Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

01

Caricato da

FrancisBaconDescrizione originale:

Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

01

Caricato da

FrancisBaconCopyright:

Formati disponibili

Section

1

General Information

1.1.0 Introduction 1.1.1 Project To-Do Checklist (Electrical) 1.1.2 Drawing Design Checklist (Electrical) 1.1.3 Site Design Checklist (Electrical) 1.1.4 Existing Condition Service and Distribution Checklist 1.1.5 Design Coordination Checklist (Electrical) 1.1.6 Fire Alarm System Checklist 1.2.0 Electrical Symbols 1.3.0 Mounting Heights for Electrical Devices 1.4.0 NEMA Configuration Chart for General-Purpose Nonlocking Plugs and Receptacles 1.4.1 NEMA Configuration Chart for Specific-Purpose Locking Plugs and Receptacles 1.5.0 IEEE Standard Protective Device Numbers 1.6.0 Comparison of Specific Applications of NEMA Standard Enclosures for Indoor Nonhazardous Locations 1.6.1 Comparison of Specific Applications of NEMA Standard Enclosures for Outdoor Nonhazardous Locations 1.6.2 Comparison of Specific Applications of NEMA Standard Enclosures for Indoor Hazardous Locations 1.6.3 Knockout Dimensions for NEMA Standard Enclosures 1.7.0 Formulas and Terms 1.8.0 Introduction: Typical Equipment Sizes, Weights, and Ratings 1.8.1 Typical Equipment Sizes: 600-V Class 1.8.2 Transformer Weight (lb) by kVA 1.8.3 Generator Weight (lb) by kW 1.8.4 Weight (lb/lf) of Four-Pole Aluminum and Copper Bus Duct by Ampere Rating 1.8.5 Conduit Weight Comparisons (lb per 100 ft) Empty 1.8.6 Conduit Weight Comparisons (lb per 100 ft) with Maximum Cable Fill 1.9.0 Seismic Requirements

1.1.0

Introduction

This section provides information of a general nature that is needed frequently by electrical design and construction professionals. Information that follows in subsequent sections is more specific in its applications.

1.1

1.2

Section One

1.1.1 Project To-Do Checklist (Electrical) 1.1.1

(continued)

General Information

1.3

1.1.1

(continued)

1.4

Section One

1.1.1

General Information

1.5

1.1.2 Drawing Design Checklist (Electrical) 1.1.2

(continued)

1.6

Section One

1.1.2

(continued)

General Information

1.7

1.1.2

1.8

Section One

1.1.3 Site Design Checklist (Electrical) 1.1.3

(continued)

General Information

1.9

1.1.3

1.10

Section One

1.1.4 Existing Condition Service and Distribution Checklist 1.1.4

(continued)

General Information

1.11

1.1.4

(continued)

1.12

Section One

1.1.4

General Information

1.13

1.1.5 Design Coordination Checklist (Electrical) 1.1.5

(continued)

1.14

Section One

1.1.5

(continued)

General Information

1.15

1.1.5

1.16

Section One

1.1.6 Fire Alarm System Checklist 1.1.6

(continued)

General Information

1.17

1.1.6

(continued)

1.18

Section One

1.1.6

(continued)

General Information

1.19

1.1.6

1.20

Section One

1.2.0 Electrical Symbols

Electrical symbols can vary widely, but the following closely adhere to industry standards. Industry standard symbols often are modified to meet client- and/or project-specific requirements.

1.2.0

(continued)

General Information

1.21

1.2.0

(continued)

1.22 Section One

1.2.0

(continued)

General Information

1.23

1.2.0

(continued)

1.24

Section One

1.2.0

(continued)

General Information

1.25

1.2.0

(continued)

1.26

Section One

1.2.0

(continued)

General Information

1.27

1.2.0

(continued)

1.28

Section One

1.2.0

(continued)

General Information

1.29

1.2.0

(continued)

1.30

Section One

1.2.0

General Information

1.31

1.3.0 Mounting Heights for Electrical Devices

Mounting heights for electrical devices are influenced by and must be closely coordinated with the architectural design. However, there are industry standard practices followed by architects as well as code and legal requirements, such as Americans with Disabilities Act (ADA) guidelines. The following recommended mounting heights for electrical devices provide a good guideline in the absence of any specific information and are ADA compliant.

