Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Note Hand-Soldering e

Caricato da

micpreampDescrizione originale:

Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Note Hand-Soldering e

Caricato da

micpreampCopyright:

Formati disponibili

Notes of hand soldering for MLCC

Murata will explain what kind of problem will be caused in MLCC when it is soldered and solder correction by soldering iron. Also Murata will explain how to solve it.

Agenda

1. What kind of problem will be caused when MLCC is soldered by soldering iron? 2. Relationship between preheating temperature of PCB bending strength 3. Mechanism of bending strength deterioration 4. Method of hand soldering. 4.1 Using soldering iron 4.2 Using hot air gun 4.3 Hot air gun operating procedure

1. What kind of problem will be caused when MLCC is soldered by soldering iron? Cracking might be occurred into MLCC due to thermal shock by rapid and local heating from soldering iron. The bending strength might decrease due to low temperature preheating condition of PCB. (because of increasing remained tensile stress) Then, What shall we do?

Optimized preheating condition of PCB and MLCC is necessary.

3

2. The Relationship between preheating temperature of PCB and bending strength

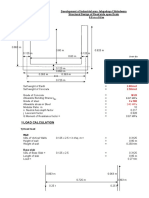

: Bending strength test Test board:100mmx40mm thicknes:1.6mm FR4 solder:Sn-3Ag-0.5Cu Products shall be judged to be defective if the change in capacitance has exceeded12.5% Test sample : MLCC 0805 X7R 0.1uF 50V Sample condition : MLCC sample is soldered on the test board by reflow soldering, Then, one side of solder fillet is melted again by soldering iron At this time, test board is preheated to 4 conditions of temperature. Preheating condition : room temp.(25deg C), 75deg C, 125deg C, 175deg C, and only reflow (not hand soldering) Test method

Not preheating

Survival rate (%)

Hand work by soldering iron after reflow will decrease bending strength.

Only reflow

Optimized preheating temperature condition of PCB is effective to improve decreasing bending strength.

Bend length (mm) 4

3. Mechanism of bending strength destroy

The stress under cooling after reflow MLCC is strong with compressive stress, but is weak with tensile stress.

concentrated point of stress

(2)MLCC (3)solder

(1) : compressive stress by shrinking PCB (2) : tensile stress by shrinking MLCC (3) : tensile stress by shrinking solder

(ref) Line expansion coefficient (ppm/deg C) FR4 board20, MLCC11, solder22

(1)PCB reflow soldering Compressive stress (+) Tensile stress (-)

Hand soldering without preheating of PCB Compressive stress (+) Tensile stress (-)

Remained stress of concentrated point

Remained stress of Concentrated point

Remained tensile stress of hand soldering without preheating of the PCB is bigger than reflow soldering.

5

4. Hand soldering method

4.1 using soldering iron

1 temperature condition about the temperature of the soldering iron head BC type/3mm iron head is recommended because of large thermal capacity about preheating of the PCB At a high temperature , considering heatproof of parts as much as possible As the PCB, it is necessary to check the time of heating 2) Example of preheating PCB One-side mounted substrates hot plate hot air gun

Preheating of MLCC 90120 90120 90-120sec. Preheating of MLCC & 90 90 PCB 90sec min. B Type/R0.5

BC Type/3mm

Both-side mounted substrates (as below)

Size 1206 max 1210 min

Temp. of Iron head

Preheating of the PCB,MLCC

T 150 deg. C max 130 deg. C max

350 deg. C max 150 deg. C min 280 deg. C max 150 deg. C min

Quotation from JEITA safety application guide RCR-2335B

4. Hand soldering method.

4.2 using hot air gun

Nozzle setting each side 5sec soldering

angle 40degree

350 Temperature (deg. C) 300 250 200 150 100 50 0 0 10 20 30 Time (sec) 40

Nozzle 1hole

The back Surface

distance5mm

Photo image

50

0603 X7R 1000pF

100 Survival rate (%) Survival rate (%) 80 60 40 20 0 0 1 2 3 4 Bend length (mm) 5 6 7 Soldering iron w/o preheating Only reflow Hot air gun

100 80 60 40 20 0 0

1206 X7R 1uF

Soldering iron w/o preheating Only reflow Hot air gun

Only using hot air gun is better than using soldering iron without preheating substrate.

