Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Triturador de Entulho Rubble-Master-Rm60

Caricato da

João SantiagoDescrizione originale:

Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Triturador de Entulho Rubble-Master-Rm60

Caricato da

João SantiagoCopyright:

Formati disponibili

1 2

Technical description Applications

Please note that figures are European standard: 1 thousand = 1.000 1 point 3 = 0,3

Content

RM60 the flexible trouble-shooter

RM60 USPs

Throughput 50-80 t/h with only 13 t transport weight 20-30% more daily capacity thanks to high throughput continuity Automatic feeding with 2 speed levels Low loading edge 1.90 m Straightforward handling with remote control Ground-based service Integrated system to deal with blockages (release system optional) Efficient magnetic separator Extremely effective diesel-electric drive concept Low diesel consumption 9 - 12 l/h Cost effective from only 5,000 t/year Attractive, low investment start-up Can be expanded to a complete recycling centre with pre- and post-screening

User profile

For newcomers to recycling Local service providers such as council sites and container/skip services Service provider for local authorities Producers of building materials to recycle production waste such as bricks, tiles and slabs, ready-mixed concrete, concrete parts Secondary crusher

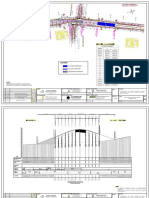

Working position RM60

8050

5750

Maximum working length Maximum working width

8050 mm 2240 mm

Transport position RM60

Maximum transporting length Maximum transporting width without ladder Transporting height without ballustrade and ladder Total weight:

6300 mm 2240 mm 2640 mm 12.000 kg

Transportma 2370

Transportma ohne Gelnde 2750 Transportma mit Gelnde 2920

Technical description

1800

1930

RUBBLE MASTER RM60 - Basic Version

Feed material: all types of building rubble Feed size: edge length up to 500 mm Throughput capacity:50 t / h Final grain: cubic grain - 50 mm Total weight: 12 to Transport system: hook unit on truck Feed hopper: Feed belt: capacity approx. 1 m3 The trough is constructed of solid, reinforced steel. belt width shaft separation belt speed, selectable drive power belt quality 800 mm 3840 mm 0,14 or 0.09 m / s 2,3 / 1,6 kW RIP STOP 500/3 5+2

Technical description

The drive is conveyed through a worm and spur gear with polechanging electric motor. The drive drum is fitted with 8 mm thick rubber with diamond tread. The drum is cambered and lateral guide rollers are fitted to prevent the conveyed material wandering to one side. In the feed area impact strips are fitted instead of support rollers. A belt guide approximately 350 mm high stretches to the crusher inlet. The belt is crimped in order to guarantee optimal transfer into the crusher inlet. Impact crusher: Inlet Impact circle diameter 640 x 550 mm 740 mm

The crusher is armoured with 20 mm thick wear plates in the area of the side walls and with 30 - 40 mm thick wear plates in the area of the rear wall. The impact arm is fitted with 70 mm HARDOX wear plates. The housing is constructed in sections and the rear wall can be swung out hydraulically. The advance of the spring-loaded impact arm occurs mechanically through displacement of the tensioning spindle. The upper suspension point can be adjusted for altering the kinematics of the arm.

Drive:

Deutz diesel engine BF4M 2012E 67 kW at 2000 rpm Electrically operated clutch with hydraulic clutch to assist starting when operating the plant in crushing or generator operation. Synchronous generator, 19 kVA The enclosed generator room contains all the equipment needed to provide the necessary power, and also the power section of the switchgear cabinet. The power unit consisting of diesel engine, air filter and clutch unit is mounted on its own subframe for ease of maintenance. Diesel tank capacity: 180 l

Discharge belt:

moveable into the main outlet frame through a crank gearshaft separation 4000 mm belt width 650 mm belt speed 1,25 m / s drive power 3 kW belt quality 315/2 4+3 lateral stiffening The drive is provided by a drum motor fitted with 8 mm thick rubber with diamond tread. Impact strips are fitted instead of support rollers in the discharge area. The conveyor belt is designed with 80 mm high corrugated edges and 30 mm high transverse cleats. The belt is also sealed against dust emission up to the crusher discharge. A belt tapper is mounted at the head of the belt to ensure that even strongly adhering material is detached. A plough scraper protects the tail pulley. For transportation the discharge belt can also be moved on rollers into the main outlet frame using a hand crank.

