Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Cement Website

Caricato da

Adarsh ChoudharyDescrizione originale:

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Cement Website

Caricato da

Adarsh ChoudharyCopyright:

Formati disponibili

Cement

Jaypee group is the 3rd largest cement producer in the country. The groups cement facilities are located in the Satna Cluster (U.P), which has one of the highest cement production growth rates in India. The group produces special blend of Portland Pozzolana Cement under the brand name Jaypee Cement (PPC). Its cement division currently operates modern, computerized process control cement plants with an aggregate installed capacity of 26.20 MnTPA. The company is in the midst of capacity expansion of its cement business in Northern, Southern, Central, Eastern and Western parts of the country and is slated to be a 35.90 MnTPA by FY12 (expected) with Captive Thermal Power plants totaling 672 MW. Keeping pace with the advancements in the IT industry, all the 260 cement dumps are networked using TDM/TDMA VSATs along with a dedicated hub to provide 24/7 connectivity between the plants and all the 120 points of cement distribution in order to ensure track the truck initiative and provide seamless integration. This initiative is the first of its kind in the cement industry in India. In the near future, the group plans to expand its cement capacities via acquisition and greenfield additions to maximize economies of scale and build on vision to focus on large size plants from inception. The Group is committed towards the safety and health of employees and the public. Our motto is ' Work For Safe, Healthy, Clean & Green

Environment '.

History of Cement

Manufacture of cement has a history, which traces back to millennia. The Romans who were prolific builders used burnt calcareous (calcium bearing) rocks along with pozzolanic materials in an era Before Christ. The structures built by them, like the Pantheon, are still there for us to see proving the goodness of cementitious materials as input material for construction.Post industrialization and as infrastructure development started globally, demands for cement have been growing steadily both quantitatively & qualitatively. India is the second largest cement producer in the world after China and cement consumption has been growing at a CAGR of over 8% p.a. in the last five years. The group cement facilities are located in the Satna cluster, which has one of the highest cement production growth rates in India .

Manufacturing Process Mining The cement manufacturing process starts from the mining of limestone, which is the main raw material for making cement. Limestone is excavated from open cast mines after drilling and blasting and loaded on to dumpers which transport the material and unload into hoppers of the limestone crushers. Crushing Stacking & Reclaiming of Limestone The LS Crushers crush the limestone to minus 80 mm size and discharge the material onto a belt conveyor which takes it to the stacker via the Bulk material analyser. The material is stacked in longitudinal stockpiles. Limestone is extracted transversely from the stockpiles by the reclaimers and conveyed to the Raw Mill hoppers for grinding of raw meal. Crushing Stacking & Reclaiming of Coal The process of making cement clinker requires heat. Coal is used as the fuel for providing heat. Raw Coal received from the collieries is stored in a coal yard. Raw Coal is dropped on a belt conveyor from a hopper and is taken to and crushed in a crusher. Crushed coal discharged from the Coal Crusher is stored in a longitudinal stockpile from where it is reclaimed by a reclaimer and taken to the coal mill hoppers for grinding of fine coal.

Raw Meal Drying/Grinding & Homogenisation Reclaimed limestone along with some laterite stored in their respective hoppers is fed to the Raw Mill for fine grinding. The hot gasses coming from the clinkerisation section are used in the raw mill for drying and transport of the ground raw meal to the Electrostatic Precipitator / Bag House, where it is collected and then stored and homogenised in the concrete silo. Raw Meal extracted from the silo (now called Kiln feed) is fed to the top of the Preheater for Pyroprocessing. Clinkerisation Cement Clinker is made by pyroprocessing of Kiln feed in the preheater and the rotary kiln. Fine coal is fired as fuel to provide the necessary heat in the kiln and the Precalciner located at the bottom of the 5/6 stage preheater. Hot clinker discharged from the Kiln drops on the grate cooler and gets cooled. The cooler discharges the clinker onto the pan / bucket conveyor and it is transported to the clinker stockpiles / silos. The clinker is taken from the stockpile / silo to the ball mill hoppers for cement grinding. Cement Grinding & Storage Clinker and Gypsum (for OPC) and also Pozzolana (for PPC) are extracted from their respective hoppers and fed to the Cement Mills. These Ball Mills grind the feed to a fine powder and the Mill discharge is fed to an elevator, which takes the material to a separator, which separates fine product and the coarse. The latter is sent to the mill inlet for regrinding and the fine product is stored in concrete silos. Packing Cement extracted from silos is conveyed to the automatic electronic packers where it is packed in 50 Kgs. Polythene bags and dispatched in trucks. Electrical Power For total power requirement of 90 MW (Jaypee Rewa Plant and Jaypee Bela Plant), we have CPP 1 - 25.0 MW CPP 2 - 25.0 MW CPP 3 - 37.0 MW Four DG sets provide an emergency backup.

