Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

High-performance Cylinder Liners Materials for Diesel Engines

Caricato da

Vaisakh PillaiDescrizione originale:

Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

High-performance Cylinder Liners Materials for Diesel Engines

Caricato da

Vaisakh PillaiCopyright:

Formati disponibili

You will find the figures mentioned in this article in the German issue of MTZ 02/2006 beginning on page

124.

Hochfeste Zylinderlaufbuchsen fr Dieselmotoren

High-performance Cylinder Liners for Diesel Engines

Permanently increasing pressure and temperature conditions in the combustion chamber of turbocharged low engine-out emission diesel motors (EU5, US 07 and US 10) are taking todays standard cast iron cylinder liner materials to their limits in terms of strength and wear resistance primarily in commercial vehicles. Stringent emissions legislation and engine-internal optimization measures that have considerable impact on the design of cylinder liners are the key drivers. To support the continuing engine optimization, Federal-Mogul has developed two new high-performance cylinder liners materials, which are presented here for the first time.

1 Introduction

Emissions legislation that is getting ever more stringent on a global scale is increasingly driving the development of engine components for commercial vehicles. Emission standards such as EU 5 and US 07/US 10 pose new challenges to the development of commercial vehicle diesel engines related to exaust gas recirculation (EGR). Higher EGR rates und the particulate filter, which reduce the engine power output, are sometimes compensated by adding displacement. To limit the complexity of developing a new engine, one option is to reduce the liner wall thickness. That, however, can only be

Authors:

Steffen Hoppe and Eric Fritsche

done, if the liner material has a substantially higher strength. Added challenges result from development work that seeks to lower fuel and oil consumption that optimizes the diesel combustion process by increasing the cylinder peak pressure to up to 220 bar and varyies the injection timing (phasing). It takes materials with a high level of ultimate tensile strength and a high Youngs modulus (modulus of elasticity) to minimize cylinder distortion and thus lower oil consumption. Todays standard materials offer no sufficient levels of strength reserve. The new cast iron materials GOE323 and GOE330 are developments which Federal-Mogul utilizes for high and maximum stress conditions.

MTZ 02/2006 Volume 67 23

MATERIALS

Cylinder Liners

2 High-performance Cylinder Liners for Commercial Vehicle Applications

New developments in the commercial vehicle area for instance ask for tensile strengths of 340 to 400 MPa and a Youngs modulus of 130 to 150 GPa. The material developments for cylinder liners as portrayed here are cast iron materials that have been strength optimized in different ways: GOE323 (GJL) is a micro alloy cast iron with flake graphite. GOE330 (GJV) is a compacted graphite cast iron and belongs to the group of ductile cast irons.

2.1 Mico Alloy Cast Iron with Lamellar Graphite

In a cast iron material with flake graphite the carbon surplus has the shape of thin, irregularly shaped graphite laminas. As a rule cast iron of this type has a comparatively low tensile strength, however, this is combined with a good level of thermal conductivity and good damping properties plus a low corrosion susceptibility - all of which are welcome characteristics for engine applications. The material GOE323 (GJL) shows a fine pearlitic microstructure (mixture of the phases ferrite and cementite/carbide of iron) with fine graphite flakes of the E and A type according to ASTM (American Society for Testing and Materials standard) with a length of between 4 and 6 only in the matrix as well as a maximum of 5 per cent ferrite plus additional special carbides of iron, Figure 1. Sophisticated alloy technology ensures a graphite morphology mainly of the ASTM type E, wich means an increasement of strength as compared to common grey cast iron alloys. An enhancement of fatigue life is also related to the graphite type specified above, due to its damping effect on the susceptibility to notching. Adding perlite stabilisators plus Cr, Mo and Ni increases the mechanical properties significantly. At a minimum of 330 MPa tensile strength and a Youngs modulus of at least 115 GOE323 has the characteristics of a high strength cast iron material.

