Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Hydraulic Press

Caricato da

Muhammad Iqbal ZahidDescrizione originale:

Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Hydraulic Press

Caricato da

Muhammad Iqbal ZahidCopyright:

Formati disponibili

Hydraulic Press (Gate Type)

Specific Pressure required per cm (or per inch) on product or platen to decide the tonnage of the press Heating Media (Steam or electrical) curing temperature, curing time sequence to decide the method of heating, cycle of operation of the press. Therefore, an expert advice for selection of most appropriate press is utmost important, which you get free from RAVI Engg. that make Ravi Hydraulic Presses the 'Zero Error' Presses.

The Following seven unique features are the outcome of our dedication to design and manufacture totally reliable machinery, which Ravi Hydraulic Presses the 'Zero Error' Press. Our Customers all over the country vouch for this. The more they these presses, the better they think of them. Zero Deflection The rugged design of press frames reduces the deflection of platens to practically zero at full load moulding. Resulting in uniform moulding force over the entire plate surface. One-Piece Cylinder Cylinder are one -piece. No welding or fabricated Cylinders - No Failures Gland Ring With Zero loading Specially designed cylinder assembly assures nearly zero load on gland and studs for accurate and safe working of chevron packers. "gland stud breaking at all." Chevron packing

Well designed, endless Chevron packagings are made out of oil resistant nitrile rubber with accurate lips for positive sealing practically "Zero-leakage" at all pressures. Ram Solid chilled cast iron ram machined, ground and hard chrome plated to give long life to chevron packings. It does not rust in idle periods. Platens Accurately machined with precisely pitched steam or electrical heating channels for absolutely even temperature distribution over the entire surface. Power Pack Single discharged piston pumps. Double discharge "Standard Hydraulic" Power packs for fast closing of press with slow presenting action. Control Panel Standard components of telemachine / L&T make are used. Provided with complete circuit diagram

Hydraulic Press (Pillar Type)

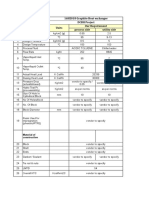

Technical Specifications for Pillar Type Hydraulic Press

Specifications Clamping force Platen Size (mm) Day Light Gap. (mm) RCMP100 RCMP150 RCMP200 RCMP250 RCMP300 RCMP400

100 Tons 150 Tons 200 Tons 250 Tons 300 Tons 400 Tons 400 x 400 400 450 x 450 400 560 x 560 400 610 x 610 450 660 x 660 450 800 x 800 500

Stroke (mm) Piston Dia. (mm) Motor (H.P) Oil Tank Capacity Heating Capacity

400 250 5 HP 350 Ltrs 6 K.W

400 300 7.5 HP 350 Ltrs 8 K.W

400 350 10 HP 400 Ltrs 9 K.W

400 400 12.5 HP 400 Ltrs 10 K.W

400 420 15 HP 450 Ltrs 12 K.W

500 500 25 HP 500 Ltrs 16 K.W

Material Specifications for Pillar Type Hydraulic Press

Pillar Made out of solid EN 8 duly ground & hard chrome plated.

Cylinder Cylinder made by solid EN 8 steel single piece. RAM Platen Chilled cast iron/Class-1 graded cast iron duly ground & hard Platen made out of solid steel with machined surface & drilling to give full serpentine circulation .

Power Pack Cut Consisting the Followings Items

Gear Pump (Polyhedron make) Pre - Fil Value Check Value Pressure Gauge Oil Level Indicator Pressure Switch Breather One No One No One No One No One No One No One No

Electrical Panel Consists of Following Items

Main motor contractor, HRC Fuses, Over load Relays, Connecting strips, AMP meter Volts Meter, Push Button & digital timer Digital temperature Indicator controller or as per your specifications with prevision of Die Ejector / Auto Bumping feature

Hydraulic Press (Pre-Cured Tread Type)

Technical Specifications for Pre-Cured Tread Type Hydraulic Press

Platen Size Structure N. Of Daylight Daylight Gap No. of Ram Type of Press Approach speed Return speed Made of Operation Made of Heating 12" x 12" "C" Frame Type 1/2/3/4/5/6 5" Six Up Stroke 15 mm / Second By Gravity Semi Automatic Steam Heated / Thermic Fluid

Meterial Specifications for Pre-Cured Tread Type Hydraulic Press

Frame Made out of mild steel single piece

Cylinder Cylinder made by solid EN 8 steel single piece RAM Platen Class - 1 graded cast iron duly ground & hard chrome plated Platen made out of solid steel with machined surface & drilling to give full serpentine circulation.

