Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Characterization and Demulsification

Caricato da

Alexandra OrtizDescrizione originale:

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Characterization and Demulsification

Caricato da

Alexandra OrtizCopyright:

Formati disponibili

Journal of Colloid and Interface Science 277 (2004) 464470 www.elsevier.

com/locate/jcis

Characterization and demulsication of poly(ethylene oxide)blockpoly(propylene oxide)blockpoly(ethylene oxide) copolymers

Zhiqing Zhang, G.Y. Xu , F. Wang, S.L. Dong, Y.M. Li

Key Laboratory of Colloid and Interface Chemistry (Shandong University), Ministry of Education, Jinan 250100, Peoples Republic of China Received 7 February 2004; accepted 22 April 2004 Available online 28 May 2004

Abstract Four poly(ethylene oxide)blockpoly(propylene oxide)blockpoly(ethylene oxide) copolymers with different molecular weights and PPO/PEO composition ratios were synthesized. The characterization of the PEOPPOPEO triblock copolymers was studied by surface tension measurement, UVvis spectra, and surface pressure method. These results clearly showed that the CMC of PEOPPOPEO was not a certain value but a concentration range, in contrast to classical surfactant, and two breaks around CMC were reected in both surface tension isotherm curves and UVvis absorption spectra. The range of CMC became wider with increasing PPO/PEO composition ratio. Surface pressure A curves revealed that the amphiphilic triblock copolymer PEOPPOPEO molecule was exible at the air/water interface. We found that the minimum area per molecule at the air/water interface increased with the proportion of PEO chains. The copolymers with the same mass fractions of PEO had similar slopes in the isotherm of the A curve. From the demulsication experiments a conclusion had been drawn that the dehydration speed increased with decreased content of PEO, but the nal dehydration rate of four demulsiers was approximate. We determined that the coalescence of water drops resulted in the breaking of crude oil emulsions from the micrograph. 2004 Published by Elsevier Inc.

Keywords: Surface tension; UVvis; Surface pressure; Crude oil emulsions; Demulsication

1. Introduction Amphiphilic block copolymers, which contain hydrophilic poly(ethylene oxide) (PEO) and hydrophobic poly(propylene oxide) (PPO) blocks, are commercially available and widely used [1,2]. These macromolecular surface-active agents can form normal micelles, reverse micelles, monolayers, star-like structures, and liquid crystals in aqueous solutions [38]. Variation of the molecular characteristics (PPO/PEO composition ratio, molecular weight) of the copolymer during the synthesis allows the production of molecules with optimum properties that meet the specic requirements of different applications. As a result, PEO PPOPEO block copolymers nd widespread industrial applications in detergency, dispersion stabilization, foaming, lubrication, demulsication, etc.

* Corresponding author. Fax: +86-531-8564750.

E-mail address: xuguiying@sdu.edu.cn (G.Y. Xu). 0021-9797/$ see front matter 2004 Published by Elsevier Inc. doi:10.1016/j.jcis.2004.04.035

Several aspects of the structural and dynamic properties of micelles of the PEOPPOPEO block copolymers have been investigated by a variety of experimental methods including surface tension [9], uorescence [10,11], UVvis absorption of selected probes [5,12,13], and small-angle X-ray scattering (SAXS) [14,15]. Interfacial properties and aggregation behaviors of PEOPPOPEO aqueous solutions, including the surface tension, critical micelle concentration, and aggregation conformation, often play a central role in determining and controlling copolymer performance in many practical applications. The emulsication of crude oil and brine/water is a common problem in the oileld industry that is most frequently resolved through the use of chemical demulsier additives. Water-in-crude-oil emulsions are formed during the production of crude oil, which is often accompanied with water. The emulsions have stability ranging from a few minutes to years, depending upon the nature of crude oil and the extent of water. Natural surfactants such as as-