Technical Services

Owning a strong, durable and beautiful home is one of the innate desires of every human being. At Jaypee, the pioneers in the construction of mega Hydroelectric projects and other infrastructure projects, we fully understand that good cement and construction material alone will not ensure strong and lasting structures. Correct construction practices and quality control at the time of construction play an equally important role. Our understanding of the construction practices and related problems has prompted us to extend customized technical services specially tailored for the Individual Home Builders and large projects. We firmly believe that quality construction leads to satisfied customers. The Jaypee Cement Technical Support Service offerings are: Technical Service Engineers Our Area Marketing Offices have a fully functional technical services department aptly supported by qualified Civil Engineers who visit and interact with the customers to asses their needs and accordingly advise them about the best construction practises so that the dream of a strong and durable home is realized. Some of the customer-centric initiatives taken up by the Technical Service Engineers are: Customized solutions to the problems of the individual home builder. Training the masons and contractors so that they are aware about good construction practices. Train the channel partners (Dealers and Retailers) about the product and its correct usage. Interact routinely with the professionals (architects and engineers) and share information regarding latest developments in the product and industry. The services of the Technical Service Engineers can be availed by all users of Jaypee Cement. For more details, please contact nearest

Jaypee Cement Area Marketing Office or Jaypee Cement Authorized Dealers. Nirman Mitr Services Mobile Concrete Testing Vans Looking at the importance of quality control tests at the time of construction, Jaypee Cement has introduced mobile testing vans under the brand name of Nirman Mitr. The vans are fully equipped to carry out strength and workability tests of concrete. The grading and quality of the aggregates used in concrete can also be tested. The services of Nirman Mitr are meant primarily for assisting the customer in making good concrete for any application viz. footing, beams, columns, lintels, slabs etc. The services of Nirman Mitr can be availed by any prospective Individual Home Builder. The services of Nirman Mitr are free of cost, subject to the availability of the van and on a first come first serve basis. Currently, Nirman Mitr Vans are operating in the following locations: 1) Delhi 5) Kanpur 9) Faridabad 2) Dehradun 6) Patna 10) Karnal 3) Allahabad 7) Gwalior 11) Panchkula 4) Lucknow 8) Indore 12) Sonepat Disclaimer:

The Technical Service and Nirman Mitr Services are non-profit, free of cost services to provide information and guidance to the Jaypee Cement users on the correct application of cement and concrete. The services are meant for general guidance only and in no way replaces the services of professional consultants on projects. No legal liability can be accepted by Jaiprakash Associates Limited for its use.

Performance

Jaypee Rewa Plant

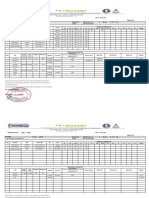

Year

Clinker Production Total Cement (MTPA) Production (MTPA) 2.317 2.173 2.561 2.918 3.106 3.131 3.087 3.204 2.579 2.413 2.562 2.819 3.207 3.253 3.043 3.218

2002-03 2003-04 2004-05 2005-06 2006-07 2007-08 2008-09 2009-10

Production Sp. Heat onsumption (Net Basis) Kcal/Kg of Clk. 768 748 704 708 698 698 691 688

Sp.Electrical Energy Consumption, kWh/t of Clk. 70.4 71.9 67.5 66.4 66.3 65.5 64.9 62

Conversion Factor 0.803 0.786 0.769 0.770 0.759 0.759 0.762 .777

Jaypee Bela Plant

Year

Clinker Production (MTPA) 1.68 1.646 1.648 1.768 1.996 2.004 2.055 2.042

Total Cement Production (MTPA) 1.783 1.837 2.046 2.152 2.414 2.337 2.257 2.387

Production Sp. Heat Consumption (Net Basis) Kcal/Kg of Clk. 716 715 700 691 706 696 694 692

Sp.Electrical Energy Consumption, kWh/t of Clk. 62.3 64.6 63.4 63.5 64.1 63.3 62.9 63.7

Conversion Factor 0.848 0.828 0.863 0.857 0.817 0.797 0.813 .801

2002-03 2003-04 2004-05 2005-06 2006-07 2007-08 2008-09 2009-10

Jaypee Ayodhya Grinding Operational, Tanda (U.P)

Year

Clinker Production (MTPA) -

Total Cement Production (MTPA) 0.756 0.88 0.91 1.032

2005-06 2006-07 2007-08 2008-09 2009-10

Production Sp. Heat Consumption (Net Basis) Kcal/Kg of Clk. -

Sp.Electrical Energy Consumption, kWh/t of CEMENT 31.16 30.75

Conversion Factor 0.729 1.4824 1.4832 .686

Jaypee Cement Blending Unit, Sadva, Allahabad (U.P)

Year

Clinker Production (MTPA) -

Total Cement Production (MTPA) 0.325 0.453 0.553 0.587 0.58 0.61 0.60 .719

2002-03 2003-04 2004-05 2005-06 2006-07 2007-08 2008-09 2009-10

Production Sp. Heat Consumption (Net Basis) Kcal/Kg of Clk. -

Sp.Electrical Energy Consumption, kWh/t of CEMENT 5.84 4.93 4.46 4.34 4.39 4.25

Conversion Factor 0.662 0.687 0.680 0.689 0.685 .6835

Jaypee Cement Grinding Unit, Panipat (Haryana)

Year

Clinker Production (MTPA) -

Total Cement Production (MTPA) 0.666 1.012

Production Sp. Heat Consumption (Net Basis) Kcal/Kg of Clk. -

Sp.Electrical Energy Consumption, kWh/t of Clk. 38.78 38.04

Conversion Factor 1.259 .7042

2008-09 2009-10

DALLA CEMENT FACTORY , Sonebhadra (UP)

