Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Types of Boiler Coal Pulverizers

Caricato da

savyasachi2020Descrizione originale:

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Types of Boiler Coal Pulverizers

Caricato da

savyasachi2020Copyright:

Formati disponibili

Types of Boiler Coal Pulverizers

http://www.brighthub.com/engineering/mechanical/articles/62778.aspx

Sign in | Join | Browse Site

pulverizer types

Searc h

Home > Engineering > Mechanical Engineering > Energy/ Power Plants

10 Comments

Types of Coal Pulverizers in Power Plants

Written by: johnzactruba Edited by: Lamar Stonecypher Published Jan 29, 2010 Pulverizing the coal to a fine powder is an important function in the operation of a power plant. This article explains the different methods of pulverizing. The key input to the coal fired power plant is the coal. Coal in the form that is available from the mines is not 1 suitable for efficient combustion in the boiler of the power plant. The pulverizing system prepares the coal for combustion.

1

There are basically three different types of pulverizing.

1. Attrition Type

MECHANICAL ENGINEERING CAD Software Construction Technology Energy/ Power Plants Engineering Materials Fluid Machines/ Hydraulics General HVACR Machine Design Manufacturing Technology Mechatronics Robotics Thermodynamics FEATURED AUTHORS

Coal feeds onto a steel rotating table. Tapered, cylindrical, or spherical rollers on top of the table, under 0 spring pressure, exert force on the coal particles on the table. When the table rotates, the coal passes between the rollers and the table and gets ground due to attrition. The hot air under pressure carries this 0 ground coal upwards. Larger particles fall back to the grinding table. These coal particles then pass through a classifier where the large particles get separated due to centrifugal action and are returned back to the 5 grinding table. Different manufacturers use different type of rollers. Bowl mills or Raymond mills use tapered rollers. MPS mill use tire type rollers and are called roller mills. The ball and race mills use spherical rollers. The main characteristics are:

Siemens answers:

www.siemens.com/answers

The digital factory Answers for industry.

Ads by Google

Lower investment costs than other types. Smaller capacity for each mill means a better degree of combustion flexibility. They require periodic roller changes as they wear out during pulverizing, increasing the maintenance cost. Harder coals require this type of pulverizers.

2. Impact and Attrition Type

Coal is fed into a rotating cylinder containing steel balls of around 50 mm diameter. When the cylinder rotates, the balls rotate along with the cylinder and fall down when they reach the top position. Coal is ground due to attrition and impact. Coal feeds into the cylinder axially at one side and discharges through the other side. Hot air or gas carries away the fine coal through the other end of the Tube. This called the Tube mill or Ball mill. These types of mills have: Initial costs that is higher. Maintenance that is considerably less. As the balls wear out during operation, the addition of fresh ball charges can be done while the mill is running. Can give a very high fineness coal with a high percentage of fines.

MOST POPULAR ARTICLES Coal Fired Thermal Power Plant: The Basic Steps and Facts General Layout of a Thermal Power Plant Types of Power Plants - Generation of Electrical Energy How does a Power Plant Boiler work? - Water and Steam System. What is a Supercritical Power Plant? Basic Calculations for a Power PlantCalculating the Coal Quantity How does a Circulating Fluidized Bed Boiler Work ? How does a Gas Turbine Power Plant Work? The Auxiliary Systems. How does a Gas Turbine Power Plant Work? The Main Equipment. How Does a Thermal Power Plant Function?

3. Impact or Hammer Type

This type consists of a rotating shaft inside a stationary cylinder . The shaft contains arms that impact the coal inside the cylinder. The impact powders the coal. The hot air carries the coal to the burners. This is more suitable for softer coals with a higher Grindability index. Periodic replacement of hammers because of wear is a requirement. Another version of this in Lignite fired power plants.This is in the form of a fan and doubles as a fan and a mill. The impellers act as the hammers. The main charectristics are: Lower costs. Suitable only for softer coals. Low fineness output. Selection of the type of pulverizer depends on

1 of 4

11/5/2011 12:37 PM

Types of Boiler Coal Pulverizers

http://www.brighthub.com/engineering/mechanical/articles/62778.aspx

Grindability of the coal. Capital cost and maintenance cost is another criteria. Patent rights and licence agreements also decide which type of pulverizer the boiler suppliers recommend. NEXT ARTICLE Comments | Flag

WE ALSO RECOMMEND...

Coal Pulverising in Boilers Coal Hang-up in Bowl Mill Classification of Steam Boilers Soot Blowers in Thermal Power Plants Effect of Mill Outlet Temperature on Boiler Performance

Ads by Google

FFIEC 2011 Guidelines 1

Gain Insights on Key Strategies To Meet And Exceed FFIEC Guidelines www.Actimize.com/FFIEC 1 Like

0

Add New Comment

Optional: Login below.