Z. Zhang et al. / Journal of Colloid and Interface Science 277 (2004) 464470

465

phaltenes, resins, carboxylic acids, and solids such as clay and waxes stabilize these emulsions. It is essential to break these emulsions before transportation through pipelines and prior to rening [1619]. Commercial demulsiers are polymeric surfactants such as copolymers of polyoxyethylene and polypropylene or alkylphenolformaldehyde resins or blends of different surface-active substances. PEOPPO PEO block copolymers can be used as demulsiers. These demulsiers are surface-active agents and develop high surface pressures at crude oil/water interfaces. This results in replacement of rigid lms of natural crude oil surfactants by a lm which is conducive to coalescence of water droplets. The efciency with which a surfactant acts as a demulsier depends on many factors related to the structure of the surfactant. Such factors include the distribution of the demulsier throughout the bulk volume of the emulsion, the partitioning of the demulsier between the phases, and the temperature, pH, and salt content of the aqueous phase. Other factors of importance are the mode of injection of the demulsier, the concentration of the demulsier, the type of solvent carrier, the amount of water in the emulsion, and the age of the emulsion [20,21]. The main purpose of this present work is to study the character and demulsication of poly(ethylene oxide) blockpoly(propylene oxide)blockpoly(ethylene oxide) copolymers, setting up the relationship between the molecular structure of PEOPPOPEO and the demulsication of crude oil emulsions. In order to achieve this purpose, four triblock copolymers were synthesized. We found that there are signicant effects of the molecular structure, including molecular weight and PPO/PEO composition ratio, on the characterization and demulsication. These results are very important for the applications of the PEOPPOPEO block copolymers.

2. Experimental 2.1. Synthesis of triblock copolymer Four triblock copolymers, BP74, BP73, BP64, and BP63, were synthesized through anion polymerization with different proportions of propylene oxide and ethylene oxide, and trimethylene glycol was used as an initiator in the presence of potassium hydroxide (see Scheme 1). The reactions were carried out at temperatures from 120 to 140 C and a pressure of 0.3 MPa in a pressure kettle with an agitator. Their structural descriptions are presented in Table 1. Molecular weight was measured by end group analysis and the content of PEO was validated by 2 H NMR quantitative analysis. Triblock copolymers (BP74, BP73) and (BP64, BP63) have the same size PPO block and decreasing size PEO blocks, respectively, whereas (BP74, BP64) and (BP73, BP63) have the same content of PEO and PPO/PEO weight ratio, respectively. 2.2. Cloud points Cloud points of 1% PEOPPOPEO solutions were determined visually by testing the temperature at which turbidity was observed. We also noted the temperature at which turbidity disappeared on cooling. The average of the three results was taken as the cloud point of the system. 2.3. Surface tension measurements The surface tension was measured at 25.0 C using the Wilhelmy plate method with a K12 processor tensiometer (Switzerland, Krss Co.; the precise degree of measurement is 0.01 mN m1 ).

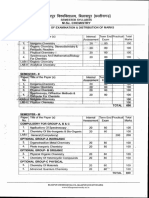

Scheme 1. Synthesis of the PEOPPOPEO triblock copolymers. Table 1 Triblock copolymers structural information PEOPPOPEO BP74 BP73 BP64 BP63 MW a 6960 5960 5800 4970 NPPO 72 72 60 60 NPEO b 32 20 26 17 PEO wt% 40 30 40 30 Compositionc (EO)32 (PO)72 (EO)32 (EO)20 (PO)72 (EO)20 (EO)26 (PO)60 (EO)26 (EO)17 (PO)60 (EO)17 Cloud point ( C) 16.2 11.2 20.6 13.5

a Measured by end group analysis. b Number of PEO monomers in each of the two hydrophilic chains. c Calculated according to the amount of adding monomer.

