Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Battery Charger1

Caricato da

moannaDescrizione originale:

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Battery Charger1

Caricato da

moannaCopyright:

Formati disponibili

----------------------- Page 1----------------------APPLICATION NOTE From Nickel-Cadmium To Nickel-Hydride Fast Battery Charger J. NICOLAI, L.

WUIDART INTRODUCTION Today, many cordless and portable equipment are supplied by a rechargeable batte ry (NickelCadmium, NiCd or Nickel-Hydride, NiMH). Individual applications su ch as portable phones, camcorders, cordless power tools, portable appliances and audio equipment highlight the enormous contribution made by rechargeable batteries to our comfortable lifestyl e. NiCd battery chargers charging in one hour and even less are already widespread. Ultra fast charging of NiCd batteries in less than 15 minutes is a very attractive feature in applications where the battery is rapidly discharged, as in power tools such as cordless dril ls [1]. Nevertheless, when fast charging, the use of a non-adapted charge termination me thod may lead to a significant reduction of the battery service life. This could cause a prejudice against the appliance manufacturer's image, as when the battery service life is reduced, the user is practically led to a costly replacement of the complete battery pack. The trend is now to replace NiCd batteries by the more envir onmentally friendly NiMH batteries. Several charger applications such as notebook computers and portable phones already require NiCd /NiMH compatible battery chargers. In this case, the most common charge monitoring method used for a NiCd battery (negative delta voltage :[- V]) is no longer suited to the NiMH battery. In this application, the charge termination method is based on the detection of the inflexion point in the battery voltage curve. This inflexion point detection method is not only "NiCd-NiMH compatible", it also significantly increases the NiCd battery life-time when fas t charging. Such a performant charger can be totally managed by a low cost 8-bit microcontro ller (MCU), the SGS-THOMSON ST6210. Safe charging is achieved by the combination of three ba ck-up charge termination methods :[- V] detection, temperature monitoring and timer cut-off. An additional benefit of using such a 20 pin standard microcontroller lies in its h igh adaptability of application features.

The proposed charging power converters use the Switched Mode Power Supply techno logy (SMPS), operating from AC mains or DC voltage sources. A 3 5W/100kHz offline and a 15W/100kHz DC/DC chargers are described in this note. AN417 / 01,94 ----------------------- Page 2----------------------FROM NICKEL-CADMIUM TO NICKEL-HYDRIDE FAST BATTERY CHARGER 1 CHARGE TERMINATION METHODS Basically, NiCd and NiMH batteries are charged by a constant current source (see Figure 1). Figure 1. A battery charger is made of a constant curr ent source controlled by a microcontroller which monitors the battery voltage variation with its internal analog-to-digital converter Vin cell voltage I charge battery micro controller NiCd ST62xx or NiMH As soon as the full capacity of ted by the microcontroller, the charging is stopped by turning the ples of power converters operating as current sources are given later. used in two different charging methods depending upon 2/16 ----------------------- Page 3----------------------FROM NICKEL-CADMIUM TO NICKEL-HYDRIDE FAST BATTERY CHARGER 1.1 The [- V] method the battery off. has been detec exam

current

Schematic

The same converter hardware can be the appliance requirements.

When a NiCd battery reaches full charge, its voltage decreases slightly (see Fig ure 2). The

negative delta voltage method [- V] consists of stopping the charge as soon as th e voltage slope versus time becomes negative. This first charge termination technique is o ptimized to fast charge a NiCd battery to its full capacity. Figure 2. The negative delta voltage method fast charge is terminated at point A. V deg C cell voltage temperature 1.6 60 A -dV 1.5 50 1.4 battery voltage 40 1.3 30 battery temperature 1.2 20 charging time In fact, a NiCd battery charged with the [- V] method is slightly overcharged: Fi gure 2 shows that the battery temperature has substantially increased at point A when charge is terminated, which may decrease the life-time of the battery. More precisely in Figure 3, mos t of the current fed to the battery between point B and the negative voltage drop A is not direct ly converted into active battery charge, but into heat. This can be seen in the temperature c urve shown in Figure 3. The point B corresponds to the inflexion point of the battery voltage curve versus time. The [- V] method is definitely no longer suited when it comes to charging NiMH ba tteries: the NiMH charging reaction is permanently exothermic (releases heat), so the battery temperature

would become excessive in its [- V] area of the voltage curve (see Figure 3). Another characteristic of the NiMH batteries makes the [- V] method unsuitable: s ome types of NiMH batteries do not exhibit a significant voltage drop as NiCd batteries do when reaching their full capacity. 3/16 ----------------------- Page 4----------------------FROM NICKEL-CADMIUM TO NICKEL-HYDRIDE FAST BATTERY CHARGER 1.2 A The inflexion point method

second charge termination method much more adapted to NiMH batteries consists of detecting the inflexion point of the voltage curve, thus avoiding any excessive overheating of the battery. This method therefore significantly increases the battery life-time . Figure 3. Fast charge terminates at point B in the inflexion point method. V deg C cell voltage temperature 1.6 60 A 1.5 B 50 1.4 battery voltage 40 1.3 30 battery temperature 1.2 20 charging time 4/16

