Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

US3060165 Toxic Ricin

Caricato da

James LindonCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

US3060165 Toxic Ricin

Caricato da

James LindonCopyright:

Formati disponibili

United States Patent OEce ,, .,.

3,060,865 ,, ,, ,, ,, ,,

2

BRF,PARATICPN OF TOXIC RPCW Hany L. Craig, Chcinnzti, and Otto H. Allderks, Wyoming, Ohio, and Alsoph H. Corwin and Sally H. Dieke, Baltimore, and Charlo$te L. Karel, Siher Spring, Md.,

assignors to the United States of America as represented by the Secretary of the Army Wiled July 3, 1952, Ser. No. 297,142 2 Claims. (621. 260-123.5) This invention relates to the method of preparing toxic ricin. Ricin is a protoplasmic poison prepared from castor beans after the extraction of castor oil therefrom. It is most effective as a poison when injected intravenously or inhaled, the latter requiring extreme comminution and small particle size to be effective. It is believed that the toxic action is catalytic rather than stoichiometric which probably accounts for the high toxicity of the agent. Because of its relative instability, ricin must be handled with extreme care. In neutral aqueous solution it is stable only up to 60"-75' C., and in solid for'm up to 100-llOo C., although for short exposures, temperatures up to 130' may be tolerated. It is sensitive to acids, alkalis and halogen and may also be inactivated by mechanical working such as grinding or pulverizing. These factors are of great importance in developing a satisfactory method for preparing the material. Although ricin has been prepared in crystalline con&tion in the laboratory in small quantities, it becomes necessary, for purposes of toxicological warfare, to prepare relatively large quantities in a high state of purity. This necessitates that as much as possible of the non-toxic material present be removed in the process. In preparing the protein material, the castor beans are first ground and pressed to remove most of the oil. The pressed cake still retains about 15% oil and this may be removed by means of solvents which will extract an additional 150 pounds of oil per ton of beans and reduce the oil retained in the cake to a little over 1%. In the event that the expressing step is supplemented by solvent extraction, it is important to prevent detoxification of the protein during the solvent reinoval step. If residual solvent is removed from the ground beans by blowing with steam, considerable detofication results. Blowing with nitrogen effectively prevents detoxification but is expensive when carried out on a large scale. After the oil has been removed, the pressed cake or pomace is extracted by agitating with water at a p H of 3.8k0.1 at 25" C. which removes substantially all of the toxic protein. The extraction process is operative within a p H range of about 3 to 4.5 although the preferred range is about 3.5 to 4. The optimum operating point is a pH of 3.8e.1, as indicated above. A careful pH control is essential in order that as much non-toxic protein as possible may be eliminated and also that the filtration rate may be held at a satisfactory value. Either HC1 or HzS04may be used to get the desired pH for the extraction water, but HzS04 is preferred due to its lower corrosion rate and ease of handling in concentrated form. The acid should be used in reasonably dilute form to prevent undue local concentrations during its addition. A 5% concentration is satisfactory. Following the extraction, the slurry is filtered using either a conveiltional recessed plate filter or a continuous string discharge vacuum filter. With the latter about 7% of filter aid, based on meal weight, was found necessary for satisfactory filtration. The filtrate from the water extraction step, which contains the ricin, was treated with a 16.7% solution of Na2S04 to precipitate the protein. This solution is com3,6)60,165 posed of 20 pounds of salt in 100 pounds of water and the amount used was such that the sait content equalled 20% of the filtrate weight. This amount and concentration of salt solution was about optimum considering the factors of cost and toxin recovery. Somewhat higher concentrations and larger amounts of solution can be used, however. The precipitation process is not limited to the use of Na2S04, since a saturated solution of NaCl can be used successfully, but Na2S04 solution gives better nitrogen 10 fractionation, more rapid precipitation, and can be operated under wider p H limits. It is desirable to raise the pH to about 7-8 before precipitation as this gives better ecovery and greater non-toxic nitrogen removal. The p H was raised to this value by using NaOH or Na2C03, the 15 latter being preferred. The base used was quite dilute in order to prevent detoxification due to high local concentrations in the solution. A 5% solution of NaOIl was used, whereas with Na2C03a 12% solution was preferred. In general, this higher pH during precipitation gave a 20 greater non-toxic nitrogen fractionation and at the same time maintained the toxin loss at less than 2%. After precipitation, the slurry was filtered using from 1 to 4 % filter aid, based on slurry weight, for satisfactory filtration; the amount of filter aid needed being dependent 25 on the type of press used. Washing the filter cake with Na2S04 solution removed additional non-toxic nitrogen which is desirable. In this washing step a 16.7% sohtion of Na2S04 was again used. This washing step removed an additional 15% of non-toxic nitrogen from the 30 cake. After filtration the filter cake, which contains the ricin in combination with the Na2S04,may be dried and slurried with CCl, to separate the ricin by flotation. Separation of the ricin after a single precipitation and washing step 35 is possible, but it is preferred to carry the process through an additional extraction and precipitation step. This is accomplished by slurrying the filter cake in three times its weight of water and the p H of the slurry is again brought to 3.8k.1 by means of 5% H2S04. The slurry is filtered 40 and a second precipitation is brought about by adding Na2S04solution. Although pH control here is not wholly essential it is advantageous to bring the pH to approximate neutrality by adding 12% NazCO,. A precipitation time of 45 minutes was necessary to obtain complete removal 45 of the toxin. In filtering out the precipitate, no filter aid was used and the filter cake was washed with Na2S04solution on the filter whereby an additional amount of nontoxic nitrogen was removed from the cake. This washing was effective only the first time and repeated washings had little effect in removing further non-toxic nitrogen. The ricin-NazS04precipitate was 'dried at about 50" to 60" C. on a hot air tray dryer. The dried product was ground to pass a 40 mesh screen and agitated with 5 times its weight of CC14, which served the separate the ricin Ii5 from the Na2S04 by flotation. After settling, the ricin was skimmed off the top. This reduced the Na2S04content of the mixture from a previous 40 to 50% down to 15 to 18%. About 1 to 2% of nitrogen remained in the Na2S04 salt which could then be used for subsequent precipitations. The final precipitation produced a particle size of 1-2 mu. On drying the wet cake, however, the ricin cemented together forming larger particles. These could not be broken down to their original size by ordinary grinding 65 methods and since a very fine particle size was necessary in order that the product might be used as a toxic weapon, it was thought desirable to seek some method to prevent the agglomeration or cementing process that took place 70 on drying. T o attempt to affect this result, physical conditions prevailing under the precipitation process were changed.

