Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

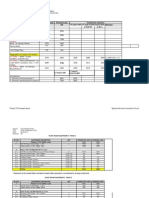

Electrical System Data Sheet

Caricato da

pmlikrishnaDescrizione originale:

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Electrical System Data Sheet

Caricato da

pmlikrishnaCopyright:

Formati disponibili

Power Plant Electrical System Data Sheet

Various Voltage levels in the Plant: Power Generation Voltage Power evacuation Voltage Unit Auxiliary Service voltage Station Switch gear voltage Station auxiliary service voltage DC Battery Voltage Switch gear Control Voltage C&I supply Voltage Supply Variations 33,11,6.6,3.3 kV & 415/240V power supply voltage Frequency Variation Combined variation of voltage & frequency DC System Ripple content in battery charger output (when battery not in circuit) . . : .: .: .. ..: : 6.6/11/15.75/16/21 kV, AC : 132/220/400/765 kV, AC : 11/6.6/3.3 kV, AC 415 V,AC 33 kV, AC 11/6.6/3.3 kV, AC 415 V, AC 220/110 V DC 220/110 V DC 24 /48 V DC 10 % 3% 10 % (Absolute) + 10 %, - 15 % <1% rms

Unit Auxiliary Switch gear voltage Intermediate Station Switch gear voltage:

Switch Yard:

System Voltage 132(136)/220(245)/400(420)/765(800) Kv, AC Fault Interrupting Capacity 40 kA for 1 sec Basic Impulse level 650/1050 /1425/.kVp Pollution level for creepage distance 25 mm / kV (Heavily polluted) Total creepage distance 3400/6125/10500/20000 mm Protected creepage distance 1701/3065/5254/1007 mm Clearances (The clearances adopted in the 132/220/400/800 kV switchyard shall be in line with latest CBIP/CEA standards.)

Clearances:

CLEARANCE ABOVE GROUNDS(Clause 77 of Indian Electricity Rules): m. m. 33 KV 5100 66 KV 5490 132 KV 6100 220 KV 7015 400 KV 8840 MINIMUM CLEARANCE BETWEEN POWER LINES : Nominal System Voltage of line to be crossed : KV 11 33 66 132 220 400 11 2.44 2.44 2.44 3.05 4.58 6.10 33 2.44 2.44 3.05 4.58 6.60 66 2.44 3.05 4.58 6.10 132 3.05 4.58 6.10 Page 1

Power Plant Electrical System Data Sheet

220 - 4.58 6.10 400 - 6.10 Higher voltage line normally be kept over lower voltage line.

As per 1SS 1621961 minimum electrical clearance from live part to earth and safety clearance In case of different voltage must be kept as follows : VOLTAGE ELECTRICAL CLEARANCE (mm) SAFETY CLEARANCE in KV Phase-Earth Phase-Phase SIS (mm) 33 381 432 2740 66 658 786 3050 132 1127 1473 3810 220 2082 2388 4570 400 3500 4000 6100

Insulation levels:

800 kV System One minute power frequency withstand voltage Impulse withstand voltage 400 kV System One minute power frequency withstand voltage Impulse withstand voltage 220 kV System One minute power frequency withstand voltage Impulse withstand voltage 132 kV System One minute power frequency withstand voltage Impulse withstand voltage 33 kV System One minute power frequency withstand voltage Impulse withstand voltage 11 kV System One minute power frequency withstand voltage Impulse withstand voltage 6.6 kV System One minute power frequency withstand voltage Impulse withstand voltage 3.3 kV System One minute power frequency withstand voltage Impulse withstand voltage 415 V System One minute power frequency withstand voltage Impulse withstand voltage Short circuit withstand rating 800 kV system 400 kV system 220 kV system 132 kV system 33 kV system Page 2 40 kA or 1 sec 40 kA for 1sec 40 kA for 1sec 40 kA for 1sec 40 kA for 1sec 2400kV(rms) 1550 kV (peak) ! ! 460 kV(rms) 1050 kV(peak)

! ! ! !