Bend length (mm)

4. Hand soldering method.

4.3 hot air gun operating procedure 1. Pre-soldering on the pads by soldering iron 2. Coating flux on outer electrodes of MLCC 3. Melting again the pre-solder by hot air gun 4. Setting MLCC on pads and soldering one side electrode by hot air 5. Soldering another side electrode using solder wire on the pad , melting solder by hot air gun 6. Cooling

distance between MLCC and Nozzle : more than 5mm Angle : 45deg. Temperature of hot air : less than 400deg.C Flux of air : min. level Inside diameter : 2mm Time 1206 max : 10sec. max 1210 min : 30sec. max

1 hole nozzle 2mm

0603Size

JEITA safety application guide RCR-2335B-1 amendment1 (2009/8 revised) 8

Potrebbero piacerti anche

- Friction Stir Welding of Aluminum MMC: Tracy W. Nelson, Dick LederichDocumento22 pagineFriction Stir Welding of Aluminum MMC: Tracy W. Nelson, Dick LederichSanthosh Kumar KodhandapaniNessuna valutazione finora

- Structural Dynamics of Electronic and Photonic SystemsDa EverandStructural Dynamics of Electronic and Photonic SystemsNessuna valutazione finora

- Jntuworld: Advances in Manufacturing TechnnologyDocumento1 paginaJntuworld: Advances in Manufacturing TechnnologycomputerstudentNessuna valutazione finora

- HIGH CARBON 35Cr-45Ni-1Nb: Alloy TypeDocumento2 pagineHIGH CARBON 35Cr-45Ni-1Nb: Alloy TypeSaravanan Pitchandi100% (1)

- Uncinventional Machining Process Interview QuestionsDocumento14 pagineUncinventional Machining Process Interview QuestionsimsaiyathNessuna valutazione finora

- CMT Welding Research PaperDocumento23 pagineCMT Welding Research PaperUpendra93Nessuna valutazione finora

- Mecanismos de Falha Nos Capacitores de CerâmicaDocumento9 pagineMecanismos de Falha Nos Capacitores de CerâmicaLeonardo RennóNessuna valutazione finora

- Wave Soldering: Wave Soldering Is A Bulk Soldering Process Used in TheDocumento5 pagineWave Soldering: Wave Soldering Is A Bulk Soldering Process Used in TheMadhusudanan Ashok0% (1)

- Final Exam Key AnswerDocumento6 pagineFinal Exam Key Answergirma worku100% (1)

- BMMP3533 - Labsheet - EDM Die Sinker 20192020Documento5 pagineBMMP3533 - Labsheet - EDM Die Sinker 20192020Amilin HatiaraNessuna valutazione finora

- Answer of Midterm Exam 2 PDFDocumento6 pagineAnswer of Midterm Exam 2 PDFFaisal Al-assafNessuna valutazione finora

- AN-1501 Handling InstructionsDocumento8 pagineAN-1501 Handling InstructionsmSmallNessuna valutazione finora

- SCHEME Test UiTM WeldingDocumento2 pagineSCHEME Test UiTM Weldinglimakupang_matNessuna valutazione finora

- Adv - Design of Weldments Seme1 2004Documento4 pagineAdv - Design of Weldments Seme1 2004mukesh3021Nessuna valutazione finora

- DH 1232NSDocumento1 paginaDH 1232NSGopiNathNessuna valutazione finora

- MCQ's Tips Paper 1Documento3 pagineMCQ's Tips Paper 1miteshNessuna valutazione finora

- Resistance Spot Welding Parameters Optimal Selection For Automotive Steel PlateDocumento6 pagineResistance Spot Welding Parameters Optimal Selection For Automotive Steel PlateMahmoud SingerNessuna valutazione finora

- Specification STANDAR WLDocumento7 pagineSpecification STANDAR WLJakJhonNessuna valutazione finora

