Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

UCC Placement Report Summary

Caricato da

Johnny KeaneDescrizione originale:

Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

UCC Placement Report Summary

Caricato da

Johnny KeaneCopyright:

Formati disponibili

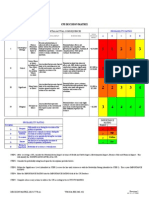

UCC PLACEMENT REPORT

TABLE OF CONTENTS

SUMMARY: ........................................................................ 2 COMPANY: ......................................................................... 3 WORK PLACEMENT: ........................................................... 4 APPRASIAL OF WORK PLACEMENT: ................................. 13 ADMINISTRATION OF 2011 PROGRAMME: ..................... 15 APPENDIX: ....................................................................... 16

Page 1 of 27

UCC PLACEMENT REPORT

SUMMARY:

J Murphy & Sons Limited is a holding company encapsulating Civil Engineering, Tunnelling, Building & Property Development and is one of the largest construction firms in Great Britain & Ireland. The placement offered a great opportunity to gain industry experience while working on large scale projects. Upon reflection, my placement period, as a whole, has been a thoroughly enjoyable experience. My fourteen week placement was predominantly spent working as an Engineer / Project Manager with Colm Forde who is a Project Manager with the Power Division of J Murphy & Sons Ltd. This placement represented a unique opportunity to gain invaluable experience in one of the emerging sectors within the Murphy Group. The tasks offered a nice blend of time spent working in the office, attending meetings, and also making site visits. I feel that this mixture of both site and office experience provided a great insight into the work carried out in both environments. For me, this has been the most pleasing aspect of the work placement in the sense that the whole ideal of this module, in my opinion, is to gain industry experience and I feel that I have essentially doubled my experience through the combination of office and site works. As mentioned previously, my placement revolved around works carried out by the Power Division of J Murphy & Sons. The division essentially offers the management, design, installation and maintenance of electrical EHV / HV / LV solutions in transmission and distribution. Colm was PM for several projects, all at various stages of completion: Oceans Estate 22kV Cable Diversions (UKPN) Fife Road Supervision and Installation of 22kV Cable (UKPN) Islington St. Pancras: Feasibility Study for Proposed 132kV Route (UKPN) Willesden Sub Neasden BSP: Feasibility Study for Proposed 132kV Route (LUL)

The majority of the works I was involved in were carried out on behalf of UK Power Networks (UKPN) with the exception of the Willesden Neasden feasibility study on behalf of London Underground Limited (LUL). The cable works provided a great insight into the methodology behind the installation of HV cabling. On the other hand, the feasibility studies highlighted the major factors which have to be considered when analysing the viability of a proposed route. All projects greatly enhanced my communication and teamwork skills, gaining invaluable experience in the process.

Page 2 of 27

UCC PLACEMENT REPORT

COMPANY:

The holding company J Murphy & Sons Ltd. engulfs Civil Engineering, Tunnelling, Pipelines, Piling and Building & Property Development. Having initially worked as a subcontractor in the mid to late 1940s specialising in bomb site clearance, cabling and electrification, roads, water supplies and drainage across the UK, John Murphy founded JMS in 1951, specialising in the essential reconstruction of the countrys electrical infrastructure. Over the years, the company grew and expanded its interests and in 2009, JMS reported turnover of 408,017,410 resulting in pre-tax profits of 24,886,796 while maintaining a labour force of 2,815. Although these profits were significantly reduced in comparison to previous years, it still represented a substantial success given the economic climate. The company owns, manages and maintains a substantial holding of transport, specialist plant and equipment valued at in excess of 48 Million. This vast capital investment greatly supports activities and ensures the company has the flexibility to respond to customer needs. The depth of knowledge, experience and capability within the company allows for the provision of a fully in-house solution to any project regardless of scale or difficulty. The activities of the Murphy Group in the United Kingdom and Ireland are grounded by the structured management of one of the industrys largest permanent work forces, enabling the delivery of multiple projects to the highest and most consistent standards. The company regularly invests in its employees keeping their welfare and safety in mind, sharing knowledge and best practice and constantly improving internal processes. JMS also understand the importance of allowing for the future by developing collaborative arrangements (such as Electricity Alliance) and keeping an eye on the wider industry, establishing new clients and maintaining long-term alliances, profitably managing the business and re-investing in research and development, managing the environmental impact and contributing to communities. The Power Division employs approximately fifty staff, excluding the operatives carrying out on site works. This collection of staff essentially consists of Delivery Managers, Senior Project Managers, Project Managers, Engineers, Quantity Surveyors, Plant Managers and Office Managers. The majority of these staff are based in the Power Divisions main office in Kentish Town. The main clients of the Power Division, from my experience, are EDF Energy / UKPN, LUL and National Grid. The majority of the works essentially involve a total management approach to the installation of LV, HV and EHV electrical cables. The division also carries out replacement and refurbishment works to the same high standards. Geographical factors have a huge impact on the works carried out by the division meaning that no two jobs are alike. Whether it be cable installation in roads, along railway lines, overground, underground or passing under rivers, every project represents different challenges to overcome, meaning that the work is always new and interesting.