70kV(rms) 145kV (peak)

20 kV (rms) 60 kV (peak)

Power Plant Electrical System Data Sheet

21 kV system 15.75 /16 kV system 11 kV system 6.6 kV system 3.3 kV system 415 V system Neutral Grounding System 11/15.75/16/21 kV Generator 800 kV system 400 kV system 220 kV system 132 kV system 33 kV system 21 kV system 15.75/16 kV system 11kV system 6.6 kV system 3.3 kV system 415 V system DC system Generators: Type Rated capacity Rated terminal voltage Voltage variation range Rated frequency Frequency variation range Rated power factor Rated speed Insulation class Stator cooling Rotor cooling Excitation : : : : : : : : : : : :

40 kA for 3/1 sec 40 kA for 3/1 sec 31.5 kA for 3/1 sec 31.5 kA for 1sec 31.5 kA for 1 sec 50 kA for 1 sec

Generator neutral earthed through 1, distribution transformer with secondary load resistor Solidly earthed system Solidly earthed system Solidly earthed system Solidly earthed system Medium resistance grounding Medium resistance grounding Medium resistance grounding Medium resistance grounding Medium resistance grounding Medium resistance grounding Solidly earthed system Unearthed (UE)

Synchronous Turbo-Generator 300 MW 15.75 kV 10% of rated voltage 50 Hz -5% to +3% (47.5 Hz to 51.5 Hz) 0.85 lag 3000 rpm F (Temperature rise limited to class B) Conductor by Water and core by Hydrogen By Hydrogen Brushless rotating diodes/ static

Transformers:

Transformer S. No. Description Generator Transformer (GT) Station Reserve Transformer (SRT) Station Transformer (ST) Unit Auxiliary Transformer (UAT) LV Auxiliary Transforme r (LT AT)

Page 3

Power Plant Electrical System Data Sheet

To cater the unit auxiliary loads (Boiler, Turbine & Generator). To match the Generator MCR rating and shall be at an design ambient temperature of 50 C To meet the station, Intake and Colony loads. To meet the station loads and one unit load operation Momentary paralleling of UAT with ST shall be considered With all the loads running, it should be feasible to start the largest motor Momentary paralleling of UAT with ST shall be considered 2.0 Rating (minimum) Voltage Ratio Vector Group 225/300/375 MVA 80/100 MVA 50/ MVA 20/25 MVA 15.75 kV / 6.9 kV Dyn1 3 phase, outdoor, Oil Immersed 750/1000/12 50/1500/200 0 kVA 6.9 kV / 0.433 kV Dyn11 3 phase, indoor, Oil Immersed or Dry type to suit the environment ONAN / ONAF OFF Circuit, 2X2.5 %

1.0

Sizing Criterion

To meet the LT auxiliary loads

3.0 4.0

420 kV / 15.75 kV YNd11

420kV/34.5kV YNyn0 3 phase, outdoor, Oil Immersed

33 kV / 6.9 kV YNyn0yn0

5.0

Type

3 phase, outdoor, Oil Immersed

3 phase, outdoor, Oil Immersed

6.0 7.0

Cooling Tap Changer & Range

ONAN / ONAF/OFAF OCTC, 2.5X8 %

ONAN/ONAF OLTC,2.5X8%

ONAN / ONAF OLTC, 10 % insteps of 2.5 %

ONAN / ONAF OLTC, 1.25X8 % 95 kVp 60 kVp

Basic Impulse level (Insulation level) 8.0 HT LT 950 kVp 125 kVp 950 kVp 170 kVp 170 kVp 60 kVp 60 kVp 2.5 kVp

S.No

1

Switch Gears: Description

Type

33kV

metal clad / metal enclosed, cubicle type, free floor standing, dust & vermin proof, draw out type single front construction Page 4

6.6kV

metal clad / metal enclosed, cubicle type, free floor standing, dust & vermin proof, draw out type single front construction

415V

metal clad / metal enclosed, cubicle type, free floor standing, dust & vermin proof, draw out type single front construction

Construction

Power Plant Electrical System Data Sheet

3 4 5 6 7

Design IP Protection fault level Incomers Fault Level

Double Bus Bar IP-52 31.5 kA for 1 sec SF6 / VCB Breakers 40 kA for 1 sec

single Bus Bar IP-52 31.5 kA for 1 sec SF6 / VCB Breakers 40 kA for 1 sec

Sectionalized single Bus Bar IP-52 50 kA for 1 Sec EDO ACB with microprocessor based releases 50 kA for 1 sec

8 9 10 11 12 13

Max. working height from FFL Min working height from FFL Max. Panel height from FFL

