Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Latest TS Quanitifier Process Wise

Caricato da

ancientblacksCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Latest TS Quanitifier Process Wise

Caricato da

ancientblacksCopyright:

Formati disponibili

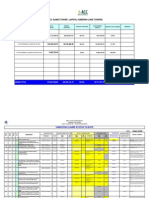

Business Process Quantifier Summary

UOM

Short Term

Long Term

Nov-08

Dec-08

Jan-09

Feb-09

Mar-09

Apr-09

May-09

Jun-09

Jul-09

Aug-09

Sep-09

Oct-09

SFL - AD, Plant - II

01

No. of Abnormalties Identified

Nos.

02

Break Down Trend

Hrs.

60

30

28

26

13

12

15.5

16

12.5

23.75

13.00

10.25

11.00

11.50

03

MTTR

Hrs.

04

Plan Vs Actual

100

100

100

100

100

100

100

100

100

100

100

100

100

100

Hrs.

125

100

175

190

200

280

280

300

320

380

370

360

370

400

100

100

Hrs.

40

60

62

69

45

Lakhs

505

700

506

277

179

Sl. No.

05

Business Process Name

Maintenance

Process Quantifier

No. of Man Hours Spent

100

100

100

100

06

Plan Vs Actual

07

MTBF

08

Growth in Turnover

09

Hours Lost due to Want of Spares

Hrs.

10

10

No. of Time Frequency Changed due to OOC

Occ

No. of Deviations From Plan

Occ

Cost Spent on Calibration

Rs/-

35000

30000

No. of Improvements Projects

Nos.

No. of Times Customer Property Lost /

Damage

Occ

No. of NC's in Contol of Documents

Occ

No. of NC's in Contol of Records

Occ

No of Times Audit Plan Deviated

Occ

NCR's in QMS Audit

Occ

10

100

100

100

100

100

100

11

Calibration Process

12

13

14

15

16

Continual

Improvement

Control of Customer

Property

Control of Document

Control of Records

17

18

Internal Audit

45

48

45

48

52

62

69

69

69

37500

39500

44585

45350

19

Corrective Action Initiated within Stipulated

Time

20

Inhouse Rejection Trend

PPM

14000

10000

1888

1989

1524

1457

3548

16213

21845

12148

14886

14960

16171

16964

21

No. of Repeated Complaints

Occ

22

Warranty Cost

Rs.

7 lacs

5 lacs

9581

24042

132218

87899

89873

354008

607000

650000

486000

158000

83035

478169

Customer Line Rejections

PPM

500

100

1888

1989

30

480

149

353

83

259

353

354

379

250

24

No. of Times NC Products Despatched to

Customer

Occ

25

Layout Inspection & Functional Testing (Plan

Vs Actual)

100

100

100

100

100

100

100

100

100

100

100

100

100

100

26

No. of Customer Complaints

Occ

23

Quality

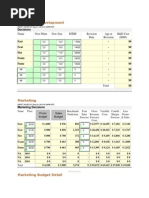

Business Process Quantifier Summary

Nov-08

Dec-08

Jan-09

Feb-09

Mar-09

Apr-09

May-09

Jun-09

Jul-09

Aug-09

Sep-09

Oct-09

28

Long Term

27

Short Term

Sl. No.

UOM

SFL - AD, Plant - II

NCR's in Product Identification & Traceability

Occ

Items Rejected due to Shelf Life Expiry

Occ

Business Process Name

Stores

Process Quantifier

29

Schedule Vs Adherence Trend

100

100

99.76

99.76

99.73

99.64

99.6

99.62

99.64

99.69

99.81

99.82

99.83

99.84

30

Plan Vs Actual

100

100

99.81

99.83

99.85

99.87

99.8

99.81

99.83

99.84

99.85

99.87

99.87

99.89

31

No of Times Line Stoppages at Customer End

Occ

No. of Line Stoppages due to Tooling

Occ

Inhouse Rejection due to Tooling

PPM

3.00

2.00

3.00

1.58

2.24

3.6

2.2

3.4

2.76

10.28

2.17

3.4

3.81

32

33

Production Process

34

COPQ

35

No. of Cust Complaints due to Packing

Occ

36

Premium Freight

Rs/-

37

Plant Level Contribution

Lacs

11

20

17.23

17.24

17.24

No. of Pending Actions in MRM

Occ

No. of Continual Improvements Projects

Nos.