3,080,166

3

This included changing the temperature of precipitation and the rate of agitation. Other changes included precipitation with ony partial saturation of Na2S04 and the use of wetting and seeding agents. None of these expedients produced any significant improvement in particle size. Ordinary dry ball and hammer milling of the dried ricin produced considerable detoxifiiation perhaps due to the generation of excess heat. The use of CC14 slurry plus the use of low temperature and low moisture content of the ricin reduced detoxification during ball milling. Spray drying proved to be an even better method of securing a reasonably small particle size. Best results were achieved by using a solution havinp about 20% solids, an inlet temperature of 150" C. and an atomizing air pressure of 150 to 180 p.s.i. The particle size secured was 6 to 8 mu. The best means of securing a small particle size was by air grinding. This was carried out in an apparatus having a chamber with conical top and bottom. The material to be ground has been fed into this chamber and is withdrawn from the bottom and forced back into the center of the chamber tangentially through a venturi. Compressed air of about 100 p.s.i. was fed to the venturi to provide the grinding force. The fines are drawn off the top and the Iarge particles settle to the bottom to be recirculated and reground. This process produced particles having a mass median diameter of 2.5 to 3.5 mu.

4

Numerous variations are possible in the several steps of the process commencing with the water extraction and precipitation which may be a single ,or multiple step. Mthough a single extraction step can be used, as indicated 5 before, some process modifications are necessary for its successful operation on a plant scale. Double extraction proved to be quite efficient but additional steps beyond the second extraction step were not found necessary. The drawing is selfdescriptive and shows the various 10 steps of the process described. We claim: 1. I n a method of preparing toxic ricin from castor beans comprising slurrying an expressed castor bean cake with water to remove the water soluble ricin and precipi15 tating the ricin from the filtrate, the further steps which include slurrying the precipitate with CC14 and separating the ricin by flotation. 2. A process in accordance with claim 1 in which the precipitate is dried prior to slurrying.

20

References Cited in the file of this patent Kabat et al.: J. Biol. Chem., vol. 168, 1947, pages 62939. Kunitz et al.: J. Gen. Physiol, vol. 32 (1948), pages 25 25-31.

Oct.

23, 1962

H.

