Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Transformation Toughening of Partially Stabilized Zirconia

Caricato da

Anirudh Venkatraman KrishnanDescrizione originale:

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Transformation Toughening of Partially Stabilized Zirconia

Caricato da

Anirudh Venkatraman KrishnanCopyright:

Formati disponibili

V Krishnan Anirudh 2008A4PS284H

V KRISHNAN ANIRUDH

ADVANTAGES OF CERAMICS

V KRISHNAN ANIRUDH

ADVANTAGES OF CERAMICS

V KRISHNAN ANIRUDH

ADVANTAGES OF CERAMICS

V KRISHNAN ANIRUDH

ADVANTAGES OF CERAMICS

V KRISHNAN ANIRUDH

DISADVANTAGES OF CERAMICS

V KRISHNAN ANIRUDH

Ceramics are inherently resilient to oxidation and deterioration at elevated temperatures. But they are very prone to brittle fractures, else, some of these materials would be ideal for use in high temperature and severe stress applications. Such applications also include automobile and aircraft gas turbine engines

V KRISHNAN ANIRUDH

Research has been conducted to improve toughness. Hot pressing with additives and reaction bonding improve toughness

V KRISHNAN ANIRUDH

ZIRCONIUM DIOXIDE (Zirconia)

Zirconium dioxide is one of the most studied ceramic materials. Pure ZrO2 has a monoclinic crystal structure at room temperature and transitions to tetragonal and cubic at increasing temperatures. The volume expansion caused by the cubic to tetragonal to monoclinic transformation induces very large stresses and will cause pure ZrO2 to crack upon cooling from high temperatures. Several different oxides are added to zirconia to stabilize the tetragonal and/or cubic phases: MgO, Y2O3, CaO and Ce2O3, amongst others

10

V KRISHNAN ANIRUDH

CRYSTAL STRUCTURES

ZrO2 exists in 3 structures.

Monoclinic : Up to 11700C Tetragonal: 1170 23700C Cubic: above 23700C

11

V KRISHNAN ANIRUDH

Zirconia is very useful in its 'stabilized' state. If sufficient quantities of the metastable tetragonal phase is present, then an applied stress, magnified by the stress concentration at a crack tip, can cause the tetragonal phase to convert to monoclinic, with the associated volume expansion. This phase transformation can then put the crack into compression, retarding its growth, and enhancing the fracture toughness. This mechanism is known as transformation toughening, and significantly extends the reliability and lifetime of products made with stabilized zirconia.

12

V KRISHNAN ANIRUDH

13

V KRISHNAN ANIRUDH

The process of "transformation toughening" is based on the assumption that zirconia undergoes several martensitic phase transformations (cubic tetragonal monoclinic) between room temperature and practical sintering temperatures. Thus, due to the volume restrictions induced by the solid matrix, metastable crystalline structures can become frozen in which impart an internal strain field surrounding each zirconia inclusion upon cooling. This enables a zirconia particle to absorb the energy of an approaching crack tip front in its nearby vicinity

14

V KRISHNAN ANIRUDH

STABILIZATION OF ZIRCONIA

Stabilizing of zirconia can be achieved by adding 3 to 7 wt.% of CaO. At this composition, at about 10000C, both cubic and tetragonal phases will exist. Upon cooling to room temperature under normal conditions, the monoclinic and CaZr4O9 phases dont form (as predicted from the phase diagram) Consequently, the cubic and tetragonal phases are retained and crack formation is circumvented

15

V KRISHNAN ANIRUDH

STABILIZATION OF ZIRCONIA

16

V KRISHNAN ANIRUDH

STABILIZATION OF ZIRCONIA

Stabilizing of zirconia can also be achieved by adding 3.6 wt.% of Y2O3. At this composition, at about 11000C, tetragonal phase is pretty stable. Upon cooling to room temperature under relatively rapid cooling, the tetragonal phase is retained. From the phase diagram it is evident that a monoclinic ZrO2 is the stable phase, which coexists with this now unstable tetragonal phase in metastable equilibrium.