Showing 10 comments

Sort by Subscribe by email Subscribe by RSS

Real-time updating is enabled. (Pause)

Dear Sir, We are interested to purchase the new pulverizer 613 BOWL Mill. Kindly send us technical literature and price at the earliest material to be ground Rock Phosphate.

Regards, Muhammad Afzal Chaudhry Managing Director Lyallpur Chemicals & Fertilizer(Pvt) Ltd Jaranwala, PAKISTAN Ph # +92-41-4313021-22 Fax # +92-41-4312628

Hi I am Prince Sambo. I work for a copper smelter. I sometimes experience problems of a coal mill tripping. There are 4 coal mills sized EL44. These millls were manufactured by Babcock & Wilcox. Came you please help me with the following questions: What are the common causes of a coal mill to trip? What is the remedy once the problem has occurred? What is the

2 of 4

11/5/2011 12:37 PM

Types of Boiler Coal Pulverizers

http://www.brighthub.com/engineering/mechanical/articles/62778.aspx

preventative measure for coal mill trip?

Coal pulverizers require a lot of maintenanace and is usually periodically shutdown for maintenance. So if you have a removable type of orifice you can simply remove this and put a new one. This could be something like the optometrists testing glasses where they keep on changing the lens to fin the correct lens size. You could mount the orifice in between two flanges. By loosening the flanges the orifice can be slipped in and out. Or if you want a more elaborate method you can design something like a cammera lens shutter , which by turning from outside will be able to change the orifice size.

1 respected sir, coal-air balancing in pulverized coal (PC PIPES) pipes is one of the major problem in a thermal power plant. so design of optimum geometry of orifices is one of the solution of this problem.but in this design of orifice is changed due to erosion 1 after some time. so we have to stop the work to change these orifices.so balancing cannot be done online. so to remove this problem insertion of wedge element is another method rectangular slot is made on the top of pipe so that a rectangular wedge can be0inserted in pipe. BY adjusting the amount of insertion("h/d" ration of wedge),flow resistance across the pipeline could be adjusted. where "h" is the distace from the tip of wedge to bottom of pipe and "d" is the dia of pipe. 0 sir would u suggest me some other methods to overcome this coal-air balance problem i m presently studying in iit delhi n my guide warning that u hv to be very careful on 18th september , my presentation is 0 held on that day. sir i m mentally upset and continously thinking about what can be others method. but hopeless as time is very less. Obtaining good grading is now not the criterion for me. In front of him i will unable to stand comfortably even single minute if i dnt suggest him some another method. plz sir help me out of this problem i will be highly thankful to u in 5 my future life.

Inerting systems are used to ifrst kill the fire. CO2, N2 or steam is used as an inerting system. On indication of fire air and fuel feed is cut off. The inerting medium is injected. Water is used only at the last to flush or clean.

how to protect the pulverizer from fire or explotion

thank u sir...how can we say beater mill is energy efficient sir?

sir how can we say beater mill saves power?for the same capacity beater mills rotate at high speed compare to bowl mill.then how its save power? and,did u mean to say if we are using beater mill, then no fans are required to take the coal into the furnace.

Lignites are generally softer coals requiring lesser grinding power than bituminous coals. Lignites have much higher moisture content and require large quantities of hot air or gas. This is why beater mills are used. The mill doubles as fan and pulveriser saving power and equipment cost.

3 of 4

11/5/2011 12:37 PM

Types of Boiler Coal Pulverizers

http://www.brighthub.com/engineering/mechanical/articles/62778.aspx

sir, i'm dhinesh working in coal based thermal power plant.i have a doubt related to pulverizer.why cant we use a mill other than beater mill for pulverizing lignite? what's the power consumption of beater mill(210T/hr) and other mills for handling the same capacity?can we use bowl mill for lignite fired boilers?can u help me!!

blog comments powered by DISQUS

About Bright Hub Contact Us Advertise with Us Become a Writer RSS

1

Site Map Terms of Use Privacy Policy Copyright Policy

WRITE FOR BRIGHT HUB

Bright Hub is looking for talented writers to contribute to one of the fastest growing communities online. If you have something bright to say, say it here! Learn more here.

Enter Your Search...

SIGN UP FOR OUR NEWSLETTER

Mechanical Engineering Channel News | View All News

2011 Bright Hub Inc. All rights reserved.

Enter Your Email...