Page 3 of 27

UCC PLACEMENT REPORT

WORK PLACEMENT:

The term of work placement commenced on the 6th of June 2011, reporting to Murphys Head Office in Kentish Town, London. I was appointed to work under the supervision of Colm Forde, Project Manager with Murphys Power Division, starting in earnest with him on the 13th of June. For the remaining period of the first week, I accompanied Mick Creagh, Electrical Manager with the Power Division, on his daily activities such as visiting various Substations, recording details of Trial Holes and measuring & calculating cable lengths. During this period, I also accompanied Mick on a site visit to Deephams Sewage Treatment Works in Edmonton, East London where JMS are carrying out a 35 million upgrade to the works. The upgrades involve rebuilding the sewage works inlet, where sewage enters the works, and fitting a new pumping station and better screens to sieve out debris. Two new storm tanks will be built to hold excess sewage flows, and self-cleaning devices will be fitted to the existing storm tanks to ensure they empty more quickly and reduce odour. I feel that this first week was a very beneficial introduction, as it gave me a great overview of the various types of works carried out by the Power Division. The majority of the works revolve around Electrical Cables. Installation of new cabling, decommissioning of existing cables and cable diversions, usually under existing public roads, all take place on a regular basis. There was a natural progression from getting a general overview of activities in the first week to gradually gaining more and more trust and responsibility in carrying out specialised tasks. Upon commencing work with Colm, he was acting as Project Manager for three works at various stages of completion. I quickly learned that my main duties would be to assist Colm in ensuring that the projects were completed on time and within budget. The works carried out by the Power Division represented a significant change from the traditional structural / civil industry. Thus, the placement also offered the opportunity to gain an insight into the works being carried out by the division which is emerging as one of the main sectors within the Murphy Group.

Page 4 of 27

UCC PLACEMENT REPORT

OCEANS ESTATE 22kV DIVERSIONS:

The works being undertaken at Oceans Estate were on behalf of UKPN and essentially involved the diversion of 4 no. 22kV Electrical Circuits. The diversion was required due to a new Social Housing Scheme being undertaken by Wates Construction on behalf of the London Borough of Tower Hamlets. The existing cables were running under a portion of the site for the 9-storey Social Housing Scheme at a depth of approximately 1.3m, and therefore required diverting to allow the completion of the housing scheme. While carrying out a site visit to Oceans Estate, I also got an opportunity to visit the nearby Wates site. I received a guided tour of the site from the Construction Manager. The main area of engineering interest was the post-tensioning steel which was being employed for the floor slabs in this development. I was informed that the designers were able to reduce the thickness of the slab by 75mm due to the use of post-tensioning steel. The most noticeable feature of the post-tensioning steel was its deflected shape and simply how little re-bar was required relative to ordinary reinforced concrete. Once the poured concrete reaches about 10 N/mm2, the steel is jacked in order to obtain the required resistance. Upon my arrival to Oceans Estate, the works had been underway with some time. Trial Hole investigations had been completed and the installation of ductwork was proceeding well. It should be made clear that any diversion works are generally carried out between two existing Joint Bays. All cable works essentially have to be carried out between two joint bays or pulling pits, whether they be new or existing Joint Bays. Joint Bays are usually located up to a maximum of approximately 500m apart. It is essentially the point where one length of cable is connected to another to continue the circuit. These connections are carried out by specialist jointers who, in the case of Oceans Estate, were Skanska employees. JMS do not have the facility to joint cable and the jointers were provided directly by UKPN in any case. The works began with the location of the existing joint bays at either end of the required diversion and they were subsequently excavated to a preliminary depth. At the feasibility stage, a route from joint bay to joint bay is identified for the trench. From one joint bay, the trench is marked out on the road surface, leading to the other joint bay. The path of the trench takes into account other existing services in the road. A floor saw is used to mark the outer extremities of the trench. At this point, a breaker, which is a steel attachment connected to JCBs or diggers is used to break out the top layers of the road surface. The material is transported away via excavator, dumper and grab lorry. Excavations are then carried out to the required depth for the trench. This is completed using a combination of an excavator and hand digging as required. The trench excavations were generally carried out in manageable sections of approximately 30 40m so as to minimise the disruption to traffic along the 250m route in a residential area.

Page 5 of 27

UCC PLACEMENT REPORT

The trench configuration which can be seen in the appendix gives relatively fixed layers of material which must be installed in the trench: A small layer of CBS is applied on the base of the trench The ducts are laid as specified and surrounded by CBS Additional ducts to hold Pilots / Fibres are laid on top of the larger HV Cable Ducts A further layer of CBS is placed on top of the ducts Stokboards are placed on top of this which serve as a final warning as to the presence of HV Electrical Cables for any future excavations A substantial layer of Type 1 is subsequently installed The trench is then backfilled to road level using 20mm base followed by a layer of HRA

It should be noted that the exact depths of these layers can vary significantly from job to job and even section to section. The appendix shows a typical section for 22kV Circuits. The larger, lower layer of 160mm ducts will hold one circuit each. The ducts are supplied in 6m lengths and are connected using collars. Once this process of excavation, laying of ducts and reinstatement is complete from one joint bay to the other, it is essentially ready for cable installation. In advance of pulling cable, further excavation works are required at each joint bay to expose the existing joints. This also means the procurement of a temporary works design which has to be installed to ensure the safety of all persons entering the excavation. Once the temporary works design is in place, further hand digging is carried out to expose the existing joints which have to be decommissioned by the jointers. It should be noted that Method Statements have to be generated, distributed and signed previous to any works such as Trial Holes, Installation of Ducts, Excavation of Joint Bays and Installation of Cables. Once the site is ready for cable installation, calculations have to be carried out to determine the required quantity of cable and ensure that a sufficient meterage comes in the correct form: The total length of the route was approximately 250m with 4 no. Circuits. Each circuit has a triplex formation, as shown below, requiring 3 lengths of 250m. Therefore a minimum of 3,000 metres of cable was required for the installation. The cable is installed in each duct in the formation shown:

Thus, all three lengths of cable need to be pulled into the one duct simultaneously. In order to carry out this process, 3 separate drums of cable are required and they are mounted on a cable stand as shown in the appendix. Three drums each of slightly more than 1,000m would be the ideal.

*Please refer to appendix for location of Joint Bays.