17

V KRISHNAN ANIRUDH

STABILIZATION OF ZIRCONIA

18

V KRISHNAN ANIRUDH

STABILIZATION OF ZIRCONIA

Stabilizing of zirconia can also be achieved by adding 9 mol% of MgO. At this composition, sintering at about 18000C, and then rapidly cooling it to room temperature, will result in the all-metastable cubic structure. If this material is reheated to 14000C, and held for sufficiently long time, a fine metastable submicroscopic precipitate with the tetragonal structure is precipitated.

19

V KRISHNAN ANIRUDH

STABILIZATION OF ZIRCONIA

20

V KRISHNAN ANIRUDH

USES OF CUBIC ZIRCONIA

Single crystals of the cubic phase of zirconia are commonly used as diamond simulant in jewellery. Visually discerning a good quality cubic zirconia gem from a diamond is difficult, and most jewellers will have a thermal conductivity tester to identify cubic zirconia by its low thermal conductivity (diamond is a very good thermal conductor). This material is also used in the manufacture of sub-frames for the construction of dental restorations such as crowns and bridges, which are then veneered with a conventional feldspathic porcelain

21

V KRISHNAN ANIRUDH

USES OF CUBIC ZIRCONIA

The cubic phase of zirconia has a very low thermal conductivity, which has led to its use as a thermal barrier coating or TBC in jet and diesel engines to allow operation at higher temperatures. Thermodynamically the higher the operation temperature of an engine, the greater the possible efficiency (see Carnot heat engine). As of 2004, a great deal of research is going on to improve the quality and durability of these coatings. Also, it is used as a refractory material, in insulation, abrasives, enamels and ceramic glazes. Stabilized zirconia is used in oxygen sensors and fuel cell membranes because it has the ability to allow oxygen ions to move freely through the crystal structure at high temperatures. This high ionic conductivity (and a low electronic conductivity) makes it one of the most useful electro-ceramics.

Potrebbero piacerti anche

- Centrifugal FansDocumento19 pagineCentrifugal FansMark John Santos60% (5)

- Closed-Book Practice-Ch 13 (2017!04!18)Documento9 pagineClosed-Book Practice-Ch 13 (2017!04!18)JuanNessuna valutazione finora

- Analytical Chemistry of Zirconium and Hafnium: International Series of Monographs in Analytical ChemistryDa EverandAnalytical Chemistry of Zirconium and Hafnium: International Series of Monographs in Analytical ChemistryNessuna valutazione finora

- Zirconium Information Center Zirconium Information Center Properties, Applications and Research Properties, Applications and ResearchDocumento6 pagineZirconium Information Center Zirconium Information Center Properties, Applications and Research Properties, Applications and ResearchLai Wei KhangNessuna valutazione finora

- 23 - Toughened Ceramics 1Documento28 pagine23 - Toughened Ceramics 1Md. Rafiqul IslamNessuna valutazione finora

- 114-张举-Progress and Developing Trend of Purging Plugs for Refining LadleDocumento4 pagine114-张举-Progress and Developing Trend of Purging Plugs for Refining LadleSrinivas MangipudiNessuna valutazione finora

- ZR O2Documento25 pagineZR O2radoslavoffNessuna valutazione finora

- IntJOralHealthDent 7-2-110 119Documento29 pagineIntJOralHealthDent 7-2-110 119namuNessuna valutazione finora

- 3 ZirconiaDocumento4 pagine3 ZirconiaFifth Year Dentistry ZUNessuna valutazione finora

- Application and Fabrication of Materials (ZrO2)Documento2 pagineApplication and Fabrication of Materials (ZrO2)Syafiq NasirNessuna valutazione finora

- Roll 38 YTTRIA STABILIZED ZIRCONIADocumento22 pagineRoll 38 YTTRIA STABILIZED ZIRCONIAHarish KhundrakpamNessuna valutazione finora

- Zirconium Alloy Industry ApplicationsDocumento16 pagineZirconium Alloy Industry Applicationsmarc53042Nessuna valutazione finora

- Ceramics in Gas TurbinesDocumento12 pagineCeramics in Gas TurbinesDomingo Pinto100% (1)

- Material IN939Documento12 pagineMaterial IN939J SaadatNessuna valutazione finora

- Myung Heat TreatmentDocumento9 pagineMyung Heat TreatmentBabcsánné Kiss JuditNessuna valutazione finora