Power Pack Unit Consisting of the followings Items

Motor (ABB / Alstom / Crompton Gear Pump ( Douty make) Gear Plunger Pump (High & Low Pressure) Pre-Fill-Value 10 HP + 3 HP One No One No One No

Check Value Pressure Gauge Oil Level Indicator Pressure Switch Breather

One No One No One No One No One No

(The power Pack complete with all necessary pipes Lines, Drain, Coupling, auto opening system etc.)

Electrical Panel Consists Following Items

Main motor contractor, HRC Fuses, Over load Relays, Connecting strips, Amp meter Volt Meter, Push Bottom & One No. digital timer (99 minutes). 05 No Digital temperature Indicator. The Prices are complete with all Hydraulic & Panel Control Board

CONTACT US

Ravi Engineering Works, New Delhi

Contact Person Address Mr. Sachin Sethi 29/19, Street No. 6, Anand Parbat Industrial Area New Delhi - 110 005 (India) Tel. : +(91)-(11)55489741/55489742/28715517/28717282 Fax : E-mail : +(91)-(11)-25731310/28714369 ravieng@vsnl.com sales@rubbermachineries.com purchase@rubbermachineries.com

Potrebbero piacerti anche

- Hydraulic Baling PressDocumento3 pagineHydraulic Baling Pressajay pandeyNessuna valutazione finora

- General Introduction of Hydraulic PressDocumento2 pagineGeneral Introduction of Hydraulic PressKabil RajNessuna valutazione finora

- Horizontal High Temperature Vacuum Chamber Furnace - Schmetz, PDFDocumento8 pagineHorizontal High Temperature Vacuum Chamber Furnace - Schmetz, PDFEmanuelValenciaHenao100% (1)

- Heater DetailsDocumento35 pagineHeater DetailsPushkar Pandit100% (1)

- Split ACDocumento8 pagineSplit ACGaurav GujarNessuna valutazione finora

- Time Study PresentationDocumento16 pagineTime Study PresentationMubasher RajputNessuna valutazione finora

- Washing Machine Motor ControllerDocumento2 pagineWashing Machine Motor ControllerSuneel Venkat100% (1)

- Developments in Injection Moulding 3Documento331 pagineDevelopments in Injection Moulding 3Salah HammamiNessuna valutazione finora

- Exercise Session 4 and Lab 2: Washing Machine: The Programming TaskDocumento4 pagineExercise Session 4 and Lab 2: Washing Machine: The Programming TaskAtul Pratap Singh0% (1)

- Report of Battery ModelDocumento13 pagineReport of Battery ModelvbvirulkarNessuna valutazione finora

- How To Compute Tonnage Requirements in Hydraulic PressDocumento2 pagineHow To Compute Tonnage Requirements in Hydraulic PressRahul KhoslaNessuna valutazione finora

- Anchor Liquid Line Roto Fill 300Documento4 pagineAnchor Liquid Line Roto Fill 300Ahmet MetinNessuna valutazione finora

- Injection MouldingDocumento12 pagineInjection MouldingFranzMigNessuna valutazione finora

- Hydraulic Pressing of Advanced Ceramics: Process EngineeringDocumento6 pagineHydraulic Pressing of Advanced Ceramics: Process EngineeringSergey ChuchmarevNessuna valutazione finora

- Hydraulic Press MachineDocumento16 pagineHydraulic Press MachineAsdNessuna valutazione finora

- Deep Drawing - ProjectDocumento112 pagineDeep Drawing - ProjectideepujNessuna valutazione finora

- Synopsis Mini Hydraulic PressDocumento4 pagineSynopsis Mini Hydraulic PressRaja Mane0% (2)

- Work StudyDocumento16 pagineWork StudyAkanksha kondaNessuna valutazione finora

- Injection Moulding: Points CoveredDocumento14 pagineInjection Moulding: Points Coveredanilkolekar0% (1)

- Design of A Micro Injection Moulding Machine For Thermosetting Moulding MaterialsDocumento3 pagineDesign of A Micro Injection Moulding Machine For Thermosetting Moulding Materialsregil01Nessuna valutazione finora