Page 6 of 27

UCC PLACEMENT REPORT

The installation process involves blowing the ropes whereby a Bag is tied onto the front of rope and placed in the duct at the Oceans St. JB and then a cap which connects to the compressor is put onto this end of the duct with a small hole for the rope to feed through. The compressor is used to blow the rope through to the other Joint Bay (JB 22) where it is tied up. A winch is situated outside the Oceans St. JB. Once the ropes have been blown, brushes are connected to the ropes and pulled towards the JB 22 end by an additional winch set-up at the JB 22 end. At end of the brushes is steel wire feeding out of the main winch. As the rope is pulled through, with the brushes connected to the end, it is re-drummed at the JB 22 end, while the brushes clean the ducts, carrying the steel wire behind. The cable drums are situated at the JB 22 end where the steel wire is pulled to. An adaptor which can be seen in the appendix is used to connect the three cable drums to the steel wire. The winch at the Oceans St. JB is then used to pull the steel wire back through the ducts bringing the cables with it. At the JB 22 end, the cable is cut and cable caps are placed on both ends before the process is started again for next circuit. However it should be noted that the ropes for all four circuits and pilots are blown together but the ducts are cleaned / steel wire fed through after each pull. Following the installation of pilot cables through a similar process, the works are essentially complete. The penultimate stage is the jointing and decommissioning of the new and existing cables respectively. This stage is subject to severe time delays as it is solely dependent on the availability of the Jointers. 24-hour security is also present at this stage to protect the highly valuable copper core cable. Following the jointing and decommissioning of the respective cables, vast quantities of sandbags are placed around the joints in each Joint Bay. Finally, the two Joint Bays are reinstated back to the original Road Surface in the same layers as the trench, as detailed in the Section A-A Drawing in the Appendix.

Page 7 of 27

UCC PLACEMENT REPORT

FIFE ROAD 22kV CABLE INSTALLATION:

The works carried out by JMS in Fife Road, Newham, East London also revolved around the installation of 22kV HV Cable. UKPN proposed a substantial project on the site which essentially involved the development of a new substation and related ductwork leading into the substation. Countryside Construction were the main contractor commissioned to construct the substation and related ductwork. Therefore, JMS were only responsible for the actual installation of the 22kV HV Cable. However, JMS were also required in a consultancy role to carry out regular check-ups on the quality of the ductwork being installed. The excavation, ductwork and subsequent backfilling was similar to that in Oceans Estate. Following on from this, on completion of the ductwork, JMS had made provisions for a CCTV Survey to be carried out to ensure the integrity of the route provided by the ducts. This process is carried out by another specialist and essentially guarantees a clean pull when the cable is installed, i.e. that there will be nothing in the ducts obstructing the path of the cable. Cable installation takes place as near as possible to the arrival of the Jointers so as to minimise the high cost of security. Upon my departure, the cable was yet to be installed on the site. However, I did play an integral role in works nonetheless: In the absence of the PM, Colm Forde, I was tasked with ordering the cable for the installation works. This essentially consisted of measuring the route and calculating the total required length of cable. Armed with this information, I was then required to visit UKPNs storage area in New Cross to procure the required cable. The most important factor when ordering the cable is to understand how the cable is to be installed. Similar to Oceans Estate, the circuits contained 22kV Cable in triplex formation. However, the total length of the route was approximately 200m and only three circuits were required. Therefore, a minimum of 1800m of cable was required. As with Oceans Estate, a 3-drum cable stand would be used to pull the cable so it was vital that a minimum of 600m on all 3 drums was provided for the cable pulling gang so as to avoid any unnecessary re-drumming or additional jointing. Following on from the future cable installation, the Joint Bays will be backfilled in a similar format to that of Oceans Estate until they are reinstated to ground level.

Page 8 of 27

UCC PLACEMENT REPORT

ISLINGTON ST. PANCRAS FEASIBLITY STUDY:

The Islington St. Pancras Feasibility Study was undertaken on behalf of UKPN. The study essentially involved the investigation of the viability of installing 3 no. 132kV circuits and associated pilots. The proposed circuits would run along a road route joining the Islington and St. Pancras Substations. This feasibility study offered a valuable insight into the other aspects of Project Management. Whereas Oceans Estate and Fife Road had mainly involved site work, the two feasibilities would now mainly involve desktop research. Given that all four projects were essentially being carried out around the same time, it ensured a nice blend of site and office works from day to day. In relation to this feasibility study, my main duties essentially involved the analysis of the OS Tile and associated composites in an attempt to plot a viable route joining the two substations. The composites give an indication of the known services for the relevant area supplied by the consultant. Select Surveys Ltd. provided the OS tile with all the known utilities superimposed over it. From this it is possible to study the drawing and determine which roads are viable and which roads are too heavily congested with existing services and would not have sufficient space for a 1.3m wide trench. I was then tasked with plotting the proposed route and marking over 95 Trial Holes along the route, mainly at points where there were existing services, in an AutoCad Drawing. In addition to this, there were several meetings held with the main stakeholders in the project, namely UKPN, Islington Council, Camden Council and TFL. The meetings ranged from heated Commercial Meetings with the client (UKPN) in relation to the budgeted cost of the feasibility, to more relaxed meetings with the Local Councils where we sought approval for the various proposed routes. My main responsibilities involved the preparation of Drawings and concise reports on the proposed route working under severe time restraints, joining in the discussions at the meetings where relevant as well as the recording of minutes for all the various meetings. Upon my departure, there had been little progress made on this particular study following the most recent meeting with UKPN, Camden & Islington Councils and TFL where there had been serious concerns expressed over the viability of the proposed route. The works were essentially postponed pending a response from UKPN.