- Yttria-Stabilized Zirconia - Alumina Composite Sintering Temperature Effect On Thermal DiffusivityDocumento11 pagineYttria-Stabilized Zirconia - Alumina Composite Sintering Temperature Effect On Thermal DiffusivityProgram Studi Pendidikan Fisika UnmulNessuna valutazione finora

- Calcia Stabilized ZirconiaDocumento3 pagineCalcia Stabilized Zirconiaedwardbloomcer06Nessuna valutazione finora

- Zirconia: Properties and Application - A Review: RosthodonticsDocumento6 pagineZirconia: Properties and Application - A Review: Rosthodonticshaseeb khanNessuna valutazione finora

- Critical Parameters To Obtain Yb Doped Lu O and Zno Transparent CeramicsDocumento6 pagineCritical Parameters To Obtain Yb Doped Lu O and Zno Transparent CeramicsSyiera MujibNessuna valutazione finora

- Structural Ceramic Materials: ZIRCONIA - Structure, Properties, ApplicationsDocumento14 pagineStructural Ceramic Materials: ZIRCONIA - Structure, Properties, ApplicationsMu BaNessuna valutazione finora

- Corrosion Resistance of X5CrNi18-10 Stainless SteeDocumento6 pagineCorrosion Resistance of X5CrNi18-10 Stainless SteeKis GáborNessuna valutazione finora

- Chapter 2 - Substrate Preparation PDFDocumento99 pagineChapter 2 - Substrate Preparation PDFNur AmirahNessuna valutazione finora

- Ceramics International: SciencedirectDocumento7 pagineCeramics International: SciencedirectBabcsánné Kiss JuditNessuna valutazione finora

- 2023MSEII Handout9Documento12 pagine2023MSEII Handout9王竣右Nessuna valutazione finora

- Radiation Damage and Nuclear FuelsDocumento9 pagineRadiation Damage and Nuclear FuelswordssmithNessuna valutazione finora

- Hama No 1993Documento13 pagineHama No 1993uristerinNessuna valutazione finora

- Microstructural Examination of Ceramic MaterialDocumento16 pagineMicrostructural Examination of Ceramic MaterialRudrang ChauhanNessuna valutazione finora

- Ultra-High-Porosity Zirconia Ceramics Fabricated by Novel Room-Temperature Freeze-CastingDocumento4 pagineUltra-High-Porosity Zirconia Ceramics Fabricated by Novel Room-Temperature Freeze-CastingmzrtjrNessuna valutazione finora

- Unit - V Advanced Materials & Applications: 5.0 CeramicsDocumento6 pagineUnit - V Advanced Materials & Applications: 5.0 Ceramicsjoel jNessuna valutazione finora

- Zirconia 170303000441Documento100 pagineZirconia 170303000441Chandan kumar SawNessuna valutazione finora

- Lecture 2 Si Growth - 2022Documento20 pagineLecture 2 Si Growth - 2022DrNasser MorganNessuna valutazione finora

- BF 03355657Documento4 pagineBF 03355657m.j.hemmati72Nessuna valutazione finora

- Coating Rings and Balls PDFDocumento8 pagineCoating Rings and Balls PDFAnonymous NxpnI6jC100% (2)

- Hot Corrosion of An Electrodeposited Ni-11 WT % CR Nanocomposite Under Molten Na (Sub 2) So (Sub 4) - K (Sub 2) So (Sub 4) - NaclDocumento7 pagineHot Corrosion of An Electrodeposited Ni-11 WT % CR Nanocomposite Under Molten Na (Sub 2) So (Sub 4) - K (Sub 2) So (Sub 4) - NaclMelin YohanaNessuna valutazione finora

- Hot Corrosion of An Electrodeposited Ni-11 WT % CR Nanocomposite Under Molten Na (Sub 2) So (Sub 4) - K (Sub 2) So (Sub 4) - NaclDocumento7 pagineHot Corrosion of An Electrodeposited Ni-11 WT % CR Nanocomposite Under Molten Na (Sub 2) So (Sub 4) - K (Sub 2) So (Sub 4) - NaclMelin YohanaNessuna valutazione finora

- Mobium in Nuclear: Zircomum Ber Yllium ReactorsDocumento4 pagineMobium in Nuclear: Zircomum Ber Yllium ReactorsBasit FebrianNessuna valutazione finora