0

4 of 4

11/5/2011 12:37 PM

Potrebbero piacerti anche

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5795)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (345)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (121)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (74)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- 3g 4g Call FlowDocumento16 pagine3g 4g Call Flowpoiuytreza26Nessuna valutazione finora

- VM 6083 - 60B1 Data SheetDocumento3 pagineVM 6083 - 60B1 Data SheetMinh HoàngNessuna valutazione finora

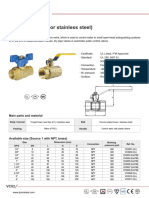

- VC02 Brass Ball Valve Full Port Full BoreDocumento2 pagineVC02 Brass Ball Valve Full Port Full Boremahadeva1Nessuna valutazione finora

- Quadcopter Design DocumentDocumento23 pagineQuadcopter Design Documentapi-556772195Nessuna valutazione finora

- Platinum Collection v-22 Osprey ManualDocumento24 paginePlatinum Collection v-22 Osprey ManualP0wer3D100% (2)

- GD200A Manual EnglishDocumento269 pagineGD200A Manual Englishtran dieuNessuna valutazione finora

- Neurophone Ebook EnglDocumento19 pagineNeurophone Ebook EnglViolin_teacher100% (3)

- ExpertFit Student Version OverviewDocumento23 pagineExpertFit Student Version Overviewlucas matheusNessuna valutazione finora

- What Is JavaScriptDocumento10 pagineWhat Is JavaScriptKhalinux AnonimoNessuna valutazione finora

- Fisher Imprints: Inter-Disciplinary PressDocumento8 pagineFisher Imprints: Inter-Disciplinary PressUndi GunawanNessuna valutazione finora

- Seismic Assessment of RC Building According To ATC 40, FEMA 356 and FEMA 440Documento10 pagineSeismic Assessment of RC Building According To ATC 40, FEMA 356 and FEMA 440sobah assidqiNessuna valutazione finora

- S11ES Ig 16Documento4 pagineS11ES Ig 16allanrnmanalotoNessuna valutazione finora

- 3 - Pitot-Static Inst, System & ADC - OcrDocumento110 pagine3 - Pitot-Static Inst, System & ADC - OcrtmhoangvnaNessuna valutazione finora

- D&D 5e Conditions Player ReferenceDocumento1 paginaD&D 5e Conditions Player ReferenceFrank Wilcox, Jr (fewilcox)Nessuna valutazione finora

- ISRA University FormDocumento4 pagineISRA University Formpure14Nessuna valutazione finora

- TECDCT-2145 Cisco FabricPathDocumento156 pagineTECDCT-2145 Cisco FabricPathWeiboraoNessuna valutazione finora

- Sts Lesson 6Documento13 pagineSts Lesson 6Ivy Joy BelzaNessuna valutazione finora

- Multi Trade PrefabricationDocumento6 pagineMulti Trade PrefabricationPaul KwongNessuna valutazione finora

- POCLP010101 Wood PelletsDocumento1 paginaPOCLP010101 Wood PelletsPratiwi CocoNessuna valutazione finora

- ABB - PCS 6000 STATCOM - Reference ListDocumento8 pagineABB - PCS 6000 STATCOM - Reference ListProyectos IPC S.A.S - Manuel CadenaNessuna valutazione finora

- Yousif Yassin PDFDocumento124 pagineYousif Yassin PDFJAVIYAROSNessuna valutazione finora

- Brochure Otis Gen360 enDocumento32 pagineBrochure Otis Gen360 enshimanshkNessuna valutazione finora

- A Database of Aerothermal Measurements in Hypersonic Flow in "BuildingDocumento60 pagineA Database of Aerothermal Measurements in Hypersonic Flow in "BuildingNeoNessuna valutazione finora

- Self Priming Centrifugal Pump: Models 03H1-GL, 03H1-GR, 03H3-GL and 03H3-GRDocumento4 pagineSelf Priming Centrifugal Pump: Models 03H1-GL, 03H1-GR, 03H3-GL and 03H3-GRdougNessuna valutazione finora

- Sub Station ReportDocumento43 pagineSub Station ReportSithartha SouryaNessuna valutazione finora

- Proposal For Voice AppDocumento3 pagineProposal For Voice Appavneet1993Nessuna valutazione finora

- 2.0 DCV-Brochure BV Valves (Pages) R01 PDFDocumento12 pagine2.0 DCV-Brochure BV Valves (Pages) R01 PDFAliZenatiNessuna valutazione finora

- Deepwell Submersible Motor 50HzDocumento38 pagineDeepwell Submersible Motor 50HzSujanto WidjajaNessuna valutazione finora

- A. Irimia Diéguez 2023 - TPBDocumento23 pagineA. Irimia Diéguez 2023 - TPBakuntansi syariahNessuna valutazione finora

- Testing A SCRDocumento2 pagineTesting A SCRtenisonNessuna valutazione finora