GPa the GOE330 material is a maximum strength material. As is well known the manufacturing of GJV is only possible by tightly controlling certain casting process parameters [1]. Federal Mogul has succeeded in finding a process that is reliable both in the metallurgical field and as far as the production method is concerned. This process does not include adding any helping substances such as Titanium (Ti) to support the vermicular development as this would cause a significantly poorer machinability due to carbide of titan precipitation in the microstructure [2]. By exactly controlling the Mg alloy and its output (efficiency) the nodular structure of GOE300 can be defined within in tight limits. Adding alloy components ensures a finely developed pearlitic base microstructure with a low ferritic content of maximum 5 per cent, which has the above mentioned influence on the graphite modification but also has a strong, positive influence on fatigue strength and incipient cracking. The centrifugal casting that is used as the sole method to manufacture GOE330 ensures a uniformly dense structure throughout the complete cylinder liner as a result to the centrifugal forces.

strength levels of 380 MPa and a Youngs modulus of 140 GPa minimum. Based on cast iron with lamellar graphite the development efforts will target a further increase of strength and Youngs modulus beyond the already high level of GOE323 (GJL). As discussed above the excellent properties of GOE330 already fulfil the requests from the material property point of view. Rather the development work will seek for an improved machinability which is important from the cost angle. An optimized casting process seems to be a promising stragey in combination with appropriate new machining technology. Even higher EGR rate levels, which cause more particulate drag-in, make wear resistance a growing issue. In a situation that is also characterized by longer service intervals the cylinder liner topography has an important influence [3].

5 Conclusion

The high performance and maximum performance cylinder liner materials GOE323 and GOE330 provide engine designers with suitable material options for new approaches to optimizing engine-out emissions as this means adding stress on the cylinder system by increasing pressure, temperature and particulate drag-in (EGR). The materials are designed for the rapidly growing demands on tensile strength and wear resistance that are to be expected. The improved material strength also supports the strategy to compensate the loss of power caused by high EGR rates by adding displacement and reducing liner wall thickness to minimize the effects on the engine dimensions. Further development will increasingly focus on improved cavitation characteristics and the minimization of liner distortion.

3 Cylinder Liner Properties

The new materials have been subjected to several tests to determine the material and product properties. For a liner material the dynamic properties are the most important results besides the static/mechanic properties and the wear properties. GOE330 achieves top results in this respect, Table 1. The measured fatigue strength (rotating beam fatigue test) of 278 MPa is 125 per cent higher than that of conventional grey cast. The GOE323 material achieves a value of 190 MPa which is notably high for a grey cast that has not been heat treated. This result translates into a fatigue strength gain of 70 MPa or around 60 per cent on conventional grey cast. The engine operation wear characteristics of the liner materials portrayed here meet the life endurance standards for commercial vehicles with or withour EGR. A combination with surface hardening of the cylinder running surface has been successfully engine tested in particular with combustion parameters typically valid in North America, Figure 3.

References

[1] Lampic-Oplnder, M.: Gueisen mit Vermiculargrafit GJV Teil 1: Metallurgische Grundlagen. In: Gieerei-Praxis 1/2001, Fachverlag Schiele & Schn, Berlin [2] Lampic-Oplnder, M.: Gueisen mit Vermiculargrafit GJV Teil 4.1: Zerspanen - Einflugren. In: Gieerei-Praxis 8/2001, Fachverlag Schiele & Schn, Berlin [3] Robota, A., Zwein, F.: Einfluss der Zylinderlaufflchentopografie auf den lverbrauch und die Partikelemission eines DI-Dieselmotors. In: MTZ 60 (1999), Vieweg Verlag, Wiesbaden

2.2 Grey Cast with Compacted Graphite

The GOE330 (GJV) material is a cast iron with compacted or vermicular graphite that is distibuted in the microstructure in the shape of vermicula (= shaped like tiny worms), Figure 2. Similar to the process of making spheroidal graphite cast iron the graphite modification is caused by adding a magnesium alloy. At a tensile strength of at least 500 MPa and a Youngs modulus of 140

24 MTZ 02/2006 Volume 67

4 Outlook

Both materials are in the phases of series production or production ramp-up for commercial vehicle manufacturers. Continually higher engine requirements will demand

Potrebbero piacerti anche

- Compacted Graphite Iron For Diesel PDFDocumento11 pagineCompacted Graphite Iron For Diesel PDFGeorgi PanayotovNessuna valutazione finora