- Module3-Part 2Documento16 pagineModule3-Part 2amithaanumadhusoodhananNessuna valutazione finora

- Sliprings and Carbon Brushes For Turbo AlternatorsDocumento24 pagineSliprings and Carbon Brushes For Turbo Alternatorsfaisal100% (1)

- Clinker CoolingDocumento6 pagineClinker CoolingGanapathy Subramaniam100% (1)

- Heat Resistant CeramicsDocumento26 pagineHeat Resistant Ceramicsivy_oforiNessuna valutazione finora

- Carbon Film ResistorDocumento2 pagineCarbon Film ResistorMarkee ChoiNessuna valutazione finora

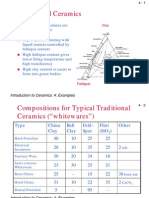

- Introduction To CeramicsDocumento29 pagineIntroduction To CeramicsShrikrishna BirajdarNessuna valutazione finora

- Compaction and Pressureless Sintering of ZirconiaDocumento9 pagineCompaction and Pressureless Sintering of ZirconiaWalaa Hassan Salem Abd El KareemNessuna valutazione finora

- Aluminium Die CastingDocumento8 pagineAluminium Die CastingsivamettNessuna valutazione finora

- Differences in Densification Behaviour oDocumento8 pagineDifferences in Densification Behaviour olamia97Nessuna valutazione finora

- Shallow and Deep Dry Etching of Silicon Using ICP Cryogenic Reactive Ion Etching ProcessDocumento8 pagineShallow and Deep Dry Etching of Silicon Using ICP Cryogenic Reactive Ion Etching Processwhite shadowNessuna valutazione finora

- Deville 2003Documento8 pagineDeville 2003Tejas krishnakanthNessuna valutazione finora

- DownloadfileDocumento9 pagineDownloadfilefredymademydayNessuna valutazione finora

- 1 s2.0 S0010938X14001619 MainDocumento7 pagine1 s2.0 S0010938X14001619 MainEDWIN HUMBERTO CADAVID IGLESIASNessuna valutazione finora

- Mse 3107 (1,2)Documento77 pagineMse 3107 (1,2)Sheikh Sabbir SarforazNessuna valutazione finora

- Ceramic Fabrication Methods (Iib) : Glass Forming CementationDocumento26 pagineCeramic Fabrication Methods (Iib) : Glass Forming CementationAtakan BüyükNessuna valutazione finora

- High Temperature Corrosion Failure of Super Alloy Turbine Blades PDFDocumento14 pagineHigh Temperature Corrosion Failure of Super Alloy Turbine Blades PDFhengki wibowoNessuna valutazione finora

- Medical Applications of Diamond Particles and SurfacesDocumento10 pagineMedical Applications of Diamond Particles and SurfacesJenner FeijoóNessuna valutazione finora

- Cu-Cr Alloy Work PlanDocumento16 pagineCu-Cr Alloy Work PlanSatyam vankayalaNessuna valutazione finora

- CeramicsDocumento29 pagineCeramicsAnil Kumar YaduganNessuna valutazione finora

- AnnealingDocumento6 pagineAnnealingelizabeth merzyNessuna valutazione finora

- Synthesis and Characterization of Nanocrystalline Powders For Partially Stabilized Zirconia CeramicsDocumento5 pagineSynthesis and Characterization of Nanocrystalline Powders For Partially Stabilized Zirconia Ceramicsamirlove206Nessuna valutazione finora

- Trends in Zircon Processing: A.C. Bidaye and I.G. SharmaDocumento5 pagineTrends in Zircon Processing: A.C. Bidaye and I.G. SharmaminingnovaNessuna valutazione finora

- MM454 Lec 43-44 PDFDocumento22 pagineMM454 Lec 43-44 PDFAhmad JanNessuna valutazione finora

- Phase and Phase EquilibriumDocumento53 paginePhase and Phase EquilibriumNaman DaveNessuna valutazione finora

- Corrosion-Resistant Braze Joints: Novel, High-Chromium Containing Braze Filler MetalsDocumento4 pagineCorrosion-Resistant Braze Joints: Novel, High-Chromium Containing Braze Filler MetalsJorge Luis Olivar QuinteroNessuna valutazione finora