Year

Clinker Production (MTPA) 0.351 1.373

Total Cement Production (MTPA) .146

2008-09 2009-10

Production Sp. Heat Consumption (Net Basis) Kcal/Kg of Clk. 892 804

Sp.Electrical Energy Consumption, kWh/t of Clk. 94.38 86.79

Conversion Factor .7287

CHUNAR CEMENT FACTORY, Mirzapur (UP)

Year

Clinker Production (MTPA) -

Total Cement Production (MTPA) 0.039 0.612 1.702

2007-08 2008-09 2009-10

Production Sp. Heat Consumption (Net Basis) Kcal/Kg of Clk. -

Sp.Electrical Energy Consumption, kWh/t of CEMENT 45.80 42.30 43.91

Conversion Factor 0.747 0.729 .7129

Jaypee Gujarat Cement Plant, Sewagram Gujarat

Year

Clinker Production (MTPA) .43

Total Cement Production (MTPA) .27

2009-10

Production Sp. Heat Consumption (Net Basis) Kcal/Kg of Clk. 788

Sp.Electrical Energy Consumption, kWh/t of Clk. 74.59

Conversion Factor ..9628

Jaypee Wanakbori Cement Grinding Unit, Gujarat

Year

Clinker Production (MTPA) -

Total Cement Production (MTPA) .069

2009-10

Production Sp. Heat Consumption (Net Basis) Kcal/Kg of Clk. -

Sp.Electrical Energy Consumption, kWh/t of CEMENT 54.34

Conversion Factor .7936

Jaypee Sidhi Cement Plant , Sidhi

Year

Clinker Production (MTPA) 1.166

Total Cement Production (MTPA) .405

2009-10

Production Sp. Heat Consumption (Net Basis) Kcal/Kg of Clk. 751.42

Sp.Electrical Energy Consumption, kWh/t of Clk. 67.02

Conversion Factor .7800

Jaypee Roorkee Cement Grinding Unit , Roorkee

Year

Clinker Production (MTPA) -

Total Cement Production (MTPA) 0.114

2008-09 2009-10

Production Sp. Heat Consumption (Net Basis) Kcal/Kg of Clk. -

Sp.Electrical Energy Consumption, kWh/t of CEMENT 57.07

Conversion Factor .0.77

Jaypee Himachal Cement Plant , Baga

Year

Clinker Production (MTPA) .206

Total Cement Production (MTPA) -

2009-10

Production Sp. Heat Consumption (Net Basis) Kcal/Kg of Clk. 796.68

Sp.Electrical Energy Consumption, kWh/t of Clk. 71.24

Conversion Factor -

Jaypee Himachal Cement Grinding & Blending Unit, Bagheri

Year

Clinker Production (MTPA) -

Total Cement Production (MTPA) .096

2009-10

Production Sp. Heat Consumption (Net Basis) Kcal/Kg of Clk. -

Sp.Electrical Energy Consumption, kWh/t of CEMENT 47.42

Conversion Factor .82

Cement Brands Jaypee produces a wide variety of cements, which are specifically designed to cater to the customers requirements for different types of cements in each of its markets. All the brands, which the Company produces, are so evolved in their characteristics and properties that they will surpass BIS Standards. For each brand, the relevant BIS standards are mentioned in enclosed table along with a comparison with the BIS requirement. The state-of-the-art cement plants operated by the Jaypee Group are equipped with the most modern technology from the globally leading technology providers. Extensive Instrumentation & fully automatic and computerized process control system, custom designed Quality Control software like QSO Expert and CADES in the Mines, Cross Belt Expert Analyser using the Prompt Gamma Neutron Activation Analysis - for the first time in India, X-Ray Fluorescence and X-Ray Diffraction analysers and optical microscope, enable production of cement of the highest quality consistently on a sustained basis. Jaypee Rewa Plant Quality control laboratory is accredited laboratory from National Accreditation Board for Calibration & Testing Laboratories, for chemical and mechanical Cement testing. All brands are marketed in attractive HDPE bags, containing 50 Kgs of quality cement from Jaypee. Bags are identified with a conspicuous Jaypee Logo, which also over the years has come to be regarded as a Hallmark of quality. Jaypee produces & markets both Portland Pozzolana Cement (PPC) & all grades of Ordinary Portland Cement (OPC). A brief introduction of each brand is enumerated as below:PORTLAND POZZOLANA CEMENT Jaypee Cement produces special blend of Portland Pozzolana Cement and markets it under the popular brand name Jaypee Cement (PPC) . JAYPEE CEMENT (PPC) Jaypee Cement (PPC) is a market leader among all blended/composite cements in the markets of U.P, Bihar, M.P., Punjab, Haryana, Delhi & Nepal. Its unique design and blend, with high strength clinker and superior quality flyash has made it the popular cement for construction of large number of strong and durable structures in these states. Fine particles of Jaypee Cement (PPC) when mixed with water readily form a smooth paste, which results in a smooth surface. When used with sand and aggregates it yields a very strong & durable concrete. Jaypee Cement (PPC) helps to produce more cohesive concrete and mortar which is also less prone to segregation and bleeding. Due to this quality, Jaypee Cement (PPC) is suitable for any type of structural application. *(Curing is done as per specified norms) Use of superior quality flyash in Jaypee Cement (PPC) not only reduces the incidence of lime leaching from concrete and mortar but also results in refined pore structure, reduced permeability and long term strength gain. These attributes make the construction strong, compact, impermeable and resistant to chemical attacks. Jaypee Cement (PPC) is being used for a number of applications like housing, commercial complexes, roads, wells, canals, dams etc. which establishes Jaypee Cement (PPC) as the preferred choice of the discerning customer. It is particularly well suited for the tropical climatic conditions of India. Table-1: Typical Chemical and Physical Properties of Jaypee Cement (PPC). Particulars Typical Range Requirement of IS: 1489 (PART-1) 1991 CHEMICAL PROPERTIES 1. 2. 3. 4. 5. Insoluble Residue (% by mass) Magnesia (% by mass) Sulphuric Anhydride (% by mass) Total Loss on Ignition (% by mass) Chloride (% by mass) PHYSICAL PROPERTIES 1 2 Fineness (M2/Kg) Setting Time (Minutes) Initial Final 3 Expansion Le. Chatelier (mm) Auto clave (%) 0.50-1.00 0.05-0.10 10.00 Max. 0.8 Max. 340-360 180-220 220-240 300 Min. 30 Min. 600 Max. 24.0-27.0 2.00-3.00 1.50-1.80 2.0-3.0 0.015-0.017 X + 4 (100-X) / 100 Max 6.00 Max. 3.00 Max. 5.00 Max. 0.10 Max.(For N.C.)* 0.05 Max.(For P.C.)*

