Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Analysis of Resistance Characteristics of Conductive Concrete Using Press-Electrode Method

Caricato da

Shaik AbdullaDescrizione originale:

Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Analysis of Resistance Characteristics of Conductive Concrete Using Press-Electrode Method

Caricato da

Shaik AbdullaCopyright:

Formati disponibili

International Journal of Environmental and Earth Sciences 1:1 2010

Analysis of Resistance Characteristics of Conductive Concrete Using Press-Electrode Method

Chun-Yao Lee and Siang-Ren Wang

AbstractThis paper aims to discuss the influence of resistance characteristic on the high conductive concrete considering the changes of voltage and environment. The high conductive concrete with appropriate proportion is produced to the press-electrode method. The curve of resistivity with the changes of voltage and environment is plotted and the changes of resistivity are explored. Keywordsconductive concrete, resistivity.

II. CONDUCTIVE CONCRETE AND MODELS A. Introduction of conductive concrete The conductive concrete is mixed with a certain amount of conductive material in the cement. Some part of the aggregate in the concrete is replaced by adding metal fibers and metal substances. The conductive concrete known as a compound concrete for special purpose not only maintains its basic mechanical property, but also makes it constitute a conductive network. With the same function as the resistance reducing agent with a lower resistivity, the conductive concrete is particularly employed to the reinforced concrete and road surface. Moreover, the conductive capacity of conductive concrete is different according to the conductive materials and doping concentration. In this paper, materials, proportion and production procedures applied to the conductive concrete is adopted from the reference [5]. The main concrete materials are cement, coarse aggregate, and fine aggregate, and the proportions for each material are 20%-30%, 15%-20%, and 15%-20%, respectively. The conductive material (30%) is further divided to steel fiber (5%), and steel grit (25%). The value of water-cement ratio is between 0.3 and 0.4 approximately. The detailed specification is shown in Table I.

TABLE I MATERIAL AND PROPORTION OF THE CONDUCTIVE CONCRETE Material Proportion Annotation Cement 25% The cement of type I Coarse aggregates 20% Maximum diameter is 30mm Fine aggregates 15% Maximum diameter is 2mm Steel fiber 5% Maximum length is 40mm Steel grit 25% Maximum diameter is 1.42mm Water-cement ratio 0.4 The weight ratio of water and cement The proportion of water is about 15%

I. INTRODUCTION

ITH unique physical property, concrete is widely used around the world. To ensure the road smooth, transportation safety, and the airports operation efficiency, the conductive concrete is commonly to be applied to pave on the roadway. The conductive concrete applied to the road surface with snow is particularly effective, since the road surface can be cleaned rapidly and efficiently. For road maintenance in the area with snow in winter, this project becomes significant [1]-[3]. In addition, for a grounding system, the soil resistivity is the critical concern for a grounding system. The conductive concrete with low resistivity characteristics can be applied to grounding system. In the case of grounding resistance of the transmission tower, if the concrete with conductive property combined with the original grounding grid is applied as the foundation of tower, the grounding resistance of the tower would be greatly reduced. Power from lightning can be dissipated to the earth rapidly, and the transmission reliability can be enhanced. For this reason, many scholars have devoted to the studies related to conductive concrete in recent years [4], [5]. The conductive concrete with conductive and magnetic capacity applied to grounding system would moderately reduce the damage caused by lightning and surge. Therefore, this paper aims to study the resistance characteristics of the conductive concrete using press-electrode method and discusses the influences of voltage and environment corresponding to the resistance characteristics of the high conductive concrete.

This work was supported in part by the National Science Council of Republic of China under Contract NSC 99-2632-E-033-001-MY3. C.-Y. Lee and S.-R. Wang are with the Department of Electrical Engineering, Chung Yuan Christian University, Taoyuan County, Taiwan, 32023. (Phone: +886-3-265-4827; e-mail: chun-yao@ieee.org).

