Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Exc

Caricato da

NimeshDescrizione originale:

Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Exc

Caricato da

NimeshCopyright:

Formati disponibili

In known systems, field current for the main generator portion is developed at a beginning of operation in a starting mode by providing

AC power at a controlled frequency and voltage to a set of exciter field windings. AC power is developed in armature windings of the exciter by transformer action and such power is rectified by a rotating rectifier and provided to the field winding of the main generator portion. In order to prevent saturation of the exciter armature windings, it is necessary to provide the AC power to the exciter field windings at a certain voltsper-hertz ratio. In addition, in order to operate the generator as a motor at unity power factor, it is necessary to provide a certain voltage to the exciter field windings for a given armature current. In the case of a brushless generator which is designed to produce 400 hz., 115 volt power, it is necessary to provide 90 volts to the exciter field windings during operation in the starting mode. This voltage, in turn, must be provided at 1200 hz. to prevent saturation of the exciter armature windings. Since starting is usually accomplished using 400 hz., 115 volt AC power supplied by a ground cart or other external AC source, it has been found necessary to use an auxiliary inverter to convert such power into the required 1200 hz., 90 volt power for starting. In some applications, the use of an auxiliary inverter may be considered undesirable.

Electric generators work on the principle of Faradays electromagnetic induction. The essential part of this principle is the magnetic field. The magnetic filed is produced from a DC power source from an Exciter that is part of the generator system. Read on ... The main requirement for electricity generation as per the basic principle is a magnetic field. The generator while producing electricity also has to produce this at a constant voltage for the electrical system to work properly. Controlling the magnetic field controls the voltage output of the generator. How does one produce and control this magnetic field in a large generator? The rotor or the field coils in a generator produce the magnetic flux that is essential to the production of the electric power. The rotor is a rotating electromagnet that requires a DC ( Direct Current) electric power source to excite the magnetic field. This power comes from an exciter. In earlier days, the exciter was a small DC generator coupled to the same shaft as the rotor. Therefore, when the rotor rotates this exciter produces the power for the electromagnet. Control of the exciter output is done by varying the field current of the exciter. This output from the exiter then controls the magnetic field of the rotor to produce a constant voltage output by the generator. This DC current feeds to the rotor through slip rings. In modern generators the exciters are static. The DC power for the electromagnet is from the main generator output itself. A number of high power thyristors rectify the AC current to produce a DC current which feeds to the rotor through slip rings. This eliminates the operation and maintenance problems

DC Exciter

Static Exciter

Brushless Exciter

associated with having another rotating machine. Static exciters offer a better control of the output than an electromechanical control. During start up, when there is no output from the generator, a large battery bank provides the necessary power for excitation. Another method is the brushless system. In this system the armature of the exciter is on the rotor shaft itself. The DC output of this armature, after rectification by solid-state devices, goes to the rotor coils. Since the armature and rotor are on the same rotating shaft, this eliminates the need for slip rings. Hence it reduces maintenance and operational requirements and thus improving reliability

Read more: http://www.brighthub.com/engineering/mechanical/articles/45650.aspx#ixzz0v10 29I9k

Potrebbero piacerti anche

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (119)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (587)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2219)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (344)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (894)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (73)

- EHV Prot - 2011Documento70 pagineEHV Prot - 2011NimeshNessuna valutazione finora

- MV VFDDocumento34 pagineMV VFDKelvin LiewNessuna valutazione finora

- Vachanamrut GujaratiDocumento760 pagineVachanamrut Gujaratiapi-287811173Nessuna valutazione finora

- Service Manual GT46 MACDocumento887 pagineService Manual GT46 MACmadhwan sharma100% (2)

- ABB - Generator Protections GuideDocumento45 pagineABB - Generator Protections GuideAyesha ShaikhNessuna valutazione finora

- US Navy Course NAVEDTRA 14323 - Aviation Electricity & Electronics - Power Generation & DistributDocumento54 pagineUS Navy Course NAVEDTRA 14323 - Aviation Electricity & Electronics - Power Generation & DistributGeorges100% (1)

- Bus Bar SchemesDocumento35 pagineBus Bar SchemesbijoyNessuna valutazione finora

- ACS880 IGBT Supply Control Program: Firmware ManualDocumento254 pagineACS880 IGBT Supply Control Program: Firmware ManualGopinath PadhiNessuna valutazione finora