466

Z. Zhang et al. / Journal of Colloid and Interface Science 277 (2004) 464470

2.4. UVvis experiment The solubilization of I2 /I in the PEOPPOPEO micelles was studied by UVvis spectroscopy. The UVvis spectra of the solution were monitored at wavelengths from 200 to 800 nm at a scan rate of 300 nm min1 . All samples were recorded at room temperature using a Hitachi U-4100 UVvis spectrophotometer (resolution 0.1 nm) after baseline correction. 2.5. Surface pressure The surface pressure was determined on an NIMA 601 monolayer balance (MLB, NIMA Co., UK). The chloroform was used as a spreading agent with a concentration of 0.05 g l1 . A 20-l solution was spread on the subphase (water) in the LB trough slowly and uniformly with the syringe, and the chloroform was allowed to evaporate for 30 min. After the stabilization of the initial surface pressure, the monolayer was compressed and the A isotherm was recorded. 2.6. Demulsication of emulsion and demulsier effectiveness The emulsions were prepared by mixing water and crude oil (from the Shengli oileld) in HT-II homogenizer. In all the emulsions the water/oil ratio was 1:1. The speed was ca. 1200 rpm for 5 min. Demulsication was studied at 50 C and 100 mg l1 doses of the demulsiers. Water separation was recorded after various intervals of time, till 3 h.

becomes wider with decreasing content of PEO. The wide molecular-weight distribution of the copolymers studied and the presence of hydrophobic impurities have been singled out in the past as possible factors that caused differences in the CMC values obtained by surface tension methods. This behavior was attributed to the replacement of highly surfaceactive, short-PEO-chain-length molecules (contributing to a low surface tension value) on the interface by the major component, when these highly surface-active molecules were solubilized in micelles formed by the major component. At low concentrations the surface tension decreased with increasing concentration for all copolymers, in accord with the Gibbs adsorption isotherm. A change in slope was observed in the surface tension curve at a characteristic copolymer concentration, after which the surface tension values continued to decrease until a plateau was reached. The twobreaks behavior was observed in the surface tension vs log concentration plots for all four copolymers studied, as shown in Fig. 1. 3.2. UVvis results UVvis spectra of I2 /I treated with different concentration PEOPPOPEO solutions are presented in Fig. 2. In solutions there exists the reaction I2 + I I ; I has two 3 3 absorption peaks at 288 and 350 nm [12,24]. As the copolymer concentration increases, the absorption band shifts to longer wavelengths, and at C > CMC the band intensity begins to increase. The max value is 350 nm in the initial state and red-shifted with concentrations C > CMC, which indicates that micelles are formed. The increased intensity arises from the fact that I2 is gradually dissolved in PEOPPO PEO micelles with higher concentration, when 2I I2 occurred and more I emerged because of I2 + I I . 3 3 For BP74 and BP64 treated at low concentrations (C < 10 mg l1 ), the spectral curves were fully recovered, but for C > 10 mg l1 the spectral shape returns with increased intensity, whereas the peak intensity of BP73 and BP63 increased when C > 3 mg l1 . In this concentration, micelles are formed. The result is in accordance with the surface tension measurement. Fig. 3 shows that the UVvis absorption at 350 nm has two breaks with increasing concentration. Meanwhile, we observed a peculiar phenomenon from the curve; the second break of BP74 and BP64 absorbance is increasing with the concentration, but BP73 and BP63 are reduced. This difference could be attributed to the difference in the structure and conformation of the copolymer. BP73 and BP63 are more hydrophobic, and the cloud points are lower than those of BP74 and BP64, so the turbidity conceals the absorbance of I , and the absorbance intensity is decreased. 3 3.3. Surface pressure A curve is an important reection to demonstrate the physiochemical properties of the monolayer [2527]. The

3. Results and discussion 3.1. Surface activity A parameter of great fundamental value is the critical micellization concentration, CMC, the copolymers concentration at which micelles start forming. The micellization of block copolymers is inherently more complex than that of conventional, low-molecular-weight surfactant. The CMC of conventional surfactants is a constant at a certain temperature, while block copolymers have a wide CMC range in the surface tension isotherm. A large difference is often noted between the CMC values determined by difference methods because their sensitivity to the quantity of monomers present in solution may vary. Furthermore, composition polydispersity, batch variations, differences in the concentration ranges covered in CMC experiments, or the lack of sufcient temperature control may be responsible for the observed variations [22,23]. We determine the surface tensions of aqueous solutions of PEOPPOPEO copolymers over the range 0.1 10,000 mg l1 . From Fig. 1 we can see the CMC range of BP74 and BP64 is from 10 to 80 mg l1 , while BP73 and BP63 are about from 3 to 100 mg l1 . The range of CMC

Z. Zhang et al. / Journal of Colloid and Interface Science 277 (2004) 464470

467

Fig. 1. The surface tension isotherms of four PEOPPOPEO copolymers.