- CGI Material Promising for Diesel Engine Cylinder BlocksDocumento10 pagineCGI Material Promising for Diesel Engine Cylinder BlocksAtilla AkkenarNessuna valutazione finora

- Semi-solid moulding improves automotive component durabilityDocumento6 pagineSemi-solid moulding improves automotive component durabilitybilal sarfrazNessuna valutazione finora

- Selectively Reinforced Squeeze Cast PistonsDocumento6 pagineSelectively Reinforced Squeeze Cast PistonsAswath RamNessuna valutazione finora

- PowderMet2015-San Diego FinalDocumento12 paginePowderMet2015-San Diego FinalMilan JoshiNessuna valutazione finora

- Achieving Agma 10 Quality LevelDocumento7 pagineAchieving Agma 10 Quality LevelSuresh GopalanNessuna valutazione finora

- The Paton Welding JournalDocumento9 pagineThe Paton Welding JournalpewinataliyaNessuna valutazione finora

- 002 02Documento18 pagine002 02Sandip GaikwadNessuna valutazione finora

- 167Documento6 pagine167apajicesNessuna valutazione finora

- Body of ThesisDocumento51 pagineBody of Thesiskamel touilebNessuna valutazione finora

- Building Reliability Through Improved Lubrication Program in Metal Industry - PaperDocumento5 pagineBuilding Reliability Through Improved Lubrication Program in Metal Industry - PaperFrancis XavierNessuna valutazione finora

- Material Selection For Brake DiscDocumento10 pagineMaterial Selection For Brake Discmost_lost89% (38)

- Magnesium Production Cost Assessment for Automotive ApplicationsDocumento5 pagineMagnesium Production Cost Assessment for Automotive ApplicationsThiago DomingosNessuna valutazione finora

- Plasma Spray Coating On PistonDocumento45 paginePlasma Spray Coating On Pistonrajkiran_rajNessuna valutazione finora

- Production Experience With Compacted Graphite Iron Automotive ComponentsDocumento11 pagineProduction Experience With Compacted Graphite Iron Automotive ComponentssmitashivaleNessuna valutazione finora

- Ultra High-Strength Steel SheetsDocumento6 pagineUltra High-Strength Steel SheetsMihai EnăşelNessuna valutazione finora

- FEA Analysis and Experimental Investigation of The Ceramic Coating On Aluminum PistonDocumento14 pagineFEA Analysis and Experimental Investigation of The Ceramic Coating On Aluminum PistonIJRASETPublicationsNessuna valutazione finora

- Fea Analysis and Experimental Investigation of Ceramic Coating On Aluminium Piston Material by Plasma Spray CoatingDocumento11 pagineFea Analysis and Experimental Investigation of Ceramic Coating On Aluminium Piston Material by Plasma Spray Coatingvikky coolNessuna valutazione finora

- Influence of Hardening On The Microstructure and The Wear Capacity of Gears Made of Fe1.5Cr0.2Mo Sintered SteelDocumento9 pagineInfluence of Hardening On The Microstructure and The Wear Capacity of Gears Made of Fe1.5Cr0.2Mo Sintered SteelElior ArielNessuna valutazione finora

- Experimental Investigations On The Performance and Emissoin CharacteristicsDocumento6 pagineExperimental Investigations On The Performance and Emissoin CharacteristicsIAEME PublicationNessuna valutazione finora

- GBT 1591 2018 enDocumento33 pagineGBT 1591 2018 ennelsonNessuna valutazione finora

- Experimental Investigation of Coasting On Piston by Thermal Torch MethodDocumento31 pagineExperimental Investigation of Coasting On Piston by Thermal Torch MethodĐįñêśh ĎkNessuna valutazione finora

- A Literature Review On The Performance Analysis of 4 Stroke Diesel Engines With Ceramic Coating Material-36993 PDFDocumento7 pagineA Literature Review On The Performance Analysis of 4 Stroke Diesel Engines With Ceramic Coating Material-36993 PDFShiva ShankarNessuna valutazione finora