Page 9 of 27

UCC PLACEMENT REPORT

WILLESDEN GRID NEASDEN BSP FEASIBILITY STUDY:

The feasibility study on Willesden Grid Substation Neasden BSP consumed much of the latter weeks of the placement period with JMS. The kick-start meeting for the project took place on the 30th of June 2011 and was essentially a spin-off from a 132kV installation works which is now well into the construction stage in the St. Johns Wood area of London, also being completed by JMS. The feasibility study was undertaken on behalf of LUL and involved investigating the viability of installing 2 no. 132kV Circuits along a route joining Willesden Grid Substation and Neasden BSP. Two main route options were outlined by the client for further investigation: The Road Route was a Desktop Feasibility Study which essentially involved the identification of a viable route, developing a list of contacts of all stakeholders and submitting a preliminary route option report giving a breakdown of the proposed route. This route consisted of exiting Willesden Grid Substation at the road side and trenching about 4 km in a format quite similar to that of Oceans Estate. From here, a UTX of approximately 100 150 m would be required to enter Neasden Depot. Further trenching works would then lead to the BSP. The proposed Road Route was essentially commissioned to serve as a back up to LULs preferred Rail Route Option. Whereas the Road Route was commissioned as a desktop study which essentially identified the route, the Rail Route Option required the development of a CDS. A Conceptual Design Statement is a highly detailed feasibility study and is a document which, upon completion, should identify a definite route as well as any possible problems with constructability. Once the document is submitted to LUL, it allows them to circulate the CDS so that companies may make informed tenders for the construction phase. The main difference between a Feasibility Study and a CDS is simply the level of detail that is required. In this case, a feasibility essentially identifies the route and the stakeholders etc, in addition the CDS would propose cable configurations along the route as well as any required CMS, and it also involves contacting the stakeholders and gaining an agreement in principle for the proposed works as opposed to merely knowing who the stakeholders are in the case of a desktop feasibility. The CDS also involves procuring specialist consultants for boreholes at proposed UTX positions as well as an EMC specialist to ensure there is no de-rating of cables. My main duties during this project involved the development of cable route drawings and cross-sections which included the analysis of existing drawings. The works also required drafting a programme of works and cost loading the programme in conjunction with other members of the Power Division. As well as, drafting a budget cost, creation of a Provisional Route Option Report for the Rail Route, initial drafting of the CDS document, attending

Page 10 of 27

UCC PLACEMENT REPORT

meetings and keeping minutes and finally, keeping timesheets for all members of the team as the work was carried out on a time-charge basis. The study also involved carrying out various site surveys for both the Road and Rail Route Options. In addition, the Rail Route feasibility involved dealing with Network Rail who own the Freight Line which the 2no. 132kV Circuits were to run alongside. Several site surveys were carried out on the tracks to identify viable routes and also in an attempt to locate existing circuits. Access to the track requires successful completion of a twoday H&S training course or at a minimum a temporary pass which may only be used up to twelve times a year. The completion of the training course and the general access to the tracks was another great experience which I would not have enjoyed previously. In relation to the actual site surveys, the main objective is to gather as much information while trackside for future reference. This involves noting and picturing any relevant information and also recording any relevant dimensions of the track for future section drawings. Gaining access to the track can be difficult so it is vital to gather as much information as possible when the opportunity arises.

Page 11 of 27

UCC PLACEMENT REPORT

SKILLS / EXPERIENCE:

Upon reflection, the four various projects offered a great opportunity to develop a broad range of skills and experience. The variation between on-site works and desktop studies allowed for a nice mix of different work environments and hence an immense range of experiences. The on-site works greatly improved my experience in the methodology associated with cable installation including all the various plant used. Communication skills were also greatly improved when dealing with the operatives and giving instruction. Similarly, during the actual cable installation stage, I was responsible for ensuring that the correct type cable was installed in each duct and therefore had to ensure that the drawings were interpreted correctly and that this information was then related to the Cable Pulling Gang clearly and concisely. Similarly, interpersonal skills were vastly improved when dealing with Hire Companies and placing orders for materials such as concrete, timber, backfill material, etc. In relation to the office works, skills such as problem solving, business awareness, IT, meeting deadlines and initiative were all required on a regular basis.

My initiative and problem solving skills were applied and enhanced while creating the cable configuration drawings along the rail route for the Willesden Neasden Feasibility Study. Innovative Cable Management Systems had to be designed in order to allow the cable to pass through areas of limited clearance while maintaining the required separation between the circuits. The integral skill of Business Awareness was greatly improved through attending various Commercial Meetings with the clients (LUL & UKPN). During these meetings, the main agenda is the overall cost of the works. I quickly learned the importance of finding a balance between price, quality and time which satisfies all stakeholders where possible. Also, my IT Skills were constantly required and challenged over the period of the work placement, across all four projects. This ranged from Report Writing to creating As-Built Drawings, from developing schedules on Microsoft Project / Primavera to plotting routes on OS Tiles and from creating Cable Schedules to H&S and CDS Files. However, the main skill which I feel has been greatly improved over the course of the placement is my ability to work under pressure and meet impending deadlines. This manifested itself in many ways over the course of the placement, ranging from generating booklets for meetings, creating AutoCad Drawings, producing Allocation Sheets and Weekly & Monthly Reports, and forming tender documents in the face of encroaching deadlines. The main objective was to consistently have the documents completed on time for meetings / presentations while still maintaining JMSs high standards.

