. MSI Engineering Departments during Manufacturing Process Designing and Development process prepares initial FMEAs, Control Plans, and Operator process Instructions. These are then modified to reflect MSC actual conditions. 7.5.1.1 Controls Plans are developed at the system, subsystem, component and / or material level for the product supplied, for different stages of process development i.e. prototype pre-launch and production, from the process FMEA output. Control Plans are reviewed and updated when any change occurs effecting product, manufacturing process, measurement, logistics, supply source or FMEA. 7.5.1.2 The manufacturing departments carry out production based on the Operator Process Instructions and prepare any additional work instructions necessary, and checklists for employee responsible for the operation of process including set up personnel, which are accessible for use at the work station. 7.5.1.3 First piece set up is approved, before allowing mass production by authorized person during each job change of each operation. 7.5.1.4 Detailed checklists developed for each process equipment are used for preventive maintenance and predictive maintenance as per the maintenance plans developed yearly and reviewed monthly. Equipment, tooling and gages not likely to be used for a considerable time are packaged and preserved per a checklist. A system has been established to assure minimum stocks of replacement parts for all key manufacturing equipment. Maintenance objectives are developed in the beginning of financial year which are evaluated and improved at planned intervals. 7.5.1.5 A system for maintenance of production tooling has been established including maintenance personnel storage and recovery, setup, tool change program for perishable tools; tool and tool design modification, documentation, tool identification and tool status. 7.5.1.6 The production scheduling is customer order/ forecast driven and supplies are made just in time based on customer schedules/releases and electronic dispatch instructions (EDI). 7.5.1.7 Customer feedback from service or field performance concerns is transmitted to the company via web customer web site, e-mail, and phone calls. 7.5.1.8 MSC currently does not have any service agreements with customers. If in the future Service Provisions become a requirement, we would develop a procedure to incorporate those requirements

Note: Printed documents are not controlled copies-check master computer files for latest revisions

Issued by: Ralph Sulser Approved by: Keith Shepard

Edition: 01 Date: 04/02/03 Rev. 0

MUSASHI SOUTH CAROLINA

Related procedures/Instructions: Shear Operations Hot Forging Press Start Up Hot Forging Press Die Change Heat Treatment Shot Blast-Billets and Forged Gears Handling, Storage, Packing, Preservation Customer Supplied Parts and Packaging Final Inspection & Packing of Visteon Gears

PRODUCT REALIZATION

Page 26 of 45

DOC NO.:MSC-QM1 SECTION#: 7

PD-WI- SH-101 PD-WI- HF- 102 &103 PD-WI-HF-105 PD-WI-HT-100 PD-WI-FSB-101 PC SP 001 PH SP 001 PD-WI-HT-109

7.5.2

Validation of Processes for Production

Before starting mass production, validation of processes, equipment and personnel is performed. A system has been established and maintained for revalidation of the processes. Validation is performed by determining CPks at run rate on customer designated characteristics, and records are maintained. The validation process is defined by the customer, or PPAP for specific criteria for review and approval, equipment approval, personnel qualification, methods / procedures, records requirements and revalidation. Procedure No. QC-SP-009 PSW/PPAP

7.5.3

Identification and Traceability

The Company has established a system for product identification and traceability, which requires that products be identifiable to the applicable specifications, as appropriate. Incoming materials, WIP, and finished packaging are identified by a lot tag giving details of part lot numbers, part name, and part number. Identification of all products at different stages of activity in the plant is maintained from the beginning billet shear operation through finished product to final packaging operation to the customer for all products. Work In-Process is also identifiable and traceable by part number lot tags. The products lot traceability is also identified through the data documented on the each parts check sheets. These sheets become quality records at each operation, and are traceable to date of production operations, inspection/testing / packing. The traceability lot tags are assigned at each operation and logged in and out, and is also provided on packaged products sent to the customers. The inspection and test status of items are identified through lot identification tags, inspection records, designated staging/storage areas and placards, as applicable. The identification, inspection and test status of incoming items are identified based on suppliers tags/labels, and certificate of conformance and / or the inspection and tests performed. These are then stored at designated locations. Separate areas have been identified and marked for incoming materials, and non-conforming items. Procedure No. QC SP 015 Product Identification & Traceability Procedure No. QC SP 005 Lot Control

7.5.4

Customer Property

MSC takes due care with customer property while under the MSCs control, or being used by the MSC. MSC may receive products, samples, drawings and packaging from the customers. A documented procedure identifies, verifies, protects and safeguards the customer property provided for use or incorporation into the product. If any customer property is lost, damaged or otherwise found to be unsuitable during verification for further use, it is reported to the customer and the necessary records are maintained.

Procedure No.