- Split Type of Air ConditionerDocumento8 pagineSplit Type of Air ConditionersadNessuna valutazione finora

- 1447734892-Design and Development of Manually Operated Multipurpose Bi-Piston Hydraulic PressDocumento9 pagine1447734892-Design and Development of Manually Operated Multipurpose Bi-Piston Hydraulic PressIrawan MalikNessuna valutazione finora

- Refrigeration and Air Conditioning PDFDocumento43 pagineRefrigeration and Air Conditioning PDFshivNessuna valutazione finora

- LG Refrigerator Repair in HyderabadDocumento22 pagineLG Refrigerator Repair in HyderabaddharaniNessuna valutazione finora

- Washing Machine: Case Study: Embedded SystemDocumento16 pagineWashing Machine: Case Study: Embedded SystemPreetam KarmakarNessuna valutazione finora

- Procedures For Daily Inspection and Testing of Mechanical Power Presses and Press BrakesDocumento16 pagineProcedures For Daily Inspection and Testing of Mechanical Power Presses and Press BrakesjoseluispitaNessuna valutazione finora

- Smed PDFDocumento10 pagineSmed PDFSakline MinarNessuna valutazione finora

- Design of Mechanical Press PDFDocumento8 pagineDesign of Mechanical Press PDFArsl RanaNessuna valutazione finora

- Deep DrawingDocumento2 pagineDeep Drawingalexmonse2014Nessuna valutazione finora

- Arcelor Deep Draw MaterialDocumento7 pagineArcelor Deep Draw MaterialJayDadrassNessuna valutazione finora

- Types of PlasticsDocumento6 pagineTypes of PlasticsFarrukh ShahzadNessuna valutazione finora

- Deep Draw Technology 02Documento40 pagineDeep Draw Technology 02joseprf6180Nessuna valutazione finora

- Chapter 2: Casting Processes: Proses TuanganDocumento76 pagineChapter 2: Casting Processes: Proses TuanganhizanorhudaNessuna valutazione finora

- Omega Injection Moulding MachineDocumento9 pagineOmega Injection Moulding Machinerajpujara50% (2)

- Rubber Injection-MouldingDocumento25 pagineRubber Injection-MouldingRikki MalhotraNessuna valutazione finora

- Deep Drawing Is One of The Most Crucial and Widely Used Practices of Metal Forming. It IsDocumento1 paginaDeep Drawing Is One of The Most Crucial and Widely Used Practices of Metal Forming. It IsgauravNessuna valutazione finora

- Energy Consumption Analysis of ABS Plastic Parts Injected in A Hybrid Injection Moulding MachineDocumento9 pagineEnergy Consumption Analysis of ABS Plastic Parts Injected in A Hybrid Injection Moulding MachineGabriel Lopez BarajasNessuna valutazione finora

- How To Make and Use A Slow-Cooker Temperature ControllerDocumento21 pagineHow To Make and Use A Slow-Cooker Temperature ControllerLaron ClarkNessuna valutazione finora

- Motorized Hydraulic PressDocumento4 pagineMotorized Hydraulic PressDhiraj Shinde100% (2)

- TALAT Lecture 3704: Deep DrawingDocumento15 pagineTALAT Lecture 3704: Deep DrawingCORE MaterialsNessuna valutazione finora

- FIBROTHAL Handbook Heating and Insulation SystemsDocumento44 pagineFIBROTHAL Handbook Heating and Insulation SystemsMuhammad AbrarNessuna valutazione finora

- Work StudyDocumento20 pagineWork Studyjesus784Nessuna valutazione finora

- Chapter 1 Refrigeration CycleDocumento19 pagineChapter 1 Refrigeration CycleMira FazziraNessuna valutazione finora

- Samsung Refrigerator Repair Service Center Borivali in Mumbai MaharashtraDocumento13 pagineSamsung Refrigerator Repair Service Center Borivali in Mumbai MaharashtraAttractive reddyNessuna valutazione finora

- LIT00569 UltraThickTurret PN 2014 RevC Lo-ResDocumento96 pagineLIT00569 UltraThickTurret PN 2014 RevC Lo-ResAntonio AguilarNessuna valutazione finora

- Internship Presentation: By: Fardaan ShariffDocumento22 pagineInternship Presentation: By: Fardaan ShariffMohammed imran100% (1)