TABLE 1.3.0

(continued)

1.32

Section One

TABLE 1.3.0

(continued)

General Information

1.33

TABLE 1.3.0

1.34

Section One

1.4.0 NEMA Configuration Chart for General-Purpose Nonlocking Plugs and Receptacles Reproduced from NEMO WD 6-88, Wiring DevicesDimensional Requirements

(revision and redesignation of ANSI C73-73).

1.4.0

( 1999, NFPA)

General Information

1.35

1.4.1 NEMA Configuration Chart for Specific-Purpose Locking Plugs and Receptacles Reproduced from NEMO WD 6-88, Wiring DevicesDimensional Requirements

(revision and redesignation of ANSI C73-73).

1.4.1

( 1999, NFPA)

1.36

Section One

1.5.0 IEEE Standard Protective Device Numbers TABLE 1.5.0

(continued)

General Information

1.37

TABLE 1.5.0

(continued)

1.38

Section One

TABLE 1.5.0

(continued)

General Information

1.39

TABLE 1.5.0

(continued)

1.40

Section One

TABLE 1.5.0

(continued)

General Information

1.41

TABLE 1.5.0

1.42

Section One

1.6.0 Comparison of Specific Applications of NEMA Standard Enclosures for Indoor Nonhazardous Locations TABLE 1.6.0

1.6.1 Comparison of Specific Applications of NEMA Standard Enclosures for Outdoor Nonhazardous Locations TABLE 1.6.1

1.6.2 Comparison of Specific Applications of NEMA Standard Enclosures for Indoor Hazardous Locations TABLE 1.6.2

(If the installation is outdoors and/or additional protection is required by Tables 1.6.0 and 1.6.1, a combination-type enclosure is required. See paragraph 3.2.)

General Information

1.43

1.6.3 Knockout Dimensions for NEMA Standard Enclosures TABLE 1.6.3

1.44

Section One

1.7.0 Formulas and Terms 1.7.0

General Information

1.45

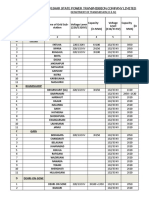

1.8.0 Introduction: Typical Equipment Sizes, Weights, and Ratings

Tables 1.8.1 through 1.8.7 provide typical equipment sizes, weights, and ratings to assist in the preliminary design and layout of an electrical distribution system. The reader is cautioned that these data are only representative of industry manufacturers and should consult specific vendors for detailed information. This information could prove useful in determining initial space requirements and weight impacts for structural purposes.

1.8.1 Typical Equipment Sizes: 600-V Class TABLE 1.8.1

1.46

Section One

1.8.2

Transformer Weight (lb) by kVA

TABLE 1.8.2

1.8.3

Generator Weight (lb) by kW

TABLE 1.8.3

General Information

1.47

1.8.4 Weight (lb/lf) of Four-Pole Aluminum and Copper Bus Duct by Ampere Rating TABLE 1.8.4

1.8.5 Conduit Weight Comparisons (lb per 100 ft) Empty TABLE 1.8.5

1.8.6 Conduit Weight Comparisons (lb per 100 ft) with Maximum Cable Fill TABLE 1.8.6

1.48

Section One

1.9.0 Seismic Requirements

The design of seismic restraint systems for electrical distribution equipment and raceways is usually done by a structural engineer through performance specifications by the electrical design professional. It is therefore necessary for the electrical designer generally to be familiar with the seismic code requirements and the seismic zone that are applicable to a project. The following will serve as an introduction.

1.9.0

Potrebbero piacerti anche

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- Manual Soft Starter 3RW44 enDocumento262 pagineManual Soft Starter 3RW44 ennvijaymohan0% (1)

- MV Air Insulated Switchgear, Model Unisafe: 1VDU29001-YNDocumento36 pagineMV Air Insulated Switchgear, Model Unisafe: 1VDU29001-YNComsip400Nessuna valutazione finora

- ACQ810 Start Verme Kılavuzu Eng PDFDocumento24 pagineACQ810 Start Verme Kılavuzu Eng PDFkvramanan_1Nessuna valutazione finora

- ACQ810-04-55-160kw Hardware PDFDocumento106 pagineACQ810-04-55-160kw Hardware PDFkvramanan_1Nessuna valutazione finora

- SIRIUS IC10 Chap06 English 2014 PDFDocumento120 pagineSIRIUS IC10 Chap06 English 2014 PDFkvramanan_1Nessuna valutazione finora