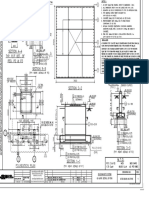

B. Models The press-electrode method is applied to measure the resistivity of conductive concrete in this paper. Then, the resistivity related to time, temperature and voltage are obtained. The measurement method is depicted as follow. The press-electrode method is a simple measurement adopted from the concept in reference [6]. The conductive concrete is regarded as a resistance. The specimen of the

International Journal of Environmental and Earth Sciences 1:1 2010

conductive concrete shares a pair of electrodes for measuring voltage and current, as shown in Fig. 1. This method makes use of adjustable frame to press the electrode and the conductive concrete, that is, this method makes the electrode and the conductive concrete close together. The selected electrode material is made of copper foil and its size should be the same with the cross-sectional area of conductive concrete. Meanwhile, two electrode sides are connected to two wires in

Fig. 2. Measured diagram of the press-electrode method.

III. PRACTICAL MODEL AND MEASUREMENT

A. The practical models The press-electrode method is implemented by means of adjustable pressed device. Because the pressed device is iron made equipment, both the ends of the outer electrode covered with acrylic is to avoid electricity from leaking to the equipment. The moderate pressure is taken to press cooper electrode and the conductive concrete. The conductive concrete

Fig. 1. Structure of the press-electrode method.

which the wire is linked to an ammeter and the DC source is supplied. Consequently, the values of voltage and current are recorded. Formula Ohms law is applied to the two methods and the resistance Rc of the conductive concrete between b and c, and the resistivity are obtained, as shown (1) and (2), respectively.

2 Rr + Rc =

R= l A

C.

V I

(1) (2)

which Rr : electrode resistance () Rc : V : I : : l : A: resistance of the conductive concrete between b and c () the voltage between b and c (V) the current flowing through b and c resistivity of the conductive concrete (m) the length between b and c (m) contact sectional area between the conductive concrete and electrode (m2)

Fig. 3. Flowchart of the resistivity measurement.

International Journal of Environmental and Earth Sciences 1:1 2010

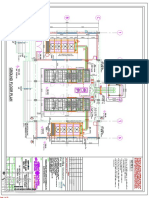

with DC source at electrode side is subsequently connected to ammeter and voltmeter. The measurement instruments contain a set of power supply and two sets of meters, as shown in Fig. 2. The voltage and current considering various factors are recorded.

Date Day 1 Day 2 Day 3 Day 4 Day 5 Day 6 Day 7

TABLE II DATA OF THE RESISTIVITY IN STABLE TEST 2 4 6 Measurement min(s) min(s) min(s) Press-electrode 65.84 65.41 65.66 Press-electrode Press-electrode Press-electrode Press-electrode Press-electrode Press-electrode 76.76 86.28 94.45 102.34 113.49 122.66 76.84 86.31 94.63 102.61 112.95 122.78 77.07 86.36 94.69 102.31 113.75 121.66

8 min(s) 65.45 77.41 86.91 94.92 102.71 112.57 121.13

B. Step of the measurement To measure the effect of time and temperatures using the press-electrode method, a better measurement is chosen when the smaller resistivity without severe change as time varying. Meanwhile, the conductive concrete is placed outside, and the temperature and environmental conditions are recorded. The measurement flowchart is shown in Fig. 3, and the steps are briefly listed below. a. The equipment is prepared for press-electrode method. b. The voltage and current of the conductive concrete are measured using the proposed methods, and the resistivity is calculated according to Ohm's law. c. The stability test is recorded once per 60 seconds. d. The conductive concrete is placed outdoors and it is measured at different temperature and climate conditions. e. The resistivity-time and resistivity-temperature curves are drawn. f. The results of the measurement method is discussed.

IV. THE DATA AND THE MEASURED RESULTS For a better understanding of the influence on the resistivity of the high conductive concrete, temperature and humidity are considered, and the stability of the high conductive concrete is tested using the press-electrode method. The results have shown that by using the press-electrode method, more influencing factors are comprised and the error of the resistivity is relatively high. However, using the method, the generated polarization in process of connecting voltage source cannot be avoided and contact resistance between electrode and the conductive concrete is not reduced. Therefore, the resistivity measurement of the conductive concrete at different voltage cannot obtained through the press-electrode method.