- Gas Turbine TribologyDocumento12 pagineGas Turbine TribologyChukkur Hali100% (2)

- 1 s2.0 S2214785317300123 MainDocumento7 pagine1 s2.0 S2214785317300123 Mainjayakrishnan.plamthundilsuNessuna valutazione finora

- Materials For Gas Turbines An Overview: November 2011Documento23 pagineMaterials For Gas Turbines An Overview: November 2011MahsaNessuna valutazione finora

- Improved Aluminium Alloy Properties from Boron Grain RefinementDocumento4 pagineImproved Aluminium Alloy Properties from Boron Grain RefinementAsdrubal Antonio Gonzalez DiazNessuna valutazione finora

- Materials and Manufacturing of Advanced Industrial Gas Turbine ComponentsDocumento5 pagineMaterials and Manufacturing of Advanced Industrial Gas Turbine ComponentsMikecz JuliannaNessuna valutazione finora

- Pap 1263Documento10 paginePap 1263dselva_kumaranNessuna valutazione finora

- Recent Technology of Powder Metallurgy and ApplicationsDocumento32 pagineRecent Technology of Powder Metallurgy and ApplicationsMuralli Jayaganesan100% (2)

- Improving Cylinder Liner StrengthDocumento4 pagineImproving Cylinder Liner StrengthgjganipineniNessuna valutazione finora

- Characteristics of Carbon Fiber Phenolic CompositeDocumento8 pagineCharacteristics of Carbon Fiber Phenolic CompositeEduardo Fernandez SanchezNessuna valutazione finora

- "Development of Single Cylinder Four Stroke Low Heat Rejection Engine Using Piston Coating"-A ReviewDocumento5 pagine"Development of Single Cylinder Four Stroke Low Heat Rejection Engine Using Piston Coating"-A ReviewnityamNessuna valutazione finora

- Development of Reciprocating Parts and Crankshaft in Honda's Third Formula One EraDocumento10 pagineDevelopment of Reciprocating Parts and Crankshaft in Honda's Third Formula One EraBlaze123xNessuna valutazione finora

- 2015 Advance Materials For GTDocumento10 pagine2015 Advance Materials For GTThomas Cuerq100% (1)

- New Project 2Documento5 pagineNew Project 2Aashik AhamedNessuna valutazione finora

- Automotive Engine Block PDFDocumento14 pagineAutomotive Engine Block PDFNico ViciNessuna valutazione finora

- Practical Issues in The Manufacture of High Efficiency Electric MotorsDocumento9 paginePractical Issues in The Manufacture of High Efficiency Electric Motorspmgaa100% (1)

- Magnesium Alloys For Structural Applications Recent AdvancesDocumento11 pagineMagnesium Alloys For Structural Applications Recent AdvancesJayakumar AngappanNessuna valutazione finora

- Materials For Gas Turbines - An OverviewDocumento23 pagineMaterials For Gas Turbines - An OverviewBerkath Ali KhanNessuna valutazione finora

- 19 OpDocumento7 pagine19 OpSrikanth SridharanNessuna valutazione finora

- Finite Element Indentation Analysis of AutomotiveDocumento7 pagineFinite Element Indentation Analysis of AutomotiveytabakovNessuna valutazione finora

- Hub & Drum - Design and Process Review and Validation: Rodrigo Cunha Silvia Faria Iombriller Thiago Vaz Da CostaDocumento8 pagineHub & Drum - Design and Process Review and Validation: Rodrigo Cunha Silvia Faria Iombriller Thiago Vaz Da CostaMarcelo Losekann100% (1)

- Magnesium-Alloy Engine Cylinder BlockDocumento8 pagineMagnesium-Alloy Engine Cylinder BlockIsmet ZülfikarNessuna valutazione finora

- 2004 Jcomb PF AmDocumento8 pagine2004 Jcomb PF AmMohammedSirajUddinNessuna valutazione finora

- Application of Ceramic Coating For Combustion Chamber Equipments of IC Engine: A ReviewDocumento5 pagineApplication of Ceramic Coating For Combustion Chamber Equipments of IC Engine: A ReviewRobert MihaiNessuna valutazione finora