10

3.86

4.35

3.64

4.04

4.21

4.92

4.63

4.37

5.11

4.95

5.09

4.78

No. of Deviation From Plan

Occ

No. of Preventive Actions Initiated

Nos.

43

Inventory Turns

Turns

20

24

15.4

16.05

10.20

10.35

10.75

13.25

15.95

13.75

14.26

15.12

16.00

16.36

44

Premium Freight

Rs/-

Supplier Quality Rating

100

100

46

Receipt Vs Schedule

100

100

99.60

99.62

99.65

99.62

99.62

99.65

99.62

99.59

99.56

99.53

99.62

99.65

47

No. of Line Stoppages (Due to WOM)

Occ

20

10

38

Business Plan & MRM

39

40

41

42

45

48

Measurement System

Analysis

Preventive Action

Procurement Process

Training

49

Gauge R&R Trend

92.58

92.1

Needs identified Vs. training completed

92.84

93.2

As per training calender

No. of Reportable Accidents (Major)

Occ

No. of Non-reportable Accidents (Minor)

Occ

51

Man hour Lost due to Accident

Hrs.

52

Supplier Overall Rating

98

100

91.5

92.05

91.82

92.5

Supplier Quality Rating

100

100

92.58

92.1

92.84

93.2

Supplier Audit Score

100

100

75.9

76.2

76.4

78.8

50

53

54

Safety

Supplier Monitoring

Potrebbero piacerti anche

- Claim ListDocumento52 pagineClaim Listsui1981100% (2)

- 900K Earnings in One Year WSO ReportDocumento14 pagine900K Earnings in One Year WSO ReportlacatrinaentrajineraNessuna valutazione finora

- Vegetron Limited Key Assumptions: Depreciation Rates Current Assets RequirementDocumento29 pagineVegetron Limited Key Assumptions: Depreciation Rates Current Assets RequirementLeo JohnNessuna valutazione finora

- Option Trading Tactics With Oliver Velez PDFDocumento62 pagineOption Trading Tactics With Oliver Velez PDFhansondrew100% (1)

- Welding Consumable Calculation (WCC) : Doc. No Project Client Project Details Technical Requirement ConsumablesDocumento8 pagineWelding Consumable Calculation (WCC) : Doc. No Project Client Project Details Technical Requirement Consumableskeymal9195Nessuna valutazione finora

- HR CompendiumDocumento13 pagineHR CompendiumNeelu Aggrawal100% (1)

- WLB ReportDocumento18 pagineWLB ReportDr-Shefali GargNessuna valutazione finora

- 2 Supplier Registration Form For Direct Material OnlyDocumento11 pagine2 Supplier Registration Form For Direct Material OnlySmitesh VangalwarNessuna valutazione finora

- Project Control Sheet - For Defined Scope of WorkDocumento15 pagineProject Control Sheet - For Defined Scope of WorkMuhammad AmmarNessuna valutazione finora

- Sunwind AB Case StudyDocumento6 pagineSunwind AB Case StudyTanmoy BoseNessuna valutazione finora

- Value Stream Map: Order EntryDocumento4 pagineValue Stream Map: Order EntryMansoor AliNessuna valutazione finora

- CUEGISDocumento2 pagineCUEGISAuryn Astrawita HendroSaputri100% (1)

- 16 SolutionsDocumento10 pagine16 SolutionsFebrie Dharma KuncoroNessuna valutazione finora

- Takt Time: A Guide to the Very Basic Lean CalculationDa EverandTakt Time: A Guide to the Very Basic Lean CalculationValutazione: 5 su 5 stelle5/5 (2)

- Sap Fi-Gl PDFDocumento4 pagineSap Fi-Gl PDFpavan8412Nessuna valutazione finora

- (OM - Group Assignment - Sunwind) (Group No. 3)Documento6 pagine(OM - Group Assignment - Sunwind) (Group No. 3)Sambit Patra100% (2)