Technical description

The rotor is equipped with 4 hammers which can be replaced easily.Two (long) hammers are active during the crushing process while the two other (reactive) hammers have only rotor protective function. The disc construction of the basic rotor body is fastened to the shaft with clamping pieces. Material pockets are located in the discharge area of the crusher which protect the belt construction underneath from direct impact. The drive is transmitted over V-belts. A drum scraper is integrated in the inlet for the feed belt to ensure that adhering material is scraped directly into the inlet of the mill.

Control system:

Technical description

The controller section of the switchgear cabinet is located on the shaft of the discharge belt suspension. Manual selection is possible between two different feed belt speeds so as to adapt to the feed situation. Feeding at both speeds is dependent on the crusher loading. If the crusher is overloaded, the feed belt is switched off and is switched on again as soon as the crusher has regained its nominal speed. If the speed drops below a minimum, the diesel engine is stopped. This prevents overheating of the turboclutch through seizure of the crusher rotor. Engagement and disengagement of the clutch is carried out from the switchgear cabinet by means of a push-button. Throughput: 30 : 70 litres / hour

Dust suppression:

Pressure: 5 : 10 bar Tank volume: 500 litres Dust is kept down by spraying a water mist into the crusher. Pressure and flow rate can be adapted to the dust level.

Permanent- Magnetic Seperator:

Dimensions of permanent magnet: Conveyor belt width: Belt speed: Magnetic conveyor weight: Total weight: Working distance: Tilting frame: Drive unit: 620 x 420 x 240 mm 650 mm 1,2 m/s 400 kg 532 kg approx. 250 mm

manipulation by hydraulic cylinder gear motor 0,75 kW / 400 V, 50 Hz

Technical description

See Job Stories for further applications

Applications

Applications

See Job Stories for further applications

See Job Stories for further applications

Applications

Applications

See Job Stories for further applications

See Job Stories for further applications

Applications

Potrebbero piacerti anche

- Rubbler MasterDocumento12 pagineRubbler MasterbaoyingNessuna valutazione finora

- 1412TP 204 204Documento8 pagine1412TP 204 204Muhammad UmairNessuna valutazione finora

- 623CT Sales Specification NewDocumento19 pagine623CT Sales Specification NewDaniel Alejandro Navarro Jara100% (1)

- Presentation Slide showQJ341 QJ241..ppsxDocumento120 paginePresentation Slide showQJ341 QJ241..ppsxdaniel100% (1)

- Terex Finlay I-110RS Impact Crusher PDFDocumento4 pagineTerex Finlay I-110RS Impact Crusher PDFeaglego00Nessuna valutazione finora

- Sandvik QJ341 Upgrade Presentation PDFDocumento10 pagineSandvik QJ341 Upgrade Presentation PDFAlexander Príncipe RiveraNessuna valutazione finora

- Pegson Maxtrak 1000Documento340 paginePegson Maxtrak 1000Andres Pico GordonNessuna valutazione finora

- Chieftain 2200 3 DeckDocumento1 paginaChieftain 2200 3 DeckSrinivas NandikantiNessuna valutazione finora

- C38 Operating Instructions PDFDocumento71 pagineC38 Operating Instructions PDFAnonymous OfU0JS100% (1)

- Manual Powertrak 750Documento7 pagineManual Powertrak 750JG Ramirez MNessuna valutazione finora

- The Extec C-12: Features and Benefits BookDocumento21 pagineThe Extec C-12: Features and Benefits BookReyna CoaquiraNessuna valutazione finora

- Extec Turbo (Wheeled) Manual enDocumento39 pagineExtec Turbo (Wheeled) Manual enadasrafalskiNessuna valutazione finora

- Premiertrak 400 r400 Crushing Brochure en 2014Documento1 paginaPremiertrak 400 r400 Crushing Brochure en 2014anon_728840059Nessuna valutazione finora

- Extec C12 - Sandvik QJ341 Parts List PDFDocumento4 pagineExtec C12 - Sandvik QJ341 Parts List PDFghitaNessuna valutazione finora