TABLE III DATA OF THE RESISTIVITY IN ENVIRONMENT TEST (PRESS-ELECTRODE METHOD) Drying Temperature () 16 17 18 19 21 23 24 Resistivity (m) 65.83 65.79 65.62 65.56 65.41 65.28 65.15 () 10 11 12 13 14 15 16 Wetting Temperature Resistivity (m) 49.38 48.56 48.31 48.02 47.79 47.53 47.13

A. Time The conductive concrete is not a general dry solid material. When connected to voltage source, the conductive particles inside of the conductive concrete are affected. This phenomenon displays the unstable data obtained from voltmeter and ammeter and results in measurement error every time. To understand the stability and accuracy of the press-electrode method in the process of measurement, the stability of conductive concrete is firstly tested. The data in terms of the press-electrode method is recorded once 60 seconds, and 10 data are recorded in one day. Finally, these data are applied to calculate the resistivity in the unit of (m). The result of the 7-day measurement is shown in Table. II. B. Temperature and moisture of the environment The conductive concrete is placed outdoors. To observe the influence of conductive concrete on resistivity in different environments, including dry and wet conditions, the recorded

Fig. 4. Relation curve of resistivity and temperature in press-electrode method.

data comprising the measurement values in sunny and rainy days are compared. The measurement data using press-electrode method are shown in Table III. Besides, these data is plotted to observe the curves related to resistivity, and outdoor temperature and climate as well, as shown in Fig. 4. V. ANALYSIS AND DISCUSSION OF THE RESULTS The resistivity of the high conductive concrete using press-electrode method is investigated. The resistance characteristics are observed. Since the pore solution of the conductive concrete is gradually decreased in the dry environment, and steel fiber and steel grit would go rust slightly in the alkaline environment of cement, the conductive capacity is gradually decreased. For this, the two factors directly influence the current and make the resistivity increase. The

International Journal of Environmental and Earth Sciences 1:1 2010

result of the stability has shown that resistivity of the conductive concrete significantly increases and the resistivity curve also rises by days, as shown in Table II. Practically, the contact resistance is the main problem that causes to error for the press-electrode method. If there is any gap between the electrode and the concrete, the contact area is decreased, and the current is relatively decreased. By calculation, the contact area is a constant, and hence the resistivity is significantly increased. Moreover, the polarization is generated in the process of power supply for the press-electrode method. The anions are gathered at positive pole and cations are gathered at negative pole. The ions are deposited around the electrode, referred as the polarization response of the concrete. This phenomenon leads to back EMF and makes the measured current value smaller than actual value. As the ions are gradually accumulated around the electrode, the polarization is getting obvious until the polarization is balanced. On the other hand, the conductive concrete with pore solution is capable of either absorbing or evaporating water depending on the moisture change, for this reason, the resistivity of the conductive concrete is varied as the environment change. By observing Fig. 4, when the conductive concrete is placed outdoors, the resistivity of the conductive concrete is influenced by temperature and humidity. The higher the temperature and humidity are, the lower resistivity is, as shown in Table III. Considering the influencing factor of the internal water, after the concrete hydration, many ionic substances, electrolytes, is dissolved in the water and interconnected by capillary. Therefore, as the water increases, the conductive concrete of conductivity is increased and the tightness of the concrete structures is maintained. Comparing the factors between temperature and moisture, the resistivity of conductive concrete is evidently to be affected by water content. In this way, the warm and humid environment results in a lower resistivity for conductive concrete. VI. CONCLUSION The resistivity of the high conductive concrete is computed in this paper using Ohms law, and the press-electrode method is applied to measure and record in different conditions, including time, temperature and voltage. The results have shown that either the higher temperature or the higher humidity results in a smaller the resistivity. In addition, the voltage change also affects internal temperature and the structure of the conductive concrete. The greater the voltage is, the smaller the resistivity is. In sum, the resistivity of the high conductive concrete is not a constant value. The resistivity is not only slightly changed day by day, but also affected by external environment.