- Best Pracices TerminationDocumento9 pagineBest Pracices Terminationsuresh kumarNessuna valutazione finora

- Kantaflex Insulating Rubber Mats: An Iso 9001-2000 Certified CompanyDocumento1 paginaKantaflex Insulating Rubber Mats: An Iso 9001-2000 Certified Companykvramanan_1Nessuna valutazione finora

- Ac Drive GeneralDocumento36 pagineAc Drive Generalkvramanan_1Nessuna valutazione finora

- Siemens Sirius 3RW30 3RW40 Manual PDFDocumento212 pagineSiemens Sirius 3RW30 3RW40 Manual PDFElias Nassif GomezNessuna valutazione finora

- Design Criteria ElectricalDocumento38 pagineDesign Criteria Electricalkvramanan_1100% (3)

- Copper Clad Earth ElectrodDocumento7 pagineCopper Clad Earth Electrodkvramanan_1Nessuna valutazione finora

- Generator Load Angle MeasurementDocumento8 pagineGenerator Load Angle MeasurementFahim Faruqui100% (1)

- DatasheetService PDFDocumento5 pagineDatasheetService PDFkvramanan_1Nessuna valutazione finora

- IS 3043 EarthingDocumento94 pagineIS 3043 Earthingpankajakshi4830Nessuna valutazione finora

- Electrical Contrrols-12 Dec09Documento11 pagineElectrical Contrrols-12 Dec09kvramanan_1Nessuna valutazione finora

- Kantaflex Insulating Rubber Mats: An Iso 9001-2000 Certified CompanyDocumento1 paginaKantaflex Insulating Rubber Mats: An Iso 9001-2000 Certified Companykvramanan_1Nessuna valutazione finora

- Substationsfinal2013 PDFDocumento137 pagineSubstationsfinal2013 PDFManoj RanaNessuna valutazione finora

- Earthing 12 Dec09Documento10 pagineEarthing 12 Dec09kvramanan_1Nessuna valutazione finora

- The Power The NetworkDocumento3 pagineThe Power The Networkkvramanan_1Nessuna valutazione finora

- Electromat CatalogueDocumento24 pagineElectromat Cataloguekvramanan_1Nessuna valutazione finora

- Electrical Contrrols-12 Dec09Documento11 pagineElectrical Contrrols-12 Dec09kvramanan_1Nessuna valutazione finora

- Oil Analsysi-12 Dec09Documento2 pagineOil Analsysi-12 Dec09kvramanan_1Nessuna valutazione finora

- Microgrid GensetsDocumento185 pagineMicrogrid Gensetsgurunathan14100% (1)

- Is.15652.2006 - Indian Standard For Insulating Mats For Electrical Applications.Documento19 pagineIs.15652.2006 - Indian Standard For Insulating Mats For Electrical Applications.shanmars007Nessuna valutazione finora

- Electrical Contrrols-12 Dec09Documento11 pagineElectrical Contrrols-12 Dec09kvramanan_1Nessuna valutazione finora

- Paper 6Documento6 paginePaper 6kvramanan_1Nessuna valutazione finora

- Elc Catalog Elc PmeDocumento16 pagineElc Catalog Elc Pmekvramanan_1Nessuna valutazione finora

- Paper 6Documento6 paginePaper 6kvramanan_1Nessuna valutazione finora

- Paper 6Documento6 paginePaper 6kvramanan_1Nessuna valutazione finora

- Micro Hydro Projects Interconnection Equipment Standards and SpecificationDocumento85 pagineMicro Hydro Projects Interconnection Equipment Standards and Specificationkvramanan_1Nessuna valutazione finora

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (344)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (399)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (73)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (120)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- Schneider Electric Didactic Catalog 2013 PDFDocumento164 pagineSchneider Electric Didactic Catalog 2013 PDFJagdish RajanNessuna valutazione finora

- Converters and Rectifiers (NEW)Documento29 pagineConverters and Rectifiers (NEW)I AM NOT CHINESENessuna valutazione finora

- Electronic Motor Protection Relays - G - EMPR-DMPRDocumento44 pagineElectronic Motor Protection Relays - G - EMPR-DMPRTruong HungNessuna valutazione finora

- Synchronous Generator Fundamentals and OperationDocumento28 pagineSynchronous Generator Fundamentals and OperationSarah Frazier100% (2)