- 1012TSDocumento87 pagine1012TSסטניסלב טלשבסקיNessuna valutazione finora

- Premiertrak 300 & R300 Operations Manual 1.0 (En)Documento17 paginePremiertrak 300 & R300 Operations Manual 1.0 (En)Luis Paladines BravoNessuna valutazione finora

- How To - Replace A Broken Transmitter Using A New Tiger TG-T9-2 TransmitterDocumento11 pagineHow To - Replace A Broken Transmitter Using A New Tiger TG-T9-2 TransmitterWilson RsmNessuna valutazione finora

- RM80 GO!: Start Out and Earn Money With Mobile Rubble RecyclingDocumento8 pagineRM80 GO!: Start Out and Earn Money With Mobile Rubble RecyclingramirovillegasNessuna valutazione finora

- Metrotrak 18 4 05Documento193 pagineMetrotrak 18 4 05PabloMatiasC100% (1)

- O193240v101 01 Screen Redesign Bro Mc110ievo2 GBDocumento23 pagineO193240v101 01 Screen Redesign Bro Mc110ievo2 GBroberth ponceNessuna valutazione finora

- REV 1 Scalper SalesDocumento42 pagineREV 1 Scalper SalesDyego GarciaNessuna valutazione finora

- Hybrid Range Brochure July 2020Documento5 pagineHybrid Range Brochure July 2020Amol SinhaNessuna valutazione finora

- Premiertrak 400X Technical Specification Rev 1 - 01.01.2019Documento24 paginePremiertrak 400X Technical Specification Rev 1 - 01.01.2019Andres AstudilloNessuna valutazione finora

- Set Up Guide Qi430 (1440)Documento35 pagineSet Up Guide Qi430 (1440)Mf Lui100% (2)

- E7 Hydraulic Diagram-ESDocumento2 pagineE7 Hydraulic Diagram-ESCésar A. Chacón100% (1)

- En 01.318 - RM 70go! 2.0 Short Manual Start v1Documento22 pagineEn 01.318 - RM 70go! 2.0 Short Manual Start v1andrew stablesNessuna valutazione finora

- General Spec Sheet Power Crusher PC 1270Documento2 pagineGeneral Spec Sheet Power Crusher PC 1270ion_zloteaNessuna valutazione finora

- Powerscreen 1000 Maxtrak: Cone CrusherDocumento13 paginePowerscreen 1000 Maxtrak: Cone CrusherVanderley AlvesNessuna valutazione finora

- Mobirex MR 130 Z Evo 2: Contractor LineDocumento2 pagineMobirex MR 130 Z Evo 2: Contractor LineMaxNessuna valutazione finora

- Techspec QA140Documento2 pagineTechspec QA140Dyego GarciaNessuna valutazione finora

- Parts Manual: QH440-en-201112 With Caterpillar C13 Tier 3a EngineDocumento116 pagineParts Manual: QH440-en-201112 With Caterpillar C13 Tier 3a EngineLuis ValenciaNessuna valutazione finora

- Ficha Tecnica Chieftain 2100x 3 Deck TrackDocumento9 pagineFicha Tecnica Chieftain 2100x 3 Deck TrackChristian LangleyNessuna valutazione finora

- New 4 Bearing Screenbox Assembly'sDocumento33 pagineNew 4 Bearing Screenbox Assembly'sJorge GalarceNessuna valutazione finora

- Screening Spares Book - Layout 1Documento81 pagineScreening Spares Book - Layout 1eaglego00100% (1)

- C12 SpecDocumento43 pagineC12 SpecJoseNessuna valutazione finora

- Powerscreen 1300 Maxtrak Tech Spec Rev 5-01-01-2013Documento12 paginePowerscreen 1300 Maxtrak Tech Spec Rev 5-01-01-2013baoyingNessuna valutazione finora

- Cone Crushers: C-1540 C-1540RS C-1550Documento8 pagineCone Crushers: C-1540 C-1540RS C-1550brajesh123Nessuna valutazione finora

- Cone Orange GBDocumento8 pagineCone Orange GBr mcleodNessuna valutazione finora

