Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Rollers and Slip Gauges

Caricato da

Anand BabuCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Rollers and Slip Gauges

Caricato da

Anand BabuCopyright:

Formati disponibili

QIS COLLEGE OF ENGG. & TECH.ONGOLE,A.P.

METROLOGY LAB

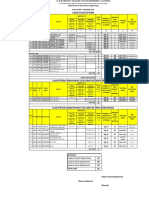

MEASUREMENT OF TAPER ANGLE USING ROLLERS SLIP GAUGES AND SINE BAR

10

MEASUREMENT OF TAPER ANGLE USING ROLLERS & SLIP GAUGES AND SINE BAR

QIS COLLEGE OF ENGG. & TECH.ONGOLE,A.P.

METROLOGY LAB

MEASUREMENT OF TAPER ANGLE USING ROLLERS & SLIP GAUGES AND SINE BAR

AIM:

To determine the taper angle of the given specimen using slips & rollers and Sine Bar and check the angle using Bevel Protractor.

APPARATUS: Two rollers of equal diameter, Micrometer, Sine Bar, slip gauge

set.

THEORY:

Taper is defined as uniform reduction in dimension (may be width, height or diameter) over specified length. For example for the shank of a twist drill bit, if the taper is specified as 1:10, it means that for every 10 mm length there will be a reduction of diameter by 1 mm (from major to minor dia). Taper is employed on elements like cotter, keys and shanks of twist drill bits, end mills, reamers adapters etc. Presence of taper enables self locking of the element in the corresponding mating part. Slip Gauges: Slip gauges for rectangular blocks of alloy steel having a cross section of about 30 by 10 mm. These blocks are carefully finished on the This is measuring faces to such a fine degree of finish. Flatness and accuracy that any two such faces when perfectly clean may be wiring together. twisting motion whilst maintaining contact pressure. accomplished by pressing the faces into contact and then imparting a small When two gauges are wrung or more blocks so joined is exactly the sum of the constituent gauges. By combining gauges from a suitably arranged combination, almost any dimension may be built up.

11

MEASUREMENT OF TAPER ANGLE USING ROLLERS & SLIP GAUGES AND SINE BAR

QIS COLLEGE OF ENGG. & TECH.ONGOLE,A.P.

METROLOGY LAB

Experimental Set Up:

Fig.1

Fig.2

Fig 3.

12

MEASUREMENT OF TAPER ANGLE USING ROLLERS & SLIP GAUGES AND SINE BAR

QIS COLLEGE OF ENGG. & TECH.ONGOLE,A.P.

METROLOGY LAB

PROCEDURE:

1. Place the Taper specimen on the surface plate as shown in the figure. 2. Pile up slip gauge combinations of equal heights H1 and place them on opposite sides of taper specimen. 3. Place two rollers of equal diameter on slip gauge combinations. 4. Take measurement over the rollers with the help of micrometer (say M1) 5. Take slip gauge combinations of another height H2 and repeat steps 3 and 4 let the measurement over the rollers be M2 6. If is the included angle of taper specimen. Taper angle may be obtained as follows: Tan /2 =

M 2 M1 2( H 2 H 1 )

7. To check the uniformity of taper H2 may be varied by two to three values and may be calculated. 8. Verify the obtained taper angle using Bevel Protractor. SINE BAR Sine Bar is a precision instrument used along with slip gauges for the measurement of angles sine bar is used: (i) (ii) to measure the angles very accurately to locate the work to a given angle within very close limits It consists of a steel bar and two rollers. The sine bar is made of high carbon, high chromium corrosion resistant steel, suitably hardened, precision ground and stabilized. The rollers are of accurate and equal diameters. They are attached to the bar at each end. The axes of these rollers are parallel to each other and also to the upper surface of the bar. The normal distance between the axes of the rollers is exactly 100 mm, 200 mm or 300 mm. When the rollers are brought in contact with a flat surface, the top of the bar is parallel to the surface. The various parts are hardened and stabilized before grinding and lapping. All the working surfaces of the bar and the cylindrical surfaces are fined to surface finish of 0.2 m. A grade sine bar is made with an accuracy of 0.01 mm/m of length, and B grade sine bars with an accuracy of 0.02 mm/m of length. 13 MEASUREMENT OF TAPER ANGLE USING ROLLERS & SLIP GAUGES AND SINE BAR

QIS COLLEGE OF ENGG. & TECH.ONGOLE,A.P.