----------------------- Page 5----------------------FROM NICKEL-CADMIUM TO NICKEL-HYDRIDE FAST BATTERY CHARGER Figure 4. NiMH versus NiCd charging characteristics: the NiMH battery temperatu re rise is larger during fast charge, and its -[ V] is less important, as its voltage slop e variation. NiCd v oltage NiMH voltage NiMH te mperature NiCd temperature charging time Detecting the inflexion point of the voltage curve with the MCU requires the eva luation of the first derivative of the battery voltage curve versus time, and to detect its sum mit. 5/16 ----------------------- Page 6----------------------FROM NICKEL-CADMIUM TO NICKEL-HYDRIDE FAST BATTERY CHARGER 2 PRINCIPLE OF THE INFLEXION METHOD Every 4 seconds, the analog to digital converter (ADC) o f the ST6210 microcontroller measures the battery voltage and temperature. If the temperature is above a pred etermined threshold (40 degrees Celsius for example), fast charge is terminated. The battery voltage is actually measured several times in seri es, and an average of the measurements is made, to reduce measurement errors due to high frequency noise (for example generated by a switched mode charging current). Further, a rolling average of the present and previous measurements is made, to remove low frequency noise due to electrochemical battery voltage variations (see previous description of this technique in bibliography reference [1]). This averaged battery voltage data is used to extract a time derivative, by calculating the difference between present voltage and the voltage n samples earlier. Because of the voltage digitization, which is measured by the ADC of the MCU, the first derivative curv e features a typical discontinuous aspect (see Figure 5). For this reason, the MCU calculates a digital smoothing of this discontinuous de

rivative. The inflexion point is then identified by detecting est summit encountered on the smoothed derivative curve (point B in Figure 5). When this summit is detected, fast charge is terminated. Figure 5. Inflexion point method. battery voltage and derivative B

the

first

high

smoothed derivative voltage derivative battery voltage charging time -> 6/16 ----------------------- Page 7----------------------FROM NICKEL-CADMIUM TO NICKEL-HYDRIDE FAST BATTERY CHARGER 3 CHARGE CONTROL PROGRAM DESCRIPTION The microcontroller detects the inflexion point in the battery voltage versus ti me curve while charging. When full charge is detected, the MCU puts the charger in trickle char ge mode. As safety protection, the MCU also terminates fast charge if -[ V] is detected, or the battery temperature exceeds a predetermined threshold, or a timer with programmable time duration expires. Figure 6 shows the simplified flowchart of the program for the complete charge c ontrol. The overall system is reset after each new input source voltage connection. It is al so reset when a charged battery is removed, and replaced by a discharged battery. Figure 6. Simplified program flowchart. START MEASURE BATTERY VOLTAGE 256 TIMES NOISE FILTERING AND AVERAGING CALCULATE DERIVATIVE SMOOTH DERIVATIVE Y ARE WE AT INFLEXION ?

N Y ARE WE AT DELTA-V ? N Y IS TIMER EXPIRED ? N WAIT 4 SECONDS Y IS TEMPERATURE ABOVE THRESHOLD ? N N IS BATTERY PRESENT ? Y TR ICKLE MODE NEW BATTER Y INSERTED ? N Y 7/16 ----------------------- Page 8----------------------FROM NICKEL-CADMIUM TO NICKEL-HYDRIDE FAST BATTERY CHARGER 4 TEST RESULTS Figures 7 and 8 show curves of a NiCd battery charge respectively terminated by -[ V] and inflexion point methods. A similar comparison is made with a NiMH battery in Figures 9 and 10. The charging current is 2.2 A, the NiCd battery was a 1.4 Ah type and the NiMH battery a 2.2 Ah type. These measurement results clearly show that the battery temperature increase is much smaller with the inflexion method than with the conventional -[ V] method. M oreover, these curves demonstrate that a one hour charge of NiM H batteries can be properly monitored by the ST6210 MCU. Figure 7. Charge of a 1.4 Ah NiCd battery with the -[ V] method: charging current 2.2 A, total time 48 mn, temperature increase 9.6C. cell voltage

temperature 32 deg voltage temperature 22.4 deg charging time 8/16 ----------------------- Page 9----------------------FROM NICKEL-CADMIUM TO NICKEL-HYDRIDE FAST BATTERY CHARGER Figure 8. Charge of a 1.4 Ah NiCd battery with the inflexion method: charging current 2.2 A, total time 41 mn, temperature increase 5C. cell voltage temperature smoothed derivative 26 deg voltage temperature 21 deg charging time Figure 9. Charge of a 2.2 Ah NiMH battery with the -[ V] method: charging current 2.2 A, total time 63 mn, temperature increase 18.2C. cell temperature voltage voltage 41 deg temperature 22.8 deg