- Chieftain 2200: Subject To Change Without Prior Notice Original Instructions TEREX GB LTD 2012Documento329 pagineChieftain 2200: Subject To Change Without Prior Notice Original Instructions TEREX GB LTD 2012MECANISMO REFACCIONESNessuna valutazione finora

- Catalogo Detallado Qa451Documento37 pagineCatalogo Detallado Qa451JesusFloresRodriguezNessuna valutazione finora

- Bell Jaw Brochure - EnglishDocumento12 pagineBell Jaw Brochure - EnglishChristopherNessuna valutazione finora

- Cobra 230 Tech SpecDocumento28 pagineCobra 230 Tech SpecJP BlancaNessuna valutazione finora

- MR 110 / 130 EVO MaintenanceDocumento8 pagineMR 110 / 130 EVO MaintenanceEdsonLuizPoleselloNessuna valutazione finora

- Core Products Guide 2013Documento26 pagineCore Products Guide 2013Daniel BianchiniNessuna valutazione finora

- Transmision Trituradora TesabDocumento4 pagineTransmision Trituradora Tesabjorge alfonsoNessuna valutazione finora

- C-1540 Spareparts NovyDocumento285 pagineC-1540 Spareparts NovyНиколай МамедовNessuna valutazione finora

- Ucm03 036806Documento4 pagineUcm03 036806Jam PelNessuna valutazione finora

- Sandvik Mobiles: Scalper Key Sales PointsDocumento42 pagineSandvik Mobiles: Scalper Key Sales PointsDyego GarciaNessuna valutazione finora

- 1000 Maxtrak Crushing Brochure en 2014 PDFDocumento1 pagina1000 Maxtrak Crushing Brochure en 2014 PDFEndro SuhadiNessuna valutazione finora

- En 01.251 - RM 70go! 2.0 Short Manual Help v2Documento63 pagineEn 01.251 - RM 70go! 2.0 Short Manual Help v2andrew stablesNessuna valutazione finora

- Terex Finlay 694 Screener Product SpecDocumento6 pagineTerex Finlay 694 Screener Product SpeckamalNessuna valutazione finora

- Part 1 Operations Manual REV 004Documento98 paginePart 1 Operations Manual REV 004James Manuel100% (1)

- 1000SR Brochure 2017 EN PDFDocumento1 pagina1000SR Brochure 2017 EN PDFmarceloaav1Nessuna valutazione finora

- TrioTC51 Instruction Manual 20120920 (SN. 316, 320 - 324, 344)Documento99 pagineTrioTC51 Instruction Manual 20120920 (SN. 316, 320 - 324, 344)Justice Machiwana100% (3)

- QH M-PRO S Operations Manual 04-07Documento46 pagineQH M-PRO S Operations Manual 04-07jesus silva100% (2)

- J-1175 Dual Power Jaw Crusher: SpecificationDocumento8 pagineJ-1175 Dual Power Jaw Crusher: SpecificationAndrey L'vovNessuna valutazione finora

- Bank Valves 1000SRDocumento3 pagineBank Valves 1000SRTaurus LandNessuna valutazione finora

- Compact Recycler Rubble Master RM 80go!: UspsDocumento8 pagineCompact Recycler Rubble Master RM 80go!: UspsramirovillegasNessuna valutazione finora

- Mobile Crusher 900x600Documento7 pagineMobile Crusher 900x600macross086100% (7)

- Farm Machinery - Tractors - A Collection of Articles on the Operation, Mechanics and Maintenance of TractorsDa EverandFarm Machinery - Tractors - A Collection of Articles on the Operation, Mechanics and Maintenance of TractorsNessuna valutazione finora

- 2506A-E15TAG2 ElectropaK PDFDocumento2 pagine2506A-E15TAG2 ElectropaK PDFAulia Okky0% (1)

- Biodosel ProizvodnjaDocumento553 pagineBiodosel Proizvodnjanodi79Nessuna valutazione finora

- Aa1a33 01Documento2 pagineAa1a33 01FelipeNessuna valutazione finora

- Introduction To CompletionsDocumento9 pagineIntroduction To Completionsalex_santiago_6Nessuna valutazione finora

- Speciality Performance Packings PDFDocumento16 pagineSpeciality Performance Packings PDFHEMANTKHERANessuna valutazione finora