- Crack Detection Methods For Lead-Free Solder Joints: Milos Dusek & Christopher HuntDocumento26 pagineCrack Detection Methods For Lead-Free Solder Joints: Milos Dusek & Christopher HuntpastelquenteNessuna valutazione finora

- CH 28Documento6 pagineCH 28koech02118Nessuna valutazione finora

- 60mm Size Ring Type: Large Ring Structure Contributes To MultifunctioningDocumento3 pagine60mm Size Ring Type: Large Ring Structure Contributes To MultifunctioningshyhuNessuna valutazione finora

- Ch-12 Unconventional MachiningDocumento135 pagineCh-12 Unconventional MachiningSaumil ShahNessuna valutazione finora

- Model Answer - Sheet (1&2)Documento17 pagineModel Answer - Sheet (1&2)YSMHXSTS SYTMXSNessuna valutazione finora

- ThermistorDocumento44 pagineThermistorjuca_br2002Nessuna valutazione finora

- 4.5×3.55mm Side Push Type (Surface Mount Type) : Sidepush With High Solder Strength & Tactile FeelingDocumento3 pagine4.5×3.55mm Side Push Type (Surface Mount Type) : Sidepush With High Solder Strength & Tactile FeelingshyhuNessuna valutazione finora

- Local PWHTDocumento6 pagineLocal PWHTcmeshibu100% (1)

- AnswersDocumento34 pagineAnswersMahmoud Elsayed MohamedNessuna valutazione finora

- Sped2: 4.5mm-Travel Push-Push TypeDocumento3 pagineSped2: 4.5mm-Travel Push-Push TypeshyhuNessuna valutazione finora

- 1 Modulo IWEDocumento4 pagine1 Modulo IWEgiovannidelduca1974Nessuna valutazione finora

- Rework ConditionsDocumento1 paginaRework Conditionsroman reeseNessuna valutazione finora

- Practice 6 - Questions - CSWIPDocumento12 paginePractice 6 - Questions - CSWIPravichandran0506Nessuna valutazione finora

- Flyback Transformers: SchematicsDocumento2 pagineFlyback Transformers: Schematicscatsoithahuong84Nessuna valutazione finora

- HW 8 Non Traditional Machining Ch26Documento2 pagineHW 8 Non Traditional Machining Ch26BobNessuna valutazione finora

- Total Hight of 3.1mm. Surface Mount Package With Ground TerminalDocumento3 pagineTotal Hight of 3.1mm. Surface Mount Package With Ground TerminalshyhuNessuna valutazione finora

- BY Debabrata Sahu REGD NO:-1721109146: Production EngineeringDocumento20 pagineBY Debabrata Sahu REGD NO:-1721109146: Production EngineeringRabindra DashNessuna valutazione finora

- Test Bank Mid 2Documento13 pagineTest Bank Mid 2mhd slmnNessuna valutazione finora

- Unit 4 Lesson 4Documento7 pagineUnit 4 Lesson 4mahmoud yarahmadiNessuna valutazione finora

- Tesys Contactors DDocumento6 pagineTesys Contactors DJabir QuadriNessuna valutazione finora

- Side Push Half-Mount Type With 1.6mm Height (Surface Mount Type)Documento3 pagineSide Push Half-Mount Type With 1.6mm Height (Surface Mount Type)shyhuNessuna valutazione finora

- Low-Profile, 1.2mm Height, Long Travel TypeDocumento3 pagineLow-Profile, 1.2mm Height, Long Travel TypeshyhuNessuna valutazione finora

- 45mm Size Ring Type: Large Ring, Heavy Torque Device Perfect For Large Ring Knob DesignDocumento3 pagine45mm Size Ring Type: Large Ring, Heavy Torque Device Perfect For Large Ring Knob DesignshyhuNessuna valutazione finora

- HIC Failure Investigation ReportDocumento25 pagineHIC Failure Investigation Reportravindra_jivaniNessuna valutazione finora