Fig. 2. UVvis spectra of four PEOPPOPEO copolymers at different concentrations.

468

Z. Zhang et al. / Journal of Colloid and Interface Science 277 (2004) 464470

areas per molecule is BP63 < BP73 < BP64 < BP74. The copolymers with the same mass fractions of PEO have similar slopes, as can be seen in the isotherm of the A curve. On bases of the same content of PEO, the minimum area per molecule increases with the molecular weight of the PEO PPOPEO copolymers. When the hydrophobic fraction PPO is uniform, the increasing PEO proportion results in the extension of the molecular conguration, so the area occupied by PEOPPOPEO molecules is increasing. It is evident that the PEO chain play an important role on the air/water interface and can contribute to the molecular area. 3.4. Demulsication A stable emulsion exists only when emulsifying agents are present. Elimination, alteration, or neutralization of the emulsifying agents will allow immiscible liquids to separate. Addition of suitable chemicals with demulsifying properties specic to the crude oil to be treated will generally provide quick, cost-effective, and exible resolution of emulsions. Success of chemical demulsifying methods is dependent upon the following: (1) An adequate quantity of a properly selected chemical must enter the emulsion. (2) Thorough mixing of the chemical in the emulsion must occur. (3) Adequate heat may be required to facilitate or fully resolve an emulsion. (4) Sufcient residence time in vessels must exist to permit settling of demulsied water droplets.

Fig. 4. The A curve for monomers of four PEOPPOPEO copolymers at 25 C.

Fig. 3. UVvis evolution of the absorbance at 350 nm as a function of copolymer concentration.

amphiphilic copolymers that are used as lm-forming materials can spread and disperse on the water surface and form a stable monomolecular lm only if the interaction between the phase surface and polymer is large than the cohesion of polymers themselves. The A curve of PEOPPOPEO at gas/liquid interface is shown in Fig. 4. Isotherms for each of the PEOPPOPEO copolymers are qualitatively alike. At low pressure the PEO PPOPEO molecules adsorb on the air/water interface in an extended conguration. With increasing pressure, a change in conguration occurs and the copolymer monolayer becomes more compact. On water surface the polymers spread due to the PEO chains, but can easily give rise to aggregates forming, upon compression, a continuous sticky lm, which is difcult to transfer onto solid substrate. The minimum areas per molecule at the air/aqueous solutions interface can be obtained from the A curve by making tangent of linear part of curve. From the intercept of the -axis the minimum areas per molecule of BP74, BP73, BP64, BP63 are about 0.55, 0.43, 0.47, and 0.38 nm2 , respectively. Our data indicate that the order of occupied

Crude oil emulsions are stabilized by high-molecularweight surfactants, viz., asphaltenes and resins. They do not develop high surface pressures, and therefore steric stabilization of water-in-crude-oil emulsions is the most plausible mechanism of stabilization of such emulsions. Demulsier molecules and natural surfactants compete with each other for adsorption onto the water-drop lm. When demulsier molecules, which lower interfacial tension much more than the natural surfactants, are adsorbed at the interface, the lm becomes unstable in the direction of coalescence of water drops. Fig. 5 shows that the dehydration speed of BP73 and BP63 is higher than that of BP74 and BP64. Many experiments have proved that the dehydration speed increases with decreasing PEO content of the demulsier. But the end dehydration rate of the four demulsiers is approximate; 90% of the water was separated from the emulsions by using all four demulsiers after 3 h. It is shown that the block copolymer surfactants are excellent as demulsiers for breaking crude oils from the Shengli oileld (Peoples Republic of China, Shandong). The crude oil emulsions were photographed under a JEM100CX microscope and the coalescence of water drops were observed. Emulsions formed in the petroleum industry are

Z. Zhang et al. / Journal of Colloid and Interface Science 277 (2004) 464470

469

Fig. 5. Effect of demulsiers on the dehydration rate with time.