- A460 584 36 81 BA OM457-460LA 01-15 GB OnlineDocumento104 pagineA460 584 36 81 BA OM457-460LA 01-15 GB OnlineMed Man50% (2)

- AS 2016 059 - Introduction of Terrano - AMT (Automatic Manual Transmission) PDFDocumento4 pagineAS 2016 059 - Introduction of Terrano - AMT (Automatic Manual Transmission) PDFSeshagiri DeenadayaluNessuna valutazione finora

- Brochure - IWCF Well Intervention 2019 (190110)Documento3 pagineBrochure - IWCF Well Intervention 2019 (190110)Prayoga KurniawanNessuna valutazione finora

- Tecumseh HSK35 HSK40 HSSK50Documento8 pagineTecumseh HSK35 HSK40 HSSK50LUCAPRATNessuna valutazione finora

- Vacuum Pump Service InfoDocumento2 pagineVacuum Pump Service InfoMoaed KanbarNessuna valutazione finora

- 2.1 Pipe Work IdentificationDocumento1 pagina2.1 Pipe Work IdentificationBan Saad Abu HammourNessuna valutazione finora

- ECDocumento1.208 pagineECcatacho7100% (1)

- Instruction Manual Manual de Instrucciones Manuel D'instructionsDocumento14 pagineInstruction Manual Manual de Instrucciones Manuel D'instructionsAdrian HofnărNessuna valutazione finora

- Loki's DMT ExtractionGuide PDFDocumento27 pagineLoki's DMT ExtractionGuide PDFOriginal Peoples100% (1)

- Appendix - 1 Periodicity ERDMP, T4S, IMS PDFDocumento2 pagineAppendix - 1 Periodicity ERDMP, T4S, IMS PDFG V Manikanta - BGLNessuna valutazione finora

- Syaukani Muhammad AliDocumento6 pagineSyaukani Muhammad AlidotcomNessuna valutazione finora

- Marking Scheme Essay Question: Answer Q1Documento5 pagineMarking Scheme Essay Question: Answer Q1jesunathan44@yahoo.comNessuna valutazione finora

- 10 16 2007 Cummins CRS3 3i 2 PDFDocumento18 pagine10 16 2007 Cummins CRS3 3i 2 PDFTimon2005Nessuna valutazione finora

- This Manual Includes: Repair Procedures Fault Codes Electrical and Hydraulic SchematicsDocumento187 pagineThis Manual Includes: Repair Procedures Fault Codes Electrical and Hydraulic Schematicsaa100% (1)

- Pre-Spud Checklist # 4Documento2 paginePre-Spud Checklist # 4Yougchu LuanNessuna valutazione finora

- Legend:-: Puranapool Zoo Park / TadbundDocumento5 pagineLegend:-: Puranapool Zoo Park / TadbundNithyanandhan TranzionNessuna valutazione finora

- Module 8 EnergyDocumento23 pagineModule 8 EnergyJosephus Villear Meano33% (3)

- Caracteristici Tehnice Smart Si YarisDocumento7 pagineCaracteristici Tehnice Smart Si YarisRadu_ISNessuna valutazione finora

- Visar Owners Manual v3 PDFDocumento53 pagineVisar Owners Manual v3 PDFivanNessuna valutazione finora

- KCALCDocumento12 pagineKCALCPaty ParedsNessuna valutazione finora

- 3 03 Small Bore Latest New DevelopmentDocumento36 pagine3 03 Small Bore Latest New DevelopmentCelesNessuna valutazione finora

- Determination of Organic Chloride Content in Crude Oil: Standard Test Methods ForDocumento8 pagineDetermination of Organic Chloride Content in Crude Oil: Standard Test Methods ForJl BorrazNessuna valutazione finora

- Enerpac RRH-Series, Hollow Plunger CylindersDocumento2 pagineEnerpac RRH-Series, Hollow Plunger CylinderstdzeienNessuna valutazione finora

- Ajay Kumar (Iocl)Documento15 pagineAjay Kumar (Iocl)Ajay GuptaNessuna valutazione finora

- Bulletin - 118 - E Audit in Sugar & DistilleryDocumento4 pagineBulletin - 118 - E Audit in Sugar & DistilleryBala MuruganNessuna valutazione finora