- Side Push Surface Mount Type With 1.55mm Height SKTD SeriesDocumento3 pagineSide Push Surface Mount Type With 1.55mm Height SKTD SeriesshyhuNessuna valutazione finora

- Tests According To IEC-En Standards (WAGO)Documento11 pagineTests According To IEC-En Standards (WAGO)va3ttnNessuna valutazione finora

- API 510 CB Mockup 3 R0 26112010Documento18 pagineAPI 510 CB Mockup 3 R0 26112010essnelsonNessuna valutazione finora

- Unit 4: Micro Machining and Nano Fabrication TechniquesDocumento21 pagineUnit 4: Micro Machining and Nano Fabrication TechniquesSachin SBNessuna valutazione finora

- Tube HydraulicsDocumento8 pagineTube HydraulicsrijalharunNessuna valutazione finora

- Sample MSD PaperDocumento2 pagineSample MSD PaperKylo Ren0% (1)

- Quiet Type With 0.9mm Stroke (Surface Mount Type)Documento3 pagineQuiet Type With 0.9mm Stroke (Surface Mount Type)shyhuNessuna valutazione finora

- Wis 5 Eoca AnswersDocumento34 pagineWis 5 Eoca AnswersAli ClubistNessuna valutazione finora

- DR xc035Documento68 pagineDR xc035Александр БалашовNessuna valutazione finora

- Effect of Different Metalurgical Phases On The Welding Residual Stresses of Base MetalDocumento71 pagineEffect of Different Metalurgical Phases On The Welding Residual Stresses of Base Metalsalmanzafar_37304938Nessuna valutazione finora

- Duplex Beaune 2010Documento10 pagineDuplex Beaune 2010aliNessuna valutazione finora

- Chip Evacuation of PCB Micro-Drilling and High-Speed PhotographyDocumento7 pagineChip Evacuation of PCB Micro-Drilling and High-Speed PhotographyChethan GowdaNessuna valutazione finora

- Specification: Specification of Electrical Double Layer CapacitorDocumento16 pagineSpecification: Specification of Electrical Double Layer CapacitorselocaNessuna valutazione finora

- Design Guidelines for Surface Mount TechnologyDa EverandDesign Guidelines for Surface Mount TechnologyValutazione: 5 su 5 stelle5/5 (1)

- Dynamic Damage and FragmentationDa EverandDynamic Damage and FragmentationDavid Edward LambertNessuna valutazione finora

- Fundamental Aspects of Dislocation Interactions: Low-Energy Dislocation Structures IIIDa EverandFundamental Aspects of Dislocation Interactions: Low-Energy Dislocation Structures IIIG. KostorzNessuna valutazione finora

- (Appendix 1) Solids: Oelze ECE/TAM 373 Notes - Chapter 5 PG 27Documento8 pagine(Appendix 1) Solids: Oelze ECE/TAM 373 Notes - Chapter 5 PG 27AlinaBogoiNessuna valutazione finora

- A) B) B - Cos A) B, When A 90°: Material Charpy V Impact StrengthDocumento3 pagineA) B) B - Cos A) B, When A 90°: Material Charpy V Impact StrengthsonuNessuna valutazione finora

- How To Implement Elastoplasticity in A Model Using External Materials - COMSOL BlogDocumento17 pagineHow To Implement Elastoplasticity in A Model Using External Materials - COMSOL BlogSebastiao SilvaNessuna valutazione finora

- Dental Polymers: Typical Applications of Polymers in DentistryDocumento9 pagineDental Polymers: Typical Applications of Polymers in DentistryEuro UndisaNessuna valutazione finora

- RCC Drain DesignDocumento11 pagineRCC Drain DesignShashank Yadav100% (3)

- Buried Pipe AnalysisDocumento6 pagineBuried Pipe AnalysisAnonymous Jq5ttTCNessuna valutazione finora

- LRFD Axially Loaded Compression MembersDocumento4 pagineLRFD Axially Loaded Compression Membersالكشكولي رضوانNessuna valutazione finora

- DSC Beginners GuideDocumento9 pagineDSC Beginners GuidelumineurNessuna valutazione finora