charging time 9/16 ----------------------- Page 10----------------------FROM NICKEL-CADMIUM TO NICKEL-HYDRIDE FAST BATTERY CHARGER Figure 10. Charge of a 2.2 Ah NiMH battery with the inflexion method: charging current 2.2 A, total time 57 mn, temperature increase 7.5C. cell temperature voltage smoothed voltage derivative voltage 26.5 deg temperature 19 deg charging time Charge of different battery types with an 2.2 A current source. Battery Temperature increase NiCd 1.4 Ah 9.6C inflexion point 5C NiMH 2.2 Ah 18.2C inflexion point 7.5C 10/16 ----------------------- Page 11----------------------FROM NICKEL-CADMIUM TO NICKEL-HYDRIDE FAST BATTERY CHARGER 5 CHARGER SCHEMATIC EXAMPLES 57 mn -[V] 63 mn 41 mn Monitoring -[V] Duration 48 mn

5.1

Block diagram

The charger is a power supply operating as a constant current source. Such a cur rent source can be made with a SMPS working from the AC mains or from a DC voltage source. F igures 11 and 12 give block diagrams of an offline SMPS charger and a DC to DC charger. Figure 11. Block diagram of an off-line SMPS charger. NiMH or AC mains SMPS NiCd battery PWM current temperature mode UC3845 voltage Figure 12. Block diagrams of aDC/DC charger. NiMH or DC voltage SMPS NiCd battery PWM current temperature mode ST6210 UC3843 voltage 11/16 ----------------------- Page 12----------------------MCU ST6210 MCU

FROM NICKEL-CADMIUM TO NICKEL-HYDRIDE FAST BATTERY CHARGER 5.2 Battery charger examples

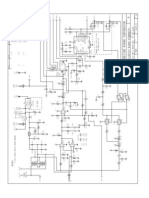

Offline charger Figure 13 gives an example of an offline 35 watt battery c harger working at 100 kHz. This SMPS can deliver up to 3.5 amps DC to a 6 cell battery. Typical charging time of a 1.4 Ah 7.2v NiCd battery pack is around 30 minutes. This offline ch arger is an asymmetrical half bridge totally controlled from the primary side with a standard PWM control IC, the UC3845, regulating in current mode (see bibliography [3]). The asymmetrical half bridge structure allows the use of two standard 500V power MOSFETS IRF820 without snubber network, as voltage across each power M OSFET is systematically clamped to the input DC voltage by two demagnetization diodes (BYT01/400). The MCU controls the SMPS section through a single optocoupler, either in battery charge mode or in trickle mode. Note that the high side power MOSFET is simply driven by an auxiliary winding of the power transformer, avoiding the use of an additional pulse transformer. The switching frequency is set at 100 kHz in order to keep the magnetic parts to a reasonable manufacturing cost level (see bibliography [2]). The power transformer and the output inductor can be integrated on a single ferrite core to allow a signifi cant shrinking of the power converter size. This integrated magnetic technique has been used in a 80 watts / 15 minutes charger (see bibliography [2]). By a simple resizing of the discrete power devices ratings, and by applying the [- V] termination method, the same off-line converter hardware has been used to charge a typical 7V2/1.2 Ah NiCd pack of cordless drill in less than 15 minutes (see bibliography [1] [2]). DC/DC charger Figure 14 shows a 15 watt 100 kHz battery charger supplied from a 12 oltage. The DC input voltage can be supplied from a car battery, or from a 50/60 mer rectified voltage. This DC/DC charger is controlled by the PWM control circuit For example, such a 15 watt converter is able to deliver 1.5 amp DC, ve 1500 mAh NiMH cells in approximately 1 hour. 12/16 ----------------------- Page 13----------------------Vdc input v Hz transfor UC3843. charging fi

c u r g r e n t m o d e

F i

u r e

1 3.