- Practical Introduction To Power System Protection & ControlDocumento94 paginePractical Introduction To Power System Protection & Controlriogomes73% (11)

- Gas Turbine PresentationDocumento54 pagineGas Turbine Presentationvasanth11kv100% (2)

- EBS Series Drives Installation Manual: User DocumentationDocumento42 pagineEBS Series Drives Installation Manual: User Documentationerasmo100% (1)

- Restricted Earth Fault Protection For Transformers: 1.0 GeneralDocumento6 pagineRestricted Earth Fault Protection For Transformers: 1.0 GeneralNimeshNessuna valutazione finora

- Protection of AUX POWER SUPPLYDocumento51 pagineProtection of AUX POWER SUPPLYNimeshNessuna valutazione finora

- Detect and Extinguish Fires in Gas Turbines with CO2 and Fire Detection SystemsDocumento3 pagineDetect and Extinguish Fires in Gas Turbines with CO2 and Fire Detection SystemsNimeshNessuna valutazione finora

- Negative Sequence ProtectionDocumento4 pagineNegative Sequence ProtectionNimeshNessuna valutazione finora

- Generator Protection SchemesDocumento10 pagineGenerator Protection SchemesSravya LeoNessuna valutazione finora

- HRSG Cold Start Up As Per ManualDocumento1 paginaHRSG Cold Start Up As Per ManualNimeshNessuna valutazione finora

- Design and Construction of Control System For Automatic Voltage StabilizerDocumento6 pagineDesign and Construction of Control System For Automatic Voltage StabilizerEditor IJTSRDNessuna valutazione finora

- Amal Power Station Typical GTG Tripping Matrix: P Etroleum Develop Ment OmanDocumento6 pagineAmal Power Station Typical GTG Tripping Matrix: P Etroleum Develop Ment OmanNimeshNessuna valutazione finora

- Boiler Water NotesDocumento7 pagineBoiler Water NotesOng SooShinNessuna valutazione finora

- EssayDocumento1 paginaEssayNimeshNessuna valutazione finora

- Design and Construction of 20 K VA Automatic Voltage Stabilizer Control SystemDocumento11 pagineDesign and Construction of 20 K VA Automatic Voltage Stabilizer Control SystemNimeshNessuna valutazione finora

- Student EssaysDocumento24 pagineStudent EssaysNimeshNessuna valutazione finora

- Neutral Failure DetectionDocumento9 pagineNeutral Failure DetectionNimeshNessuna valutazione finora

- Armature Reaction in Alternator or Synchronous Generator PDFDocumento4 pagineArmature Reaction in Alternator or Synchronous Generator PDFNimeshNessuna valutazione finora

- Buck Boost SizingDocumento3 pagineBuck Boost SizingNimeshNessuna valutazione finora

- Buck Boost SizingDocumento3 pagineBuck Boost SizingNimeshNessuna valutazione finora

- Design and Construction of Control System For Automatic Voltage StabilizerDocumento6 pagineDesign and Construction of Control System For Automatic Voltage StabilizerEditor IJTSRDNessuna valutazione finora

- Neutral Failure DetectionDocumento9 pagineNeutral Failure DetectionNimeshNessuna valutazione finora

- Bus ProtectionPROTECTIONDocumento4 pagineBus ProtectionPROTECTIONHamayoun MurtazaNessuna valutazione finora

- Design and Construction of Control System For Automatic Voltage StabilizerDocumento6 pagineDesign and Construction of Control System For Automatic Voltage StabilizerEditor IJTSRDNessuna valutazione finora

- TestsDocumento109 pagineTestsajeetpatwardhanNessuna valutazione finora

- Insulation (Temperature) Classes: Lammers Exico LimitedDocumento1 paginaInsulation (Temperature) Classes: Lammers Exico LimitedNimeshNessuna valutazione finora

- VBA CODE TO CORRECT CASE AND FORMAT CELLSDocumento6 pagineVBA CODE TO CORRECT CASE AND FORMAT CELLSNimeshNessuna valutazione finora

- Armature Reaction in Alternator or Synchronous GeneratorDocumento4 pagineArmature Reaction in Alternator or Synchronous GeneratorNimeshNessuna valutazione finora

- High Frequency Link Inverters and Multiresonant ControllersDocumento192 pagineHigh Frequency Link Inverters and Multiresonant ControllerssaichanNessuna valutazione finora