- Ferrite Content Effect On Autenitic Ss Weld at Cryogenic TempDocumento12 pagineFerrite Content Effect On Autenitic Ss Weld at Cryogenic TemparunkumarNessuna valutazione finora

- A Literature Review On The Performance Analysis of 4 Stroke Diesel Engines With Ceramic Coating Material-36993Documento7 pagineA Literature Review On The Performance Analysis of 4 Stroke Diesel Engines With Ceramic Coating Material-36993ARUN VNessuna valutazione finora

- Materials For Gas Turbines An OverviewDocumento23 pagineMaterials For Gas Turbines An OverviewNgân LêNessuna valutazione finora

- Thermal Barrier Coatings On Ic Engines 13012013123658 Thermal Barrier Coatings On Ic EnginesDocumento32 pagineThermal Barrier Coatings On Ic Engines 13012013123658 Thermal Barrier Coatings On Ic EnginesNagaraj KundapuraNessuna valutazione finora

- Tribo-Evaluation of Aluminium Based Metal Matrix Composites Used For Automobile Brake Pad ApplicationsDocumento6 pagineTribo-Evaluation of Aluminium Based Metal Matrix Composites Used For Automobile Brake Pad ApplicationsSEP-PublisherNessuna valutazione finora

- Cold-Rolled and Galvannealed (GA) High Strength Steel Sheets For Automotive Cabin StructureDocumento9 pagineCold-Rolled and Galvannealed (GA) High Strength Steel Sheets For Automotive Cabin StructureAlexandre Lima LopesNessuna valutazione finora

- Optimizing The Heat Treatment Process of Cast Aluminium AlloysDocumento25 pagineOptimizing The Heat Treatment Process of Cast Aluminium AlloysAndrei SorinNessuna valutazione finora

- Proceedings of the 8th International Symposium on Superalloy 718 and DerivativesDa EverandProceedings of the 8th International Symposium on Superalloy 718 and DerivativesNessuna valutazione finora

- Weld Like a Pro: Beginning to Advanced TechniquesDa EverandWeld Like a Pro: Beginning to Advanced TechniquesValutazione: 4.5 su 5 stelle4.5/5 (6)

- Thermo-hydrodynamic Lubrication in Hydrodynamic BearingsDa EverandThermo-hydrodynamic Lubrication in Hydrodynamic BearingsNessuna valutazione finora

- ReadmeDocumento1 paginaReadmeVaisakh PillaiNessuna valutazione finora

- Operation Management Information SystemDocumento568 pagineOperation Management Information Systemsahai_mayur05Nessuna valutazione finora

- Russian Delegation Total Quality Management (TQM) : Commercial Vegetable and Fruit Production An Integrated ApproachDocumento13 pagineRussian Delegation Total Quality Management (TQM) : Commercial Vegetable and Fruit Production An Integrated ApproachmrdheerajjainNessuna valutazione finora

- KolamthullalDocumento5 pagineKolamthullalVaisakh PillaiNessuna valutazione finora

- (Geoffrey Lawrence, Kristen Lyons, Tabatha Walling (BookFi) PDFDocumento321 pagine(Geoffrey Lawrence, Kristen Lyons, Tabatha Walling (BookFi) PDFIManNessuna valutazione finora

- Dpu96 Sitras PDFDocumento214 pagineDpu96 Sitras PDFConrad Ziebold VanakenNessuna valutazione finora

- Orient Price List NewDocumento3 pagineOrient Price List Newrohan12345670% (1)

- Fundamix Brochure EN WebDocumento9 pagineFundamix Brochure EN Webjgjb4csrj7Nessuna valutazione finora

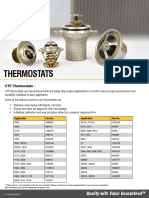

- TERMOSTATOSDocumento1 paginaTERMOSTATOSSERGIOEDWARDONessuna valutazione finora

- Test Bank For Achieve For Interactive General Chemistry, 1e by Macmillan Learning Test BankDocumento9 pagineTest Bank For Achieve For Interactive General Chemistry, 1e by Macmillan Learning Test BankNail BaskoNessuna valutazione finora