L. CRAIG ETAL

PREPARATION OF TOXIC RICIN

Filed July 3, 1952

Castpr beans

I

)

Expressing

I Cake

I

I

Slurry with water: pH of 3.8 4 01 using 5% HO . S, ,

Wash

I I

a . C Preci~itatewith NGSOA: pH of 7 using 12% N, O

I

Wash filter cake with 16.7% Na.SOA

I

Single extraction

I Extract with water: pH df 3.8I 0.1 using 5% HaSO4 1

I

I

Wash

]

using 12% No&

V

Cake

I Precipitate

)

r Filtrate ] I

with Na,S04

: pH of 7

1 Filter I

I

Optional

Wash filter cake with 16.7% N, O a , S

Settle and skim off Ricin

1

prindNvE;FJToRS

&

Settled N, O a , S reuse

By &

Harry L. Craig 0 H. Alderks . Alsoph H. Corwin Sallv H: Dieke C h p y

ATTORNEY

Potrebbero piacerti anche

- Legal Chemistry: A Guide to the Detection of Poisons, Examination of Tea, Stains, Etc., as Applied to Chemical JurisprudenceDa EverandLegal Chemistry: A Guide to the Detection of Poisons, Examination of Tea, Stains, Etc., as Applied to Chemical JurisprudenceNessuna valutazione finora

- Newer Methods of Preparative Organic Chemistry V3Da EverandNewer Methods of Preparative Organic Chemistry V3Wilhelm FoerstValutazione: 5 su 5 stelle5/5 (1)

- Homemade Cyanid and RicinDocumento7 pagineHomemade Cyanid and Ricinghost100% (1)

- Cyanide and Ricin Homemade PDFDocumento7 pagineCyanide and Ricin Homemade PDFСергей ЯрмолаNessuna valutazione finora

- (Chemistry Drugs Poisons) Homemade Cyanide and RicinDocumento7 pagine(Chemistry Drugs Poisons) Homemade Cyanide and Ricinapi-3699610100% (9)

- Pages From Review of Forensic Medicine and Toxicology (Ussama Maqbool)Documento2 paginePages From Review of Forensic Medicine and Toxicology (Ussama Maqbool)anon_281423826Nessuna valutazione finora

- Ricin The 10 Most Poisonous Common PlantsDocumento2 pagineRicin The 10 Most Poisonous Common Plantspen2trinity3200Nessuna valutazione finora

- Cheap Way To Prepare Betaine Explosives (: Required ChemicalsDocumento4 pagineCheap Way To Prepare Betaine Explosives (: Required Chemicalsasdsa asdsdNessuna valutazione finora

- Psyc1022 Topic 1Documento8 paginePsyc1022 Topic 1PatriciaNessuna valutazione finora

- Understanding The Spice' PhenomenonDocumento34 pagineUnderstanding The Spice' Phenomenonsorandum100% (1)

- Ricin Purification ProtocolDocumento39 pagineRicin Purification Protocolbhavnachawla90100% (1)

- RicinDocumento22 pagineRicinIrina ScutariNessuna valutazione finora

- HMTDDocumento2 pagineHMTDIain Chilliemeister KingNessuna valutazione finora

- Standard Flash, Concussion, Concussion XL, Super Sparkle Silver, Super Sparkle Gold Instructions For Use WARNING! Not For Consumer UseDocumento1 paginaStandard Flash, Concussion, Concussion XL, Super Sparkle Silver, Super Sparkle Gold Instructions For Use WARNING! Not For Consumer UseWayne Lund100% (1)

- RicinDocumento69 pagineRicinAllen WuNessuna valutazione finora

- How To Make An Atomic BombDocumento2 pagineHow To Make An Atomic BombRahul MenonNessuna valutazione finora

- TATPDocumento2 pagineTATPkimkiko100% (3)

- Things That Go BoomDocumento105 pagineThings That Go Boomprwill00100% (1)

- General, Organic, and Improvised Chemistry Page 3 PDFDocumento117 pagineGeneral, Organic, and Improvised Chemistry Page 3 PDFCivil WarNessuna valutazione finora

- Microbial Synthesis of (R) - and (S) - 3,4 Dimethoxyamphetamines Through Stereoselective TransaminationDocumento4 pagineMicrobial Synthesis of (R) - and (S) - 3,4 Dimethoxyamphetamines Through Stereoselective TransaminationChamula K MasNessuna valutazione finora

- 6in White Elephant Pattern ShellDocumento2 pagine6in White Elephant Pattern Shellkrstas774Nessuna valutazione finora

- Terrorist Explosives Handbook Vol. 1 The IRA - Jack McphersonDocumento17 pagineTerrorist Explosives Handbook Vol. 1 The IRA - Jack Mcphersonmanhboanbo50% (2)