- Takt Time - Understanding the Core Principle of Lean Manufacturing: Toyota Production System ConceptsDa EverandTakt Time - Understanding the Core Principle of Lean Manufacturing: Toyota Production System ConceptsValutazione: 5 su 5 stelle5/5 (1)

- Linde Truck Expert Service and Operational Manuals Wiring Diagrams EtcDocumento627 pagineLinde Truck Expert Service and Operational Manuals Wiring Diagrams EtcSoftall Nelu79% (14)

- Module No. 4. Construction Estimates and Value EngineeringDocumento35 pagineModule No. 4. Construction Estimates and Value EngineeringAnghelo AlyenaNessuna valutazione finora

- Cell 1 Cell 2 Cell 3 Cell 4 Cell 5 Cell 5 Cell 5 Cell 6 Cell 7 Cell 9 Cell 10Documento3 pagineCell 1 Cell 2 Cell 3 Cell 4 Cell 5 Cell 5 Cell 5 Cell 6 Cell 7 Cell 9 Cell 10Balachandar SathananthanNessuna valutazione finora

- Oswal Woollen Mills LTD Summer ProjectDocumento54 pagineOswal Woollen Mills LTD Summer ProjectSophia JamesNessuna valutazione finora

- Kingfisher Airlines Balance SheetDocumento11 pagineKingfisher Airlines Balance SheetOmair FazalNessuna valutazione finora

- WeeklyPlan 091213Documento29 pagineWeeklyPlan 091213Juan Carlos Toralva OvalleNessuna valutazione finora

- Erection Programme For 500Mw Boiler - NTPC Korba: Pressure PartsDocumento8 pagineErection Programme For 500Mw Boiler - NTPC Korba: Pressure PartskmbkrisNessuna valutazione finora

- 05 AFz - CILA (Compatibility Mode)Documento20 pagine05 AFz - CILA (Compatibility Mode)adibNessuna valutazione finora

- Project WorkplanDocumento6 pagineProject WorkplanHussein Abdou HassanNessuna valutazione finora

- Assignment 2&3 - Liza DsouzaDocumento67 pagineAssignment 2&3 - Liza DsouzaLiza DsouzaNessuna valutazione finora

- Measurement Sheet For Ag Piping ErectionDocumento16 pagineMeasurement Sheet For Ag Piping ErectionDebashish ChatterjeeNessuna valutazione finora

- Company ReportDocumento20 pagineCompany Report95018045Nessuna valutazione finora

- Chandrapur Super Thermal Power Station: Daily Plant Performance Report StationDocumento14 pagineChandrapur Super Thermal Power Station: Daily Plant Performance Report StationGajanan JagtapNessuna valutazione finora

- FS Lubricants. Oil Analysis ProgramDocumento8 pagineFS Lubricants. Oil Analysis ProgramManoj Kumar SinghNessuna valutazione finora

- Cycle - Time Report FormatDocumento19 pagineCycle - Time Report FormathuokeqiangNessuna valutazione finora

- Taller 2 OEEDocumento4 pagineTaller 2 OEEAnonymous xlp6qlVJ67% (3)

- CIMB Commodities Daily Briefing 20130205Documento6 pagineCIMB Commodities Daily Briefing 20130205r3iherNessuna valutazione finora

- 4Q13 - PresentationDocumento35 pagine4Q13 - PresentationUsiminas_RINessuna valutazione finora

- Komatsu PC1250LC 7 SN 20085 Hand OutDocumento71 pagineKomatsu PC1250LC 7 SN 20085 Hand Outrrverma8080Nessuna valutazione finora

- Report On Cement IndustryDocumento33 pagineReport On Cement Industrykanu vij67% (9)

- Essar SteelDocumento10 pagineEssar Steelchin2dabgarNessuna valutazione finora

- Agency:Sai Shrey Infrastructure (Guj) PVT LTD Bill Wise Details of Fabrication & Erection Quantities From RA01 To RA 06Documento3 pagineAgency:Sai Shrey Infrastructure (Guj) PVT LTD Bill Wise Details of Fabrication & Erection Quantities From RA01 To RA 06vinod_eicsNessuna valutazione finora