- Eikon E4Documento60 pagineEikon E4mawi baeNessuna valutazione finora

- Experiment 5Documento3 pagineExperiment 5Farhana LisaNessuna valutazione finora

- Advanced ATM Security System by Using Smart Card and IOT TechnologyDocumento69 pagineAdvanced ATM Security System by Using Smart Card and IOT Technologykota naikNessuna valutazione finora

- RM2048A Rectifier Manual 1 0 PDFDocumento13 pagineRM2048A Rectifier Manual 1 0 PDFNcodeAnhNessuna valutazione finora

- Bi-Directional PSFB DC-DC Converter With Unique PWM Control Schemes and Seamless Mode Transitions Using Enhanced Digital ControlDocumento18 pagineBi-Directional PSFB DC-DC Converter With Unique PWM Control Schemes and Seamless Mode Transitions Using Enhanced Digital ControlEmbedded RetechNessuna valutazione finora

- Simulation of AC-DC Step Up and Step Down Converter: B.Partheeban, P.G. ScholarDocumento6 pagineSimulation of AC-DC Step Up and Step Down Converter: B.Partheeban, P.G. ScholarVeeramuthu LingamNessuna valutazione finora

- Data SheetDocumento3 pagineData Sheetfadel_destroNessuna valutazione finora

- IEEE Seminar Houston UPS and Battery Systems October 2015Documento20 pagineIEEE Seminar Houston UPS and Battery Systems October 2015royclhorNessuna valutazione finora

- Applied Electronics: Instructor: Dr. Ahmad El-BannaDocumento66 pagineApplied Electronics: Instructor: Dr. Ahmad El-BannaArgan AmiinNessuna valutazione finora

- Gea30738b MV6 - en - 160517 - V8Documento16 pagineGea30738b MV6 - en - 160517 - V8sykimk8921Nessuna valutazione finora

- HAL Lucknow: Training Report on Instrument FactoryDocumento48 pagineHAL Lucknow: Training Report on Instrument FactoryGaurav ChaturvediNessuna valutazione finora

- Service Manual: Viewsonic Va703B / Va703M Model No Vs11280 17" Color TFT LCD DisplayDocumento84 pagineService Manual: Viewsonic Va703B / Va703M Model No Vs11280 17" Color TFT LCD DisplayAry JuniorNessuna valutazione finora

- Sem 1 ElectronicsDocumento867 pagineSem 1 Electronicsjlincy2010Nessuna valutazione finora

- Data Sheet Stamford UCI274E1-Wending 311-3 PhaseDocumento9 pagineData Sheet Stamford UCI274E1-Wending 311-3 PhaseCimmangNessuna valutazione finora

- Studyguide Advanced ElectronicsDocumento27 pagineStudyguide Advanced ElectronicsApollos JehuNessuna valutazione finora

- S60SC4M Mxqwqqs PDFDocumento11 pagineS60SC4M Mxqwqqs PDFBaharak BaghiNessuna valutazione finora

- NASA CR-1785, Radiation Effects Design HDBKDocumento475 pagineNASA CR-1785, Radiation Effects Design HDBKRGK77Nessuna valutazione finora

- 20A, 80V Trench Schottky Rectifier: TSPB20U80SDocumento5 pagine20A, 80V Trench Schottky Rectifier: TSPB20U80SbugliNessuna valutazione finora

- Cblephpu 20Documento6 pagineCblephpu 20Mahadev SharmaNessuna valutazione finora

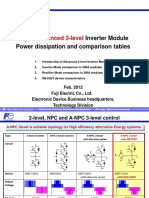

- Advanced 3-Level: T-Type Inverter Module Power Dissipation and Comparison TablesDocumento32 pagineAdvanced 3-Level: T-Type Inverter Module Power Dissipation and Comparison TablesFelipeFalconiNessuna valutazione finora

- Service Manual LCD Monitor Dell 2209WADocumento85 pagineService Manual LCD Monitor Dell 2209WAtda8362aNessuna valutazione finora

- MIT OpenCourseWare Http://Ocw - Mit.eduDocumento7 pagineMIT OpenCourseWare Http://Ocw - Mit.edusnehithNessuna valutazione finora

- Wireless Power Transfer Charging System For Electric VehiclesDocumento4 pagineWireless Power Transfer Charging System For Electric VehiclesBrightchip TechnologiesNessuna valutazione finora

- Panasonic Nn-gf560m SMDocumento33 paginePanasonic Nn-gf560m SMdavidNessuna valutazione finora