Generally, the conductive concrete is widely used for deicing; however, this paper focuses on the application of conductive concrete to grounding system. The important parameter, resistivity, is an indicator in terms of grounding system. The resistance characteristics of the conductive concrete are obtained based on the proposed methods and measured data in this paper. The characteristics of the high conductive concrete corresponding to the grounding standard completely can be applied to grounding effectively. ACKNOWLEDGMENT The authors would like to thank Professor Chih-Ju Chou and his research center in Dept. Electrical Engineering of National Taipei University of Technology in providing the suggestions of the research. The authors also would like to thank Professor Ming-Yi Liu, Chung-Min Ho and their Labs. in Chung Yuan Christian University in providing the measurement equipments. REFERENCES

[1] C. Y. Tuan, S. A. Yehia, Implementation of Conductive Concrete Overlay for Bridge Deck Deicing at Roca, Nebraska, Transportation Research E-Circular, No. E-C063, Jun. 2004, pp. 363-378. [2] [3] C. Y. Tuan, Conductive Concrete for Bridge Deck Deicing and Anti-Icing, University of Nebraska, Lincoln, Jul. 2004, pp.168. C. Y. Tuan, Roca Spur Bridge: The Implementation of an Innovative Deicing Technology, American Society of Civil Engineers, Vol. 22, Issue 1, Mar. 2008, pp. 1-15. [4] Yehia S, Christopher Y T, Ferdon D, eta1. Conductive concrete overlay for bridge deck deicing: mixture proportioning, optimization, and properties [J], ACI Materials Journal, 2000, 97(2): pp. 172-181. [5] Hou Zuo-Fu, Li Zhuo-Qiu, Hu Sheng-Liang, Resistivity Research on Carbon Fibre Electrically Conductive Concrete for Deicing and Snow Melting, Journal of Yangtze University (Nat Sci Edit) Vo1. 2, No. 7, pp. 264-266, Ju1. 2005. [6] Shen Gang, Dong Faqin, He Dengliang, Study on Graphite and Steel Fiber Composite Electrically Conductive concrete, Bulletin of the Chinese Ceramic Society, No. 6, 2004. Chun-Yao Lee (SM04, M08) received his Ph.D. in electrical engineering from National Taiwan University of Science and Technology in 2007. In 2008, he joined Chung Yuan Christian University as a faculty member. Dr. Lee was a visiting Ph.D. at University of Washington, Seattle, during 2004-05 and worked for engineering division, Taipei Government as distribution system designer during 2001-2008. His research interests include power distribution and filter design. Dr. Lee is a member of the IEEE Taipei Section Siang-Ren Wang was born in Taiwan in 1986. He received his B.S. degree in electrical engineering from Chung Yuan Christian University in 2008. Mr. Wang will be an electrical engineer in a year in Taiwan.

10

Potrebbero piacerti anche

- Evaluation of Concrete Permeability by Critical Voltage: Xinying Lu, Meixia Chen, Fang YuanDocumento3 pagineEvaluation of Concrete Permeability by Critical Voltage: Xinying Lu, Meixia Chen, Fang YuanAngel_JK99Nessuna valutazione finora

- Concrete Electrical ResistivityDocumento7 pagineConcrete Electrical Resistivitysoulmateforeverforu100% (1)

- Effect of Voltage On Mechanical Properties of CarbDocumento7 pagineEffect of Voltage On Mechanical Properties of CarbAditya SutarNessuna valutazione finora

- ID FanDocumento7 pagineID FanDony RamdhaniNessuna valutazione finora

- Electrical Resistivity Measurement of Concrete - Wikipedia - PDF (NON CONTACTDocumento4 pagineElectrical Resistivity Measurement of Concrete - Wikipedia - PDF (NON CONTACTjucar fernandezNessuna valutazione finora

- PrintedDocumento7 paginePrintedFari PratomosiwiNessuna valutazione finora

- AC Mitigation Sample ReportDocumento14 pagineAC Mitigation Sample ReportebalideNessuna valutazione finora

- Hydration Monitoring of Cement-Based MaterialsDocumento10 pagineHydration Monitoring of Cement-Based MaterialsJerry SethiNessuna valutazione finora

- A New Method For Measuring Contact ResistanceDocumento4 pagineA New Method For Measuring Contact ResistanceSenthil CuddaloraNessuna valutazione finora

- Electrical Discharge Machining of Oxide Nanocomposite: Nanomodification of Surface and Subsurface LayersDocumento28 pagineElectrical Discharge Machining of Oxide Nanocomposite: Nanomodification of Surface and Subsurface LayersLucian DragosNessuna valutazione finora

- Mechatronics Electrical PowerDocumento8 pagineMechatronics Electrical PowerDedijumaediNessuna valutazione finora