METROLOGY LAB

Sine Bar

Slip Gauges

Work Piece

Surface Plate

Principle of Sine bar: The principle of operation of a sine bar is based on the laws of trigonometry. To set a given angle, one roller of the bar is placed on the surface plate and the combination of slip gauges is inserted uner the second 14

MEASUREMENT OF TAPER ANGLE USING ROLLERS & SLIP GAUGES AND SINE BAR

QIS COLLEGE OF ENGG. & TECH.ONGOLE,A.P.

METROLOGY LAB

roller. If h is the height of the combination of slip gauges and L the distance between the rollers centers. Then Sin =

h h or = Sin 1 L L

Thus the angle to be measured or to be set is determined by indirect method as a function of sine, for this reason, the device is called a sine bar.

Checking of Measured Angle: The measured angle is verified using Bevel Protractor.

PRECAUTIONS:

1. Slip blocks must be cleaned properly and wrung together. 2. Micrometer readings must be observed without parallax error.

RESULT:

Taper angle of the given specimen. By Rollers slips By Sine Bar = =

By Bevel protractor =

15

MEASUREMENT OF TAPER ANGLE USING ROLLERS & SLIP GAUGES AND SINE BAR

Potrebbero piacerti anche

- Thermal engineering A Clear and Concise ReferenceDa EverandThermal engineering A Clear and Concise ReferenceNessuna valutazione finora

- MQC Taper MeasurementDocumento19 pagineMQC Taper MeasurementNayem100% (1)

- Radius Measurement NewDocumento26 pagineRadius Measurement NewNayemNessuna valutazione finora

- Elementary Transmission For Transforming Rotary Into Translatory MotionDocumento14 pagineElementary Transmission For Transforming Rotary Into Translatory Motionshreyas jadhavNessuna valutazione finora

- Complex Engineering ProblemDocumento21 pagineComplex Engineering ProblemMuhammed Afnan100% (1)

- Metrology Solved ExamplesDocumento17 pagineMetrology Solved Examplesjoin2ravikantNessuna valutazione finora

- Manufacturing Process 1 Question BankDocumento8 pagineManufacturing Process 1 Question Bankashok PradhanNessuna valutazione finora

- Shaping MachineDocumento14 pagineShaping MachineMohammad Javed IqbalNessuna valutazione finora

- 7 Nptel CastingDocumento26 pagine7 Nptel CastingmayilsvhecNessuna valutazione finora

- Ce 8381som Lab ManualDocumento31 pagineCe 8381som Lab ManualAERO JPR50% (2)

- Experiment No 3Documento3 pagineExperiment No 3pomar026100% (1)

- Computer Aided Machine Drawing Lab KTU Lab QPDocumento3 pagineComputer Aided Machine Drawing Lab KTU Lab QPDrKim J SeelanNessuna valutazione finora

- Study and Operation of An Engine Lathe.: Course No: Ipe-108 Course Title: Workshop PracticeDocumento9 pagineStudy and Operation of An Engine Lathe.: Course No: Ipe-108 Course Title: Workshop PracticeSazzadNessuna valutazione finora

- Closed Coiled Helical Springs Subjected To Axial LoadsDocumento6 pagineClosed Coiled Helical Springs Subjected To Axial LoadsSnehasish Ishar100% (1)

- V2 ECU For AMT TurbinesDocumento26 pagineV2 ECU For AMT TurbinesAmin Anjom100% (1)

- Unit-4-Computer Aided DesignDocumento15 pagineUnit-4-Computer Aided DesignMuthuvel M100% (2)

- Metrology Viva QuestionsDocumento2 pagineMetrology Viva QuestionssrajubasavaNessuna valutazione finora

- Lab Manual Engineering MechanicsDocumento34 pagineLab Manual Engineering MechanicsBrajesh Kumar Sahu100% (2)

- Lecture 1Documento41 pagineLecture 1norhaslina_aa33% (3)

- Mechanical Engineering Turbomachinery Assignment QuestionsDocumento2 pagineMechanical Engineering Turbomachinery Assignment QuestionsAbebe AyingdaNessuna valutazione finora

- 21 THEORY OF METAL MACHINING SolutionsDocumento7 pagine21 THEORY OF METAL MACHINING SolutionsTiyaniNessuna valutazione finora

- Planer Quick Return MechanismDocumento21 paginePlaner Quick Return MechanismchristadcrNessuna valutazione finora

- 03a Direct Stiffness Method Spring and BarDocumento23 pagine03a Direct Stiffness Method Spring and BarAnamolNessuna valutazione finora

- Basic Mechanical Lab Manual PDFDocumento60 pagineBasic Mechanical Lab Manual PDFNATIONAL XEROX0% (1)

- Pressure Vessels - DmeDocumento47 paginePressure Vessels - DmeSumitNessuna valutazione finora