1800mm 700mm 2400mm 220V DC Top for Duct Bottom

1800mm 700mm 2400mm 220V DC Top for Duct/bottom for cable Bottom

1800mm 700mm 2400mm 240V AC,1 Top for Duct/bottom for cable Bottom

Control Supply incomer Cable Entry Outgoing Cable Entry

ELECTRIC MOTORS All motors below 160 kW Motors of 160 kW and above supply DC Motors Exhaust Fan motors kW 415 V, 3 , AC supply 11/6.6/3.3 kV, 3 , AC 220 V, Shunt wound type 240V AC,1 , up to 0.37

Unless otherwise specified, all motors shall be single speed and suitable for direct on line starting. Cables: 11 kV Cables XLPE insulated, stranded, aluminium conductor, FRLS outer sheathed, armoured, extruded PVC inner sheathed cable. XLPE insulated, stranded, aluminium conductor, FRLS outer sheathed, armoured, extruded PVC inner sheathed cable. XLPE insulated, stranded, aluminium conductor,

Page 5

6.6 kV Cables

3.3 kV Cables

Power Plant Electrical System Data Sheet

FRLS outer sheathed, armoured, extruded PVC inner sheathed cable. LT Power Cables PVC insulated, 1100 V, stranded, aluminium conductor, FRLS outer sheathed, armoured, extruded PVC inner sheathed cable. PVC insulated, 1100 V, stranded, tinned copper conductor, armoured, multi core and FRLS insulation cable.

Control Cables

Following minimums size of conductors shall be used: Lighting Cables 2.5 sq mm copper

Control Cables minimum 1.5 sq mm copper For sizing the cables, the following maximum allowable voltage drop in cables shall be considered: Motor feeders at full load (LT Transformer to motor terminal)-5 % Motor feeders during starting 15 % Emergency DG Set: Diesel Generating set (DG set) : 1250 kVA,0.8pf,415V, 3 phase, 50 Hz, 1500rpm

Configuration: .W+..S DC System: Source is of station type, sealed maintenance free (SMF) Plante type battery. Backed up by dedicated 2X100% capacity redundant battery charger. Sized suitably to feed all DC loads. UPS System: Static two stream, double conversion, with auto static bypass switch and dedicated battery with suitable capacity. Plant Lighting: S.No 1 2 3 Description Normal AC lighting Emergency Lighting Critical lighting Supply level 415V 3 4W AC 415V 3 4W AC 220V DC Remarks 100%Total lighting 20% of total lighting 10% of total lighting

ILLUMINATION LEVELS AND CHOICE OF LIGHTING FIXTURES. The area-wise distribution of average illumination levels and type of luminaries shall be as given below:

Page 6

Power Plant Electrical System Data Sheet

S. No. A.

1.

Average illumination Type of fixture level in Lux. GTG, STG Building / Switchgear building Industrial well glass vitreous enamel reflector General (auxiliary integral mounted control 200 Equipment areas) gear / industrial bulk head with integral mounted control gear Area / structure Cable Vault All switchgear room area GTG building operating floor Control room, switchyard relay room Battery rooms AC plant room Unloading and maintenance bay Electrical / Instrument laboratory, chemical laboratory (air conditioned) 200 300 250 500 150 200 250 300 Industrial type with vitreous enamel reflector Industrial type with vitreous enamel reflector Industrial medium bay with anodised aluminium reflector Decorative recessed with wide angle mirror optic anti flare type Corrosion proof Totally enclosed vapour proof with clear acrylic cover Industrial high bay Decorative recessed with wise angle mirror optic anti-glare type

1 x 150 W HPMV lamp 2 x 36 W florescent lamp 2 x 36 W florescent lamp 1 x 250 W HPMV lamp 2 x 36 W FL 2 x 36 W FL 2 x 36 W FL 400 W HPSV lamp 2 x 36 W FL

2. 3. 4. 5. 6. 7. 8. 9.

Page 7

Power Plant Electrical System Data Sheet

S. No. 10 B 1. C 1. 2. D 1. 2. E 1. 2. F 1.

Area / structure Chemical laboratory (non-air conditioned) HRSG Area HRSG area & platforms Transformer area General Near equipment Switchyard Area General Near equipment Various Off-site building Equipment room (all pump house) Outside working areas Road and Yard Lighting Main Roads Secondary Roads Perimeter (compound) lighting Parking area Workshop Building Workshop Building Administration Building Main office areas cabins (air conditioned areas) Main office areas cabins with false ceiling but non-air-conditioned. Canteen and medical center non-airconditioned areas without false ceiling.