- Spare Part Inventory Analysis Report: Normal Distribution-Curve EOQ ModelDocumento1 paginaSpare Part Inventory Analysis Report: Normal Distribution-Curve EOQ ModelRanjan ShankarNessuna valutazione finora

- Reporting: DebtorDocumento15 pagineReporting: DebtorChapter 11 DocketsNessuna valutazione finora

- Value Stream Map: Order EntryDocumento4 pagineValue Stream Map: Order EntryMansoor AliNessuna valutazione finora

- Lead Time - 001Documento18 pagineLead Time - 001Purushothama Nanje GowdaNessuna valutazione finora

- Master Sheet (1) PPT PreparationDocumento47 pagineMaster Sheet (1) PPT PreparationPradeep DeepuNessuna valutazione finora

- Capsim Original DataDocumento6 pagineCapsim Original DataXudong YangNessuna valutazione finora

- Auto Leaf SpringDocumento11 pagineAuto Leaf SpringVijayKrishnaAmaraneniNessuna valutazione finora

- Aditya Aggarwal Metal, Metal Products & Mining Naveen Tanvi Nitin Ganapule 11020841151 Shruti Mehta 11020841110Documento15 pagineAditya Aggarwal Metal, Metal Products & Mining Naveen Tanvi Nitin Ganapule 11020841151 Shruti Mehta 11020841110Nitin R GanapuleNessuna valutazione finora

- Agency: Jps Construction Bill No:Ra 01 Erection BillDocumento9 pagineAgency: Jps Construction Bill No:Ra 01 Erection Billvinod_eicsNessuna valutazione finora

- Goldman Sachs Basic Materials Conference: June 2-4, 2010Documento26 pagineGoldman Sachs Basic Materials Conference: June 2-4, 2010FibriaRINessuna valutazione finora

- Payment Due To Sec, Korea 1998: Exercise - 3Documento2 paginePayment Due To Sec, Korea 1998: Exercise - 3sanjay.diddeeNessuna valutazione finora

- Ex 9Documento2 pagineEx 9k_oonnNessuna valutazione finora

- Lincoln Crowne Engineering Sector Weekly 07032014Documento2 pagineLincoln Crowne Engineering Sector Weekly 07032014Lincoln Crowne & CompanyNessuna valutazione finora

- CH 22Documento5 pagineCH 22ProfNDAcharyaNessuna valutazione finora

- Spare Part Inventory Analysis Report: Normal Distribution-Curve EOQ ModelDocumento1 paginaSpare Part Inventory Analysis Report: Normal Distribution-Curve EOQ ModelRanjan ShankarNessuna valutazione finora

- Cost of Building Cold Storage Cold - StorageDocumento6 pagineCost of Building Cold Storage Cold - StorageChetan AgrawalNessuna valutazione finora

- Agency: Jps Construction Bill No:Ra 01 Erection BillDocumento9 pagineAgency: Jps Construction Bill No:Ra 01 Erection Billvinod_eicsNessuna valutazione finora

- Working Capital Management: TATA SteelDocumento17 pagineWorking Capital Management: TATA SteelSaurabh KhandelwalNessuna valutazione finora

- Project Ginning FactoryDocumento28 pagineProject Ginning FactoryGirish Agarwal0% (1)

- Managing OEE To Optimize Cement Plant Performance.: A Case Study For Cement IndustryDocumento26 pagineManaging OEE To Optimize Cement Plant Performance.: A Case Study For Cement IndustryMohammad QureshiNessuna valutazione finora

- Fundamental Analysis of ACCDocumento10 pagineFundamental Analysis of ACCmandeep_hs7698100% (2)

- Description Project Financing: Total Capital Cost Total Project CostDocumento32 pagineDescription Project Financing: Total Capital Cost Total Project CostMuhammad Umair KhalidNessuna valutazione finora

- Part LastDocumento2 paginePart Lastace_voltasNessuna valutazione finora

- Slab m25Documento1 paginaSlab m25bishu70Nessuna valutazione finora

- TPH 768.8 Silo Balance 8947: Total Coal TonnageDocumento2 pagineTPH 768.8 Silo Balance 8947: Total Coal TonnagegirinandiniNessuna valutazione finora