- Aufbau PrincipleDocumento4 pagineAufbau PrinciplecrbrumaNessuna valutazione finora

- Makerere University Civil Engineering Assignment on Nalubaale DamDocumento8 pagineMakerere University Civil Engineering Assignment on Nalubaale DamRobert WalusimbiNessuna valutazione finora

- Krff302ess01 Tech Sheet - w10787422 - Rev CDocumento10 pagineKrff302ess01 Tech Sheet - w10787422 - Rev CJesikaGomezSaavedraNessuna valutazione finora

- SGMF Hose BunkeringDocumento15 pagineSGMF Hose BunkeringFilipNessuna valutazione finora

- XR77CX: Installing and Operating InstructionsDocumento5 pagineXR77CX: Installing and Operating InstructionsVũ Hằng PhươngNessuna valutazione finora

- 10 MW Unit 214.00 709 55.83 1972Documento1 pagina10 MW Unit 214.00 709 55.83 1972Gangadhara P.K.Nessuna valutazione finora

- Quantum Engine Series: Ower AtingsDocumento2 pagineQuantum Engine Series: Ower AtingsAlbertoNessuna valutazione finora

- SAES-R-004 Sanitary SewersDocumento27 pagineSAES-R-004 Sanitary SewersWaqar AhmedNessuna valutazione finora

- Screw Compressor Units: For Sodium Carbonate Production (Soda Ash)Documento2 pagineScrew Compressor Units: For Sodium Carbonate Production (Soda Ash)Jaswindersingh BhatiaNessuna valutazione finora

- Comprehensive Elevator ManualDocumento23 pagineComprehensive Elevator ManualIlham fitriansyahNessuna valutazione finora

- O359h MilDocumento90 pagineO359h MilNisar AhmedNessuna valutazione finora

- GRUNDFOS DATA BOOKLET FOR HYDRO MULTI-S BOOSTER SYSTEMSDocumento32 pagineGRUNDFOS DATA BOOKLET FOR HYDRO MULTI-S BOOSTER SYSTEMSHeri SulasionoNessuna valutazione finora

- Acoustic Variables - Kasia's E-PortfolioDocumento2 pagineAcoustic Variables - Kasia's E-Portfoliomuhammad ShoaibNessuna valutazione finora

- Objective and Scope and Importance of Mineral Beneficiation With Special Reference To IndiaDocumento4 pagineObjective and Scope and Importance of Mineral Beneficiation With Special Reference To IndiaVidya Sagar100% (1)

- rt8205b Datasheet-06Documento28 paginert8205b Datasheet-06André Hipnotista100% (1)

- New Tutorial 2 Solution On ThermodynamicsDocumento7 pagineNew Tutorial 2 Solution On ThermodynamicsNaveed AhmadNessuna valutazione finora

- QT-002!02!50 HZ Lister Peter - Aksa - Mitsubishi - John Deere - Perkins Engine-Alternator Couple Table 2015.02.16Documento1 paginaQT-002!02!50 HZ Lister Peter - Aksa - Mitsubishi - John Deere - Perkins Engine-Alternator Couple Table 2015.02.16Cris_eu09Nessuna valutazione finora

- Mayo College: Dining Hall at AjmerDocumento79 pagineMayo College: Dining Hall at AjmerFaquruddinNessuna valutazione finora

- Ufc 3 430 09Documento106 pagineUfc 3 430 09carlcrowNessuna valutazione finora

- Wind Turbine Installation-ManualDocumento23 pagineWind Turbine Installation-Manualויליאם סן מרמיגיוסNessuna valutazione finora

- Principle Design Solenoid ValvesDocumento28 paginePrinciple Design Solenoid Valveshassan alrokabNessuna valutazione finora

- EnergySRP Forms MatchingDocumento2 pagineEnergySRP Forms Matchingeiad-mahmoudNessuna valutazione finora

- Fluid MechDocumento10 pagineFluid MechPrasant KumarNessuna valutazione finora

- Masterpact NT and NW: Maintenance GuideDocumento32 pagineMasterpact NT and NW: Maintenance GuideRoshin99Nessuna valutazione finora