Page 12 of 27

UCC PLACEMENT REPORT

APPRASIAL OF WORK PLACEMENT:

Work Placement is a very broad term covering a wide variety of experiences for each individual student. Committing to take part in the Work Placement module has undoubtedly been the wisest decision I have made thus far in relation to module selection. The contacts and experience gained over the fourteen week term will surely prove invaluable in the future. Participating in the Work Placement module has given me a new found vigour for the upcoming years studies as it has illuminated the opportunities which await following graduation. The placement offered many challenges and learning opportunities, and kept me interested and engaged at all times. The training courses provided for interns were of a high quality, ensuring that the students adaptation to the new environment was completed quickly and efficiently. Coupled with this, the friendly and helpful attitude of the employees on site, as well as their willingness to provide in depth feedback and help with various problems, allowed me to become part of the team very quickly. I also achieved several qualifications while on placement which only added to the overall value of the placement. Qualifications included: CSCS Training Course: Essentially the UK version of the SafePass but still a mandatory requirement on most sites LUCAS Training Course: Received Smartcard which provides access to LUL Infrastructure PTS Training Scheme: Successful completion grants entry to work on or near NWR Rail Lines under certain terms

Material learned in the degree course at UCC was explored and expanded upon daily in the work environment, giving the student a unique opportunity to consolidate and ameliorate knowledge already acquired through college. Following on from feedback from Colm, it appears that from the companys point of view, the students most valuable assets were the previous and extensive knowledge of the AutoCad facility in creating drawings and plotting routes on OS Tiles as well as the ability to produce reports and minutes to a professional standard. Similarly, I feel that the broad variety of topics covered in the UCC degree programme means that regardless of the placement, there is always previously covered material which is applicable to the works.

Page 13 of 27

UCC PLACEMENT REPORT

The additional exposure to previously unseen material such as Allocation Sheets, Site-to-Site Transfers, Material Requisitions, Weekly & Monthly Progress Reports, Commercial & Progress Meetings coupled with one on one tutoring from qualified and experienced Project Managers, Senior Project Managers and Engineers ensured the student was afforded every opportunity to increase their knowledge base to new levels. In addition to the relevance of previously completed modules in the UCC undergraduate programme to the Work Placement, I also feel the industry experience has provided me with a better idea of the topics I wish to pursue more intently in the future. In relation to any suggestions I would make for changes to the degree course which would have assisted me in the preparation for Work Placement, there is but one. Having completed a term working in the industry, I can now vividly recognise the relevance of all the topics covered in the previous three years studies. However, the one suggestion I would make would be an addition to the Surveying Module which is completed in Second Year. The content of the particular module (CE2005) is undoubtedly sufficient; my only suggestion would be in relation to the amount of practical experience gained in the use of surveying equipment. Whilst the practicals do unquestionably cover all the required skills relevant to the workplace, I feel that there is need for more regular, mandatory practicals to be carried out. Industry feedback would suggest that the most important part of any surveying is to gain as much experience as possible in order to master the skill. Repetition is the key. Therefore, if it were compulsory for students to regularly carry out additional practicals in surveying during both Second Year and perhaps Third Year, the benefits would be immense when progressing to the workplace. In summary, my time as a member of the J Murphy & Sons team has been a very enjoyable experience. The latter weeks of the work placement were quite hectic yet thoroughly enjoyable, and I now relish the opportunity to whet my appetite for knowledge and experience in the future from a Construction, Engineering and Project Management point-of-view.

Page 14 of 27

UCC PLACEMENT REPORT

ADMINISTRATION OF 2011 PROGRAMME:

Overall, the Work Placement module was handled well by both the Civil Engineering Department and the Careers Service. The initial presentation by Linda Lynch at the beginning of the second teaching period, in January, provided ample information for students to make an informed decision on whether or not they wished to partake in the placement module. Following on from this, the use of UCC Blackboard to upload CVs, advertise and apply for jobs with its clean, concise and familiar interface made the process quick and easy. The selection system for placement positions is quite fair in the sense that you essentially have to accept the first offer you receive, because if students were allowed to decline positions in anticipation of future interviews it would not reflect well on the individual student or the college as a whole in the eyes of the perspective employer. The only other students who I came into contact with whilst on placement were enrolled in a part-time graduate programme whereby they attended college one day a week and worked with the company the other four days during the college term. Obviously their industry experience would be vast upon graduation. The work carried out by these students was reasonably similar to the tasks given to us, further proving the value of our placement. However, outside of this I do not feel that it bears a relevant comparison to our Work Placement experience from an administrative point of view. The visit by Dr. Creed was valuable as his impending arrival gave us an opportunity to reflect on the work we had carried out in the initial weeks and the experience we had gained in this time. It also provided him with an insight into the tasks we were carrying out and perhaps allowed him to determine the relevance to our degree programme. In relation to recommendations for the improvement of the administrative side of the placement module, I would only have one suggestion: I feel that students would greatly appreciate completing interviews and finding out if they have been accepted to a position much earlier in the academic year. I believe it was in the middle of April of 2011 before I was informed that I had been accepted to the placement position with JMS and there had been a great deal of uncertainty with regard to my plans for the summer previous to this. While I appreciate that a lot of these timescales are dependent on feedback from the perspective companies in terms of the availability of jobs, a representatives availability to carry out the interviews and the time to process applications and announce a successful candidate, I still feel that every effort should be made to try and confirm placement jobs as early as possible in the academic year.

Page 15 of 27

UCC PLACEMENT REPORT

APPENDIX:

Fig. 1 Use of post tensioning steel

Fig. 2 Allowance made for cranking of steel at end following pour

Page 16 of 27

UCC PLACEMENT REPORT

Page 17 of 27

UCC PLACEMENT REPORT

Page 18 of 27

UCC PLACEMENT REPORT

Fig. 3 Typical Trench Section

Fig. 4 Typical Trench Section showing Ducts, Stokboards, CBS and Type 1

Page 19 of 27

UCC PLACEMENT REPORT

Fig. 5 Excavation of Joint Bay showing temporary works and location of existing joints under concrete tiles