- Critical Chloride Concentration of Rebar Corrosion in Fly Ash ConcreteDocumento18 pagineCritical Chloride Concentration of Rebar Corrosion in Fly Ash ConcreteJHON WILMAR CARDENAS PULIDONessuna valutazione finora

- Cyme GridDocumento6 pagineCyme Gridprabhakaran_hdec100% (1)

- Fluid Dynamic Simulation and Experimental Study of Honeycomb Seal Structures in Electrochemical Discharge Machining PressureDocumento17 pagineFluid Dynamic Simulation and Experimental Study of Honeycomb Seal Structures in Electrochemical Discharge Machining PressuremechjournalNessuna valutazione finora

- Aguado Measurement 1Documento6 pagineAguado Measurement 1HADHI HASSAN KHANNessuna valutazione finora

- Concrete Electrical ResistivityDocumento7 pagineConcrete Electrical ResistivityFernando MoitaNessuna valutazione finora

- CCC 9487Documento6 pagineCCC 9487maxence.bigerelleNessuna valutazione finora

- A Comparative Study of Additively Manufactured Thin Wall and Block Structure With Al-6.3%Cu Alloy Using Cold Metal Transfer ProcessDocumento11 pagineA Comparative Study of Additively Manufactured Thin Wall and Block Structure With Al-6.3%Cu Alloy Using Cold Metal Transfer ProcessJinoop A NNessuna valutazione finora

- The Permeability at Ions Chlorinates As Indicator of Durability of ConcretesDocumento4 pagineThe Permeability at Ions Chlorinates As Indicator of Durability of ConcretesInternational Journal of Application or Innovation in Engineering & ManagementNessuna valutazione finora

- Numerical Study of Coated Electrical ContactsDocumento6 pagineNumerical Study of Coated Electrical ContactsHilary OlsonNessuna valutazione finora

- LectromecDocumento12 pagineLectromec7564135Nessuna valutazione finora

- 2.1.4 Half-Cell PotentiometerDocumento3 pagine2.1.4 Half-Cell PotentiometerTejaSriNessuna valutazione finora

- Sensors: Frequency-Switchable Metamaterial Absorber Injecting Eutectic Gallium-Indium (Egain) Liquid Metal AlloyDocumento12 pagineSensors: Frequency-Switchable Metamaterial Absorber Injecting Eutectic Gallium-Indium (Egain) Liquid Metal AlloySiscaDinaNessuna valutazione finora

- Elastomeric Electronics: A Microfluidic Approach: Shi ChengDocumento20 pagineElastomeric Electronics: A Microfluidic Approach: Shi ChengVignesh RamakrishnanNessuna valutazione finora

- Impedance Spectroscopy in Reinforced Concrete: Procedure For Monitoring Steel CorrosionDocumento6 pagineImpedance Spectroscopy in Reinforced Concrete: Procedure For Monitoring Steel CorrosionhadiNessuna valutazione finora

- Detection and Mitigation of Ac Interference On 200Km PipelineDocumento5 pagineDetection and Mitigation of Ac Interference On 200Km PipelineMarcelo Varejão CasarinNessuna valutazione finora

- Electrical Resistivity of Concrete: Concepts, Applications, and Measurement TechniquesDocumento6 pagineElectrical Resistivity of Concrete: Concepts, Applications, and Measurement TechniquesDeepika DeepuNessuna valutazione finora

- Electrical Strain Gauges: A Report OnDocumento31 pagineElectrical Strain Gauges: A Report OnAnonymous GRY6OCJNessuna valutazione finora

- Analysis On Fabrication of Micro-Tools by Micro-Electrochemical Machining ProcessDocumento33 pagineAnalysis On Fabrication of Micro-Tools by Micro-Electrochemical Machining ProcessXu WeixingNessuna valutazione finora

- An Experimental Study of Air Breakdown Voltage - J. Electrical SystemsDocumento9 pagineAn Experimental Study of Air Breakdown Voltage - J. Electrical Systemsdineshsoni29685100% (1)

- Effect of Surface Shallow Traps On FlashoverDocumento7 pagineEffect of Surface Shallow Traps On FlashoverVU Thi Thu NgaNessuna valutazione finora