Compressive Strength (MPa) 3 Days 7 Days 28 Days x is declared tested has been %

24.0-26. 34.0-36.0 48.0-52.0 of at optimized Concrete to Concrete give pozzolana

16 Min. 22 Min. 33 Min. = temp.27 time 26.0 TO28.0 2C application. ) Cement)

Where Cement

The setting *N.C.(Normal *P.C.(Prestressed

time

comfortable Cement

for

Jaypee Cement (PPC) surpasses the requirements laid down by Bureau of Indian Standards (BIS) for flyash based PPC cement in IS:1489 Part (I):1991. Qualities of Jaypee Cement PPC Unmatched characteristics of Jaypee Cement (PPC) which form the basis of sound & durable construction are: Better workability due to spherical shape of flyash particles and better slump retention. Better pumpability provides more cohesive concrete and mortar. Superfine particles provide great finish to the structure. Provides un-segregated concrete of better integrity. Low heat of hydration. Reduced shrinkage and swelling. Better pore refinement, reduced permeability. Better resistance to chloride and sulphate attack Better resistance to alkali-silica reaction. Resistance to corrosive attack on steel reinforcement. Reduced lime leaching. High compressive strength. High modulus of elasticity especially at later ages. Improved bondage of concrete to steel. Long term strength gain. Conclusion Jaypee Cement (PPC) helps to produce better concrete & compressive strength keeps on growing with time. Jaypee Cement (PPC) promotes workability in fresh concrete even with less water and hence yields high strength concrete of low permeability, less bleeding, better pump-ability and superior finish. Hardened concrete made with Jaypee Cement (PPC) benefits from long term gain in compressive strength and related properties like low creep & shrinkage etc. Furthermore, the concrete is very durable and effectively resists aggressive attack of sulphate and chloride ions. It is also resistant to Alkali aggregate reaction. The concrete is not subjected to attack by acid rain due to presence of green house gases (GHGs) in higher concentrations in atmosphere. ORDINARY PORTLAND CEMENT 33 Grade Conforming to IS: 269-1989 43 Grade Conforming to IS: 8112-1989 53 Grade Conforming to IS: 12269-1987 53 S Grade Conforming to IRST-40(53 S) Jaypee Cement (OPC-43 Grade) Jaypee Cement (OPC-43 Grade) is produced from enriched limestone most suited to make high quality clinker, which on grinding gives a cement with characteristics surpassing those specified in IS: 8112 1989. (Please refer Table-2). Jaypee Cement (OPC-43 Grade) is available in 50 Kgs HDPE bags of a distinctive design and cover (bag shot).

Jaypee Cement (OPC-43 Grade), has emerged as the top choice of Engineers and Engineering Companies engaged in construction of mega projects such as National Highways, Bridges, Transmission lines, power plants, Industrial and Residential structures. Table-2: Typical Chemical and Physical Properties of Jaypee Cement (OPC-43 Grade) Particulars Typical Range

Requirement of

IS: 8112 - 1989 CHEMICAL PROPERTIES 1 2 3 4 5 6 7 Lime Saturation Factor (LSF) Alumina to that of Iron oxide Ratio % (A/F) In soluble Residue (% by mass) Magnesium oxide (% by mass) Sulphuric Anhydride (% by mass) Total Loss On Ignition (% by mass) Total Chloride ( % by mass) PHYSICAL PROPERTIES 1 2 Fineness (M2/Kg) Setting Time (Minutes) Initial Final 3 Expansion Le. Chatelier (mm) Auto clave (%) Compressive Strength (MPa) 3 Days 7 Days 28 Days tested 1.00-2.00 0.10-0.20 32.0-34.0 42.0-44.0 52.0-54.0 at 10.00 Max. 0.8 Max. 23 Min. 33 Min. 43 Min. temp.27 2C Concrete) 280-300 120-140 160-180 225 Min. 30 Min. 600 Max. 0.88-0.90 1.40-1.60 1.20-1.60 2.50-3.20 1.60-1.80 1.20-1.60 0.010-0.014 0.66 To 1.02 0.66 Min. 3.00 Max. 6.00 Max. 3.00 Max. 5.00 Max. 0.10 Max.(For N.C.)* 0.05 Max.(For P.C.)*