PH SP 001 Customer Supplied Parts and Packaging

Note: Printed documents are not controlled copies-check master computer files for latest revisions

Issued by: Ralph Sulser Approved by: Keith Shepard

Edition: 01 Date: 04/02/03 Rev. 0

MUSASHI SOUTH CAROLINA 7.5.5 Preservation of Product

PRODUCT REALIZATION

Page 27 of 45

DOC NO.:MSC-QM1 SECTION#: 7

MSC has established a documented procedures for preserving the product quality from receipt of materials through internal processing up to the delivery of finished products to the intended destination. This preservation includes the product identification, handling, packaging, storage and protection of the products. Every employee is responsible for safe handling of the products at various stages of processing. Handling, storage and transportation of products is to be controlled to prevent damage, deterioration or loss. When necessary, for particular items, special instructions are issued and monitoring is carried out to check satisfactory implementation. The appropriate handling of products is followed to avoid any deterioration of quality of product while in transit. 7.5.5.1 Appropriate storage areas are provided for materials and products for protection, and to prevent damage and deterioration of the product quality, including suitable preservation wherever necessary. The condition of the products in stock is assessed at appropriate intervals. All raw materials are issued on First In-First Out basis. An inventory management system is also used to optimize inventory turns. Work instructions have been established for inventory management. FIFO is utilized for issuing and using stock. Obsolete products are treated as non-conforming. A system for packing, packaging, marking, considering customer packaging standard and labeling / marking requirements have also been established. PC SP 001 Handling, Storage, Packing, Preservation PC WI 002 Production Planning PC WI 010 Monthly Inventory Corrections in the AS400 PC WI 011 Process Count Inventory Adjustment

7.6

Control of monitoring and measuring devices

The range of measurements and required accuracies are determined by the gage control technician. Measuring devices, including test software if necessary, used for conforming product quality, are selected based the capability of meeting the necessary accuracy and precision. This ensures that the measurement uncertainty is known and is consistent with the required measurement capability. The measuring devices that can affect products are identified and calibrated / verified / adjusted / readjusted at prescribed intervals, against measurement standards traceable to national / international measurement standards. Where no such standards exist, the basis used for calibration is recorded. If applicable, test software and test hardware used for inspection purposes are checked at prescribed intervals to assess their capability to verify the acceptability of product. Master list and calibration records containing necessary details are maintained in a controlled computer "Master file" by the QC Gage Calibration Technician, for all such devices. They are identified with a suitable indication through use of an engraved code number, a label, or color coded mark indicating the calibration status, and due dates for re-calibration. Persons using the calibrated equipment are trained to handle, store and preserve them appropriately to prevent damage and maintain the accuracy and fitness for use. Provisions to safeguard the calibrated equipment from adjustments and setting are also made as and where applicable. The calibration is carried out under controlled conditions as detailed in the relevant procedures.

Any measuring devices that fail during operation, are suspect, known to be outside its designated criteria or show evidence of physical damage affecting accuracy are removed from the location of use and isolated by the Gage Control Technician. Validity of inspection and test results of parts checked with measuring devices found to be out of calibration is assessed as applicable. If it has been determined that suspect material has been shipped, MSC will recall that material from transit, or notify customer if already delivered. 7.6.1 Measurement System Analysis is carried out for each type of measuring and test equipment, referred in the control plan, using appropriate statistical techniques. The analytical methods and acceptance criteria used conform to those in customer reference MSA manual. 7.6.2 Records of calibration / verification of all measuring devices include: equipment identification, measurement standard used for calibration, revisions following engineering changes, any out of specification reading as received for calibration with their assessment of impact, statement of conformance to specification after calibration and notification to customer if suspect material or product may have been shipped are maintained as defined in the relevant procedure.

Note: Printed documents are not controlled copies-check master computer files for latest revisions

Issued by: Ralph Sulser Approved by: Keith Shepard

Edition: 01 Date: 04/02/03 Rev. 0

MUSASHI SOUTH CAROLINA

PRODUCT REALIZATION

Page 28 of 45

DOC NO.:MSC-QM1 SECTION#: 7

7.6.3.1 MSC has an established system and procedure for the internal laboratory with a defined scope, which includes the capability to perform the required inspection, test and calibration services. The technical requirements for compliance by the laboratory include: adequacy of the laboratory procedures, qualification of the laboratory personnel conducting test, testing of commodities and capability to perform these test correctly, traceable to relevant process standard (e.g. ASTM) and review of related records. 7.6.3.2 External laboratories selected for inspection, test or calibration purposes are based on capability to perform the required inspection/ test / calibration, and its accreditation of ISO / IEC 17025 or national equivalent or its acceptability to customer. Computer Software, when used in the monitoring and measurement of specified requirements, are validated at the time of installation and records are maintained. The ability of computer software to satisfy the intended application is confirmed. As and when such software is updated, the same are again re-validated and the results are re-confirmed. Such software is re-confirmed at specified frequency as referred in the documented procedure. Procedure Nos. QC SP 017 QC SP 026 QC SP 008 PD-HT-703&705SM Gage Control Gage Calibration Scope Internal Laboratory Scope Laboratory System Skill Maps

Note: Printed documents are not controlled copies-check master computer files for latest revisions

Issued by: Ralph Sulser Approved by: Keith Shepard

Edition: 01 Date: 04/02/03 Rev. 0

MUSASHI SOUTH CAROLINA

MEASUREMENT, ANALYSIS, IMPROVEMENT Page 29 of 45

DOC NO.:MSC-QM1 SECTION#: 8

8.

Measurement, analysis and improvement

8.1 General