- Design Calculation and Performance Testing of Heating Coil in Induction Surface Hardening Machine PDFDocumento5 pagineDesign Calculation and Performance Testing of Heating Coil in Induction Surface Hardening Machine PDFMohammedNessuna valutazione finora

- Study of Impressed Current Cathodic Protection (ICCP) On The Steel Pipeline Under DC Stray Current InterferenceDocumento17 pagineStudy of Impressed Current Cathodic Protection (ICCP) On The Steel Pipeline Under DC Stray Current InterferenceMahir DžafićNessuna valutazione finora

- Apparatus Required: 1.ammeter 2.voltmeter 3.copper Wires A.thickness-B. LengthDocumento12 pagineApparatus Required: 1.ammeter 2.voltmeter 3.copper Wires A.thickness-B. LengthJason PadillaNessuna valutazione finora

- NPSC RVI InsulatorsDocumento4 pagineNPSC RVI InsulatorsJordan RileyNessuna valutazione finora

- Corrosion Resistance Performance of Fly Ash Blended Cement ConcretesDocumento7 pagineCorrosion Resistance Performance of Fly Ash Blended Cement ConcretesesatjournalsNessuna valutazione finora

- Character Is at Ion of Polyimides Under High-Temperature SlidingDocumento8 pagineCharacter Is at Ion of Polyimides Under High-Temperature SlidingAlberto GamberiniNessuna valutazione finora

- Optimization and Development of Contact Wire For High Speed LinesDocumento9 pagineOptimization and Development of Contact Wire For High Speed Linesdineshsoni29685Nessuna valutazione finora

- Applsci 10 09152 v2Documento42 pagineApplsci 10 09152 v2Gil Angelo Del ValleNessuna valutazione finora

- Cement Based ElectronicsDocumento11 pagineCement Based ElectronicsDEBORAHVSNessuna valutazione finora

- Temperature Effects On Fatigue of Polymer CompositesDocumento3 pagineTemperature Effects On Fatigue of Polymer CompositesTeoman UrceNessuna valutazione finora

- Comparison of Finite-Element and IEC Methods For Cable Thermal Analysis Under Various Operating Environments (Kady2014)Documento6 pagineComparison of Finite-Element and IEC Methods For Cable Thermal Analysis Under Various Operating Environments (Kady2014)daegerteNessuna valutazione finora

- Charpy Impact Test: An Overview of Mechanical and Physical Testing of Composite MaterialsDocumento11 pagineCharpy Impact Test: An Overview of Mechanical and Physical Testing of Composite MaterialswaniNessuna valutazione finora

- Electro Chemical Discharge MachiningDocumento20 pagineElectro Chemical Discharge MachininglokeshNessuna valutazione finora

- Refer en CIA 10Documento8 pagineRefer en CIA 10Ianina VioliNessuna valutazione finora

- The Influence of Aging Time and Moisture Content oDocumento7 pagineThe Influence of Aging Time and Moisture Content oTri Suprapti HandayaniNessuna valutazione finora

- On The Tensile Resistance of UHPC at Impact: T E P JDocumento11 pagineOn The Tensile Resistance of UHPC at Impact: T E P Jsina zolfagharyNessuna valutazione finora

- Development of Electrochemical Micro Machining For Air-Lubricated Hydrodynamic BearingsDocumento6 pagineDevelopment of Electrochemical Micro Machining For Air-Lubricated Hydrodynamic BearingsMark LambertNessuna valutazione finora

- A New Method For Determining The Connection ResistDocumento19 pagineA New Method For Determining The Connection ResistЖандос ТлешовNessuna valutazione finora

- Study On Damage of Concrete Under Uniaxial Compression Based On Electrical Resistivity MethodDocumento12 pagineStudy On Damage of Concrete Under Uniaxial Compression Based On Electrical Resistivity MethodTerry McManamanNessuna valutazione finora

- 1 - Artigo 37 PDFDocumento10 pagine1 - Artigo 37 PDFTatiane GabiNessuna valutazione finora

- Comparison of Chloride Diffusion Coefficient Evaluation Based On Electrochemical MethodsDocumento6 pagineComparison of Chloride Diffusion Coefficient Evaluation Based On Electrochemical MethodsYash DhabaliaNessuna valutazione finora