Fig. 6 Procurement of 22kV Drums for Oceans Estate

Page 20 of 27

UCC PLACEMENT REPORT

Fig. 7 Cable Stand and Mounting of Cable Drums

Page 21 of 27

UCC PLACEMENT REPORT

Fig. 8 Installation of Electrical Cable

Page 22 of 27

UCC PLACEMENT REPORT

Fig. 9 Completed Jointing of one circuit shown on RHS

Page 23 of 27

UCC PLACEMENT REPORT

Fig. 10 Installation of ductwork in Fife Road

Page 24 of 27

UCC PLACEMENT REPORT

Fig. 11 Islington St. Pancras Route Drawings

Page 25 of 27

UCC PLACEMENT REPORT

Fig. 12 Willesden Grid Substation Neasden BSP Route Overview

Page 26 of 27

UCC PLACEMENT REPORT

Fig. 13 Section Drawing showing examples of proposed Cable Management Systems

Page 27 of 27

Potrebbero piacerti anche

- Content 5 Days Training ProgramDocumento2 pagineContent 5 Days Training ProgramSamarendu BaulNessuna valutazione finora

- Work Placement ReportDocumento4 pagineWork Placement ReportmarinerollandNessuna valutazione finora

- Teamwork and success at IPEDocumento118 pagineTeamwork and success at IPEScore1234Nessuna valutazione finora

- Recruitment and Selection Procedure of ExIm Bank LTDDocumento79 pagineRecruitment and Selection Procedure of ExIm Bank LTDsagornondiNessuna valutazione finora

- PM ProjectDocumento21 paginePM ProjectHamayun RasheedNessuna valutazione finora

- Performance Measurement Systems in Construction: Roshana Takim, Akintola Akintoye and John KellyDocumento10 paginePerformance Measurement Systems in Construction: Roshana Takim, Akintola Akintoye and John KellyAsitha RathnayakeNessuna valutazione finora

- Inmt2232 2015 Sem-2 CrawleyDocumento7 pagineInmt2232 2015 Sem-2 CrawleyDoonkieNessuna valutazione finora

- Should Wealthy Nations Be Required To Share Their Wealth Among Poorer Nations by Providing Such Things As Food and EducationDocumento7 pagineShould Wealthy Nations Be Required To Share Their Wealth Among Poorer Nations by Providing Such Things As Food and EducationPham Ba DatNessuna valutazione finora

- EVS Project 1Documento68 pagineEVS Project 1aarshshah1075% (4)

- Internship ReportDocumento29 pagineInternship Reportapi-30214863675% (4)

- BIM-lean Construction-A Case StudyDocumento10 pagineBIM-lean Construction-A Case StudyGiang LamNessuna valutazione finora

- MIS604 Assessment Case Study FinalDocumento1 paginaMIS604 Assessment Case Study Finalhuma tariqNessuna valutazione finora

- PEL Transformer Unit Internship ReportDocumento39 paginePEL Transformer Unit Internship ReportMuhammad AhsenNessuna valutazione finora

- PM - Final DocumentationDocumento57 paginePM - Final DocumentationDomoNessuna valutazione finora

- Industrial Attachment ReportDocumento17 pagineIndustrial Attachment Reportlex tecNessuna valutazione finora

- Costello Qut Project Management Plan PHD Research ProposalDocumento17 pagineCostello Qut Project Management Plan PHD Research Proposalcostello_danielNessuna valutazione finora

- Project Failure AssignmentDocumento9 pagineProject Failure AssignmentJunaid Hassan0% (1)

- Albany Electric Vehicle Feasibility StudyDocumento62 pagineAlbany Electric Vehicle Feasibility StudySulaiman Khan100% (1)

- The Achievement of Organizational ObjectivesDocumento15 pagineThe Achievement of Organizational Objectivestheivathy100% (2)

- Guide To Avoiding PlagiarismDocumento31 pagineGuide To Avoiding Plagiarismalam80bdNessuna valutazione finora

- Project Proposal - Template PDFDocumento10 pagineProject Proposal - Template PDFMohamad ZulhilmiNessuna valutazione finora

- Understanding the Difference Between Goals and ObjectivesDocumento6 pagineUnderstanding the Difference Between Goals and Objectivesjayadarsini21130% (1)

- The Role of Team Effectiveness in Construction Project TeamsDocumento208 pagineThe Role of Team Effectiveness in Construction Project Teams05082618840% (1)

- PM Unit IDocumento84 paginePM Unit IAnonymous kwi5IqtWJNessuna valutazione finora

- Reflective PracticeDocumento8 pagineReflective PracticeMudzimai WanhasiNessuna valutazione finora

- Factors Affecting NewDocumento15 pagineFactors Affecting NewMwanaNgulumbi50% (2)

- Develop Critical Thinking Skills with Argumentative EssaysDocumento2 pagineDevelop Critical Thinking Skills with Argumentative Essayshehe02340% (1)

- The Importance of Project PlanningDocumento2 pagineThe Importance of Project PlanningPatrick Ferreira da SilvaNessuna valutazione finora

- Masters Project ProposalDocumento12 pagineMasters Project Proposalapi-217213523Nessuna valutazione finora

- HR Audit ChecklistDocumento28 pagineHR Audit ChecklistRogil Jacob DanielNessuna valutazione finora

- Industrial AttachmentDocumento59 pagineIndustrial Attachmentmauyon1100% (2)

- Freelancing Project ReportDocumento58 pagineFreelancing Project ReportSimran ChauhanNessuna valutazione finora

- Critical Success Factors For Construction Projects A Literature ReviewDocumento19 pagineCritical Success Factors For Construction Projects A Literature ReviewJuan AlayoNessuna valutazione finora

- Monthly Report-21-December To 20-January 20 11Documento46 pagineMonthly Report-21-December To 20-January 20 11ringlove97Nessuna valutazione finora

- Key influences driving construction innovationDocumento13 pagineKey influences driving construction innovationMaria Lucia Cuellar BustamanteNessuna valutazione finora

- How To Write A Concept PaperDocumento5 pagineHow To Write A Concept PaperJigar ChavdaNessuna valutazione finora