- Global Academy of Technology: (Accredited by Naac With "A" Grade)Documento37 pagineGlobal Academy of Technology: (Accredited by Naac With "A" Grade)James Prajwal PrajuNessuna valutazione finora

- Isostatic PressingDocumento4 pagineIsostatic PressingBelma HasanovicNessuna valutazione finora

- NPTEL - Vacuum TechnologyDocumento38 pagineNPTEL - Vacuum Technologyавдей александрNessuna valutazione finora

- Amada Thick Turret Forming ToolingDocumento20 pagineAmada Thick Turret Forming ToolingAFAB Machinery and Tools LtdNessuna valutazione finora

- Refrigeration Cycle: COP Q W COP Q WDocumento8 pagineRefrigeration Cycle: COP Q W COP Q WZain Ul AbideenNessuna valutazione finora

- Silicon Nitride CeramicDocumento43 pagineSilicon Nitride CeramicSukmaSuciNessuna valutazione finora

- Modelling Strech Blow Moulding For ContainersDocumento20 pagineModelling Strech Blow Moulding For ContainerscentroNessuna valutazione finora

- Technical Specifications For Mechanical Power Press 30T CapDocumento4 pagineTechnical Specifications For Mechanical Power Press 30T Capshanjuneo17Nessuna valutazione finora

- Plastic ProcessesDocumento27 paginePlastic Processesnitouch3564Nessuna valutazione finora

- Hot Wire Anemometer (Thermal Method)Documento3 pagineHot Wire Anemometer (Thermal Method)mukesh kumarNessuna valutazione finora

- To Study The Operation of Hydraulic Press: ObjectiveDocumento3 pagineTo Study The Operation of Hydraulic Press: ObjectiveMuhammad Abdullah ButtNessuna valutazione finora

- KSB Centrifugal PumpsDocumento12 pagineKSB Centrifugal Pumpswoodywheel100% (1)

- Donny’S Unauthorized Technical Guide to Harley-Davidson, 1936 to Present: Volume Iv: Performancing the EvolutionDa EverandDonny’S Unauthorized Technical Guide to Harley-Davidson, 1936 to Present: Volume Iv: Performancing the EvolutionValutazione: 4 su 5 stelle4/5 (1)

- Fluid Mechanics Study MaterialDocumento48 pagineFluid Mechanics Study MaterialKumar ShashwatNessuna valutazione finora

- DC ServoDocumento17 pagineDC ServoMuhammad Iqbal ZahidNessuna valutazione finora

- 7.8 Cutting Tool Materials CompleteDocumento15 pagine7.8 Cutting Tool Materials CompleteNikhil Batham67% (6)

- Reynolds TheoremDocumento2 pagineReynolds Theoremanon_612408770Nessuna valutazione finora

- MPU-6000 and MPU-6050 DatasheetDocumento54 pagineMPU-6000 and MPU-6050 DatasheetBobby MotwaniNessuna valutazione finora

- Ds Usb 1208fsDocumento5 pagineDs Usb 1208fsMuhammad Iqbal ZahidNessuna valutazione finora

- ADXL001Documento17 pagineADXL001Muhammad Iqbal ZahidNessuna valutazione finora

- Small, Low Power, 3-Axis 3 G Accelerometer ADXL335: Features General DescriptionDocumento16 pagineSmall, Low Power, 3-Axis 3 G Accelerometer ADXL335: Features General DescriptionGirish Kumar .R. GowdaNessuna valutazione finora

- ADXL001Documento17 pagineADXL001Muhammad Iqbal ZahidNessuna valutazione finora

- Dimensions Common MistakesDocumento19 pagineDimensions Common MistakesMuhammad Iqbal ZahidNessuna valutazione finora

- Holy Quran-Urdu-King Fahad Printing Press SaudiDocumento1.777 pagineHoly Quran-Urdu-King Fahad Printing Press SaudiYasir Khan100% (5)

- Intro To Sheet Metal Forming ProcessesDocumento47 pagineIntro To Sheet Metal Forming ProcessesThutchai PhoNessuna valutazione finora

- CAD/CAMDocumento13 pagineCAD/CAMMuhammad Iqbal ZahidNessuna valutazione finora

- Performance CH 33Documento54 paginePerformance CH 33Yasichalew sefinehNessuna valutazione finora

- 1762 Um002 - en PDocumento144 pagine1762 Um002 - en PDavid LucioNessuna valutazione finora