- Electrical Resistivity Measurement of ConcreteDocumento4 pagineElectrical Resistivity Measurement of ConcreteJojo Dela CruzNessuna valutazione finora

- HR Asia, Apr 2011Documento4 pagineHR Asia, Apr 2011emediageNessuna valutazione finora

- Kendriya Vidyalaya M.E.G and Centre Bangalore: Physics Project ReportDocumento17 pagineKendriya Vidyalaya M.E.G and Centre Bangalore: Physics Project ReportJason PadillaNessuna valutazione finora

- Crimping TestDocumento6 pagineCrimping TestAmit VijayvargiyaNessuna valutazione finora

- ApplPhysLett 100 262902Documento4 pagineApplPhysLett 100 262902servo234Nessuna valutazione finora

- An Essential Guide to Electronic Material Surfaces and InterfacesDa EverandAn Essential Guide to Electronic Material Surfaces and InterfacesNessuna valutazione finora

- Electrical Engineering Principles for Technicians: The Commonwealth and International Library: Electrical Engineering DivisionDa EverandElectrical Engineering Principles for Technicians: The Commonwealth and International Library: Electrical Engineering DivisionValutazione: 3 su 5 stelle3/5 (4)

- 02.civil Specs P2Documento217 pagine02.civil Specs P2Shaik AbdullaNessuna valutazione finora

- 3.1 Delivery 3.3 Storage and Maintenance of Application ToolsDocumento1 pagina3.1 Delivery 3.3 Storage and Maintenance of Application ToolsShaik AbdullaNessuna valutazione finora

- PForeword PDFDocumento3 paginePForeword PDFShaik AbdullaNessuna valutazione finora

- A747 308 81 41 37195 - Rev 1Documento1 paginaA747 308 81 41 37195 - Rev 1Shaik AbdullaNessuna valutazione finora

- PAcknowledgeDocumento2 paginePAcknowledgeShaik AbdullaNessuna valutazione finora

- Dg-1 (Remote Radiator) Above Control Room Slab: 05-MAR-2018 Atluri Mohan Krishna (B845)Documento32 pagineDg-1 (Remote Radiator) Above Control Room Slab: 05-MAR-2018 Atluri Mohan Krishna (B845)Shaik AbdullaNessuna valutazione finora

- East Elevation South Elevation: NotesDocumento1 paginaEast Elevation South Elevation: NotesShaik AbdullaNessuna valutazione finora

- Concrete: Jump To Navigationjump To Search Concrete (Disambiguation) Cement Grout Mortar (Masonry) PlasterDocumento5 pagineConcrete: Jump To Navigationjump To Search Concrete (Disambiguation) Cement Grout Mortar (Masonry) PlasterShaik AbdullaNessuna valutazione finora

- BS 6100 5 3 PDFDocumento12 pagineBS 6100 5 3 PDFShaik AbdullaNessuna valutazione finora

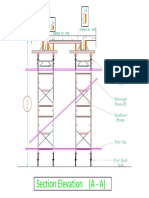

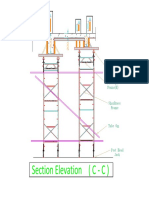

- SLOPE 1:6: Dg-1 (Remote Radiator) Above Control Room SlabDocumento7 pagineSLOPE 1:6: Dg-1 (Remote Radiator) Above Control Room SlabShaik AbdullaNessuna valutazione finora

- Slab Supporing SystemDocumento1 paginaSlab Supporing SystemShaik AbdullaNessuna valutazione finora

- Slab ShoringDocumento1 paginaSlab ShoringShaik AbdullaNessuna valutazione finora

- Guys and AnchorsDocumento34 pagineGuys and AnchorsVijay Kumar0% (1)

- Multilin: Synchronism Check EquipmentDocumento26 pagineMultilin: Synchronism Check EquipmentĐức Nguyễn XuânNessuna valutazione finora

- Ersa Soldering Station PDFDocumento22 pagineErsa Soldering Station PDFtodorloncarskiNessuna valutazione finora

- BH 0.66I Current TransformerDocumento5 pagineBH 0.66I Current TransformerCarlos AguiarNessuna valutazione finora