- Final Year Engineering Design ProjectsDocumento11 pagineFinal Year Engineering Design ProjectsVamsikrishna MalladiNessuna valutazione finora

- Literature Review On Higher Education QualityDocumento4 pagineLiterature Review On Higher Education QualityLaxminarayanaMurthyNessuna valutazione finora

- First Industrial Training at The Chemistry Department of Kyambogo UniversityDocumento13 pagineFirst Industrial Training at The Chemistry Department of Kyambogo UniversityKaaya GodfreyNessuna valutazione finora

- Externalities:: Private Costs and Private BenefitDocumento17 pagineExternalities:: Private Costs and Private Benefitpunte77Nessuna valutazione finora

- Doctor of Business Administration CourseworkDocumento8 pagineDoctor of Business Administration Courseworkbcrqy80d100% (2)

- Fire Protection For Student HostelDocumento11 pagineFire Protection For Student Hostelsasitharta100% (2)

- Project of Green BuildingDocumento53 pagineProject of Green BuildingShrikant PatilNessuna valutazione finora

- Mebrhit ProposalDocumento20 pagineMebrhit ProposaltesfayNessuna valutazione finora

- "Energy Audit ": "Energy Conservation Awareness Program " Conducted By: Caruttar Education Navrachna Trust, AnandDocumento49 pagine"Energy Audit ": "Energy Conservation Awareness Program " Conducted By: Caruttar Education Navrachna Trust, AnandJayu DarjiNessuna valutazione finora

- Du CompanyDocumento6 pagineDu CompanyRanjit Vasudevan100% (1)

- Allocating Rewards for Bank Employees' PerformanceDocumento2 pagineAllocating Rewards for Bank Employees' PerformancemanuchauhanNessuna valutazione finora

- Project On Employee SatisfactionDocumento71 pagineProject On Employee SatisfactionvinaykulagodNessuna valutazione finora

- CSR Activity AssignmentDocumento10 pagineCSR Activity AssignmentDe Eventia GuruNessuna valutazione finora

- Project ReportDocumento101 pagineProject Reportसुभाष सिँहNessuna valutazione finora

- Format For Industrial Training Report0 PDFDocumento64 pagineFormat For Industrial Training Report0 PDFashawishNessuna valutazione finora

- PM0010 SLM Unit 07Documento22 paginePM0010 SLM Unit 07idealparrotNessuna valutazione finora

- Basics of Sensors - Siemens WW (Industrial Automation Sensors)Documento112 pagineBasics of Sensors - Siemens WW (Industrial Automation Sensors)VanNinh TNNessuna valutazione finora

- Building A New SubstationDocumento6 pagineBuilding A New SubstationUsman HaroonNessuna valutazione finora

- Offshore Renewables BrochureDocumento24 pagineOffshore Renewables BrochureAhmed TahaNessuna valutazione finora

- Full ProjectDocumento10 pagineFull ProjectIsmail HussainNessuna valutazione finora

- Industry Requests Revision of Standards To Ensure Safe Operation of Cranes and Reduce CasualtiesDocumento1 paginaIndustry Requests Revision of Standards To Ensure Safe Operation of Cranes and Reduce CasualtiesjillianixNessuna valutazione finora

- MLK Projects Brochure COSSDocumento6 pagineMLK Projects Brochure COSSdmoghaNessuna valutazione finora

- CDR Electrical EngineerDocumento13 pagineCDR Electrical Engineerfh63775% (4)

- 132kV Substation Feasibility StudyDocumento16 pagine132kV Substation Feasibility StudyTafadzwa MurwiraNessuna valutazione finora

- MBA Study On Organisational Culture and Its Impact On Employees Behaviour - 237652089Documento64 pagineMBA Study On Organisational Culture and Its Impact On Employees Behaviour - 237652089sunitha kada55% (20)

- Консп 1Documento48 pagineКонсп 1VadymNessuna valutazione finora

- Perceptron Example (Practice Que)Documento26 paginePerceptron Example (Practice Que)uijnNessuna valutazione finora

- HAU Theology 103 Group Goal Commitment ReportDocumento6 pagineHAU Theology 103 Group Goal Commitment ReportEM SagunNessuna valutazione finora

- Structural Testing Facilities at University of AlbertaDocumento10 pagineStructural Testing Facilities at University of AlbertaCarlos AcnNessuna valutazione finora

- DCinv V6 Rev2 CleanDocumento38 pagineDCinv V6 Rev2 Cleanyasirarafat91Nessuna valutazione finora

- Introduction to Corporate Communication ObjectivesDocumento26 pagineIntroduction to Corporate Communication ObjectivesKali MuthuNessuna valutazione finora

- 1 PDFDocumento14 pagine1 PDFPM JFNessuna valutazione finora

- Boston Qualitative Scoring System for Rey-Osterrieth Complex Figure Effective for Detecting Cognitive Impairment in Parkinson's DiseaseDocumento9 pagineBoston Qualitative Scoring System for Rey-Osterrieth Complex Figure Effective for Detecting Cognitive Impairment in Parkinson's DiseaseJuanNessuna valutazione finora

- Dimensioning GuidelinesDocumento1 paginaDimensioning GuidelinesNabeela TunisNessuna valutazione finora

- NAVMC 3500.35A (Food Services)Documento88 pagineNAVMC 3500.35A (Food Services)Alexander HawkNessuna valutazione finora

- Advance Control Systems LabDocumento2 pagineAdvance Control Systems Labpadmajasiva100% (1)

- Grammar Booster: Lesson 1Documento1 paginaGrammar Booster: Lesson 1Diana Carolina Figueroa MendezNessuna valutazione finora

- Corporate Strategic Planning AssignmentDocumento10 pagineCorporate Strategic Planning AssignmentSumit DuttaNessuna valutazione finora