Fig. 6. The demulsication micrograph of crude oil emulsion (bright droplets are water). (a) Emulsion was mixed 5 min by an HT-II homogenizer with 1:1 water/oil ratio; (b) 30 min after demulsier was added; (c) 60 min after demulsier was added.

predominantly water-in-oil or regular emulsions, in which the oil is the continuous or external phase and the dispersed water droplets form the dispersed or internal phase. Fig. 6 shows a demulsication micrograph of the crude oil emulsion. From Fig. 6 we can see the size of the water droplets become bigger with time after demulsier is added. The role of the demulsier is to change the interfacial properties and to destabilize the surfactant-stabilized emulsion lm in the demulsication process. In the beginning, small and uniform drops occulate and some large drops begin to form at 30 min. Then two or more large drops continue to form a single larger drop: coalescence happens. It is observed that the droplet size grows fast and the droplet number reduces after demulsier is added. We concluded that coalescence of water droplets destroyed emulsions. Three terms related to stability commonly encountered in crude oil emulsion are occulation, coalescence, and breaking. Although they are sometimes used almost interchangeably, those terms are in fact quite distinct in meaning as far as the condition of an emulsion is concerned. Flocculation refers to the mutual attachment of individual emulsion drops to form ocs or loose assemblies. Flocculation can be, in many cases, a reversible process, overcome by the input of much less energy than was required in the original emulsication process. Coalescence refers to the joining of two or more drops to form a single drop of greater volume, but smaller interfacial area. Although coalescence will result in signicant microscopic changes in the

condition of the dispersed phase, it may not immediately result in a macroscopically apparent alteration of the system. The breaking of an emulsion refers to a process in which gross separation of the two phases occurs. In such an event, the identity of individual drops is lost, along with the physical and chemical properties of the emulsion. Such a process obviously represents a true loss of stability in the emulsion. It has been established that the kinetics of chemical demulsication is complicated by the interaction of three main effects, according to the micrograph. These are (1) the displacement of the asphaltenic lm from the oil water interface by the demulsier; (2) occulation; (3) coalescence of water drops.

4. Conclusion PEOPPOPEO triblock copolymers were synthesized and the properties and demulsication of PEOPPOPEO were reported. The CMC of PEOPPOPEO is not a certain value but a range, in contrast to that of classical surfactants, and two breaks around the CMC were reected both on the surface tension isotherm and in the UVvis absorbance spectra. Surface pressures were obtained for spread monolayers for the range of copolymer compositions, which reveals that the amphiphilic block copolymer molecule PEOPPO PEO is exible on the air/water interface. The copolymers with the same mass fractions of PEO have similar slopes in

470

Z. Zhang et al. / Journal of Colloid and Interface Science 277 (2004) 464470

the isotherm of the A curve. PEOPPOPEO is widely used as a demulsier. From the demulsication experiments the conclusion can be drawn that the dehydration speed increases with reduced content of PEO. Acknowledgment This work is supported by the Key Technologies R&D Program Foundation of China (02BA312B07). References

[1] C. Guo, J. Wang, H. Liu, J. Chen, Langmuir 15 (1999) 2703. [2] P. Linse, Macromolecules 26 (1993) 4437. [3] V.K. Alexander, R.N. Irina, V.A. Irina, V.B. Elena, Y.A. Valery, A.Y. Alexander, A.K. Victor, Macromolecules 28 (1995) 2303. [4] I. Goldmints, J.F. Holzwarth, K.A. Smith, T.A. Hatton, Langmuir 13 (23) (1997) 6130. [5] R. Zhang, J. Liu, J. He, B. Han, Z. Liu, T. Jiang, W. Wu, L. Rong, H. Zhao, B. Dong, G. Hu, Macromolecules 36 (2003) 1289. [6] G.M. Muoz, F. Monroy, F. Ortega, R.G. Rubio, D. Langevin, Langmuir 16 (2000) 1083. [7] R. Nagarajan, Colloids Surf. B Biointerfaces 16 (1999) 55. [8] C. Guo, H. Liu, J. Wang, J. Chen, J. Colloid Interface Sci. 209 (1999) 368.