- VarPlus Logic - 52449 PDFDocumento2 pagineVarPlus Logic - 52449 PDFJosé Alejandro RangelNessuna valutazione finora

- Troubleshooting For M38 InstrumentsDocumento7 pagineTroubleshooting For M38 Instrumentsm606Nessuna valutazione finora

- Lecture Frequency ControlDocumento35 pagineLecture Frequency ControlEhsan Ur RehmanNessuna valutazione finora

- Wecon VD2 SA Series Servo Drives Manual (Full V1.2) VfinalDocumento226 pagineWecon VD2 SA Series Servo Drives Manual (Full V1.2) VfinalJose Gregorio Lira SerranoNessuna valutazione finora

- 11.2.0.0 EmCEL-U Series DatasheetDocumento1 pagina11.2.0.0 EmCEL-U Series DatasheetGopinath SekarNessuna valutazione finora

- Pulsed Power Controller V2Documento1 paginaPulsed Power Controller V2jolcobardeNessuna valutazione finora

- NVF2 PDFDocumento11 pagineNVF2 PDFErnest ShachipukaNessuna valutazione finora

- Sensor Si30-A10. GemeloDocumento1 paginaSensor Si30-A10. GemeloRicardo Mariscal ChuscanoNessuna valutazione finora

- Pure VCO BoM 20180122Documento1 paginaPure VCO BoM 20180122Dan PisciottaNessuna valutazione finora

- Component Type SS21-UL Type: Speed Control MotorsDocumento7 pagineComponent Type SS21-UL Type: Speed Control Motorshenry barbozaNessuna valutazione finora

- Measurement of High DC & Ac VoltagesDocumento20 pagineMeasurement of High DC & Ac Voltagesrare machineNessuna valutazione finora

- GEAFOL Cast-Resin Transformers 100 To 16000kVADocumento14 pagineGEAFOL Cast-Resin Transformers 100 To 16000kVALaurentiu CatalinNessuna valutazione finora

- Inovance SveDocumento202 pagineInovance SveDragan LugonićNessuna valutazione finora

- MBV - Lube Oil Wiring - Junction BoxDocumento72 pagineMBV - Lube Oil Wiring - Junction BoxDiego NunesNessuna valutazione finora

- VAMP Protection RelaysDocumento3 pagineVAMP Protection RelaysManuel Jonas Fonseca BarbalhoNessuna valutazione finora

- Tapashwi Power ControlsDocumento7 pagineTapashwi Power Controlsnani yeshuNessuna valutazione finora

- Topic 2 - Battery Cell Balancing - What To Balance and How PDFDocumento8 pagineTopic 2 - Battery Cell Balancing - What To Balance and How PDFlitieuduyNessuna valutazione finora

- Development of Smart Multi-Level Inverter With Remote Monitoring SystemDocumento5 pagineDevelopment of Smart Multi-Level Inverter With Remote Monitoring SystemRavindra ParabNessuna valutazione finora

- PSS Connectivity Load FlowDocumento32 paginePSS Connectivity Load FlowChief Engineer TransOMNessuna valutazione finora

- Electrical Safety and NFPA 70E-2015 Study SheetDocumento2 pagineElectrical Safety and NFPA 70E-2015 Study SheetRick GouldNessuna valutazione finora

- Olis Et Al. - 2013 - Feasibility Study of Economics and Performance of Solar Photovoltaics at The Snohomish County Cathcart Landfill Sit-AnnotatedDocumento69 pagineOlis Et Al. - 2013 - Feasibility Study of Economics and Performance of Solar Photovoltaics at The Snohomish County Cathcart Landfill Sit-AnnotatedLucas NascimentoNessuna valutazione finora

- 3860 Manual ProjectorDocumento17 pagine3860 Manual ProjectorBeatriz SanchezNessuna valutazione finora

- DER Integration Research Program Power Electronics Research Assessment December 2004Documento69 pagineDER Integration Research Program Power Electronics Research Assessment December 2004Engr. AbdullahNessuna valutazione finora

- Example of Minutes of MeetingDocumento7 pagineExample of Minutes of MeetingLuqman BostNessuna valutazione finora

- "Solar Power Bank With Wireless Charging": A Project Report ONDocumento15 pagine"Solar Power Bank With Wireless Charging": A Project Report ONLokeshNessuna valutazione finora

- Reflected WaveDocumento2 pagineReflected WaveMat MaxNessuna valutazione finora