T h

10R f i r o m 1A 400V 3 i 5 t W s

1A F R MAINS

90/260VAC O 47uF M 220

200V s 110 p / 1 r i m a r y + z s C IRF820 i o d 470K 4.7R f e 70uH /4A EF25 . fl i BZX83C18 D M STPS3045CT A BYT01/400 0 k H K E L 0 N 47UF I 200V C

220uF BZW04P15 n 25V e c

I 270K U M 1/2W BZX83C18 1N4148

h BYV10/40 a 05 r OUT g e IRF820 G N r D I BZX85C18V BC327 7 3 18 25V 1K 2 N 100uF 680 TIMER PA0 19 1.5K 1 O IN VDD VSS 20 4N25 T 78L

C 4.7uF i OUT 6 10V s 8 4 K VREF OSCOUT PA2 2 BYT01/400 17 1.8K 2MHz VIN OSCIN PA1 4.7R

8.2K 1K 5 E NMI 4 27pF 27pF a n 4.7uF 6

VFB 16

1K

PA3 RT/CT COMP 1 15

L VPP/TES PB0 G C/SEN 3 1.8R

N 100K 7 25V 1N4148 a s y PB6 D 5.6K m 1uF 10 PB5 PB4 11 22K 6 R 10V 2 3 PB3 8 7 D RESET PB1 39K 1nF 5 8 PB7 PB2 13 H UC3845 9 12 Y 220R 27K 14

680pF 5.6K

m 3.3K ST62E10 I D 15K 4.7uF e E 10K t 10V r 5.6K 6.8V 120K TS271 5 4 1

5.6 K i c a 4.7uF 4.7uF l A S 10V h a T F

l f br i d g e r e g u l a t e 1 d 3 i / 1 n 6

A T

T E R Y

C H

A R

G E

----------------------- Page 14----------------------1 i F F 4 n i R / t g 1 e u O 6 g r r M a e t 1 N e I L4962 C c K 1.5A i T E r 5 7 c h L u i s 1nF + t C 3 2 i 10K 1 80uH +Vbatt d 4.

,t 1 A PACK 6V D BATTERY M / 4 I C 0 U 100uF UC3843 0 + M 25V 3 15K BYV10-40 k 7 8 VIN BYV10-40 H + T OUT 2A O VREF 2 VFB . 4 12K N 1 22nF D 8 3 z 6 4 6 1500mAH U 1 e W h 5

C RT/CT COMP I 220uF C 11 TO 25V DC 25V 2.2uF t K C/SEN o 10V 10V 0.33R D 1.5W E L C H GND I=1.5A 5 D N 4.7uF G 3

c Y h D a 4.7uF r R g I e D 16V r E

i s F 1 A l S VDD 2 T B 680 d 2MHz A OSCIN PA1 r On i 4 1K Temp T e T 680 Stop E 6 R y VPP/TES Y PB0 15 LED b 33pF 27K 33pF 5 NMI PA3 16 n OSCOUT PA2 17 v 3 18 TIMER VSS s PA0 19 o 20 a

14 a

C RESET 6.2K 8 H 8 5K 7 l o PB7 BZX55C3V3 A 3 w 9 6.8K R PB6 PB3 2 c G 10 15K o PB5 5 1 4 E 2.2uF ST62E10 1K R uA741 10V 6.8K 9.1K 10V 2.2uF 6.8K P s t 18K PB4 11 6 R12 12 PB2 13 1 PB1

2.2uF

10V

W M c o n t r o l

----------------------- Page 15----------------------FROM NICKEL-CADMIUM TO NICKEL-HYDRIDE FAST BATTERY CHARGER 6 CONCLUSION A relevant feature dominates today's electronic appliances - true portability. I n these cordless appliances, fast charging of the battery packs is often considered by the user a s a significant comfort improvement. Such an improvement can be achieved with a safe and cost-ef fective charger concept using an off-the-shelf microcontroller, the ST6210. Moreover, the present battery charger concept is NiCd/NiMH compatible, meeting t he current trend to progressively replace the NiCd battery by the more environmentally friendly NiMH battery. The charge termination method is based on the detection of the battery voltage i nflexion point in order to avoid any excessive overheating of the battery. Such a charge technique significantly improves the battery service life, preventing the user from untime ly replacing his battery pack by a costly new pack. In addition, this low cost microcontroller pr ovides a safe charge by combining three other back-up termination methods typical of high end dedicated control circuits : [- V] detection, battery temperature monitoring and timer cutoff. The natural programmability benefit of such a microcontroller-based charger desi gn allows the designer to easily implement additional user interface functions. For example, a "gas gauge" function indicating the remaining battery capacity to the user could be easily added to the present basic program, whilst retaining the same charger hardwar e structure. Finally, the

major benefit of using this off-the-shelf in the high adaptability of its application features. 15/16 ----------------------- Page 16-----------------------

ST6210

approach

lies

FROM NICKEL-CADMIUM TO NICKEL-HYDRIDE FAST BATTERY CHARGER 7 REFERENCES [1] - Ultra-fast NiCd battery charger using ST6210 Microcontroller AN 433 / L. Wuidart, P. Richter (SGS-THOMSON Microelectronics) [2] - An ultra-fast NiCd battery charger concept 43rd International Appliance Technical West Lafayette, Indiana U.S.A. / L. Wuidart Conference, May 5-6,