Cement *N.C.(Normal *P.C.(Prestressed Concrete) Jaypee Cement (OPC-53 Grade)

OPC-53 Grade has been the mainstay for fast paced construction of high strength, heavy load bearing Structures viz., Bridges, prestressed elements, penstocks, precast elements etc. requiring very high strength to negotiate the heavy static & dynamic loads. Jaypee Cement (OPC-53 Grade), because of its fine nature, good particle size distribution, optimal phase composition, imparts the properties of higher strength to the structures. The Chemical & Physical properties of Jaypee Cement (OPC-53 Grade) surpasses the properties of OPC 53 grade as defined in IS: 12269 1987. (Please Refer Table 3) Table-3: Typical Chemical and Physical Properties of Jaypee Cement (OPC-53 Grade) Particulars Typical Range CHEMICAL PROPERTIES 1 2 3 4 5 6 7 Lime Saturation Factor (LSF) Alumina to that of Iron oxide Ratio % (A/F) In soluble Residue (% by mass) Magnesium oxide (% by mass) Sulphuric Anhydride (% by mass) Total Loss On Ignition (% by mass) Total Chloride ( % by mass) PHYSICAL PROPERTIES 1 2 Fineness (M2/Kg) Setting Time (Minutes) Initial Final 3 Expansion Le. Chatelier (mm) Auto clave (%) Compressive Strength (MPa) 3 Days 7 Days 1.00-2.00 0.10-0.15 40.0-42.0 49.0-50.0 10.00 Max. 0.8 Max. 27 Min. 37 Min. 320-340 110-120 150-180 225 Min. 30 Min. 600 Max. 0.90-0.92 1.20-1.40 1.0-1.20 3.0-3.50 1.80-2.00 1.0-1.20 0.010-0.014 0.66 To 1.02 0.66 Min. 3.00 Max. 6.00 Max. 3.00 Max. 4.00 Max. 0.10 Max.(For N.C.)* 0.05 Max.(For P.C.)*

Requirement of IS: 12269 - 1987

28 Days Cement tested at temp.27 2C *N.C.(Normal Concrete) *P.C.(Prestressed Concrete) Jaypee Cement (OPC-53S Grade)

60.0-62.0

53 Min.

One of the very few cement manufacturers having the potential to manufacture this special grade of super fine cement which due to its enhanced quality and performance parameters has been approved by the RDSO of Indian Railways for manufacture of RAILWAY SLEEPERS. Jaypee Cement (OPC-53 S Grade) is also used in heavily loaded or pre stressed structures, which are subjected to high dynamic loads due to rapidly moving volumes, be it a train passing on the railway sleepers or a great volume of water moving at high speed to generate electricity in a penstock. The characteristics of Jaypee Cement (OPC-53 S Grade) vis a vis the prescribed BIS Standards IS: 12269 1987 can be seen in Table-4. Table-4: Typical Chemical and Physical Properties of Jaypee Cement (OPC-53 S Grade) Particulars Typical Range CHEMICAL PROPERTIES Lime Saturation Factor (LSF) Alumina to that of Iron oxide Ratio % (A/F) In soluble Residue (% by mass) Magnesium oxide (% by mass) Sulphuric Anhydride (% by mass) Total Loss On Ignition (% by mass) Total Chloride ( % by mass) PHYSICAL PROPERTIES 1 2 Fineness (M2/Kg) Setting Time (Minutes) Initial Final 3 Expansion Le. Chatelier (mm) Auto clave (%) Compressive Strength (MPa) 3 Days 7 Days 28 Days 2.00 0.14 40.4 49.6 Due 10.00 Max. 0.8 Max. 27 Min. 37 Min. 53 Min. 343 125 180 225 Min. 30 Min. 600 Max.

Requirement of IS: OPC-53 S 0.80 To 1.02 0.66 Min. 3.00 Max. 6.00 Max. 3.00 Max. 4.00 Max. 0.10 Max.(For N.C.)* 0.05 Max.(For P.C.)*

1 2 3 4 5 6 7

0.91-0.92 1.39 1.22 3.21 1.84 1.12 0.022

Cement tested at temp.27 2C The above cement complies with IS: 12269 -1987 for 53 Grade Ordinary Portland Cement. *N.C.(Normal Concrete Cement) *P.C.(Prestressed Concrete Cement) Despatched on - 12/03/06 Week No : 11/2006 Jaypee OPC-53S Grade cement One of the very few cement manufacturers having the capability to manufacture this special grade of cement which due to its enhanced quality and performance parameters has been approved by the RDSO and is preferred by Indian Railways for manufacture of SLEEPERS. Jaypee OPC-53 S Grade is also used in heavily loaded or prestressed structures, which are subjected to high dynamic loads due to rapidly moving volumes, be it a train passing on the railway sleepers or a great volume of water moving at high speed to generate electricity in a Dam. The characteristics of OPC-53 S Grade cement with the prescribed BIS Standards IS: 12269 1987 can be seen in the table below.