Average illumination level in Lux. 250 Grade level200 20 35

Type of fixture Corrosion proof Dust proof / dust tight well glass fixture Flood light medium beam type Dust proof / dust light well glass on fire partition walls. Flood light type Dust proof / dust tight well glass on walls. Industrial type with vitreous enamel reflector up to mounting height of 8 m Or Flood light medium beam Street light with clear acrylic cover cut-off type with integral mounted control gear Street light with clear acrylic cover cut-off type with integral mounted control gear General purpose flood light, high / medium beam flood light Industrial Medium Bay Decorative recessed type with mirror optic reflector Decorative recessed type with mirror optic reflector Decorative with wide angle mirror optic reflector 2 x 36 W FL 70 W HPMV lamp 1 x 150 W HPSV lamp 1 x 70 W HPSV 1 x 150 W HPSV lamp 1 x 100 / 200W GLS Lamp 2 x 36 FL. (T5) 250 W HPMH Lamp 1 x 150 W HPSV 1 x 70 W HPSV 1 x 70 W HPSV 250 W HPMV 2 x 36 W FL 2 x 36 W FL

20 35

250 70

15 10

2.

20

3. G 1. H 1. 2.

50

300 300 300

3.

400

2 x 36 W FL

Page 8

Power Plant Electrical System Data Sheet

S. No.

Area / structure

Average illumination level in Lux.

Type of fixture Industrial type with vitreous enameled reflector / industrial medium bay with anodized aluminium reflector Industrial type with vitreous enamel reflectors / channel mounted box type compact fluorescent lamp Batten Type Industrial well glass with integral mounted control gear / industrial bulk head with integral mounted control gear Industrial type vitreous enameled reflector Industrial bulk head / industrial bulk head with integral mounted control gear Decorative recessed type with cylindrical reflector Industrial bulk head or industrial well glass with reflector

4.

Warehouse.

200

2 x 36 W FL

I 1.

General Corridors, walk-ways, staircase, etc. Lockers, toilets, wash rooms. Etc Building periphery lighting Elevator Elevator machine room Elevator well DC Light Fitting Control room Other areas 1 x 100 W incandescent lamp 1 x 100 W incandescent lamp 100 20 2 x 36 W FL 1 x 100 W incandescent lamp / 1 X 70 W HPSV 150 2 x 36 W FL

2.

100

2 x 36 W FL 1 x 70 W HPSV lamp

3. J 1. 2. K 1. 2.

Plant communication System: 1. Wired intercom telephone system with EAPBX connecting different areas of plant, Admn. Blocks, and colony, and hook up with public utility phone system. 2. Party & Page public address system in the plant area, with master unit and required slave wall mounted units. 3. Wireless Walkie-Talkie system

Page 9

Potrebbero piacerti anche

- Earthing Calculation - Open ElectricalDocumento11 pagineEarthing Calculation - Open ElectricalChihiya Fitria NurhayatiNessuna valutazione finora

- Electrical Thumb Rules You MUST Follow (Part 1) - EEPDocumento4 pagineElectrical Thumb Rules You MUST Follow (Part 1) - EEPAshokkumar ManoharanNessuna valutazione finora

- DG SynchronizationDocumento5 pagineDG SynchronizationParag RekhiNessuna valutazione finora

- BOQ Electrical TrackingDocumento40 pagineBOQ Electrical Trackingfadli.lpgNessuna valutazione finora

- DBR Elec CCPPDocumento29 pagineDBR Elec CCPPParmeshwar Nath TripathiNessuna valutazione finora

- Ne Trail Part FirmDocumento4 pagineNe Trail Part FirmYasmine ياسمينNessuna valutazione finora

- Chapter 1 Det50063 - IntroductionDocumento12 pagineChapter 1 Det50063 - IntroductionFara FaraNessuna valutazione finora

- Key - SLD - R2Documento1 paginaKey - SLD - R2Satya Narayana BandaruNessuna valutazione finora

- LT HT Power Control Cable Schedule-R1-16 05 2013 IrsaDocumento34 pagineLT HT Power Control Cable Schedule-R1-16 05 2013 Irsaerkamlakar2234Nessuna valutazione finora

- UPS Battery SizingDocumento2 pagineUPS Battery SizingAbhijeet Durge100% (1)