- 2 Sheet Metal StructuresDocumento98 pagine2 Sheet Metal StructuresSteph AicoNessuna valutazione finora

- Theories of Failure 2Documento23 pagineTheories of Failure 2Nagendra Manral100% (1)

- Exam 1 Formula Sheet RevDocumento1 paginaExam 1 Formula Sheet RevMadi SilalahiNessuna valutazione finora

- 6005-T6 Aluminum Vs 6061-T6 AluminumDocumento4 pagine6005-T6 Aluminum Vs 6061-T6 AluminumKhamda Aja Dulu100% (1)

- Cornu Method XXDocumento7 pagineCornu Method XXArunnarenNessuna valutazione finora

- Bernt - EC3 1 5Documento44 pagineBernt - EC3 1 5Rosario BlancaNessuna valutazione finora

- Chapter 6 Thermodynamic Properties of FluidsDocumento31 pagineChapter 6 Thermodynamic Properties of FluidsMuhammad Fawwaz100% (1)

- Tutorial YuJ Magnetism PDFDocumento110 pagineTutorial YuJ Magnetism PDFAhmad AwadallahNessuna valutazione finora

- Stress Based Topology Optimization of 30 Ton C Hook Using FEM.Documento48 pagineStress Based Topology Optimization of 30 Ton C Hook Using FEM.Aravind J100% (1)

- EPFM - Elasto Plastic Fracture MechanicsDocumento11 pagineEPFM - Elasto Plastic Fracture MechanicsSaima naazNessuna valutazione finora

- ATM-025/ATM-100 Asphalt Mix Performance Tester: Compliance and Strength Where 100 KN Capacity Is SpecifiedDocumento4 pagineATM-025/ATM-100 Asphalt Mix Performance Tester: Compliance and Strength Where 100 KN Capacity Is SpecifiedJorge SandokanNessuna valutazione finora

- Pearson Chemistry Chapter 8 Flashcards - QuizletDocumento4 paginePearson Chemistry Chapter 8 Flashcards - Quizletأستغفرالله واتوب اليهNessuna valutazione finora

- Chapter 2 Beams Curved in Plan FinalDocumento12 pagineChapter 2 Beams Curved in Plan Finalyosef gemessa100% (1)

- 20 Zienkiewicz, O. C., Watson, M., and King, I. P., A Numerical Method of Visco-Elastic PDFDocumento21 pagine20 Zienkiewicz, O. C., Watson, M., and King, I. P., A Numerical Method of Visco-Elastic PDFTariq MahmoodNessuna valutazione finora

- CSI Analysis Reference ManualDocumento1 paginaCSI Analysis Reference Manualisaacw_39Nessuna valutazione finora

- Effect of Thermomechanical Treatment On The Intergranular Corrosion of Al-Mg-Si-Type Alloy BarsDocumento8 pagineEffect of Thermomechanical Treatment On The Intergranular Corrosion of Al-Mg-Si-Type Alloy BarsbharatNessuna valutazione finora

- RCC21 Subframe AnalysisDocumento10 pagineRCC21 Subframe AnalysisAmit Kumar PaulNessuna valutazione finora

- Deflection LabDocumento9 pagineDeflection LabFarid NajandNessuna valutazione finora

- Abaqus 6.12: Abaqus Keywords Reference ManualDocumento1.545 pagineAbaqus 6.12: Abaqus Keywords Reference ManualIojanan Ben AvrahamNessuna valutazione finora

- Class Lectures 5 - Beam-Column MembersDocumento10 pagineClass Lectures 5 - Beam-Column MembersvrsafeNessuna valutazione finora

- Using The Microstructure and Mechanical Behavior of Steel Materials To Develop A New Fire Investigation TechnologyDocumento7 pagineUsing The Microstructure and Mechanical Behavior of Steel Materials To Develop A New Fire Investigation TechnologyFlávio LasmarNessuna valutazione finora

- Section Properties: Design of Padeye As Per Aisc 360-2005Documento6 pagineSection Properties: Design of Padeye As Per Aisc 360-2005Enrique BarajasNessuna valutazione finora