Particulars CHEMICAL PROPERTIES 1 2 3 4 5 6 7 8 9 Lime Saturation Factor (LSF) Alumina to that of Iron oxide Ratio % (A/F) In soluble Residue (% by mass) Magnesium oxide (% by mass) Sulphuric Anhydride (% by mass) Total Loss On Ignition (% by mass) Tricalcium Aluminate (C3A) % Tricalcium Silicate (C3S) % Total Chloride ( % by mass) PHYSICAL PROPERTIES Fineness (M2/Kg) Setting Time (Minutes) Initial Final Expansion Le. Chatelier (mm) Auto clave (%) Compressive Strength (MPa) 3 Days 7 Days 28 Days

Test Results Obtained

Requirement of IS: OPC-53 S 0.80 To 1.02 0.66 Min. 2.00 Max. 5.00 Max. 5.00 Max. 4.00 Max. 10.00 Max. 45.00 Min. 0.10 Max.(For N.C.)* 0.05 Max.(For P.C.)* 370 Min. 60 Min. 600 Max. 5.00 Max. 0.8 Max. Not Specified 37.5 Min. Not Specified

0.91 1.31 0.88 3.18 1.86 1.02 6.98 49.49 0.013

1 2

407 145 195 1.00 0.18 36.0 47.0 60.0

Cement tested at temp.27 2C The above cement complies with IRS: T-40-1985 (53S) of Indian Railway Standard specification for cement used in concrete sleeper. *N.C.(Normal Concrete Cement) *P.C.(Prestressed Concrete Cement)

Mining In order to meet limestone requirement of the three Cement Plants, Jaiprakash Associates Limited has three Captive Limestone Mines Naubasta Limestone Mine, Jaypee Limestone Mine and Bankuiyan Limestone Mine. Systematic and scientific mining operations of Jaiprakash Associates Limited are supported with the help of Holder Bank Management Consultancy (HMC), Switzerland by state-of-the art computerized programming the Computer Aided Deposit Evaluation (CADE) & Quarry Scheduling Optimisation (QSO). The Mining operations are carried out by fully mechanized open cast mining methods. The equipments used include 153 mm drill machines, hydraulic excavators of 3.8 cum & 4.1 cum bucket capacities, in-situ rock breaker, heavy duty 35 MT carrying capacity dumpers, bull dozers and miscellaneous equipments. The holes drilled for blasting are charged with bottom initiation using excel detonators to minimize ground vibration and fly rock. A DS-077 Seismograph is used on a continuous basis to monitor ground vibration. The reclamation and rehabilitation of mined area is a continuous process in Jaiprakash Associates Limited. The hard overburden generated is used to back-fill the area with good topsoil and area is rehabilitated in planned way by adopting large scale afforestation.

Environment

An Environment Management Cell has been constituted to undertake environment protection measures and for development of all environmental aspects. For environmental sustainability, nearly 6-12% of operational cost is incurred in these measures which include maintenance and modification of Pollution Control equipments, hiring of professional consultants for various environmental studies, maintenance of sewage treatment plant, environmental and plantation works at plants & mines. The environment cell is divided in three parts:1. 2. 3. Air Water and Microbiological waste water Lab. Lab. lab.

Water and wastewater testing lab. with advanced Equipments is set-up at Jaypee Rewa Cement Complex. The water and wastewater testing is being done at Water lab itself. A separate Air lab is in operation for the analysis of different gases i.e. SOX & NO2 as per IS: 5182. Various parameters including heavy metals are analysed with NOVA 60 (Merck make) spectroquant spectrometer. Environmental Lab

Plantation A continual afforestation drive in Mines, Plants & Township areas and all along road is undertaken to improve the overall environment as a safeguard against pollution. The plant species are chosen corresponding to the soil quality and locally existing variety and have a survival rate of around 80%. Upto 5,88,380 trees have already been planted in & around project site. Water Conservation The Groups dry cement manufacturing process based plants have modern air pollution control equipment and as such there is no effluent from the plants; therefore the zero discharge principle is complied with. Moreover, the entire domestic sewage and waste water is treated at Sewage Treatment Plants of adequate capacity upto the tertiary treatment level after which ozonation is carried out to the tertiary treated water to get rid of any odour or pathogen in the treated water. This treated water is used in the cement manufacturing process as well as for horticulture purposes. Tertiary Treatment Process

Ozonation of Tertiary Treated water

Mines water Reservoir - A Habitat of Migratory Birds

A view of Mines Water Reservoir from Jaypee Rewa Plant

Every drop of rain water is conserved in the plant by an innovative garland canal covering a periphery of 6.2 km .The collection is diverted into the reservoirs situated in the Mines. Four Rain Water harvesting bodies covering nearly 47.0 hectares have been developed in Mines area. These reservoirs with a capacity of 32.2 lac M3 water have created a positive impact on the ground water level of adjoining villages by stabilizing the water table of the surrounding wells. Ecological Balance The reclamation and rehabilitation of mined area is a continuous process in Jaiprakash Associates Limited. The hard overburden generated is used to back-fill the area and after imparting a good topsoil cover the area is rehabilitated in a planned way by adopting large scale afforestation. The increased sighting of Hare, Jackals, Foxes, Cranes and Mongeese is testimony to the fact that the environment is becoming increasingly more conducive to life. Some Green initiatives: Scientific segregation of all types of waste at source:Segregation of Domestic & Plant solid-waste at the point of generation to make the most effective use and disposition of the solid waste. Domestic solid waste is segregated in two differently coloured bins (one for biodegradable & another for non-biodegradable)

Bio-methanation plant for bio-degradable kitchen waste collected from colony and Annpurnas. The bio-gas is used as a fuel in the Annapurna. Use of Plastic waste as Alternative fuel in cement kiln:The plastic waste collected from Rewa city and the cement plants colonies is used as alternative fuel in the cement kiln. Vermi-composting of leaf litter :The leaf-litter collected during road sweeping goes for vermi-composting in pits having vermin-culture. The compost generated is used as manure in horticulture and aforrestation.