- Sairam OopsDocumento103 pagineSairam OopsRakshit AshNessuna valutazione finora

- Ricardo R4105ZD-61kW Genset Spec SheetDocumento2 pagineRicardo R4105ZD-61kW Genset Spec SheetRonald Booc100% (3)

- ABB REL5xx RIOConverterDocumento10 pagineABB REL5xx RIOConverterzinab90100% (1)

- User Manual SteadyControlDocumento57 pagineUser Manual SteadyControlrobiny100% (2)

- Chapter 1 AnswersDocumento3 pagineChapter 1 Answersdeerhntr22Nessuna valutazione finora

- Anern Integrated Solar Garden Light-201604Documento1 paginaAnern Integrated Solar Garden Light-201604Godofredo VillenaNessuna valutazione finora

- 1-Introduction To Process ControlDocumento30 pagine1-Introduction To Process ControlRazif Metta100% (4)

- D20S-7 Sb1159e01 PDFDocumento678 pagineD20S-7 Sb1159e01 PDFGORDNessuna valutazione finora

- Blue Brain-The Future TechnologyDocumento27 pagineBlue Brain-The Future TechnologyZuber MdNessuna valutazione finora

- Cilindros Hid. CK ATOSDocumento8 pagineCilindros Hid. CK ATOSAntonio LopesNessuna valutazione finora

- LTS 3000 SpecificationDocumento4 pagineLTS 3000 SpecificationMuhammad Nabil RoslanNessuna valutazione finora

- Electrical Power Systems Wadhwa 15Documento1 paginaElectrical Power Systems Wadhwa 15ragupaNessuna valutazione finora

- 8098 Spare Parts ListDocumento29 pagine8098 Spare Parts ListJuan Gomez67% (3)

- Director Talent Acquisition HR in Fargo ND Resume Tom FennellDocumento2 pagineDirector Talent Acquisition HR in Fargo ND Resume Tom FennellTomFennellNessuna valutazione finora

- Hydraulic Vehicle Lift ST List of Parts and Appendices Stertil B.V BDocumento24 pagineHydraulic Vehicle Lift ST List of Parts and Appendices Stertil B.V BOvidiu PopaNessuna valutazione finora

- 16HE018 Graphite Heat Exchanger DCBH Project Sr. No. Particulars Units Our Requirement Process Side Utility SideDocumento2 pagine16HE018 Graphite Heat Exchanger DCBH Project Sr. No. Particulars Units Our Requirement Process Side Utility SideBhaumik BhuvaNessuna valutazione finora

- Tank Specification - Fiberglass Tanks 0408Documento13 pagineTank Specification - Fiberglass Tanks 0408shankarkl100% (2)

- Fireplace ManualDocumento40 pagineFireplace Manualresistancebeta6Nessuna valutazione finora

- Novel PWM Inverter Strategy For A Inverter Open End Winding Induction MotorDocumento7 pagineNovel PWM Inverter Strategy For A Inverter Open End Winding Induction MotorGanesh ChallaNessuna valutazione finora

- Manual Safety Relays 3SK2 en-USDocumento352 pagineManual Safety Relays 3SK2 en-USKarina Ospina100% (3)

- MagnetostictiveDocumento17 pagineMagnetostictivekanikasharma22Nessuna valutazione finora

- Aj 245 LTDocumento1 paginaAj 245 LTHernan B.Nessuna valutazione finora

- Unit Standards and Competencies Diagram: Performance StandardDocumento11 pagineUnit Standards and Competencies Diagram: Performance Standarddanica baguiNessuna valutazione finora

- Oracle Linux 6 InstallationDocumento35 pagineOracle Linux 6 InstallationendaleNessuna valutazione finora

- Emd-Mi928 Sistema de LubricacionDocumento6 pagineEmd-Mi928 Sistema de LubricacionVictor Raul Tobosque Muñoz100% (1)

- Power GenerationDocumento34 paginePower GenerationTaufiq AkbarNessuna valutazione finora

- 29-Horizontal Subsea Xmas Tree enDocumento2 pagine29-Horizontal Subsea Xmas Tree encarthik_rajaNessuna valutazione finora

- Koel Engine, Ha Operation and Maintenance Manual (Ha - SR)Documento89 pagineKoel Engine, Ha Operation and Maintenance Manual (Ha - SR)Karthik K Raja75% (12)