[3] - A cost effective ultra-fast NiCd battery charger AN 486 / L. Wuidart, JM. Ravon (SGS-THOMSON Microelectronics ) Information furnished is believed to be accurate and reliable. However, SGSTHOMSON Microelectronics assumes no responsability for the consequences of use of s uch information nor for any infringement of patents or other rights of third parties which may result from its use. No l icense is granted by implication or otherwise under any patent or patent rights of SGS-THOMSON Microelectronics. Specifications mentioned in this publication are subject to change without notice. This publication supersedes and replaces all information previously supplied. SGS-THOMSON Microelectronics products are n ot authorized for use as critical components in life support devices or systems with out the express written approval of SGS-THOMSON Microelectronics. 1994 SGS-THOMSON Microelectronics - All Rights Reser ved 2 Purchase of I C Components by SGS-THOMSON Microelectronics, conveys a lic ense under the Philips 2 2 I C Patent. Rights to use these components in an I C system, is grante d provided that the system conforms to the I2C Standard Specifications as defin ed by Philips. SGS-THOMSON Microelectronics GROUP OF COMPANIES Australia - Brazil - France - Germany - Hong Kong - Italy - Japan - Korea - Malaysia - Malta - Morocco The Netherlands - Singapore - Spain - Sweden - Switzerland - Taiwan - T hailand - United Kingdom U.S.A.

16/16

Potrebbero piacerti anche

- DSA0079910Documento16 pagineDSA0079910Kurdo KurdNessuna valutazione finora

- An859 An Intelligent One Hour Multicharger For Liion Nimh and Nicd Batteries StmicroelectronicsDocumento12 pagineAn859 An Intelligent One Hour Multicharger For Liion Nimh and Nicd Batteries StmicroelectronicsAntonNessuna valutazione finora

- Versatile Ics Enable Chemistry-Independent Battery ChargingDocumento7 pagineVersatile Ics Enable Chemistry-Independent Battery Chargingsa920189Nessuna valutazione finora

- Low-Cost Nimh Battery Charger Using The Z8F0830: Application NoteDocumento7 pagineLow-Cost Nimh Battery Charger Using The Z8F0830: Application NoteKino Tel LokNessuna valutazione finora

- An417 PDFDocumento21 pagineAn417 PDFalamgir80Nessuna valutazione finora

- Ek Kaynak LM2576Documento19 pagineEk Kaynak LM2576Şakir BayramNessuna valutazione finora

- Mcu-Based Battery Management System For Fast Charging of Iot-Based Large-Scale Battery-CellsDocumento5 pagineMcu-Based Battery Management System For Fast Charging of Iot-Based Large-Scale Battery-CellsPeriyasamyNessuna valutazione finora

- Fast-Charge IC: Features General DescriptionDocumento14 pagineFast-Charge IC: Features General DescriptionAlejandro Cortegoso MartinezNessuna valutazione finora

- Lab 2 ElectronicsDocumento3 pagineLab 2 ElectronicsKaya EmanuelNessuna valutazione finora

- UNI/O Application NoteDocumento8 pagineUNI/O Application NoteRhenan WafooNessuna valutazione finora

- Power PointDocumento8 paginePower PointSakthivel MNessuna valutazione finora

- Catalogue Battery Chargers-A4 PDFDocumento8 pagineCatalogue Battery Chargers-A4 PDFdinhvuNessuna valutazione finora

- A Novel Two Switches Based DC-DC Multilevel Voltage MultiplierDocumento5 pagineA Novel Two Switches Based DC-DC Multilevel Voltage MultiplierdanielflorescortezNessuna valutazione finora

- AN626 - Lead Acid Battery Charger Using The PIC14C000Documento0 pagineAN626 - Lead Acid Battery Charger Using The PIC14C000mlaura2Nessuna valutazione finora

- AN3392 - Building The NiCd - NiMH BatteryDocumento12 pagineAN3392 - Building The NiCd - NiMH BatteryUnu DecebalNessuna valutazione finora

- Specification For Battery & Battery ChargerDocumento11 pagineSpecification For Battery & Battery Chargersmi249Nessuna valutazione finora

- 12V - 24 V Lead-Acid Battery State of Charge Indicator: Group 9: Voltage & CurrentDocumento27 pagine12V - 24 V Lead-Acid Battery State of Charge Indicator: Group 9: Voltage & CurrentAyuguNessuna valutazione finora

- PB Battery ChargerDocumento6 paginePB Battery ChargerarezrthNessuna valutazione finora

- Design: IdeasDocumento6 pagineDesign: IdeasSamantha EwingNessuna valutazione finora

- AN3409Documento18 pagineAN3409Muhammad Yunus AndrianNessuna valutazione finora

- CB Manual PDFDocumento8 pagineCB Manual PDFdinhvuNessuna valutazione finora

- Power-Tracking Battery-Charger IC Supports Solar-Power SystemsDocumento2 paginePower-Tracking Battery-Charger IC Supports Solar-Power SystemsVIJAYPUTRANessuna valutazione finora