Statutory Detail

Title Jaypee Himachal Cement Grinding and Blending Plant, Bagheri Data on Ambient air quality and critical pollutants Jaypee Himachal Cement Plant - Baga Data on Ambient air quality monitoring Data on Stack monitoring Data on Ambient noise level monitoring Data on Sewage Treatment Plant Report Six Monthly Reports Data on Ambient air quality monitoring Data on Stack monitoring Data on Ambient noise level monitoring Data on Sewage Treatment Plant Report

Month/Year

September, 2011

September, 2011 September, 2011 September, 2011 September, 2011

Dec, 2010- May, 2011 Dec, 2010- May, 2011 Dec, 2010- May, 2011 Dec, 2010- May, 2011

Geographical Spread Jaypee Rewa Plant (JRP) Jaypee Nagar P.O. Jaypee Nagar Rewa 486450 (M.P) Tel : (07662) 400700, 229601-09 Fax : (07662) 229218 CAPACITY 3.0 MTPA Jaypee Cement Blending Unit (JCBU) Village-Sadwa Khurd, Paragana Arail Tehsil-Bara, Distt. Allahabad (U.P.) Phone: (0532) 2425012 Mob: 09956290958 Jaypee Bela Plant (JBP) Jaypee Puram P.O. Jaypee Puram Rewa 486450 (M.P) Tel : (07662) 409301 Fax : (07662) 229662 CAPACITY 2.4 MTPA Jaypee Ayodhya Grinding Operations (JAAGO) P.O Husainpur Sudhana, Village Khanaura Teh : Tanda, Distt. Ambedkar Nagar (U.P) Phone: (05273) 284809, 281020, 281015 Fax : (05273) 284609

Mob: 09935522345 CAPACITY 0.6 MTPA Dalla Cement Factory (DCF) (A Unit Of Jaiprakash Associates Ltd.) S.H.5,Kota, PO: Dalla, Sonebhadra(UP) Phone : (05445) 265778, 265801 Fax : (05445) 265776 CAPACITY 0.5 MTPA Jaypee Cement Grinding Unit (JCGU) Village Khukhrana, P.O: Asan Kala, Teh: Madlauda Distt.Panipat (Haryana) Phone: (0180) 2566811 Phone: (0180)2566812 Fax: (0180) 2566164 CAPACITY 1.5 MTPA Jaypee Sidhi Cement Plant (JSCP) Jaypee Vihar, Majhigawan P.O. Bharatpur, Sidhi 486776 Phone: (07802) 276701 - 276714 Fax: (07802) 276715 CAPACITY 2.0 MTPA

CAPACITY 1.0 MTPA

Chunar Cement Factory (CCF) (A Unit Of U.P Cement Plant) P.O. Chunar, Mirzapur (U.P)-231311 Tel: (05443) 222926, 222265, 222602 Fax:(05443) 225079 CAPACITY 2.5 MTPA Jaypee Himachal Cement Blending Unit (JHCBU) Vill. Tikari (Pandiyana) P.O. Khilian, Tehsil Nalagarh, Solan (H.P.)-174101 Phone: (01795) 229100, 266937,266934 Fax: (01795) 266935 CAPACITY 2.5 MTPA

Gujarat Anjan Cement Limited (GACL) Sewagram Vill. Vayor, Taluka Abdasa Distt.. Kutchh (Bhuj), Gujarat 370511 Phone: (02831) 279200 Fax : (02831) 279279 CAPACITY 2.4 MTPA

JAL is in the process of setting up new capacities in Northern, Central, Western & Southern parts of the country and is targeting a capacity of 26 MTPA by 2010 and 32.80 MTPA by 2011, along with Captive Thermal Power Plants (CPPs) totaling 375 MW. Once the expansion plans have been implemented, the Group will have 12 Integrated Cement Plants supported by 375 MW of captive thermal power, 9 split location plants, 11 Railway sidings and a jetty, giving the Group a pan-India presence in the cement sector.

Regional/Area Marketing Offices

Awards

Cement Division of Jaiprakash Associates Limited with its Plants at Jaypee Rewa Plant (JRP), Jaypee Bela Plant (JBP), JAAGO & JCBU has been awarded the Integrated Management System comprising of ISO-9001:2000, ISO-14001:2004 & OHSAS-18001:1999 by the world renowned Bureau Veritas Certification. ISO-9001:2000 covers Quality Management System. ISO-14001:2004 covers all Environmental Issues including conservation of Natural Resources and Reduction of Emissions and Wastes. OHSAS-18001:1999 covers Operational Safety and reduces Risk to People, Plant & Machinery.