- ANFODocumento2 pagineANFOYef PumacayoNessuna valutazione finora

- Towards The Miniaturization of Explosive Technology: University of Illinois, Urbana, IL 61801, USADocumento13 pagineTowards The Miniaturization of Explosive Technology: University of Illinois, Urbana, IL 61801, USAtempest2sNessuna valutazione finora

- Synthesis, Characterization and Thermal Studies of Keto-RDX or K-6Documento11 pagineSynthesis, Characterization and Thermal Studies of Keto-RDX or K-6Puturrú De FuáNessuna valutazione finora

- PHF-89 Plastic ExplosiveDocumento2 paginePHF-89 Plastic ExplosivehorscriNessuna valutazione finora

- Where To Buy GBL Wheelcleaner in ChinaDocumento1 paginaWhere To Buy GBL Wheelcleaner in ChinabuygblcleanersNessuna valutazione finora

- Various PCP SynthesisDocumento8 pagineVarious PCP SynthesisjolouisNessuna valutazione finora

- Alkaloids Papaver SomniferumDocumento5 pagineAlkaloids Papaver SomniferumZipporah MaganteNessuna valutazione finora

- Poisons GuideDocumento2 paginePoisons GuideDavid Roth100% (1)

- RecrystalizationDocumento4 pagineRecrystalizationFransciskasomigoranNessuna valutazione finora

- Pennywise and Pound Foolish by Uncle Fester: Chapter Twenty Five Keeping Oul of TrollbleDocumento5 paginePennywise and Pound Foolish by Uncle Fester: Chapter Twenty Five Keeping Oul of Trollbles rNessuna valutazione finora

- Chlorate Explosives Tenney DavisDocumento9 pagineChlorate Explosives Tenney DavisDoug OlsonNessuna valutazione finora

- How To Make Piranha SolutionDocumento4 pagineHow To Make Piranha Solutionklausegert viilNessuna valutazione finora

- Synthesis of ChloroformDocumento7 pagineSynthesis of Chloroformjiskate77Nessuna valutazione finora

- AnfoDocumento5 pagineAnfoFrancesco Maniscalco100% (1)

- How To Make A Bleach BombDocumento2 pagineHow To Make A Bleach BombJohn Smith100% (3)

- LSD ChemistryDocumento15 pagineLSD ChemistryJose Rafael Cerda CespedesNessuna valutazione finora

- CocainDocumento1 paginaCocainMichael Evripiotis100% (1)

- TNP Synthese23Documento10 pagineTNP Synthese23singhns16100% (1)

- Chemical Profiling of Heroin RecoveredDocumento6 pagineChemical Profiling of Heroin RecoveredColo Volta100% (1)

- BioAP Narayan Amit AIR70Documento254 pagineBioAP Narayan Amit AIR70BijoyBanikNessuna valutazione finora

- Part 1 - Some Boring (?) Chemistry: Y ONE AngerDocumento3 paginePart 1 - Some Boring (?) Chemistry: Y ONE AngerSmokeNessuna valutazione finora

- ExeplosiveDocumento11 pagineExeplosivekamalNessuna valutazione finora

- Steps For The Production of Potassium Chlorate For The Amateur ChemistDocumento18 pagineSteps For The Production of Potassium Chlorate For The Amateur ChemistBitter_Armadillo0% (1)

- BombsDocumento50 pagineBombsJustin TodopoderosoNessuna valutazione finora

- ExplosivesDocumento35 pagineExplosivesChetan SuranaNessuna valutazione finora

- Smoke ScreensDocumento3 pagineSmoke ScreensGaryoNessuna valutazione finora

- Plastique Explosive From BleachDocumento1 paginaPlastique Explosive From Bleachbombvoyarge100% (2)

- Total Synthesis of (+) - MorphineDocumento22 pagineTotal Synthesis of (+) - MorphineJaroslawkaczynskiNessuna valutazione finora

- Nitration of Hydrocarbons and Other Organic CompoundsDa EverandNitration of Hydrocarbons and Other Organic CompoundsNessuna valutazione finora

- Ricin... How To Extract Ricin From Castor Beans.Documento8 pagineRicin... How To Extract Ricin From Castor Beans.SpiceandWood88% (16)

- Slurry With Water PH of 3.8 + O. Using 5% HSODocumento3 pagineSlurry With Water PH of 3.8 + O. Using 5% HSOAna MaravillaNessuna valutazione finora