- Fault Level CalculationDocumento1 paginaFault Level CalculationparameshvkrNessuna valutazione finora

- Transformer Sizing CalculationDocumento3 pagineTransformer Sizing CalculationvenkateshbitraNessuna valutazione finora

- MV Capacitor SizingDocumento3 pagineMV Capacitor SizingRaja ShannmugamNessuna valutazione finora

- Electrical Thumb Rules You MUST FollowDocumento5 pagineElectrical Thumb Rules You MUST FollowAshwin NarayanNessuna valutazione finora

- 6.6kV CABLE SIZINGDocumento2 pagine6.6kV CABLE SIZINGmahesh_sali2003Nessuna valutazione finora

- VCB PanelsDocumento17 pagineVCB PanelsSenthil Prasadh100% (1)

- Transformer and DG Set SelectionDocumento3 pagineTransformer and DG Set SelectionZIPDASHNessuna valutazione finora

- Earthing CalculationsDocumento8 pagineEarthing CalculationsBalamurugan ArumugamNessuna valutazione finora

- Substation Equipment ListDocumento68 pagineSubstation Equipment ListVimal SinghNessuna valutazione finora

- Offer For Electrical Installation WorkDocumento6 pagineOffer For Electrical Installation Workparveen kumarNessuna valutazione finora

- Sample Load ListDocumento2 pagineSample Load Listshaikhsajid242Nessuna valutazione finora

- CT CalculationDocumento13 pagineCT CalculationMuhammad Ibad AlamNessuna valutazione finora

- Fault Level CalculationDocumento2 pagineFault Level CalculationAkhil GuptaNessuna valutazione finora

- DG CalculationDocumento3 pagineDG Calculationvaithy2011Nessuna valutazione finora

- For 132 KV Line 1Documento16 pagineFor 132 KV Line 1jagriti kumariNessuna valutazione finora

- Lighting SLDDocumento1 paginaLighting SLDParthasarathy SarathyNessuna valutazione finora

- REF Relay CT CalculatiuonDocumento1 paginaREF Relay CT Calculatiuonswagata12345Nessuna valutazione finora

- Earthing Design Report-Ramsons TradersDocumento27 pagineEarthing Design Report-Ramsons TradersAnwesh Kumar MaddikuntaNessuna valutazione finora

- Ac Ups Battery Rack SizesDocumento12 pagineAc Ups Battery Rack Sizescherif yahyaoui100% (1)

- Instalasi Fire Gas Detector System (FGDS) Tanki Floating Roof Refinery Unit Ii DumaiDocumento3 pagineInstalasi Fire Gas Detector System (FGDS) Tanki Floating Roof Refinery Unit Ii DumaiAji Abi-nya FathanNessuna valutazione finora

- KEI Cable CatalogueDocumento114 pagineKEI Cable CatalogueMousum100% (1)

- Earthing Resistance Value: Size of Capacitor For Power Factor CorrectionDocumento17 pagineEarthing Resistance Value: Size of Capacitor For Power Factor Correctiondhruv100% (2)

- UPS Sizing Calculation - EmersonDocumento5 pagineUPS Sizing Calculation - Emersonjugal8252Nessuna valutazione finora

- MCC Bus Bar Sizing CalculationDocumento12 pagineMCC Bus Bar Sizing CalculationdanishNessuna valutazione finora

- Electrical Thumb Rules - (Part 1)Documento4 pagineElectrical Thumb Rules - (Part 1)rajdeep maityNessuna valutazione finora

- Transformer KVA Sizing Calculation - Easy Version PDFDocumento2 pagineTransformer KVA Sizing Calculation - Easy Version PDFmathan_ae100% (1)

- Dry Type Lighting Transformer Deign Basis-Arar-06.11.204Documento9 pagineDry Type Lighting Transformer Deign Basis-Arar-06.11.204srigirisetty208Nessuna valutazione finora

- Electrical Load ScheduleDocumento14 pagineElectrical Load ScheduleAtty AttyNessuna valutazione finora

- Cable Size Calculation For LT & HT Motors - Electrical TechnologyDocumento15 pagineCable Size Calculation For LT & HT Motors - Electrical TechnologySaneesh SJNessuna valutazione finora

- Saudi Electricity Company: Eastern Operating Area Dammam, Saudi ArabiaDocumento9 pagineSaudi Electricity Company: Eastern Operating Area Dammam, Saudi ArabiassNessuna valutazione finora