Potrebbero piacerti anche

- Ignition SystemsDocumento10 pagineIgnition Systemselvergonzalez1Nessuna valutazione finora

- ColloquialismDocumento3 pagineColloquialismAdarsh ChoudharyNessuna valutazione finora

- Process Engineering: General Information About Courses Giving ImportanceDocumento5 pagineProcess Engineering: General Information About Courses Giving ImportanceAdarsh ChoudharyNessuna valutazione finora

- ASE Course on Data Communication and Computer NetworksDocumento1 paginaASE Course on Data Communication and Computer NetworksAdarsh ChoudharyNessuna valutazione finora

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (587)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (894)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (399)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (73)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2219)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (344)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (265)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (119)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- Rego-Fix Er Recool enDocumento28 pagineRego-Fix Er Recool endavicocasteNessuna valutazione finora

- ABEL SH Solids Handling Pumps GB-web-02 2020Documento6 pagineABEL SH Solids Handling Pumps GB-web-02 2020ha liNessuna valutazione finora

- Concrete Shell ElementDocumento25 pagineConcrete Shell ElementRudranath BhattacharyaNessuna valutazione finora

- Variable Hangers and Supports - 2018 - Rev.3.1Documento19 pagineVariable Hangers and Supports - 2018 - Rev.3.1Nassim Ben AbdeddayemNessuna valutazione finora

- Rilem 2001 Connection Concrete SteelDocumento1.365 pagineRilem 2001 Connection Concrete Steelbombaikos100% (3)

- SOP's 2020-2021Documento144 pagineSOP's 2020-2021Muhammad AbdullahNessuna valutazione finora

- Mahaweli Water Security Investment Program Site EstablishmentDocumento26 pagineMahaweli Water Security Investment Program Site EstablishmentAmila Priyadarshana DissanayakeNessuna valutazione finora

- Piping & Instrumentation Diagram 100Kld MBBR STP: Pretreatment and Filteration SystemDocumento1 paginaPiping & Instrumentation Diagram 100Kld MBBR STP: Pretreatment and Filteration SystemRabindra Singh100% (1)

- Buttress DamDocumento65 pagineButtress DamAF.RISHARD FAIS77% (13)

- Series LFN45B-M1 Specification SheetDocumento2 pagineSeries LFN45B-M1 Specification SheetWattsNessuna valutazione finora

- Teóricas - 11. Co-Cr Alloys PDFDocumento14 pagineTeóricas - 11. Co-Cr Alloys PDFrostcarNessuna valutazione finora

- Abbreviations Symbols Demolition Notes: 1 09/07/2018 Issue For Bid 2 09/13/2018 Addendum 1Documento9 pagineAbbreviations Symbols Demolition Notes: 1 09/07/2018 Issue For Bid 2 09/13/2018 Addendum 1Md. Farid UddinNessuna valutazione finora

- BVG4P 1 LOCK Parker Brass Ball ValveDocumento2 pagineBVG4P 1 LOCK Parker Brass Ball ValveMROstop.comNessuna valutazione finora

- Instrument Manifold (Monoflange) : SpecificationsDocumento1 paginaInstrument Manifold (Monoflange) : Specificationshisaj4uNessuna valutazione finora

- BARE COPPER CONDUCTOR SPECIFICATIONSDocumento1 paginaBARE COPPER CONDUCTOR SPECIFICATIONSIan de GaliciaNessuna valutazione finora

- Environmental Project ManagementDocumento44 pagineEnvironmental Project ManagementCharleneKronstedt0% (1)

- Petrofast MTC 3.1 PO-400234 Anchor Bolts - Option FDocumento2 paginePetrofast MTC 3.1 PO-400234 Anchor Bolts - Option Fحسن صالح حسن المياحيNessuna valutazione finora

- Final Review and Audit Process Flowchart Construction ProjectsDocumento1 paginaFinal Review and Audit Process Flowchart Construction ProjectsnaniappoNessuna valutazione finora

- Villa Ottolenghi by Carlo ScarpaDocumento6 pagineVilla Ottolenghi by Carlo ScarpaOana ZavoianuNessuna valutazione finora

- 13 PT ProcedureDocumento14 pagine13 PT ProcedureThân KhaNessuna valutazione finora

- Loxeal InfotechDocumento16 pagineLoxeal InfotechAlexNessuna valutazione finora

- Re 25715 - 2022-05Documento8 pagineRe 25715 - 2022-05HeiderHuertaNessuna valutazione finora

- Examining The Evolution of Jaipur S ArchDocumento13 pagineExamining The Evolution of Jaipur S ArchSham ParitNessuna valutazione finora

- Me215 1 IntroductionDocumento41 pagineMe215 1 IntroductionSonuNessuna valutazione finora

- U-Bolt Clamps HRRBS Flat Steel Bolt Clamps HRFBSDocumento8 pagineU-Bolt Clamps HRRBS Flat Steel Bolt Clamps HRFBSFakeNessuna valutazione finora

- EQR UttarkashiDocumento8 pagineEQR UttarkashiArjunNessuna valutazione finora

- PDS - SikaWrap FX-50 C-En PDFDocumento3 paginePDS - SikaWrap FX-50 C-En PDFjohanes b mudaNessuna valutazione finora

- Scour Under StructuresDocumento24 pagineScour Under StructuresRamkumarNessuna valutazione finora

- 53106-mt - Mechanics of Composite MaterialsDocumento2 pagine53106-mt - Mechanics of Composite MaterialsSRINIVASA RAO GANTANessuna valutazione finora