- UNIT-IV Question BankDocumento3 pagineUNIT-IV Question BankParamasivam VeerappanNessuna valutazione finora

- Relationship between angle of twist, torque, length and diameterDocumento6 pagineRelationship between angle of twist, torque, length and diameterAhsan MumtazNessuna valutazione finora

- LVDT Lab ManualDocumento3 pagineLVDT Lab Manualguruabhay100% (2)

- Me8501-Metrology and Measurements Course PlanDocumento3 pagineMe8501-Metrology and Measurements Course PlanNeopolean0% (1)

- Cotter Joint Design GuideDocumento15 pagineCotter Joint Design GuidenkchandruNessuna valutazione finora

- Automats and Tool LayoutsDocumento20 pagineAutomats and Tool LayoutsAyesha IshuNessuna valutazione finora

- Machine Drawing Two Mark QuestionsDocumento13 pagineMachine Drawing Two Mark QuestionsHimanshuSisodiyaNessuna valutazione finora

- Engineering Metrology 2 MarksDocumento13 pagineEngineering Metrology 2 MarksRavi SivaprakashNessuna valutazione finora

- Vibration Lab 2 Belt Friction Lab ReportDocumento15 pagineVibration Lab 2 Belt Friction Lab ReportYann YeuNessuna valutazione finora

- Turner Question and Answer Bank 2014 PDFDocumento88 pagineTurner Question and Answer Bank 2014 PDFBhanupratap MallickNessuna valutazione finora

- Governor ProblemsDocumento3 pagineGovernor ProblemsPappuRamaSubramaniamNessuna valutazione finora

- Machine Drawing Questions on Sections, Welding, Fasteners and Engine PartsDocumento3 pagineMachine Drawing Questions on Sections, Welding, Fasteners and Engine PartsfatehjitsinghNessuna valutazione finora

- Sine BarDocumento13 pagineSine BarmaneeshNessuna valutazione finora

- Lathe Feeding Mechanism Types and ComponentsDocumento22 pagineLathe Feeding Mechanism Types and Componentsadhees100% (2)

- Engineering CurvesDocumento80 pagineEngineering CurvesUtkarsh YadavNessuna valutazione finora

- Fundamental principles of straightness and flatness measurementDocumento34 pagineFundamental principles of straightness and flatness measurementtamilselvan n100% (2)

- Abrasive Jet MachiningDocumento6 pagineAbrasive Jet Machiningpatel ketan71% (7)

- Fitting Models: Semi Circular JointDocumento2 pagineFitting Models: Semi Circular Jointsubba reddyNessuna valutazione finora

- Heat Trans CH 4-2Documento32 pagineHeat Trans CH 4-2AhmadJaffarGulfarazNessuna valutazione finora

- Measure Unknown Angles Using a Sine BarDocumento4 pagineMeasure Unknown Angles Using a Sine BarMohsin Munawar67% (3)

- 28 - 4400 MCQ - IES - GATE - PSUs Mechanical EngineeringDocumento21 pagine28 - 4400 MCQ - IES - GATE - PSUs Mechanical Engineeringanilm130484meNessuna valutazione finora

- Casting and Pattern Making ProcessesDocumento11 pagineCasting and Pattern Making ProcessesAshok PradhanNessuna valutazione finora

- Flow Measurement ExerciseDocumento2 pagineFlow Measurement ExerciseamareNessuna valutazione finora

- Fluid Machinery Question Bank No.02Documento7 pagineFluid Machinery Question Bank No.02Sunil KumarNessuna valutazione finora

- Unit Iii Visual RealismDocumento59 pagineUnit Iii Visual RealismJabin JoeNessuna valutazione finora

- Heat and Mass Transfer RKRajputDocumento131 pagineHeat and Mass Transfer RKRajputanimatedjade50% (2)

- Unit II Curves & SurfacesDocumento57 pagineUnit II Curves & Surfacesvishwajeet patilNessuna valutazione finora

- Measurement of Pressure Using McLeod GaugeDocumento5 pagineMeasurement of Pressure Using McLeod GaugeSantosh SharmaNessuna valutazione finora

- Measure Taper Angle with Sine BarDocumento5 pagineMeasure Taper Angle with Sine Barঅর্ঘ্য রায়Nessuna valutazione finora

- Angular MeasurementDocumento46 pagineAngular Measurementavutu_kunduruNessuna valutazione finora

- Measure Angles Accurately with a Sine BarDocumento5 pagineMeasure Angles Accurately with a Sine BarAmolNessuna valutazione finora

- Angle MeasurementDocumento19 pagineAngle MeasurementHemant KumarNessuna valutazione finora