- Electrical Q&ADocumento388 pagineElectrical Q&AOkore Philip Nwankwo100% (2)

- How To Charge A Lead-Acid Battery With A Li-Ion Charger: Application ReportDocumento9 pagineHow To Charge A Lead-Acid Battery With A Li-Ion Charger: Application ReportnarakribNessuna valutazione finora

- NiCd-NiMH Battery Charger Using MC68HC908QY4 (Article) (2004 Motorola)Documento28 pagineNiCd-NiMH Battery Charger Using MC68HC908QY4 (Article) (2004 Motorola)lmdtasaNessuna valutazione finora

- Battery & Battery Charger Calculation RevADocumento27 pagineBattery & Battery Charger Calculation RevAhosein30Nessuna valutazione finora

- Battery Charger Sizing SS 1, Rev 03Documento15 pagineBattery Charger Sizing SS 1, Rev 03Pramod B.Wankhade100% (1)

- UC3879Documento9 pagineUC3879Christina Tio TrisnasariNessuna valutazione finora

- PP 8498 10Documento19 paginePP 8498 10Marvin GainesNessuna valutazione finora

- An1 Battery ChargerDocumento2 pagineAn1 Battery ChargerSugun Kumar PedapudiNessuna valutazione finora

- Slua 371Documento20 pagineSlua 371api-3805241Nessuna valutazione finora

- FINAL IE Lab ManualDocumento34 pagineFINAL IE Lab ManualAnudeex ShettyNessuna valutazione finora

- EV Charging - Electrical Installation DesignDocumento17 pagineEV Charging - Electrical Installation Designetnanto100% (1)

- Ahumi RelDocumento14 pagineAhumi Relarturo53Nessuna valutazione finora

- CDI - Thompson NA - 4347 PDFDocumento8 pagineCDI - Thompson NA - 4347 PDFLeonardo ConcistreNessuna valutazione finora

- Project Repor#2 - CalaguasDocumento4 pagineProject Repor#2 - CalaguasfcalaguasNessuna valutazione finora

- XYZDocumento12 pagineXYZarkadjyothiprakashNessuna valutazione finora

- Battery ChargerDocumento43 pagineBattery ChargerAhmed SheirNessuna valutazione finora

- Instruction Manual: Manufactured / Marketed byDocumento7 pagineInstruction Manual: Manufactured / Marketed byLaxmikant DigraskarNessuna valutazione finora

- Slva 437 ADocumento7 pagineSlva 437 Azigoto_2nNessuna valutazione finora

- Build A USB Powered AA NiMH and NiCd Battery ChargerDocumento89 pagineBuild A USB Powered AA NiMH and NiCd Battery ChargerelectatulNessuna valutazione finora

- 5.modeling of An Electric Vehicle Charging StationDocumento6 pagine5.modeling of An Electric Vehicle Charging Stationpeng100% (2)

- Charge Pump Design HVDocumento16 pagineCharge Pump Design HVMohammed BelkheiriNessuna valutazione finora

- High Efficiency Battery ChargerDocumento4 pagineHigh Efficiency Battery ChargersanilNessuna valutazione finora

- Universal Cell Phone Charger Circuit DiagramDocumento8 pagineUniversal Cell Phone Charger Circuit Diagramatien_series80% (30)

- Core JavaDocumento11 pagineCore JavaGangadharNessuna valutazione finora

- How To Handle The Limited DC System Voltage Window: An Eltek White PaperDocumento12 pagineHow To Handle The Limited DC System Voltage Window: An Eltek White PaperGARUIS MELINessuna valutazione finora

- Modeling and Simulation of Nickel CadmiuDocumento9 pagineModeling and Simulation of Nickel CadmiuhhelectronicsbdNessuna valutazione finora

- CBI ManualDocumento12 pagineCBI ManualIdiks OtnaythreeNessuna valutazione finora

- Low Operating Voltage and Short Settling Time CMOS Charge PumpDocumento4 pagineLow Operating Voltage and Short Settling Time CMOS Charge PumpsolidmasteryNessuna valutazione finora

- Switchgear Battery Sizing by Hand - EC&MDocumento11 pagineSwitchgear Battery Sizing by Hand - EC&MLowell Estrella-SchneiderNessuna valutazione finora

- EDN Design Ideas 2002Documento198 pagineEDN Design Ideas 2002chag1956100% (1)

- Rechargeable Batteries Applications HandbookDa EverandRechargeable Batteries Applications HandbookValutazione: 2 su 5 stelle2/5 (1)

- A High Efficiency Bi-Directional EV ChargerDocumento6 pagineA High Efficiency Bi-Directional EV ChargerGabriel MejiaNessuna valutazione finora