- Panel Design & Calculate Size of Bus Bar - Electrical Notes & Articles PDFDocumento14 paginePanel Design & Calculate Size of Bus Bar - Electrical Notes & Articles PDFENGMNessuna valutazione finora

- HT Capacitor Sizing-MotorDocumento7 pagineHT Capacitor Sizing-MotorSamarjit Narayan Chowdhury100% (1)

- 480V Bus Duct Sizing For Arar Dated 01.03.2005Documento8 pagine480V Bus Duct Sizing For Arar Dated 01.03.2005srigirisetty208Nessuna valutazione finora

- Abb Switchgear PricelistDocumento360 pagineAbb Switchgear PricelistH.S Engineering worksNessuna valutazione finora

- Cable Sizing DetailsDocumento5 pagineCable Sizing DetailsKalam NagappanNessuna valutazione finora

- Transformer SizingDocumento5 pagineTransformer SizinggktahilianiNessuna valutazione finora

- MOTOR SOFT STARTERS - Air Core ReactorsDocumento3 pagineMOTOR SOFT STARTERS - Air Core Reactorsmv_mallikNessuna valutazione finora

- Short Circuit Current On Secondary Side in KADocumento2 pagineShort Circuit Current On Secondary Side in KANaresh MudaniNessuna valutazione finora

- Sewage Treatment Package Cable Sizing: Project: Ardebil Gas Turbine Power PlantDocumento5 pagineSewage Treatment Package Cable Sizing: Project: Ardebil Gas Turbine Power Plantnourfarmajid0% (1)

- Electrical CalculationDocumento1 paginaElectrical Calculationengrwaqas_11Nessuna valutazione finora

- DG Fault Current & Earth Flat SizingDocumento2 pagineDG Fault Current & Earth Flat SizingPalani100% (1)

- Transformer Size - Voltage Drop Due To Starting of Large Size of Motors (1.1.19)Documento4 pagineTransformer Size - Voltage Drop Due To Starting of Large Size of Motors (1.1.19)Krisna Bayu AriyantoNessuna valutazione finora

- Quotation 11KV 33KV Electrical Equipment NESCL NTPC CS DA 628 DarlipaliDocumento17 pagineQuotation 11KV 33KV Electrical Equipment NESCL NTPC CS DA 628 DarlipaliSharafat AliNessuna valutazione finora

- 199-GST-0101-RevA - Electrical MV LV Transformers SpecificationDocumento14 pagine199-GST-0101-RevA - Electrical MV LV Transformers Specificationdhanny ma100% (1)

- BOQ Cum Price Scedule - Package A - BudhapalDocumento34 pagineBOQ Cum Price Scedule - Package A - BudhapalSanjay GulatiNessuna valutazione finora

- DP16004 YT10 90ZEN 140115 Elec - Power - Cable Sizing Calculation - Rev P1Documento26 pagineDP16004 YT10 90ZEN 140115 Elec - Power - Cable Sizing Calculation - Rev P1rahul.srivastavaNessuna valutazione finora

- Annexure E2 - Electrical Load Details-R3 - (09!09!2011)Documento10 pagineAnnexure E2 - Electrical Load Details-R3 - (09!09!2011)vinesh_viswanathan_3Nessuna valutazione finora

- Selection of Main & Branch CB As Per NEC-210 (14.1.14)Documento16 pagineSelection of Main & Branch CB As Per NEC-210 (14.1.14)casaouis02Nessuna valutazione finora

- Electrical Thumb RuleDocumento3 pagineElectrical Thumb RuleRadhaNessuna valutazione finora

- S.C Calculations: Short Circuit StudyDocumento17 pagineS.C Calculations: Short Circuit StudyAhmedRaafatNessuna valutazione finora

- 6210-A - Low Voltage Motor Control CentreDocumento12 pagine6210-A - Low Voltage Motor Control CentreharmlesdragonNessuna valutazione finora

- 400 KV Swyd FOR DOJDocumento49 pagine400 KV Swyd FOR DOJSam0% (1)

- Cable Video Surveillance HR6ADocumento1 paginaCable Video Surveillance HR6Aelbac08Nessuna valutazione finora

- Faq On Earthing Standards 16/08/2018: EDM# 28984244 (Published) EDM# 23131817 (Word)Documento12 pagineFaq On Earthing Standards 16/08/2018: EDM# 28984244 (Published) EDM# 23131817 (Word)anji201Nessuna valutazione finora