[9] H. Polat, S. Chander, Colloids Surf. A Physicochem. Eng. Aspects 146 (1999) 199. [10] Y.L. Su, X.F. Wei, H.Z. Liu, Langmuir 19 (2003) 2995. [11] T. Nivaggioli, P. Alexandridis, T.A. Hatton, Langmuir 11 (1995) 730. [12] M. Esseffar, W. Bouab, A. Lamsabhi, J.M. Abboud, R. Notario, J. Am. Chem. Soc. 122 (2000) 2300. [13] J. Im, O. Kwon, J. Kim, S. Lee, Macromolecules 33 (2000) 9606. [14] P. Alexandridis, R. Ivanova, B. Lindman, Langmuir 16 (2000) 3676. [15] M.A. Firestone, A.C. Wolf, S. Seifert, Biomacromolecules 4 (2003) 1539. [16] J. Djuve, X. Yang, I. Fjillanger, Colloid Polym. Sci. 279 (2001) 232. [17] D.M. Joseph, K.K. Peter, J. Colloid Interface Sci. 189 (1997) 242. [18] Y.H. Kim, D.T. Wasan, P.J. Breen, Colloids Surf. A Physicochem. Eng. Aspects 95 (1995) 235. [19] M.A. Krawezyk, D.T. Wasan, C.S. Shetty, Ind. Eng. Chem. Res. 30 (1991) 367. [20] Y.H. Kim, D.T. Wasan, Ind. Eng. Chem. Res. 35 (1996) 1141. [21] A. Bhardwaj, S. Hartland, Ind. Eng. Chem. Res. 33 (1994) 1271. [22] P. Alexandridis, V. Athanassiou, S. Fukuda, T.A. Hatton, Langmuir 10 (1994) 2604. [23] M. Almgren, W. Brown, S. Hvidt, Colloid Polym. Sci. 273 (1995) 2. [24] W.M. Jason, K. Arshad, J. Phys. Chem. A 106 (2002) 6421. [25] M. Ibn-Elhaj, L. Ouali, G. Papastavrou, H. Mohwald, Langmuir 15 (1999) 1528. [26] S.A. Maskarinec, K.Y.C. Lee, Langmuir 19 (2003) 1809. [27] N.B. Holland, Z. Xu, K. Vacheethasanee, R.E. Marchant, Macromolecules 34 (2001) 6424.

Potrebbero piacerti anche

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- Principles of Colloid and Surface Chemistry - PreviewDocumento148 paginePrinciples of Colloid and Surface Chemistry - PreviewCarla Grijo FonsecaNessuna valutazione finora

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- Lecture 2 Surface Active AgentsDocumento49 pagineLecture 2 Surface Active Agentsbattal eduNessuna valutazione finora

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- Detergents and Soaps: Basic PrinciplesDocumento35 pagineDetergents and Soaps: Basic Principlesallan owinoNessuna valutazione finora

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- Mesomorphic Phases and Phase Transitions in Membranes, Biomechanical AspectsDocumento18 pagineMesomorphic Phases and Phase Transitions in Membranes, Biomechanical AspectsTatiana AndradeNessuna valutazione finora

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- Optimization of Asa Emulsification in Internal Sizing of Paper and BoardDocumento108 pagineOptimization of Asa Emulsification in Internal Sizing of Paper and BoardHuy Nguyen100% (1)

- GPAT 13 P'ceuticsDocumento29 pagineGPAT 13 P'ceuticsGANESH KUMAR JELLANessuna valutazione finora