- Circuit Breaker: Johane A. RoblesDocumento32 pagineCircuit Breaker: Johane A. RoblesAngelika Lei GaraoNessuna valutazione finora

- Fault Modelling and Accelerated Simulation of Integrated Circuits Manufacturing Defects Under Process Varia 1Documento200 pagineFault Modelling and Accelerated Simulation of Integrated Circuits Manufacturing Defects Under Process Varia 1Alessandro BerciouxNessuna valutazione finora

- xl4 B Op ManDocumento81 paginexl4 B Op Manprema6Nessuna valutazione finora

- COMS Clock Generator/Driver For Low Voltage Operation BBDDocumento1 paginaCOMS Clock Generator/Driver For Low Voltage Operation BBDbbNessuna valutazione finora

- Research ProposalDocumento23 pagineResearch ProposalMwaniki CharlesNessuna valutazione finora

- André-Marie Ampère Was: EncyclopédieDocumento5 pagineAndré-Marie Ampère Was: EncyclopédieAngela Monato de MesaNessuna valutazione finora

- V7x DatasheetDocumento4 pagineV7x DatasheetReginald D. De Guzman100% (1)

- TDA75610LV: 4 X 45 W Power Amplifier With Full I C Diagnostics, High Efficiency and Low Voltage OperationDocumento42 pagineTDA75610LV: 4 X 45 W Power Amplifier With Full I C Diagnostics, High Efficiency and Low Voltage Operationmanuel fernandezNessuna valutazione finora

- Stepper Motor ControllerDocumento3 pagineStepper Motor Controllerelfrich100% (3)

- Capitol Drive, Capitol Compound City of Balanga 2100 Bataan PhilippinesDocumento1 paginaCapitol Drive, Capitol Compound City of Balanga 2100 Bataan PhilippinesWilson Domingo LazarteNessuna valutazione finora

- Hi 800 173 Cea H6210Documento18 pagineHi 800 173 Cea H6210Samim KhosraviNessuna valutazione finora

- Introduction of Modern Physics by Nurul Amin SirDocumento13 pagineIntroduction of Modern Physics by Nurul Amin SirFardeen KhanNessuna valutazione finora

- Ejercicios Del Capítulo 6 Flujo de PotenciaDocumento5 pagineEjercicios Del Capítulo 6 Flujo de PotenciaYaison LorenzoNessuna valutazione finora

- EE231 Lecture 2A "Network Theorems I": By: Engr. Paolo Josemari P. ZafraDocumento28 pagineEE231 Lecture 2A "Network Theorems I": By: Engr. Paolo Josemari P. ZafraPaolo Josemari ZafraNessuna valutazione finora

- Beyma BookDocumento91 pagineBeyma BookRajuNessuna valutazione finora

- Semiconductor and Digital Circuit 1693007493Documento4 pagineSemiconductor and Digital Circuit 1693007493samsuzzaman sahinNessuna valutazione finora

- PowerElectronics Grid-Forming Case Studies 15.20Documento17 paginePowerElectronics Grid-Forming Case Studies 15.20Steven Leif EsselNessuna valutazione finora

- Lecture 12Documento42 pagineLecture 12dang.phamNessuna valutazione finora

- Areva Micom P 921,922,923 RelayDocumento13 pagineAreva Micom P 921,922,923 RelaySreeram PanigrahiNessuna valutazione finora

- Overexcitation ProtectionDocumento13 pagineOverexcitation Protectionalonso100% (1)

- Medrad Mrxperion-Operation ManualDocumento98 pagineMedrad Mrxperion-Operation Manualservice iyadMedicalNessuna valutazione finora

- Plecs Tutorial: Modeling A Switched-Mode Power Supply Using PLECSDocumento8 paginePlecs Tutorial: Modeling A Switched-Mode Power Supply Using PLECSphum 1996Nessuna valutazione finora

- Electrical Multimedia 5Documento44 pagineElectrical Multimedia 5ding0398100% (1)

- EPower 029669 5 PDFDocumento14 pagineEPower 029669 5 PDFrajabharath12Nessuna valutazione finora

- 3WL SiemensDocumento110 pagine3WL SiemensrockclaudiuNessuna valutazione finora

- Wireless World 1950 12Documento41 pagineWireless World 1950 12Jan PranNessuna valutazione finora