- Ch. 26 Biomedical PhyDocumento16 pagineCh. 26 Biomedical PhyMahmoud Abu MayalehNessuna valutazione finora

- 5 KVA UPS Docs HI REL PDFDocumento53 pagine5 KVA UPS Docs HI REL PDFAbdelwhab ElsaftyNessuna valutazione finora

- PSet3 SolnDocumento4 paginePSet3 SolnMichael DillardNessuna valutazione finora

- Chapter - 10 Controlled RectifiersDocumento16 pagineChapter - 10 Controlled RectifiersmadihaNessuna valutazione finora

- Transmission and Distribution DesignDocumento79 pagineTransmission and Distribution DesignBishnuBahadur ThapaNessuna valutazione finora

- 3rd Ch1 PDFDocumento10 pagine3rd Ch1 PDFBehairy AhmedNessuna valutazione finora

- Chapter 2. Resistive Networks and Analysis Techniques-RevDocumento88 pagineChapter 2. Resistive Networks and Analysis Techniques-RevHoàng HiệpNessuna valutazione finora

- Transient Stability Report For Beneban (Taqa) Report R05Documento125 pagineTransient Stability Report For Beneban (Taqa) Report R05dhananjay_gvit2207100% (1)

- Forces and Moments: A S F B D A D A N SDocumento60 pagineForces and Moments: A S F B D A D A N Sparallax1957Nessuna valutazione finora

- Structural AnalysisDocumento44 pagineStructural AnalysisRashmi Sahoo100% (1)

- High Voltage Cable JointingDocumento7 pagineHigh Voltage Cable Jointingscrapmail9Nessuna valutazione finora

- 29 ML839 Power ElectronicsDocumento2 pagine29 ML839 Power Electronicsjimmy jimenez barriosNessuna valutazione finora

- Technical College / Thi Qar: (Electrical Machines Class) Second YearDocumento4 pagineTechnical College / Thi Qar: (Electrical Machines Class) Second YearReoo AlrikabyNessuna valutazione finora

- RAILINGSDocumento14 pagineRAILINGSIndrawan Muhhammad ZenNessuna valutazione finora

- 3d Printed Noise Canceling TengDocumento8 pagine3d Printed Noise Canceling TengIslam HelazaNessuna valutazione finora

- Computation of Leakage Flux and Magnetic Force in Transformer by Using Field-Circuit Coupled Finite Element MethodDocumento4 pagineComputation of Leakage Flux and Magnetic Force in Transformer by Using Field-Circuit Coupled Finite Element MethodmehdivinciNessuna valutazione finora

- 04-06 Power Semiconductor Diodes and CircuitsDocumento16 pagine04-06 Power Semiconductor Diodes and CircuitsAnas RajputNessuna valutazione finora

- Chap 9Documento25 pagineChap 9api-3702256Nessuna valutazione finora

- Features: 801 H - 1A - C FXXVDCDocumento3 pagineFeatures: 801 H - 1A - C FXXVDCMihaiOvidiuBeleutNessuna valutazione finora

- Generation of High Voltages & CurrentsDocumento46 pagineGeneration of High Voltages & Currentssaikarthick023Nessuna valutazione finora

- Fundamentals of Electric Circuits, Second Edition - Alexander/SadikuDocumento9 pagineFundamentals of Electric Circuits, Second Edition - Alexander/SadikubehnazmbgNessuna valutazione finora

- Charan'S Pre University (Pu) College: (Recognized by The Govt of Karnataka)Documento2 pagineCharan'S Pre University (Pu) College: (Recognized by The Govt of Karnataka)Mr Khiladi786Nessuna valutazione finora

- Sidthilaw Suwat 1997Documento147 pagineSidthilaw Suwat 1997Harsh ShrivNessuna valutazione finora

- Cavity ResonatorDocumento20 pagineCavity ResonatorHarsh KaushalyaNessuna valutazione finora

- Forces and Motion: Speed, Velocity, and Acceleration ANSWER KEY Equations: Speed: Velocity: Acceleration: ForceDocumento2 pagineForces and Motion: Speed, Velocity, and Acceleration ANSWER KEY Equations: Speed: Velocity: Acceleration: ForceArlene Diño AmuraoNessuna valutazione finora