- Exp - 8Documento4 pagineExp - 8Md KaziNessuna valutazione finora

- Power Systems-On-Chip: Practical Aspects of DesignDa EverandPower Systems-On-Chip: Practical Aspects of DesignBruno AllardNessuna valutazione finora

- Power Supply Line RegulationDocumento7 paginePower Supply Line RegulationmoannaNessuna valutazione finora

- APC Back UPS 250,400,600 - 1 PDFDocumento1 paginaAPC Back UPS 250,400,600 - 1 PDFSixto Aguero50% (2)

- Diy Lte YagiDocumento1 paginaDiy Lte YagimoannaNessuna valutazione finora

- Yagi 894 MetalDocumento6 pagineYagi 894 Metalhouarisma2009Nessuna valutazione finora

- Building My 4G LTE Mimo Antenna Prototype - About Technologies For Your Digital HomeDocumento1 paginaBuilding My 4G LTE Mimo Antenna Prototype - About Technologies For Your Digital HomemoannaNessuna valutazione finora

- Antenna RFI MonitoringDocumento71 pagineAntenna RFI MonitoringmoannaNessuna valutazione finora

- SMPSRM DDocumento73 pagineSMPSRM DtemplpaNessuna valutazione finora

- GPL Landi Renzo System - Renault - 6525A PDFDocumento87 pagineGPL Landi Renzo System - Renault - 6525A PDFmoanna100% (1)

- Baytech Service Manual For 6.0L ApplicationDocumento18 pagineBaytech Service Manual For 6.0L ApplicationmoannaNessuna valutazione finora

- 16 Ways To Design A Switch-Mode Power SupplyDocumento8 pagine16 Ways To Design A Switch-Mode Power SupplymoannaNessuna valutazione finora

- Datasheet l298bDocumento14 pagineDatasheet l298bgioganNessuna valutazione finora

- SD CardFormatter5UserManualEN v0104Documento5 pagineSD CardFormatter5UserManualEN v0104moannaNessuna valutazione finora

- LM 297Documento12 pagineLM 297Monika JhaNessuna valutazione finora

- Adding Your Google Analytics Code To Your Site: Wix Help CenterDocumento4 pagineAdding Your Google Analytics Code To Your Site: Wix Help CentermoannaNessuna valutazione finora

- JHWPDocumento12 pagineJHWPfran0772Nessuna valutazione finora

- Stepper Motor Controller - L298 - L297Documento6 pagineStepper Motor Controller - L298 - L297moannaNessuna valutazione finora

- Zafira Owner Manual - en PDFDocumento228 pagineZafira Owner Manual - en PDFmoannaNessuna valutazione finora

- Usb Data Interface KNX RMDDocumento4 pagineUsb Data Interface KNX RMDmoannaNessuna valutazione finora

- Positive Parenting PDFDocumento16 paginePositive Parenting PDFmoanna100% (3)

- Restore Your USB Key To Its Original State - USB Pen Drive LinuxDocumento4 pagineRestore Your USB Key To Its Original State - USB Pen Drive LinuxmoannaNessuna valutazione finora

- SD Card Formatter 5.0.1 User's Manual: September 4, 2018Documento11 pagineSD Card Formatter 5.0.1 User's Manual: September 4, 2018moannaNessuna valutazione finora

- Tutorials - Connecting LAN Transformers - EN (Rev1)Documento2 pagineTutorials - Connecting LAN Transformers - EN (Rev1)moannaNessuna valutazione finora

- Arduino ManualDocumento40 pagineArduino ManualDaniela Cardenas LuboNessuna valutazione finora

- Arduino ManualDocumento40 pagineArduino ManualDaniela Cardenas LuboNessuna valutazione finora

- Arduino PS2Keyboard Library General ConsiderationsDocumento4 pagineArduino PS2Keyboard Library General ConsiderationsmoannaNessuna valutazione finora

- Arduino ManualDocumento40 pagineArduino ManualDaniela Cardenas LuboNessuna valutazione finora

- How To Program A DVRDocumento152 pagineHow To Program A DVRVirtue PetersNessuna valutazione finora

- Slup 127Documento20 pagineSlup 127bekonq12we3Nessuna valutazione finora

- Process Control Fundamentals 2Documento73 pagineProcess Control Fundamentals 2Otuekong Ukpong100% (2)

- Intel® System Identification UtilityDocumento3 pagineIntel® System Identification UtilitymoannaNessuna valutazione finora

- Rigaku Journal 33-2-26-28Documento3 pagineRigaku Journal 33-2-26-28Eduardo ArdilesNessuna valutazione finora

- Chap 9 Indices, Exponentials and Logarithms Part 1 PDFDocumento44 pagineChap 9 Indices, Exponentials and Logarithms Part 1 PDFArahNessuna valutazione finora