- 77th Conference on Glass Problems: A Collection of Papers Presented at the 77th Conference on Glass Problems, Greater Columbus Convention Center, Columbus, OH, November 7-9, 2016Da Everand77th Conference on Glass Problems: A Collection of Papers Presented at the 77th Conference on Glass Problems, Greater Columbus Convention Center, Columbus, OH, November 7-9, 2016S. K. SundaramNessuna valutazione finora

- Concepts in Federal Taxation 2016 23Rd Edition Murphy Test Bank Full Chapter PDFDocumento36 pagineConcepts in Federal Taxation 2016 23Rd Edition Murphy Test Bank Full Chapter PDFantonio.letourneau987100% (9)

- Acreaty Ghana Executive SearchDocumento9 pagineAcreaty Ghana Executive SearchEugene EdiforNessuna valutazione finora

- LIC CaseDocumento9 pagineLIC CaseSaurabh SinghNessuna valutazione finora

- DigitalAutoCustomerJourney Bachelorthesis NatalieBacherDocumento168 pagineDigitalAutoCustomerJourney Bachelorthesis NatalieBacherDiegoNessuna valutazione finora

- BRAN Unit 2Documento11 pagineBRAN Unit 2Divya VanwariNessuna valutazione finora

- CTM Tutorial 2Documento4 pagineCTM Tutorial 2crsNessuna valutazione finora

- 3i Sustainabilityreport 2023Documento97 pagine3i Sustainabilityreport 2023Matthieu BlehouanNessuna valutazione finora

- General Terms and Conditions of Purchase of The Jenoptik GroupDocumento4 pagineGeneral Terms and Conditions of Purchase of The Jenoptik GroupAneelNessuna valutazione finora

- Stakeholders and CSR AnswersDocumento4 pagineStakeholders and CSR AnswersPRECIOUSNessuna valutazione finora

- Career Objective For A Fresher EngineerDocumento4 pagineCareer Objective For A Fresher Engineerlisa arifaniaNessuna valutazione finora

- Nachiket Mor Comm ReportDocumento2 pagineNachiket Mor Comm ReportPriya SunderNessuna valutazione finora

- MBA630 Price-Barret Minor Project 1Documento21 pagineMBA630 Price-Barret Minor Project 1sylvia priceNessuna valutazione finora

- AR SKLT 2017 Audit Report PDFDocumento176 pagineAR SKLT 2017 Audit Report PDFAnDhi Lastfresh MuNessuna valutazione finora

- Dissertation On Commercial BanksDocumento4 pagineDissertation On Commercial BanksNeedHelpWithPaperSingapore100% (1)

- Adoption and Application of IFRS in PakistanDocumento7 pagineAdoption and Application of IFRS in PakistanJohn JohnNessuna valutazione finora

- Andy Liang Zhu - 10C Business Summataive CW Cash-Flow and Working CapitalDocumento5 pagineAndy Liang Zhu - 10C Business Summataive CW Cash-Flow and Working CapitalAndy LiangNessuna valutazione finora

- Exempt Sale of Goods Properties and Services NotesDocumento2 pagineExempt Sale of Goods Properties and Services NotesSelene DimlaNessuna valutazione finora

- Role of Entrepreneurship in Economic DevelopmentDocumento8 pagineRole of Entrepreneurship in Economic DevelopmentHimanshu Garg100% (1)

- CCD FailureDocumento5 pagineCCD FailureSajan BhuvadNessuna valutazione finora

- HS 019 Control of RecordsDocumento13 pagineHS 019 Control of RecordsgrantNessuna valutazione finora

- Customer Experience ManagementDocumento25 pagineCustomer Experience Managementtabeth katsandeNessuna valutazione finora

- Adlabs Case StudyDocumento2 pagineAdlabs Case StudyjadeNessuna valutazione finora

- Pyq - Mat112 - Jun 2019Documento5 paginePyq - Mat112 - Jun 2019isya.ceknua05Nessuna valutazione finora