- Taper MeasurementDocumento5 pagineTaper MeasurementSabooraKhatoon100% (1)

- Chapter 3: Angular Measurements: Definition of AngleDocumento10 pagineChapter 3: Angular Measurements: Definition of AngleMohsin Munawar100% (1)

- Dsy Iv Sem Load CalculationsDocumento3 pagineDsy Iv Sem Load CalculationsAnand BabuNessuna valutazione finora

- Some Important Terms:: Isometric Axes, Lines and PlanesDocumento10 pagineSome Important Terms:: Isometric Axes, Lines and PlanesAnand BabuNessuna valutazione finora

- Final DSY SUMER 21 TIME TABLEDocumento1 paginaFinal DSY SUMER 21 TIME TABLEAnand BabuNessuna valutazione finora

- Final M.TECH SUMER 21 TIME TABLEDocumento1 paginaFinal M.TECH SUMER 21 TIME TABLEAnand BabuNessuna valutazione finora

- Metro Logy Lab ExperimentDocumento1 paginaMetro Logy Lab ExperimentAnand BabuNessuna valutazione finora

- NodeDocumento2 pagineNodeAnand BabuNessuna valutazione finora

- Wire EDM: Dielectric Liquid VoltageDocumento12 pagineWire EDM: Dielectric Liquid VoltageAnand BabuNessuna valutazione finora

- Dsy M.tech Sumer 21 Time TableDocumento1 paginaDsy M.tech Sumer 21 Time TableAnand BabuNessuna valutazione finora

- Tamer Samir Mahmoud Abdul Majeed - 2 - Introduction To CNC PDFDocumento35 pagineTamer Samir Mahmoud Abdul Majeed - 2 - Introduction To CNC PDFdsathiyaNessuna valutazione finora

- UntitledDocumento1 paginaUntitledAnand BabuNessuna valutazione finora

- Study of Reduction Behaviour of Iron Ore Lumps A: BINAYAK MOHAPATRA (10504004) DHARANIDHAR PATRA (10504021)Documento38 pagineStudy of Reduction Behaviour of Iron Ore Lumps A: BINAYAK MOHAPATRA (10504004) DHARANIDHAR PATRA (10504021)Anand BabuNessuna valutazione finora

- Study of Linear Measuring Instruments: Qis College of Engg. & Tech.:Ongole, A.P. Metrology LabDocumento9 pagineStudy of Linear Measuring Instruments: Qis College of Engg. & Tech.:Ongole, A.P. Metrology LabAnand BabuNessuna valutazione finora

- Tool Makers MicroscopeDocumento7 pagineTool Makers MicroscopeAnand Babu100% (2)

- Thread MeasurementDocumento5 pagineThread MeasurementAnand BabuNessuna valutazione finora

- Profile ProjectorDocumento6 pagineProfile ProjectorAnand Babu100% (1)

- Measurement of Surface FinishDocumento6 pagineMeasurement of Surface FinishAnand Babu100% (5)

- Gear MeasurementDocumento5 pagineGear MeasurementAnand Babu100% (1)

- Machine Tool TestingDocumento9 pagineMachine Tool TestingAnand Babu70% (10)

- Metrology Lab ManualDocumento1 paginaMetrology Lab ManualAnand BabuNessuna valutazione finora

- Lap Reoprt 1Documento9 pagineLap Reoprt 1api-350815927Nessuna valutazione finora

- Oct 2022 P4 Model AnswerDocumento25 pagineOct 2022 P4 Model AnswerabiyyaNessuna valutazione finora

- 26 - Jaxa-Rozen Cold Work Stainless Steell PDFDocumento13 pagine26 - Jaxa-Rozen Cold Work Stainless Steell PDFSergio MuñozNessuna valutazione finora

- Peek - POLYETHER ETHER KETONEDocumento58 paginePeek - POLYETHER ETHER KETONEBryan Jesher Dela Cruz100% (1)

- Newtons Second LawDocumento2 pagineNewtons Second LawTalina FlowerNessuna valutazione finora

- Preparation, Structure and Morphology of Polymer Supports: David C. SherringtonDocumento12 paginePreparation, Structure and Morphology of Polymer Supports: David C. Sherringtonkishorkumarn8212Nessuna valutazione finora

- Engineering Statistics and Probability Chapter 3 PDFDocumento25 pagineEngineering Statistics and Probability Chapter 3 PDFcarl domingoNessuna valutazione finora

- Fractional Fourier Transform and Its ApplicationsDocumento57 pagineFractional Fourier Transform and Its ApplicationsRajeev Prakash100% (2)