- Ohh (HNR: Ibane/s55' Mma@Documento3 pagineOhh (HNR: Ibane/s55' Mma@Victor Von DoomNessuna valutazione finora

- 2.0 Production of Primary Metabolites 2.1 Production of Organic Acids 2.1.1 Production of Citric AcidDocumento22 pagine2.0 Production of Primary Metabolites 2.1 Production of Organic Acids 2.1.1 Production of Citric AcidBharathiNessuna valutazione finora

- Astm d4047Documento4 pagineAstm d4047Daniel Chris TanniaNessuna valutazione finora

- A Rapid Method Lipid Blight DyerDocumento7 pagineA Rapid Method Lipid Blight DyerAbel YapoNessuna valutazione finora

- Monday-Afternoon Session.: Associate RefereeDocumento8 pagineMonday-Afternoon Session.: Associate RefereedavidcasNessuna valutazione finora

- Membrane CleaningDocumento5 pagineMembrane CleaningKamal ChokshiNessuna valutazione finora

- US3235583Documento3 pagineUS3235583bang daulayNessuna valutazione finora

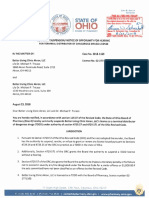

- State Of: Steven W. Schierholt, Esq. Executive Director John R. GaDocumento6 pagineState Of: Steven W. Schierholt, Esq. Executive Director John R. GaJames LindonNessuna valutazione finora

- 10.10.2018 GomezDocumento5 pagine10.10.2018 GomezJames LindonNessuna valutazione finora

- 09.06.2018 StarmanDocumento7 pagine09.06.2018 StarmanJames LindonNessuna valutazione finora

- Anderson ComplaintDocumento15 pagineAnderson ComplaintBasseemNessuna valutazione finora

- 09.14.2018 NgohDocumento9 pagine09.14.2018 NgohJames LindonNessuna valutazione finora

- State Of: PendingDocumento7 pagineState Of: PendingJames LindonNessuna valutazione finora

- 09.06.2018 Pamela ApplegateDocumento6 pagine09.06.2018 Pamela ApplegateJames LindonNessuna valutazione finora

- Sc-,:iegi?5: in The Matter Of: CASE NO. 2016-1909 License No. 02-1339450Documento6 pagineSc-,:iegi?5: in The Matter Of: CASE NO. 2016-1909 License No. 02-1339450James LindonNessuna valutazione finora

- 10.02.2018 MascioDocumento6 pagine10.02.2018 MascioJames LindonNessuna valutazione finora

- 09.26.2018 LottDocumento6 pagine09.26.2018 LottJames LindonNessuna valutazione finora

- James Lindon Attorney, Ph.D. 35104 Saddle Creek Avon, Ohio 44011-4907Documento1 paginaJames Lindon Attorney, Ph.D. 35104 Saddle Creek Avon, Ohio 44011-4907James LindonNessuna valutazione finora

- Attachment Formulary 2500Documento46 pagineAttachment Formulary 2500James LindonNessuna valutazione finora

- Robert Garrity Prison RecordDocumento1 paginaRobert Garrity Prison RecordJames LindonNessuna valutazione finora

- 1.3.18 Ohio Board of Pharmacy Notice of Opportunity For Hearing James LindonDocumento8 pagine1.3.18 Ohio Board of Pharmacy Notice of Opportunity For Hearing James LindonJames LindonNessuna valutazione finora

- 8.23.18 Better Living Clinic AkronDocumento5 pagine8.23.18 Better Living Clinic AkronJames LindonNessuna valutazione finora

- 1.25.18 Ohio Board of Pharmacy Notice of Opportunity For Hearing James LindonDocumento13 pagine1.25.18 Ohio Board of Pharmacy Notice of Opportunity For Hearing James LindonJames LindonNessuna valutazione finora

- LCBA's 79th President, Andrea Kryszak, Takes Over: Summer, 2015 Volume 10, Issue 3Documento21 pagineLCBA's 79th President, Andrea Kryszak, Takes Over: Summer, 2015 Volume 10, Issue 3James LindonNessuna valutazione finora

- Lorain County Government DirectoryDocumento53 pagineLorain County Government DirectoryJames LindonNessuna valutazione finora

- Certification of Micro Entity StatusDocumento2 pagineCertification of Micro Entity StatusJames LindonNessuna valutazione finora

- Trust Bar: User ManualDocumento39 pagineTrust Bar: User Manualpedro neto100% (1)