- 2-Eagan Model of CounsellingDocumento23 pagine2-Eagan Model of CounsellingVijesh V Kumar100% (4)

- Appointment Letter JobDocumento30 pagineAppointment Letter JobsalmanNessuna valutazione finora

- MySQL Cursor With ExampleDocumento7 pagineMySQL Cursor With ExampleNizar AchmadNessuna valutazione finora

- COS1512 202 - 2015 - 1 - BDocumento33 pagineCOS1512 202 - 2015 - 1 - BLina Slabbert-van Der Walt100% (1)

- Google Fusion Tables: A Case StudyDocumento4 pagineGoogle Fusion Tables: A Case StudySeanNessuna valutazione finora

- Omega Fluid PDFDocumento2 pagineOmega Fluid PDFapatzinfedNessuna valutazione finora

- I&C Engineer or Automation EngineerDocumento3 pagineI&C Engineer or Automation Engineerapi-79304330Nessuna valutazione finora

- HTTP - WWW - Aphref.aph - Gov.au - House - Committee - Pjcis - nsl2012 - Additional - Discussion Paper PDFDocumento61 pagineHTTP - WWW - Aphref.aph - Gov.au - House - Committee - Pjcis - nsl2012 - Additional - Discussion Paper PDFZainul Fikri ZulfikarNessuna valutazione finora

- Rhodium Catalyzed Hydroformylation - CH 07Documento14 pagineRhodium Catalyzed Hydroformylation - CH 07maildesantiagoNessuna valutazione finora

- How To Prepare Squash Specimen Samples For Microscopic ObservationDocumento3 pagineHow To Prepare Squash Specimen Samples For Microscopic ObservationSAMMYNessuna valutazione finora

- Antiepilepticdg09gdg 121231093314 Phpapp01Documento145 pagineAntiepilepticdg09gdg 121231093314 Phpapp01Vaidya NurNessuna valutazione finora

- Growing Up Psychic by Chip Coffey - ExcerptDocumento48 pagineGrowing Up Psychic by Chip Coffey - ExcerptCrown Publishing Group100% (1)

- Assignment2-9509Documento5 pagineAssignment2-9509ritadhikarycseNessuna valutazione finora

- Evidence My Favorite PlayerDocumento2 pagineEvidence My Favorite PlayerReynel Soir0% (1)

- Decision MatrixDocumento12 pagineDecision Matrixrdos14Nessuna valutazione finora

- HistoryDocumento45 pagineHistoryRay Joshua Angcan BalingkitNessuna valutazione finora

- Piping and Pipeline Calculations Manual: Construction, Design Fabrication and ExaminationDa EverandPiping and Pipeline Calculations Manual: Construction, Design Fabrication and ExaminationValutazione: 4 su 5 stelle4/5 (18)

- Transportation Engineering: Theory, Practice, and ModelingDa EverandTransportation Engineering: Theory, Practice, and ModelingNessuna valutazione finora

- The Things We Make: The Unknown History of Invention from Cathedrals to Soda CansDa EverandThe Things We Make: The Unknown History of Invention from Cathedrals to Soda CansNessuna valutazione finora

- To Engineer Is Human: The Role of Failure in Successful DesignDa EverandTo Engineer Is Human: The Role of Failure in Successful DesignValutazione: 4 su 5 stelle4/5 (137)

- Methodology for Estimating Carbon Footprint of Road Projects: Case Study: IndiaDa EverandMethodology for Estimating Carbon Footprint of Road Projects: Case Study: IndiaNessuna valutazione finora

- Cable Supported Bridges: Concept and DesignDa EverandCable Supported Bridges: Concept and DesignValutazione: 5 su 5 stelle5/5 (1)

- Crossings: How Road Ecology Is Shaping the Future of Our PlanetDa EverandCrossings: How Road Ecology Is Shaping the Future of Our PlanetValutazione: 4.5 su 5 stelle4.5/5 (10)

- The Great Bridge: The Epic Story of the Building of the Brooklyn BridgeDa EverandThe Great Bridge: The Epic Story of the Building of the Brooklyn BridgeValutazione: 4.5 su 5 stelle4.5/5 (59)

- Principles of Forensic Engineering Applied to Industrial AccidentsDa EverandPrinciples of Forensic Engineering Applied to Industrial AccidentsNessuna valutazione finora

- Summary of Neil Postman's Amusing Ourselves to DeathDa EverandSummary of Neil Postman's Amusing Ourselves to DeathValutazione: 4 su 5 stelle4/5 (2)

- The Things We Make: The Unknown History of Invention from Cathedrals to Soda CansDa EverandThe Things We Make: The Unknown History of Invention from Cathedrals to Soda CansValutazione: 4.5 su 5 stelle4.5/5 (21)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- Shallow Foundations: Discussions and Problem SolvingDa EverandShallow Foundations: Discussions and Problem SolvingValutazione: 5 su 5 stelle5/5 (1)

- Introducing Structures: A Textbook for Students of Civil and Structural Engineering, Building and ArchitectureDa EverandIntroducing Structures: A Textbook for Students of Civil and Structural Engineering, Building and ArchitectureValutazione: 4.5 su 5 stelle4.5/5 (11)

- Climate Adaptation Engineering: Risks and Economics for Infrastructure Decision-MakingDa EverandClimate Adaptation Engineering: Risks and Economics for Infrastructure Decision-MakingNessuna valutazione finora

- Field Book for Quality Control in Earthwork Operations: Project Construction Management BookDa EverandField Book for Quality Control in Earthwork Operations: Project Construction Management BookNessuna valutazione finora

- Professional Surveyors and Real Property Descriptions: Composition, Construction, and ComprehensionDa EverandProfessional Surveyors and Real Property Descriptions: Composition, Construction, and ComprehensionNessuna valutazione finora