- prEN 10138-3-2006Documento14 pagineprEN 10138-3-2006florin0% (1)

- DistillationDocumento103 pagineDistillationKrishnamoorthy VijayalakshmiNessuna valutazione finora

- Department of Chemistry: Michael J. HynesDocumento55 pagineDepartment of Chemistry: Michael J. HynesAndrés PacompíaNessuna valutazione finora

- Pages From Selection and Sizing of Pressure Relief ValvesDocumento1 paginaPages From Selection and Sizing of Pressure Relief Valveszohaib_farooqNessuna valutazione finora

- Example 4.1: School of Engineering - EN334Documento7 pagineExample 4.1: School of Engineering - EN334Ismail DoğanNessuna valutazione finora

- hw4 EM1 2018Documento2 paginehw4 EM1 2018卓宇Nessuna valutazione finora

- 18) UC203x203x46toUC254x254x73-B2CF - MCDocumento125 pagine18) UC203x203x46toUC254x254x73-B2CF - MCAsaru DeenNessuna valutazione finora

- Large Binocular Telescope 2008Documento15 pagineLarge Binocular Telescope 2008王轩Nessuna valutazione finora

- Distillation ColumnDocumento23 pagineDistillation ColumnRanjani J DeepakNessuna valutazione finora

- Welding Residual StressDocumento10 pagineWelding Residual Stressaap1Nessuna valutazione finora

- Today's Objective:: Method of SectionsDocumento20 pagineToday's Objective:: Method of SectionsAtef NazNessuna valutazione finora

- Sophisticated ChemistryDocumento9 pagineSophisticated ChemistryKingsleyNessuna valutazione finora

- Non Destructive Testing of Pipelines State and Methods For Its RepairingDocumento19 pagineNon Destructive Testing of Pipelines State and Methods For Its RepairingCarlos MusellaNessuna valutazione finora

- Au2-13, Deka2008Documento11 pagineAu2-13, Deka2008ht117Nessuna valutazione finora

- 1f Multi Voltage Multi Circuit Transmission Tower PDFDocumento7 pagine1f Multi Voltage Multi Circuit Transmission Tower PDFmulualemNessuna valutazione finora

- A) Define: I) Latitude, Ii) Declination Angle, Iii) Hour Angle, Iv) Surface B) For New Delhi (Latitude 28Documento2 pagineA) Define: I) Latitude, Ii) Declination Angle, Iii) Hour Angle, Iv) Surface B) For New Delhi (Latitude 28Mahesh ReddyNessuna valutazione finora

- Huawei Smart Cooling Solution For Data CenterDocumento56 pagineHuawei Smart Cooling Solution For Data Centerabdalla kamalNessuna valutazione finora

- Sheet 1 ChemistryDocumento6 pagineSheet 1 Chemistryapi-3810665Nessuna valutazione finora

- Geotechnical Engineering - I PDFDocumento3 pagineGeotechnical Engineering - I PDFSunny PrajapatiNessuna valutazione finora

- 3rd Q Science 2022-2023Documento2 pagine3rd Q Science 2022-2023Richard CruzNessuna valutazione finora

- ASA - Temperature Sensor - ILLZTT5069K - enDocumento1 paginaASA - Temperature Sensor - ILLZTT5069K - enKrum KashavarovNessuna valutazione finora

- Ocean Engineering: Wen-Huai Tsao, Wei-Shien Hwang TDocumento10 pagineOcean Engineering: Wen-Huai Tsao, Wei-Shien Hwang T邱俊祥Nessuna valutazione finora

- CompositeMaterials PHD Summary-2007Documento31 pagineCompositeMaterials PHD Summary-2007Ege menNessuna valutazione finora

- Sap ConcDocumento192 pagineSap ConcJose SanchezNessuna valutazione finora

- DENSITYDocumento9 pagineDENSITYJonaver RebiteNessuna valutazione finora

- Concrete Technology MCQ PDF (Erexams - Com)Documento69 pagineConcrete Technology MCQ PDF (Erexams - Com)krishna chaithanyaNessuna valutazione finora

- Physics Investigatory ProjectDocumento17 paginePhysics Investigatory Projectshankar60% (5)