- Content PDFDocumento35 pagineContent PDFRaza Shamim AkhtarNessuna valutazione finora

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (400)

- Surfactant PDFDocumento11 pagineSurfactant PDFqwertyNessuna valutazione finora

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- IIT JEE 2007 Paper 1 Solutions by NarayanaDocumento28 pagineIIT JEE 2007 Paper 1 Solutions by NarayanaAbhinav100% (4)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- Q.1 The Major Product Formed in The Following Reaction IsDocumento10 pagineQ.1 The Major Product Formed in The Following Reaction IsDoom RefugeNessuna valutazione finora

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- Journal of Petroleum 2Documento15 pagineJournal of Petroleum 2Profanwar SantosomscNessuna valutazione finora

- Aadarsh Nayak Chemistry ProjectDocumento14 pagineAadarsh Nayak Chemistry ProjectExtra 2020Nessuna valutazione finora

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- Micellization ThermodynamicsDocumento24 pagineMicellization Thermodynamicsmomopanda4Nessuna valutazione finora

- Chemistry and Technology of Yoghurt FermentationDocumento62 pagineChemistry and Technology of Yoghurt FermentationFrancisco AcostaNessuna valutazione finora

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- The in Uence of Some Surfactants On Porous Concrete PropertiesDocumento8 pagineThe in Uence of Some Surfactants On Porous Concrete PropertiesClariza TanNessuna valutazione finora

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (345)

- Novel Drug Delivery System An OverviewDocumento3 pagineNovel Drug Delivery System An OverviewEditor IJTSRDNessuna valutazione finora

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (74)

- Mr. Sagar Kishor Savale: (Department of Pharmaceutics) 2015-016Documento20 pagineMr. Sagar Kishor Savale: (Department of Pharmaceutics) 2015-016نور الهدىNessuna valutazione finora

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- Making Soap 31: Equation 1Documento8 pagineMaking Soap 31: Equation 1Cao LongNessuna valutazione finora

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- Recent Advances in Viscoelastic Surfactants For Improved Production From Hydrocarbon Reservoirs PDFDocumento35 pagineRecent Advances in Viscoelastic Surfactants For Improved Production From Hydrocarbon Reservoirs PDFLê CôngNessuna valutazione finora

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- M.sc. Chemistry001Documento36 pagineM.sc. Chemistry001Menka KaushikNessuna valutazione finora

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- Carbon and Its CompoundDocumento17 pagineCarbon and Its CompoundChakradhar RajNessuna valutazione finora

- To Estimate Quantity of Casein in Milk CDocumento21 pagineTo Estimate Quantity of Casein in Milk Csam100% (1)

- Asphatene Ppt. in Crude Oils PDFDocumento19 pagineAsphatene Ppt. in Crude Oils PDFOguamahIfeanyiNessuna valutazione finora

- Module 06Documento41 pagineModule 06Madhuri GuptaNessuna valutazione finora

- Wool DyeingDocumento43 pagineWool Dyeingsandipsoni221811Nessuna valutazione finora

- A Comprehensive Framework For Surfactant Selection and Design For Emulsion Based Chemical Product Design PDFDocumento12 pagineA Comprehensive Framework For Surfactant Selection and Design For Emulsion Based Chemical Product Design PDFArley NovaNessuna valutazione finora

- Tin Plating PDFDocumento9 pagineTin Plating PDFStephanie VirganaNessuna valutazione finora

- Inhibition of Mild Steel Corroin Cooling System - PHD - OK 1Documento10 pagineInhibition of Mild Steel Corroin Cooling System - PHD - OK 1hadianatyaNessuna valutazione finora

- Dowfax Muy BuenoDocumento20 pagineDowfax Muy Buenohugogauna100% (1)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (121)

- Lipid Nanoparticles: A Challenging Approach For Oral Delivery of BCS Class-II DrugsDocumento15 pagineLipid Nanoparticles: A Challenging Approach For Oral Delivery of BCS Class-II DrugsnoviNessuna valutazione finora

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)