- Advanced Organic Test Questionnaire Practice KeyDocumento8 pagineAdvanced Organic Test Questionnaire Practice KeyJuitchiboy Nunez DumaoNessuna valutazione finora

- Velocity Analysis and Statics CorrectionsDocumento192 pagineVelocity Analysis and Statics CorrectionsKim PerezNessuna valutazione finora

- Optical Fiber CommunicationDocumento27 pagineOptical Fiber CommunicationDrashti ShahNessuna valutazione finora

- ThermometryDocumento29 pagineThermometryaelle00Nessuna valutazione finora

- Chirimuuta. Outside ColorDocumento262 pagineChirimuuta. Outside Colorcrazijoe100% (2)

- Tolerances and FitsDocumento12 pagineTolerances and FitskoitkulperNessuna valutazione finora

- Analysis and Design of Column: Chapter ThreeDocumento23 pagineAnalysis and Design of Column: Chapter Threejebril yusufNessuna valutazione finora

- National Institute of Technology Durgapur: Department of Chemical EngineeringDocumento2 pagineNational Institute of Technology Durgapur: Department of Chemical Engineeringpiyush dwivediNessuna valutazione finora

- Concrete Mathematics: A Foundation For Computer Science: Articles You May Be Interested inDocumento3 pagineConcrete Mathematics: A Foundation For Computer Science: Articles You May Be Interested inmaruns004Nessuna valutazione finora

- 2010 Aisc Steel ToolsDocumento4 pagine2010 Aisc Steel Toolsmuh2006Nessuna valutazione finora

- The In-Situ Measurement of The Undrained Shear Strength of Clays Using The Field VaneDocumento1 paginaThe In-Situ Measurement of The Undrained Shear Strength of Clays Using The Field VaneLeo ChandraNessuna valutazione finora

- Wind Energy in MalaysiaDocumento17 pagineWind Energy in MalaysiaJia Le ChowNessuna valutazione finora

- Chemistry Form 4 A NotesDocumento67 pagineChemistry Form 4 A NotesJia En TanNessuna valutazione finora

- Paper - Fatigue Lifetime of Welded Joints Under Random Loading - Colombini P., Dolinski K. - 2001Documento11 paginePaper - Fatigue Lifetime of Welded Joints Under Random Loading - Colombini P., Dolinski K. - 2001Claudio RodriguesNessuna valutazione finora

- Software For Enumerative and Analytic CombinatoricsDocumento47 pagineSoftware For Enumerative and Analytic CombinatoricsamacfiesNessuna valutazione finora

- Tos 2ND and 3RD Periodical Test Science 8 Tom DS 1Documento5 pagineTos 2ND and 3RD Periodical Test Science 8 Tom DS 1Aileen TorioNessuna valutazione finora

- Pre-Admission Math Assessment - SampleDocumento13 paginePre-Admission Math Assessment - SamplePranav BISUMBHERNessuna valutazione finora

- Discrete Element Modelling of Rockfill Railway EmbankmentsDocumento15 pagineDiscrete Element Modelling of Rockfill Railway EmbankmentsHerdin AsyidiqNessuna valutazione finora

- Musica Universalis First DraftDocumento78 pagineMusica Universalis First DraftWilliam1091Nessuna valutazione finora

- 2017 Tubing InformationDocumento28 pagine2017 Tubing InformationSatyabrat GaanNessuna valutazione finora

- Filetype PDF Photoconduction SemiconductorDocumento2 pagineFiletype PDF Photoconduction SemiconductorGregNessuna valutazione finora

- Functions - Group 2Documento26 pagineFunctions - Group 2Annjanah AsilomNessuna valutazione finora

- MEF University Math 115 Calculus Fall 2018-19 Midterm Exam 1 2 3 4 PDocumento4 pagineMEF University Math 115 Calculus Fall 2018-19 Midterm Exam 1 2 3 4 PMELİHA KOÇNessuna valutazione finora

- A Foster Network Thermal Model For HEV/EV Battery ModelingDocumento8 pagineA Foster Network Thermal Model For HEV/EV Battery Modelingal-masriNessuna valutazione finora

- 6000 EN 00 04 Friction PDFDocumento30 pagine6000 EN 00 04 Friction PDFM Ferry AnwarNessuna valutazione finora

- E C G Sudarshan PDFDocumento39 pagineE C G Sudarshan PDFNK NKNessuna valutazione finora

- Thickening Agent - Wikipedia, The Free EncyclopediaDocumento5 pagineThickening Agent - Wikipedia, The Free EncyclopediaJohnNessuna valutazione finora

- PI Section Line - Blocks (SimPowerSystems™)Documento3 paginePI Section Line - Blocks (SimPowerSystems™)Dhondiram Maruthi KakreNessuna valutazione finora