- Performance Evaluation For Inerter-Based Dynamic Vibration AbsorbersDocumento28 paginePerformance Evaluation For Inerter-Based Dynamic Vibration Absorbersgakada prbNessuna valutazione finora

- 111年下A卷題庫Documento10 pagine111年下A卷題庫陳奕安Nessuna valutazione finora

- Optical Splitter Whitepaper - 02Documento16 pagineOptical Splitter Whitepaper - 02s_waqarNessuna valutazione finora

- Paper ChromatographyDocumento27 paginePaper ChromatographyjayNessuna valutazione finora

- Principles of Rotary Flight HelicopterDocumento2 paginePrinciples of Rotary Flight Helicopterrex-strikerNessuna valutazione finora

- Shear Strengthening of T-Beam With FRPDocumento3 pagineShear Strengthening of T-Beam With FRPRal GLNessuna valutazione finora

- Machining Processes SyllabusDocumento2 pagineMachining Processes SyllabusshailkhanNessuna valutazione finora

- B 21 - B 21M - 14Documento8 pagineB 21 - B 21M - 14Ahmed BilalNessuna valutazione finora

- Gases Tutorial 2Documento4 pagineGases Tutorial 2Idil WarsameNessuna valutazione finora

- Technical specifications for JR3 multi-axis force-torque sensor modelsDocumento1 paginaTechnical specifications for JR3 multi-axis force-torque sensor modelsSAN JUAN BAUTISTANessuna valutazione finora

- 1D Advection-Diffusion MATLAB Code SolutionsDocumento6 pagine1D Advection-Diffusion MATLAB Code SolutionsAnonymous OrhjVLXO5sNessuna valutazione finora

- Gothic cathedral structural analysisDocumento43 pagineGothic cathedral structural analysisManuelPérezNessuna valutazione finora

- CE 481 Solid Waste & Environmental PollutionDocumento140 pagineCE 481 Solid Waste & Environmental PollutionDamini ThakurNessuna valutazione finora

- Design of Rotating Electrical Machines2Documento531 pagineDesign of Rotating Electrical Machines2alirozNessuna valutazione finora

- Chemistry Project XIIDocumento13 pagineChemistry Project XIIKanav MalhotraNessuna valutazione finora

- Boiler Performance Guarantee R0Documento3 pagineBoiler Performance Guarantee R0Prafitri KurniawanNessuna valutazione finora

- Masterbatches protect plastics from UV damageDocumento1 paginaMasterbatches protect plastics from UV damageSidharth JainNessuna valutazione finora

- Weather CardDocumento2 pagineWeather Cardmekstone100% (1)

- Plate Tectonic UnitDocumento95 paginePlate Tectonic Unitapi-227272561Nessuna valutazione finora

- Biaxial Bending of SFRC Slabs Is Conventional Reinforcement NecessaryDocumento15 pagineBiaxial Bending of SFRC Slabs Is Conventional Reinforcement NecessaryDan MaceNessuna valutazione finora

- HW1 - Conditions - Olevsky - Mech - Beh - Mater PDFDocumento2 pagineHW1 - Conditions - Olevsky - Mech - Beh - Mater PDFwangbutt123Nessuna valutazione finora

- InterpolationDocumento7 pagineInterpolationElianne GabbayNessuna valutazione finora

- Arizona, Utah & New Mexico: A Guide to the State & National ParksDa EverandArizona, Utah & New Mexico: A Guide to the State & National ParksValutazione: 4 su 5 stelle4/5 (1)

- Naples, Sorrento & the Amalfi Coast Adventure Guide: Capri, Ischia, Pompeii & PositanoDa EverandNaples, Sorrento & the Amalfi Coast Adventure Guide: Capri, Ischia, Pompeii & PositanoValutazione: 5 su 5 stelle5/5 (1)

- South Central Alaska a Guide to the Hiking & Canoeing Trails ExcerptDa EverandSouth Central Alaska a Guide to the Hiking & Canoeing Trails ExcerptValutazione: 5 su 5 stelle5/5 (1)

- The Bahamas a Taste of the Islands ExcerptDa EverandThe Bahamas a Taste of the Islands ExcerptValutazione: 4 su 5 stelle4/5 (1)

- New York & New Jersey: A Guide to the State & National ParksDa EverandNew York & New Jersey: A Guide to the State & National ParksNessuna valutazione finora

- Japanese Gardens Revealed and Explained: Things To Know About The Worlds Most Beautiful GardensDa EverandJapanese Gardens Revealed and Explained: Things To Know About The Worlds Most Beautiful GardensNessuna valutazione finora