- 504 WordsDocumento3 pagine504 WordsLaman SultanovaNessuna valutazione finora

- Activity Sheets Typhoon 231212001821 A135c9f9Documento8 pagineActivity Sheets Typhoon 231212001821 A135c9f9Diamond CrsktNessuna valutazione finora

- E. M. Shaw (Auth.), Dr. Peter Smart, Dr. J. Graham Herbertson (Eds.) - Drainage Design-Springer US (1992)Documento312 pagineE. M. Shaw (Auth.), Dr. Peter Smart, Dr. J. Graham Herbertson (Eds.) - Drainage Design-Springer US (1992)Andrés Juárez Sánchez100% (1)

- Geography of Asia Complete MCQ'SDocumento17 pagineGeography of Asia Complete MCQ'SGuruKPO100% (2)

- Refractory Installation Quality Control - Inspection and Testing Monolithic Refractory Linings and MaterialsDocumento6 pagineRefractory Installation Quality Control - Inspection and Testing Monolithic Refractory Linings and MaterialsManikandan M100% (1)

- OzoneDocumento4 pagineOzoneapi-237899555Nessuna valutazione finora

- E6 6B ResultsDocumento4 pagineE6 6B ResultsJeanine Bianca LastinoNessuna valutazione finora

- 03.21 Elvial W59 Si2 enDocumento20 pagine03.21 Elvial W59 Si2 enJovanaNessuna valutazione finora

- American English Five Orange - June 2008Documento50 pagineAmerican English Five Orange - June 2008Carlos Billot AyalaNessuna valutazione finora

- Pre Mi 171Documento143 paginePre Mi 171Andres Arellano100% (1)

- Biomass and BiomesDocumento19 pagineBiomass and BiomesPrince MpofuNessuna valutazione finora

- GondwanaDocumento12 pagineGondwanautkarsh patelNessuna valutazione finora

- Geography Taiga and TundraDocumento19 pagineGeography Taiga and TundraAthvik ChandrasegaranNessuna valutazione finora

- NTS Test MaterialDocumento75 pagineNTS Test MaterialKhalid MehmoodNessuna valutazione finora

- Short Story About The WeatherDocumento1 paginaShort Story About The Weatherzigzagzig40Nessuna valutazione finora

- American Mercury November 1936Documento29 pagineAmerican Mercury November 1936Geraldt GrobbelaarNessuna valutazione finora

- Acidification of Soil and Surface Water ("Acid Rain")Documento9 pagineAcidification of Soil and Surface Water ("Acid Rain")LTE002Nessuna valutazione finora

- Trabajo Inglés Sandra Milena MontoyaDocumento6 pagineTrabajo Inglés Sandra Milena MontoyaSandra Milena MontoyaNessuna valutazione finora

- Science Form 1 Chapter 7Documento10 pagineScience Form 1 Chapter 7Angie Kong Su MeiNessuna valutazione finora

- Weather StationDocumento12 pagineWeather StationheliocoelhojrNessuna valutazione finora

- Bombardier Dash 8 Q400 Ice - and - Rain - Protection PDFDocumento30 pagineBombardier Dash 8 Q400 Ice - and - Rain - Protection PDFSwapnil kapadiaNessuna valutazione finora

- Mort&h PDFDocumento898 pagineMort&h PDFabhibawaNessuna valutazione finora

- Uzupełnij Tłumaczenia.: 4. Okna Wychodziły Do Środka Hotelu, Więc Widzieliśmy Tylko PodwórzeDocumento7 pagineUzupełnij Tłumaczenia.: 4. Okna Wychodziły Do Środka Hotelu, Więc Widzieliśmy Tylko PodwórzeEwa RachwalskaNessuna valutazione finora

- Full Blast Exam 1Documento5 pagineFull Blast Exam 1bigbencollege2930Nessuna valutazione finora

- R/C Soaring Digest - Jun 2010Documento64 pagineR/C Soaring Digest - Jun 2010Aviation/Space History Library0% (1)

- Unit 9. Preserving The Environment: Part I. PhoneticsDocumento6 pagineUnit 9. Preserving The Environment: Part I. PhoneticsTrần HiếuNessuna valutazione finora

- 09 Modulo Siemens Sm50Documento2 pagine09 Modulo Siemens Sm50felipegonzalezmarquezNessuna valutazione finora

- CurtainsDocumento42 pagineCurtainsKaur SimranNessuna valutazione finora

- Weather Forecasting ProjectDocumento17 pagineWeather Forecasting ProjectAditya Bhat88% (8)